Novel process for separating rhodium and iridium

A new process, rhodium-iridium technology, applied in the field of rhodium-iridium slag, can solve problems such as difficulties, increase in production, automatic control of unfavorable equipment, etc., and achieve the effect of shortening the production cycle and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

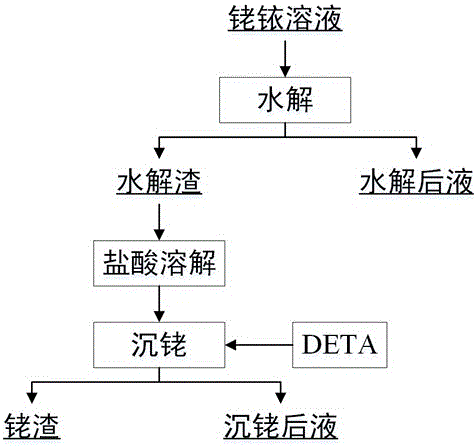

Image

Examples

Embodiment 1

[0020] Introduce chlorine gas into the rhodium-iridium-containing solution to control the potential at 950mV, stop the chlorine gas flow, then add 35% liquid caustic soda to control the pH value of the feed solution between 11, and stop the chlorine flow to reduce the pH to 8.5. After repeating the above process three times , transfer the rhodium iridium into the slag; add hydrochloric acid to dissolve the rhodium iridium slag, control the acidity at 4mol / L, and control the potential of the feed liquid at 920mV by adding a strong oxidant; raise the temperature to 70°C, add reagent DETA to precipitate rhodium according to 2 times the theoretical amount , control the temperature at 70-75°C, keep the temperature constant for half an hour, cool and filter. The precipitation rate of rhodium in the whole process is 99.85%.

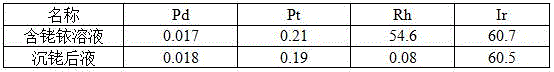

[0021] Table 1 Changes of solution components before and after precipitation in Example 1 (g / L)

[0022]

Embodiment 2

[0024] Introduce chlorine gas into the solution containing rhodium and iridium to control the potential at 940mV, stop passing chlorine gas, then add 40% liquid caustic soda to control the pH value of the feed liquid between 12, pass chlorine to reduce pH=9 and stop, repeat the above process three times , transfer the rhodium iridium into the slag; add hydrochloric acid to dissolve the rhodium iridium slag, control the acidity at 5mol / L, and control the potential of the feed liquid at 935mV by adding a strong oxidant; raise the temperature to 70°C, add reagent DETA to precipitate rhodium according to 2 times the theoretical amount , control the temperature at 70-75°C, keep the temperature constant for half an hour, cool and filter. The precipitation rate of rhodium in the whole process was 99.87%.

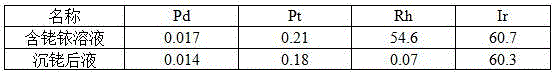

[0025] Table 2 Changes of solution components before and after precipitation in Example 2 (g / L)

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com