Preparation method of flocculent decolouring agent of printing and dying wastewater

A technology for printing and dyeing wastewater and decolorizing agent, which is applied in the textile industry wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary environmental pollution, environmental impact, waste of resources, etc., and achieve COD reduction and rapid slag sedimentation. , good flocculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Add 90kg of formaldehyde, 200kg of dicyandiamide, and 100kg of ammonium chloride into the reactor, react at 50°C for 2 hours, then drop 60kg of formaldehyde into the reactor, react at 70°C for 4 hours, cool down and discharge to obtain component A;

[0018] 2) Add 4000kg of industrial waste aluminum sludge (including 240kg of alumina) to 1000kg of water and stir evenly, add 400kg of industrial hydrochloric acid, react at 70°C for 4 hours, cool down and discharge, and mature for 12 hours to obtain component B.

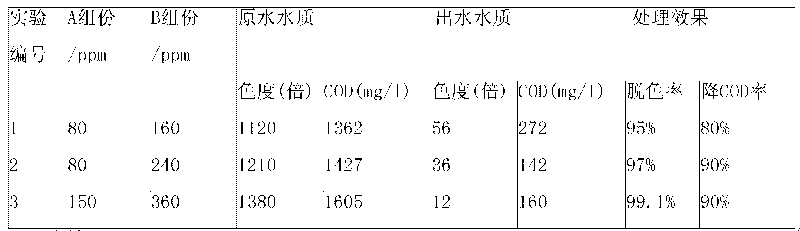

[0019] After mixing component A and component B, the effect of treating wastewater is as follows:

[0020]

Embodiment 2

[0022] 1) Add 240kg of formaldehyde, 400kg of dicyandiamide, and 250kg of ammonium chloride into the reactor, react at 60°C for 1 hour, then drop 60kg of formaldehyde into the reactor, react at 80°C for 2 hours, cool down to 60°C, add 50kg of urea, React for 1 hour, cool down and discharge to obtain A component;

[0023] 2) Add 4000kg of industrial waste aluminum sludge (including 400kg of alumina) to 1000kg of water and stir evenly, add 800kg of industrial hydrochloric acid, react at 80°C for 2 hours, cool down and discharge, and mature for 24 hours to obtain component B.

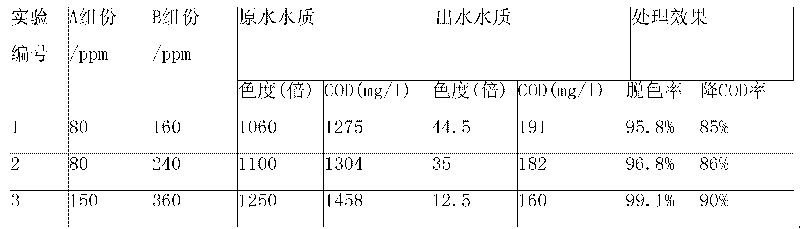

[0024] After mixing component A and component B, the effect of treating wastewater is as follows:

[0025]

Embodiment 3

[0027] 1) Add 300kg of formaldehyde, 400kg of dicyandiamide, and 350kg of ammonium chloride into the reaction kettle, react at 55°C for 1.5 hours, then add 200kg of formaldehyde, and react at 75°C for 3 hours; cool down to 50°C, then add 30kg of urea, and react for 1.5 hours , A component is obtained by discharging;

[0028] 2) Add 1000kg of water to 4500kg of industrial waste aluminum sludge (including 320kg of alumina) and stir evenly, add 600kg of industrial hydrochloric acid, react at 75°C for 1.5 hours, cool down and discharge, and mature for 18 hours to obtain component B.

[0029] The cost of chemicals per ton of waste water treated by the products of the above embodiments 1 to 3 is about 0.60-1.20 yuan, and 90% of the treated waste water can be reused, which greatly reduces water consumption, saves energy and protects the environment, and greatly reduces the cost of sewage treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com