High-concentration neutral ink color paste and preparation method thereof

A neutral ink, high-concentration technology, used in inks, pigment pastes, household appliances, etc., can solve the problems of small steric hindrance of dispersants, easy flocculation of pigments, poor color paste stability, etc., to achieve excellent matching, low Viscosity, the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

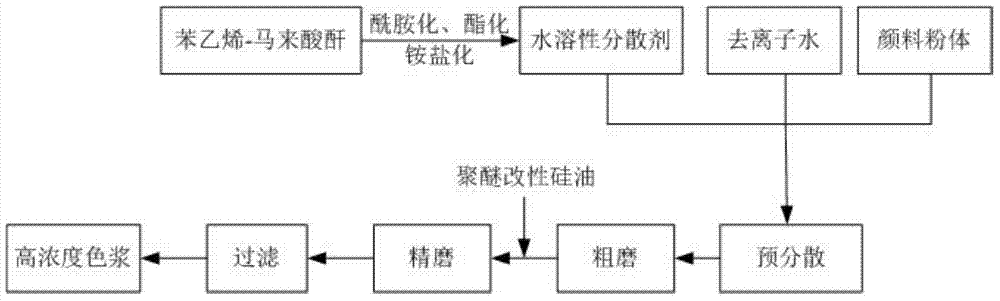

Method used

Image

Examples

preparation example Construction

[0021] (1) Preparation of styrene-maleic anhydride copolymer: mix styrene:maleic anhydride in a molar ratio of 1:0.5 to 1.5 as a reactant, use toluene as a solvent, and use a thermal free radical initiator at 60 to 85°C Initiate the free radical copolymerization reaction for 3-5 hours. After the reaction is finished, filter with suction. Use toluene as the wetting agent to wash the solid product obtained by suction filtration three times to obtain a white powder. Dry the white powder in vacuum at 40-60°C for 48 hours. Obtain styrene-maleic anhydride copolymer at last; Wherein the mol ratio of styrene and thermal radical initiator is 1:0.001~0.005, the consumption of toluene as solvent is to make the concentration of styrene be 0.1~2.5mol / L;

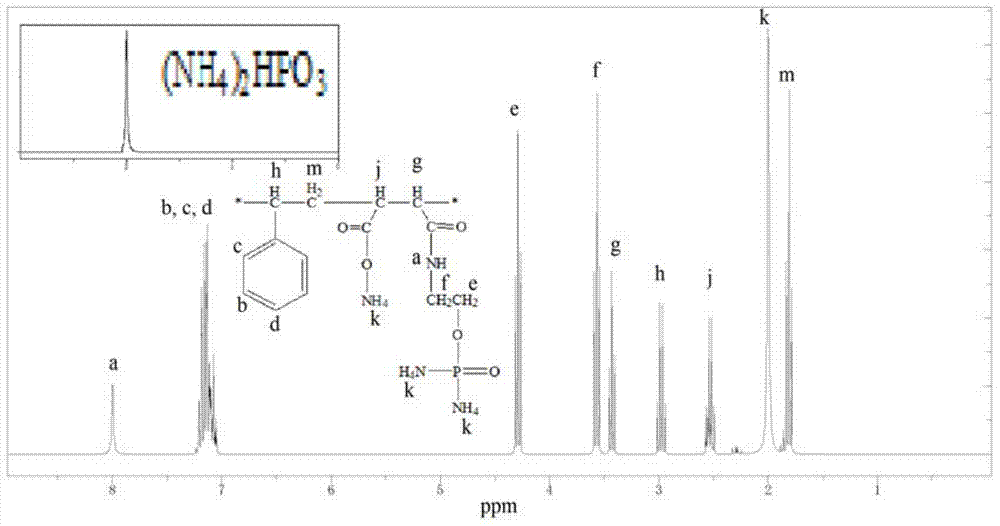

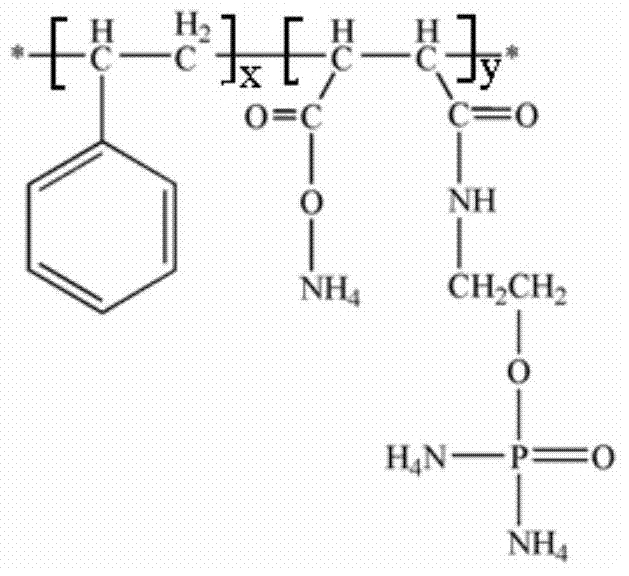

[0022] (2) Preparation of amidated styrene-maleic anhydride copolymer: Dissolve ethylene glycol amine in dimethylformamide at a concentration of 0.5 to 1.0 mol / L, then dissolve the styrene-maleic anhydride obtained in (1) Add the anhydrid...

Embodiment 1

[0028](1) Pre-dispersion and grinding: fully dissolve the water-soluble dispersant in deionized water in an amount of 2wt.% of the total color paste, and then add 40wt.% of the pigment to the total color paste. Dispersion grinding, the particle size of zirconium beads ground in the basket mill is 0.5-0.6 mm, the filling density is 60%, the rotation speed is 1000 rpm, the pre-dispersion grinding time is 90 min, the pre-dispersion grinding temperature is 20 ° C, the pre-dispersion grinding After the end, filter the grinding product with a 800-mesh screen to obtain a pre-dispersed grinding liquid; wherein the water-soluble dispersant is styrene-maleic anhydride through ethylene glycol amine amidation reaction, diammonium hydrogen phosphate esterification reaction, ammonia water Prepared by ammonium salification reaction, the HLB of the water-soluble dispersant is 5, the weight average molecular weight is 12000, and the mol ratio of the styrene segment and the maleic anhydride segm...

Embodiment 2

[0033] (1) Pre-dispersion and grinding: fully dissolve the water-soluble dispersant in deionized water in an amount of 6wt.% of the total color paste, and then add 50wt.% of the pigment to the total color paste. Dispersion grinding, the particle size of the zirconium beads ground in the basket mill is 0.5-0.6 mm, the filling density is 60%, the rotation speed is 2000 rpm, the pre-dispersion grinding time is 60 min, the pre-dispersion grinding temperature is 45 ° C, the pre-dispersion grinding After the end, the grinding product is filtered with a 1500-mesh screen to obtain a pre-dispersed grinding liquid; the water-soluble dispersant is made of styrene-maleic anhydride in sequence through the amidation reaction of ethylene glycol amine, the esterification reaction of diammonium hydrogen phosphate, and the ammonia water Prepared by ammonium salification reaction, the HLB of the water-soluble dispersant is 15, the weight-average molecular weight is 30000w, and the mol ratio of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com