Underwater vehicle with water jet propulsion technology adopted

An underwater vehicle and water-jet propulsion technology, which is applied in the field of aircraft, can solve the problems of complex water absorption and water pressure structure, lower propulsion efficiency, speed limitation, etc., and achieve improved propulsion efficiency, simple mechanism, and small water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

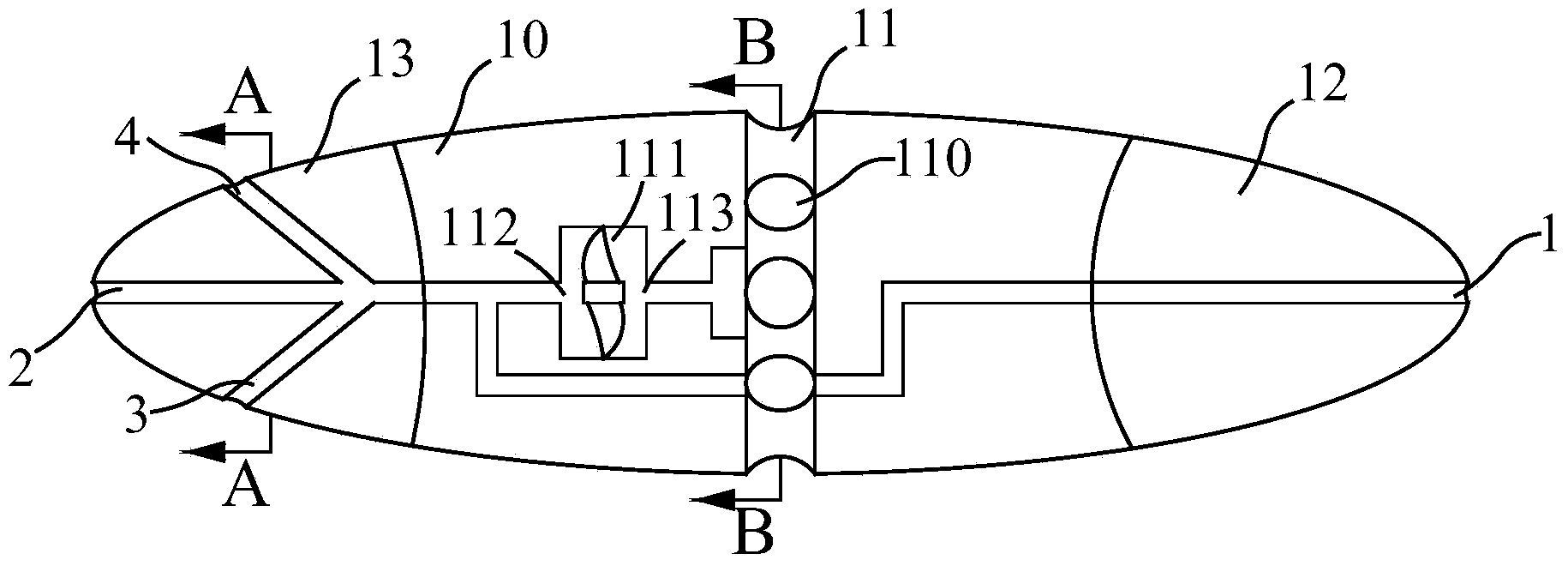

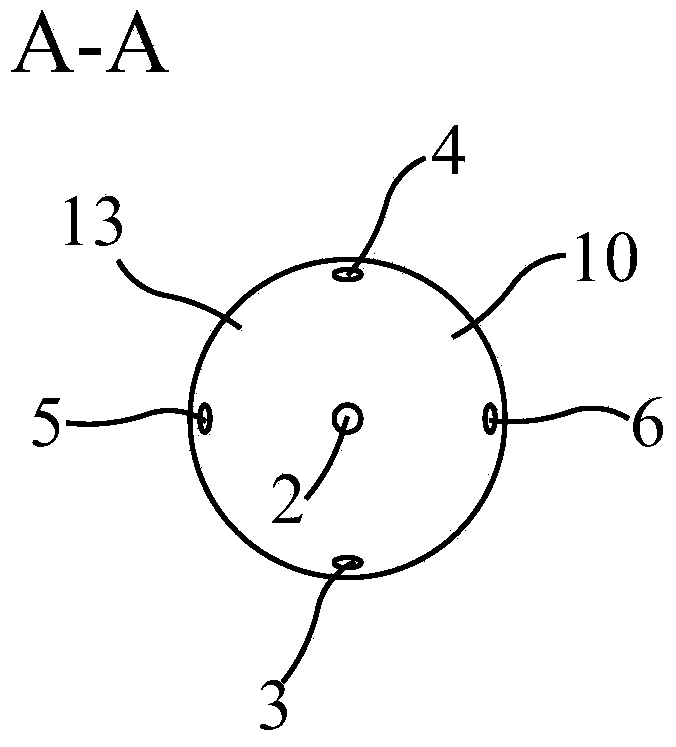

[0025] Embodiment 1, Figure 1 to Figure 6 Provides an underwater vehicle using water jet propulsion technology, including an underwater propulsion device 10 and a control system; the underwater propulsion device 10 includes a tail 13, a water inlet tray 11 and a head 12 arranged in sequence from left to right .

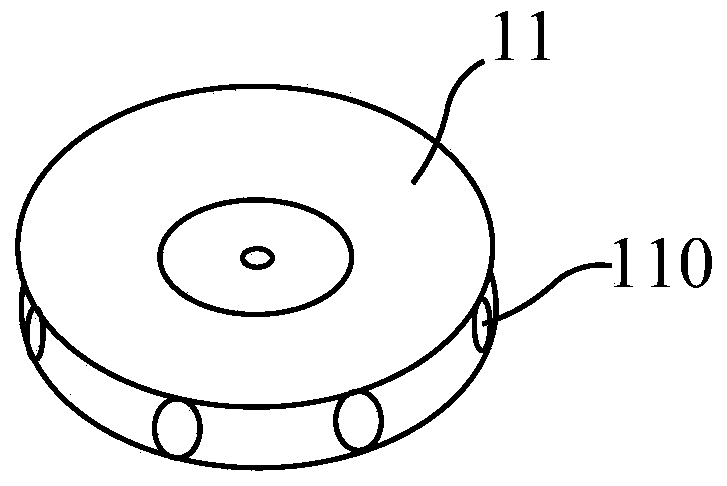

[0026] The water inlet tray 11 is a cylindrical disk made of a polymer composite material. The water inlet tray 110 is provided on the cylindrical surface of the water inlet tray 11. A high-pressure pump 111 is arranged in the water inlet tray 11. The high-pressure pump 111 The water inlet 113 of the pump is connected with the water inlet 110 of the water inlet tray; the water inlet 110 of the water inlet tray has a circumferential opening, and this kind of water inlet with a circumferential opening has the characteristics of large water intake, uniform water intake, and mutual offset of water flow pressure; Due to the use of polymer composite materials, the resista...

Embodiment 2

[0048] Embodiment 2: Another kind of operation mode of the present invention can be formed by controlling the opening and closing of a plurality of switching solenoid valves:

[0049] For example, if the front injection port I1, the rear injection port II2, the lower injection port III3, the left injection port V5 and the right injection port VI6 are closed, the high-pressure water flow will be injected through the upper injection port IV4. At this time, by adjusting Switching the solenoid valve IV 24 and the solenoid valve I 21 on and off can drive the aircraft to dive;

[0050] For example, after closing the rear injection port II2, the upper injection port IV4, the left injection port V5 and the right injection port VI6, the high-pressure water flow will be injected through the lower injection port III3 and the front injection port I1. At this time, by adjusting the switch The opening and closing of the solenoid valve III23 and the switch solenoid valve I21 can drive the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com