Method for dispersing, purifying and/or assembling nano gold rods

A kind of nano-gold rod and dispersion technology, which can be used in devices for coating liquid on surfaces, special surfaces, coatings, etc., which can solve the problems of low purification efficiency, harsh conditions, high time and economic cost, and achieve high purification yield and reaction. The effect of mild conditions and simple reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, utilize surfactant C 18 N 3 The method for dispersing nano gold rods, the steps are as follows:

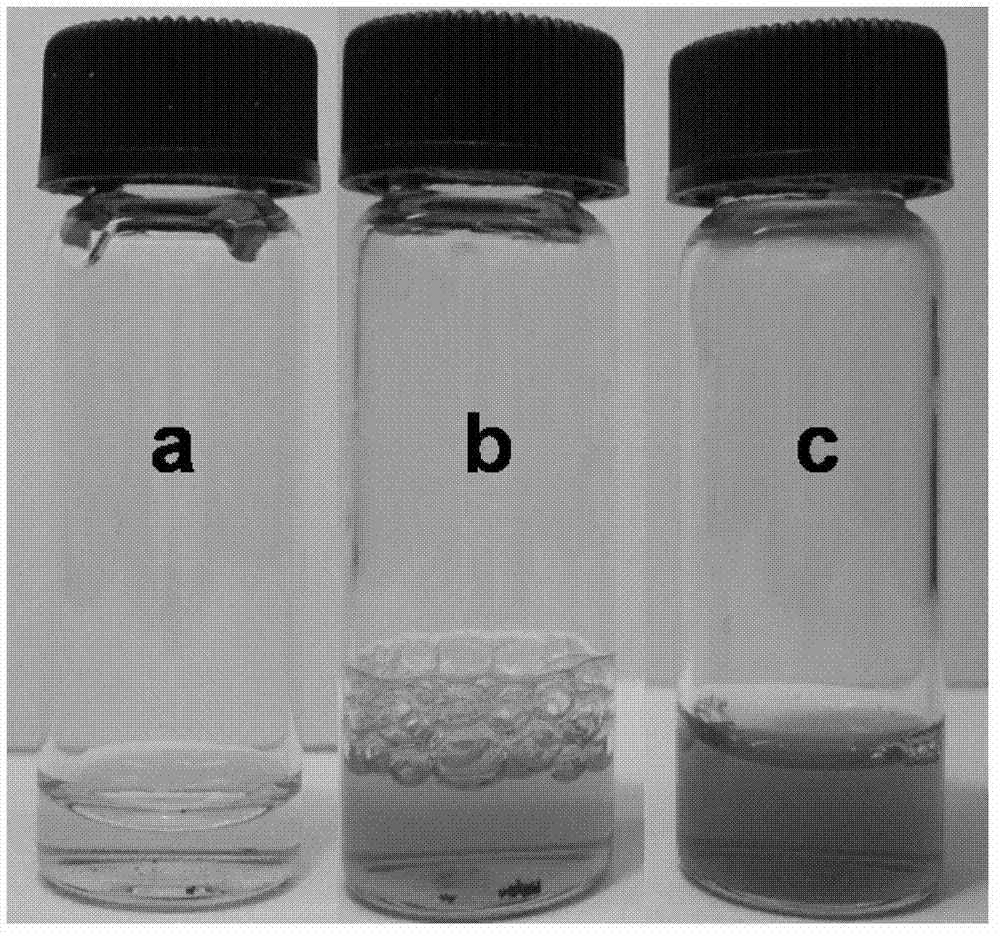

[0036] The crude product of nano-gold rods was centrifuged and washed three times under the condition of centrifugal force of 450g and 20min / time (see figure 1 (a)), in order to remove excess CTAB during the preparation process, a concentration of 0.5 mM C was added to the centrifuged product 18 N 3 Aqueous solution (1mL), 600W power ultrasonic 30s, get the good dispersion system of nano-gold rods, see figure 1 (c).

[0037] in order to do C 18 N 3 For the comparative experiment of excellent solubility, add the crude nano-gold rod product that was centrifuged and washed to remove excess CTAB into 0.1M CTAB (1mL), and ultrasonicate at 600W power for 30s. It can be observed that the crude nano-gold rod product can only partially dissolve, see figure 1 (b).

[0038] Depend on figure 1 (a) It can be seen that the crude gold nanorods after several times of...

