Method for reducing gold extraction residual liquid

A technology of residual liquid and gold extraction, which is applied to the improvement of process efficiency and other directions, can solve the problem of a large amount of copper entering, and achieve the effect of improving the product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

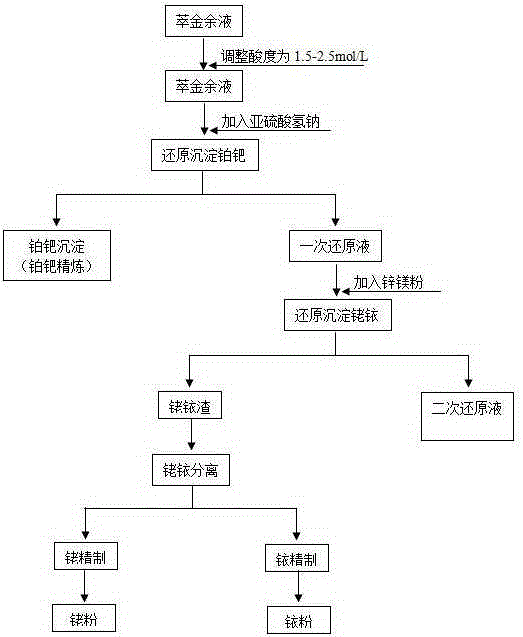

Image

Examples

Embodiment 1

[0018] Raise the temperature of 200L of gold-extracting liquid to 90°C, slowly add 40L of hydrochloric acid under stirring, stop stirring after completion, concentrate the volume to 60L, add pure water to dilute the gold-extracting liquid to 750L, and titrate the acidity of the gold-extracting liquid to 2.5mol / L, control the temperature of the residual gold extraction solution at 50°C, slowly add sodium bisulfite for reduction, adjust the acidity of the solution to 2.5mol / L with sodium hydroxide during the process, control the terminal potential to 260mv, and keep the potential at a constant potential for 30 minutes after reaching the terminal potential. Then discharge the fine filter, heat up the primary reducing solution to 50°C, slowly add zinc powder to precipitate rhodium iridium, control the end point pH to 3.5, and end point potential to -400mv, then add magnesium powder to precipitate rhodium iridium again, control the pH to 5.5, and react After reaching the end point,...

Embodiment 2

[0019] Example 2: The volume of the gold extraction raffinate is 250L, the temperature is raised to 95°C and the volume is concentrated to 70L, and pure water is added to dilute the gold extraction raffinate to 700L, the acidity of the gold extraction raffinate is titrated to 1.5mol / L, and the concentration of the gold extraction raffinate is controlled. The temperature is 60°C, slowly add sodium bisulfite for reduction under stirring, adjust the acidity of the solution to 1.5mol / L with potassium hydroxide during the reduction process, control the terminal potential to 230mv, keep the potential at a constant potential for 60 minutes after reaching the terminal potential, and then discharge the material accurately Filtrate, raise the temperature of the primary reducing solution to 60°C, slowly add zinc powder to precipitate rhodium and iridium under stirring, control the end point pH to 3.0, and the end point potential to -450mv, then add magnesium powder to precipitate rhodium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com