A method for preparing polymer hollow fiber porous membrane by chemical reaction-induced phase inversion

A technology of chemical reaction and induced phase, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of improving performance and membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

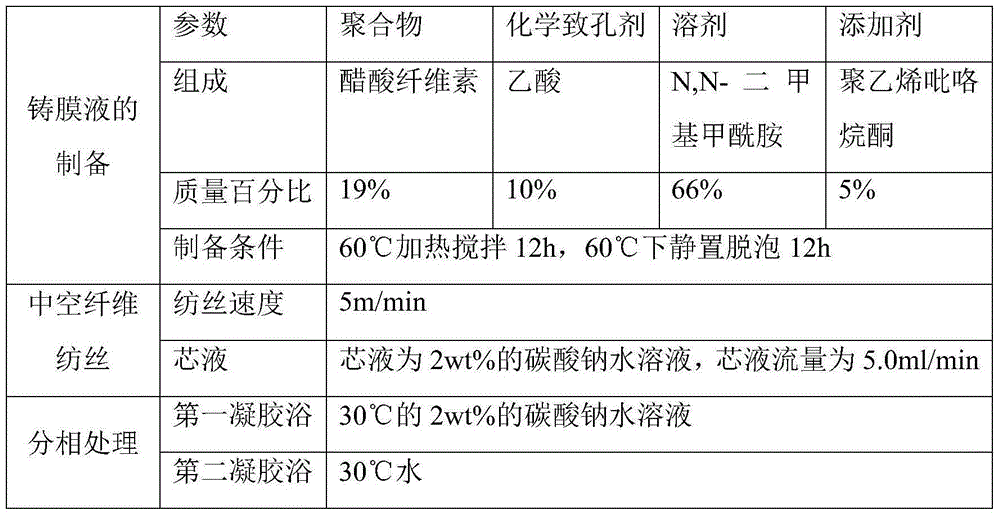

Embodiment 1

[0036] ①Preparation of casting solution: Stir and blend polymer materials, solvents, additives and chemical porogens in a certain proportion at a temperature of 50-80°C for 6-24 hours, and then stand at a constant temperature of 50-80°C for defoaming 12-24h to obtain a homogeneous casting solution.

[0037] ② Preparation of core liquid and outer gel bath: mix a certain proportion of deionized water and inorganic salts evenly, and set aside.

[0038] ③Hollow fiber spinning: using dry-wet spinning equipment at the set spinning speed, the core liquid is injected into the spinneret according to the set core liquid volume and the homogeneous casting liquid, and together from the spinneret Extruded to produce hollow fiber membranes.