Embodiment 2

[0046] Embodiment 2, utilize surfactant C 18 N 3 The method for purifying nano gold rods, the steps are as follows:

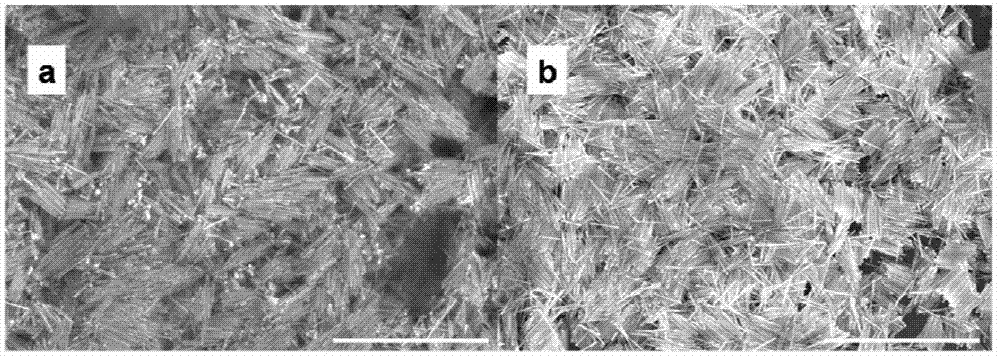

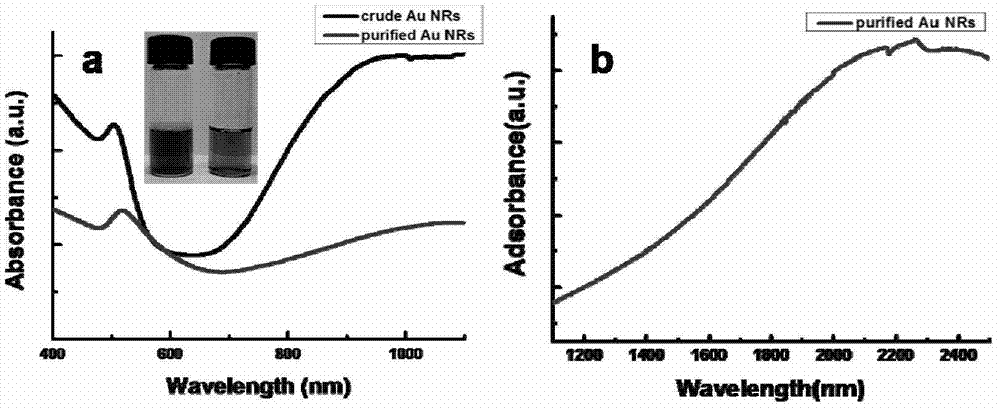

[0047] To Example 1 obtained with C 18 N 3 Dispersed nano gold rod system (in C 18 N 3 The concentration is 1mM as an example), and NaOH standard solution (0.5M, 15μL) was added to it to adjust its pH from 8.2 to 11.0. Colored (nanospheres and nanosheets suspended in it). Absorb the supernatant, add 2 mL of water 60 times the volume of the sediment to the lower layer, and ultrasonically disperse, wash 2 mL of the water-dispersed nano gold rod solution under the condition of a centrifugal force of 450 g and 20 min / time to eliminate the purification process. NaOH in and excess surfactant C 18 N 3 , the centrifuged product is the purified gold nanorods. See figure 2 (b). It can be seen from the figure that the purified gold nanorods ( figure 2 (b)) Compared with the gold nanorods before purification ( figure 2 (a) Most of the by-products, such as n...

Embodiment 3

[0048] Embodiment 3, utilize surfactant C 18 N 3 The method for assembling nano gold rods, the steps are as follows:

[0049] Add an equal volume of an aqueous solution of di(aminoethylacylmethylethyl)octadecylamine (0.1mM, 1mL) to the product obtained in Example 2, mix well, and then add a standard solution of HCl (0.5M, 20μL). After the pH was adjusted from 8.3 to 4.0, 1 mL of water was added again, and then centrifuged and washed once under the condition of centrifugal force of 450 g and 20 min / time to remove NaCl generated in the purification and subsequent processes, as well as excess acid-base regulator and surfactant C 18 N 3 , and then add 100 μL of water to the centrifuged product, after ultrasonic dispersion, take 2-5 μL and spot it on the silicon wafer, and dry it naturally with a cover above at 16°C. Figure 4 It can be seen that the gold nanorods are assembled in a large area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com