Method for preparing gold crystals by adopting surface active agent molecule C18N3

A surfactant and gold preparation technology, applied in the field of preparation of micron and nanometer materials, can solve the problems of low product yield, unclear mechanism, small product size, etc., and achieve easy control of particle size, high product purity, and good dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1. The preparation method of spherical gold nanoparticle crystal, the steps are as follows:

[0031] (1) Prepare 20ml of KCl aqueous solution (concentration: 0.5M) first, and heat it to 80°C under stirring.

[0032] (2) When the temperature reaches 80° C., add 5 ml of 10 mM C18N3 aqueous solution; add 0.4 ml of 4.5 mM chloroauric acid aqueous solution after one minute.

[0033] (3) Stop the reaction after 40 minutes of reaction. The product was put into a centrifuge and centrifuged at a speed of 8000r / min for 15min, and the gold nanoparticles were settled and washed with double distilled water. So cycle 4 times.

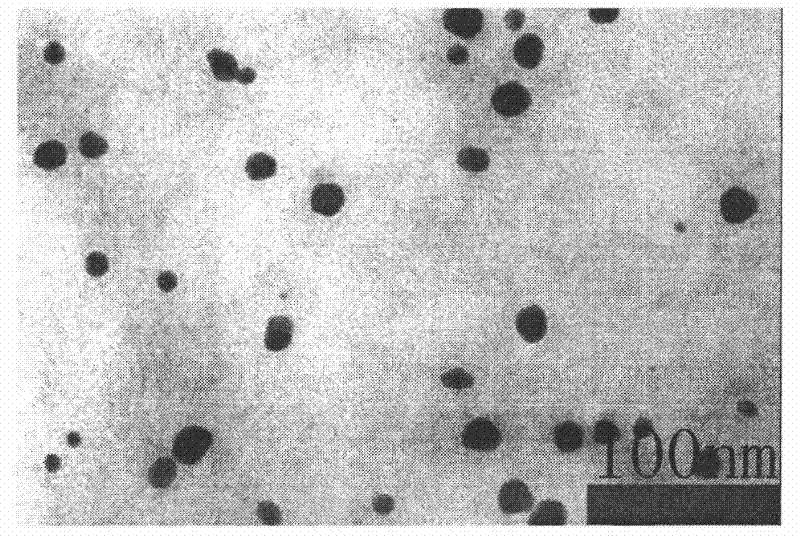

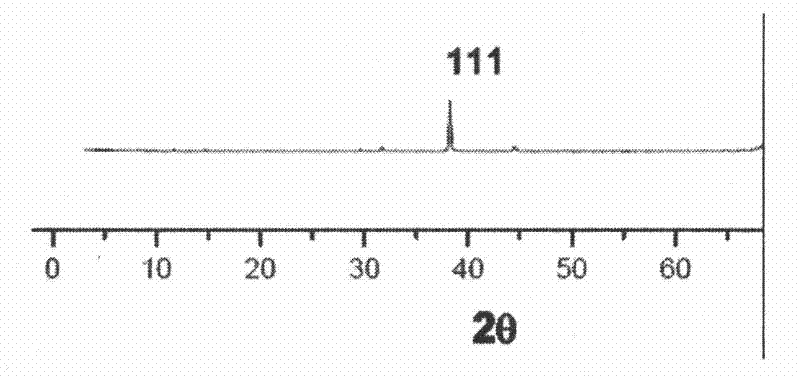

[0034] (4) Collect the precipitate obtained after centrifugation and washing with a copper grid covered with Formvorer, and observe the obtained gold nanoparticles with a transmission electron microscope. ; Figure 1(b) is the X-ray powder diffraction pattern (XRD pattern) of the product, from which it can be seen that the particles are dominated ...

Embodiment 2

[0035] The preparation method of the gold micron crystal of embodiment 2. decahedral shape, the steps are as follows:

[0036] (1) Prepare 20ml of KCl aqueous solution (concentration: 0.5M) first, and heat it to 80°C under stirring.

[0037] (2) When the temperature reaches 80° C., add 2 ml of 10 mM C18N3 aqueous solution; add 0.4 ml of 4.5 mM chloroauric acid aqueous solution after one minute.

[0038] (3) Stop the reaction after 60 minutes of reaction. The product was left to stand at room temperature for 72 hours.

[0039] (4) The product is then placed in a centrifuge and centrifuged at a speed of 6000r / min for 15min, and the gold microparticles are settled and washed with double distilled water. So cycle 4 times.

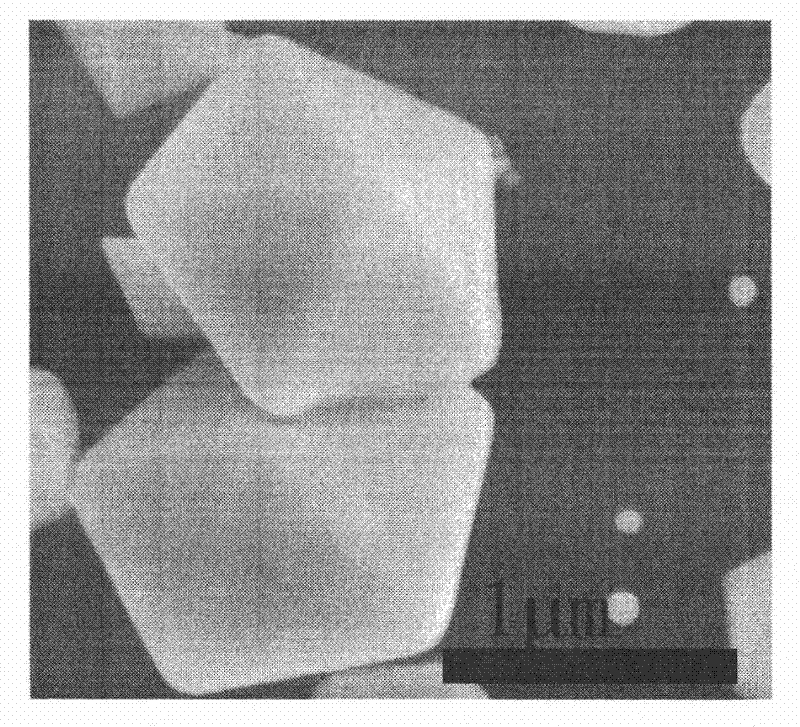

[0040] (5) collect the precipitate obtained after centrifugal washing, observe the obtained decahedron-shaped gold microcrystals with a scanning electron microscope, and the length of each side of the decahedron-shaped gold microcrystals is 2 μm, see Fig. 2 ...

Embodiment 3

[0041] The preparation method of the gold nanocrystal of embodiment 3. decahedral shape, the steps are as follows:

[0042] (1) Prepare 200ml of KCl aqueous solution (concentration: 0.5M), and heat it to 80°C under stirring.

[0043] (2) When the temperature reaches 80° C., add 2 ml of 10 mM C18N3 aqueous solution; add 0.4 ml of 4.5 mM chloroauric acid aqueous solution after one minute.

[0044] (3) Stop the reaction after 60 minutes of reaction.

[0045] (4) The product is then placed in a centrifuge and centrifuged at a speed of 6000r / min for 15min, and the gold nanoparticles are settled down and washed with double distilled water. So cycle 4 times.

[0046] (5) collect the precipitate that obtains after centrifugal washing with the copper net that has been covered with Formvorer, observe the obtained gold nanocrystal of decahedron shape with transmission electron microscope, the side length of each side of the gold nanocrystal of decahedron shape is all 20nm, see image ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com