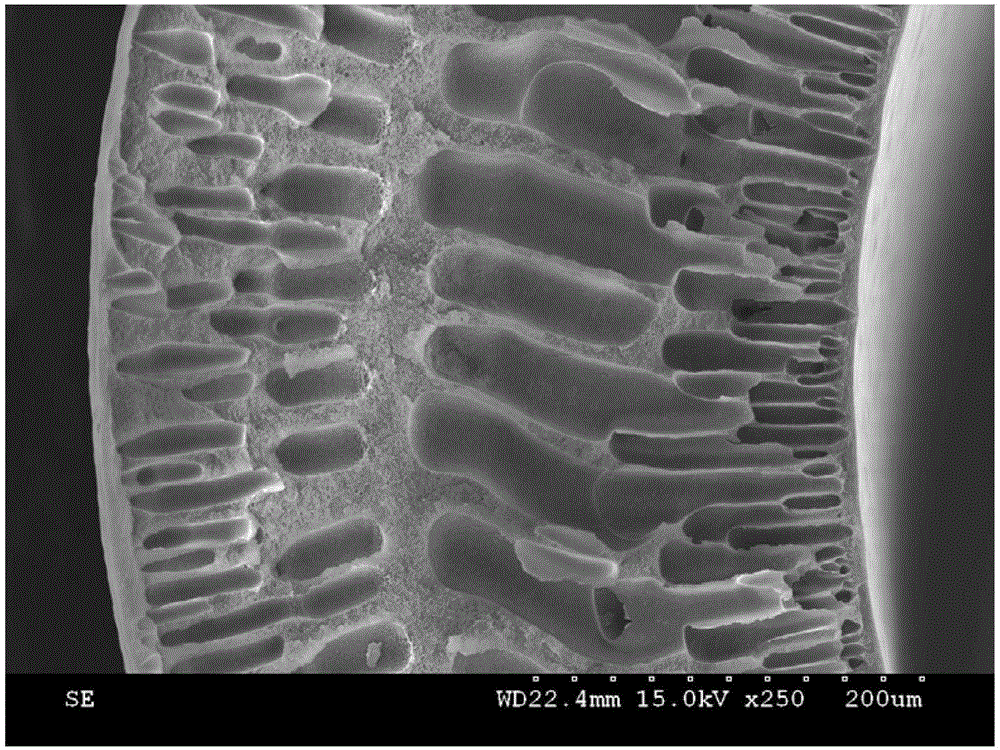

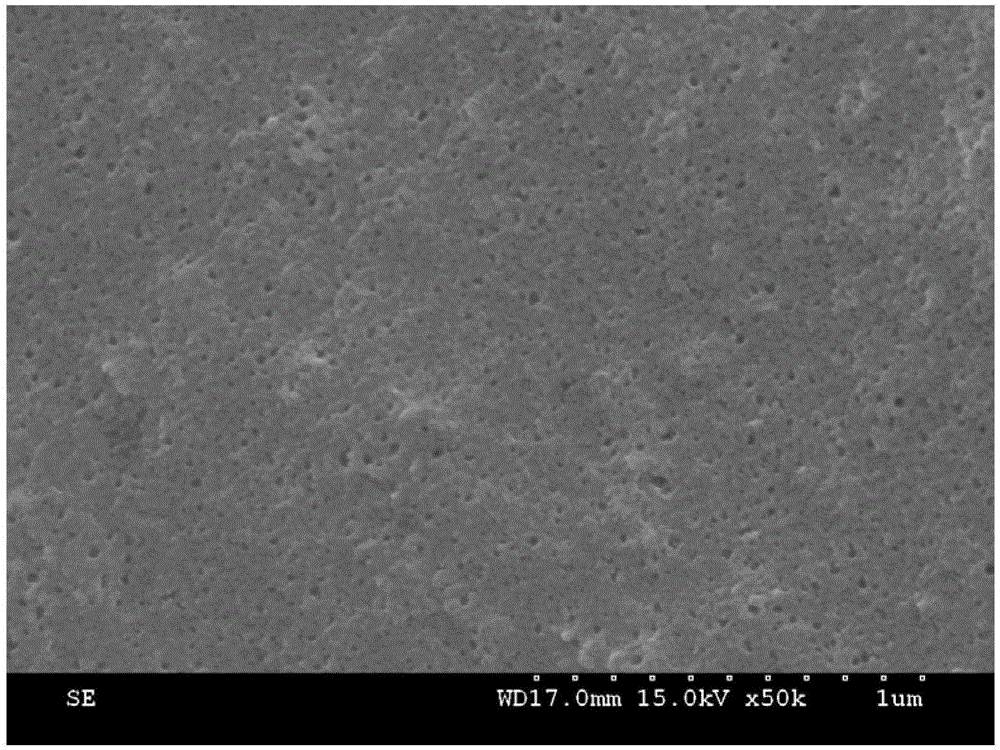

[0039] ④Phase inversion treatment: After the hollow fiber membrane obtained in step ③ is subjected to a dry spinning process of 0-30cm, it is sequentially entered into the first gel bath and the second gel bath for gel phase inversion, forming a micro...

Embodiment 2

[0046] The steps are as shown in Example 1, and the composition is shown in the table below.

[0047]

[0048] The inner diameter of the obtained hollow fiber porous membrane is about 1.40 mm, the outer diameter is about 1.84 mm, and the pure water flux at 0.1 MPa is 44.5 L / m 2 s or more, the rejection rate of BSA is more than 98%.

Embodiment 3

[0050] The steps are as shown in Example 1, and the composition is shown in the table below.

[0051]

[0052] The inner diameter of the obtained hollow fiber porous membrane is about 1.10 mm, the outer diameter is about 1.77 mm, and the pure water flux at 0.1 MPa is 124 L / m 2 s or more, the rejection rate of BSA is more than 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com