Method and device for culturing AGS (aerobic granular sludge)

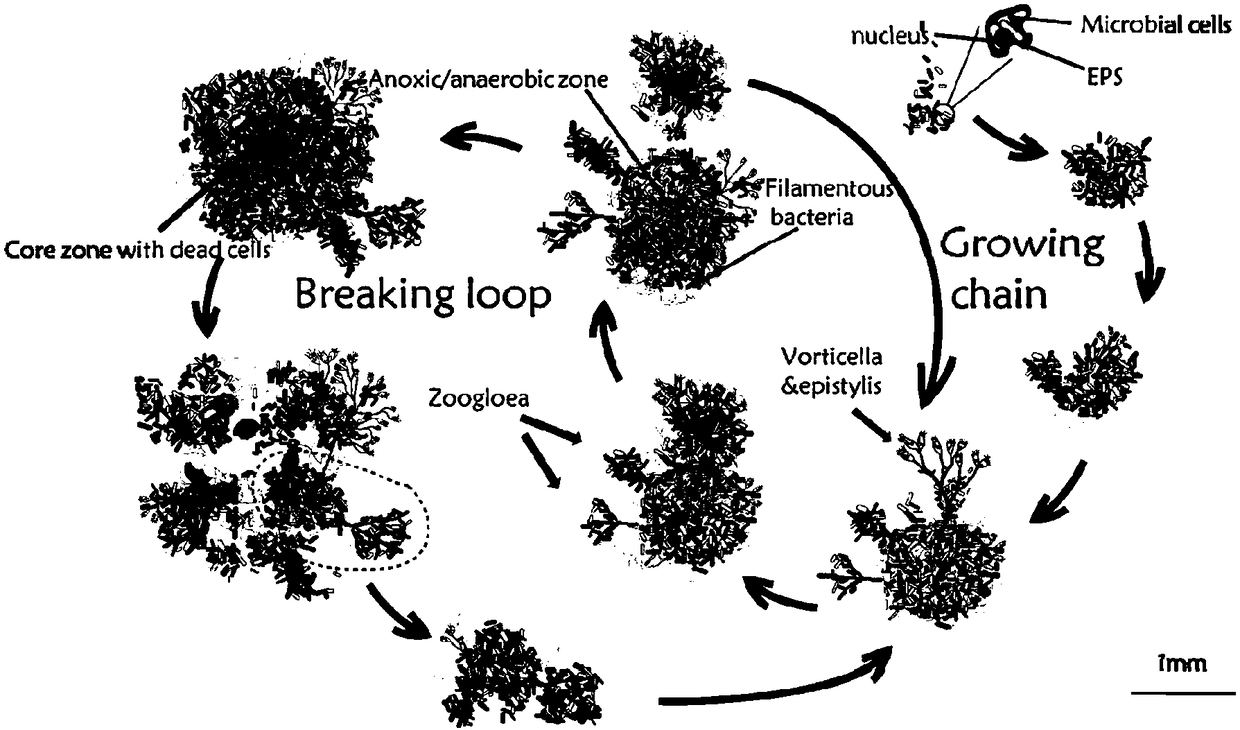

A technology of aerobic granular sludge and anaerobic granular sludge, which is applied to the device for cultivating it, uses anaerobic granular sludge to induce the cultivation of aerobic granular sludge, and cultivates aerobic granular sludge, which can solve the harsh conditions; In 1998, Heijnen and van Loosdrech applied for the problems of aerobic granular sludge, non-dense structure, and fine particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A method of using anaerobic granular sludge to induce and cultivate aerobic granular sludge in the present embodiment 1, the specific steps are as follows:

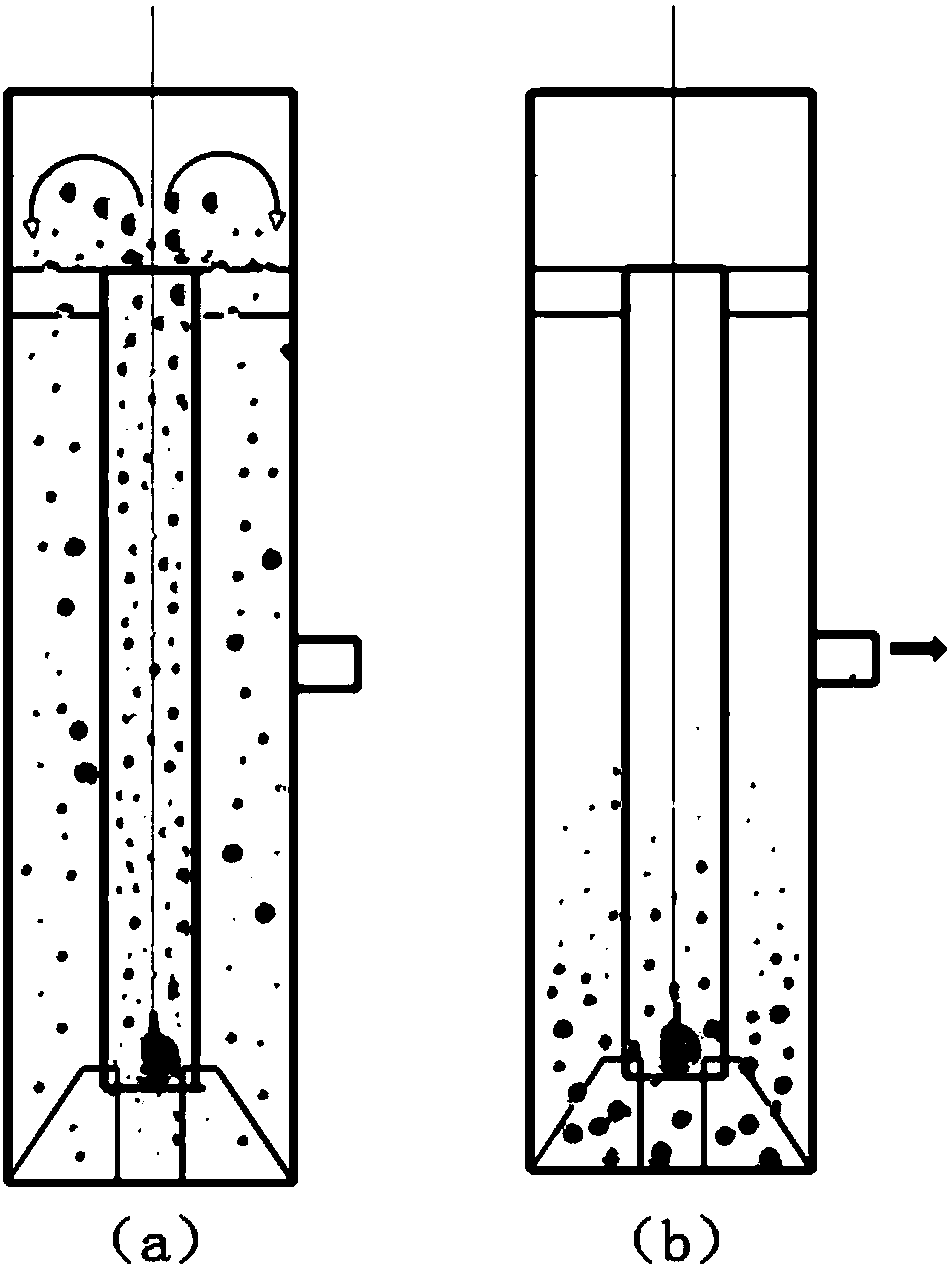

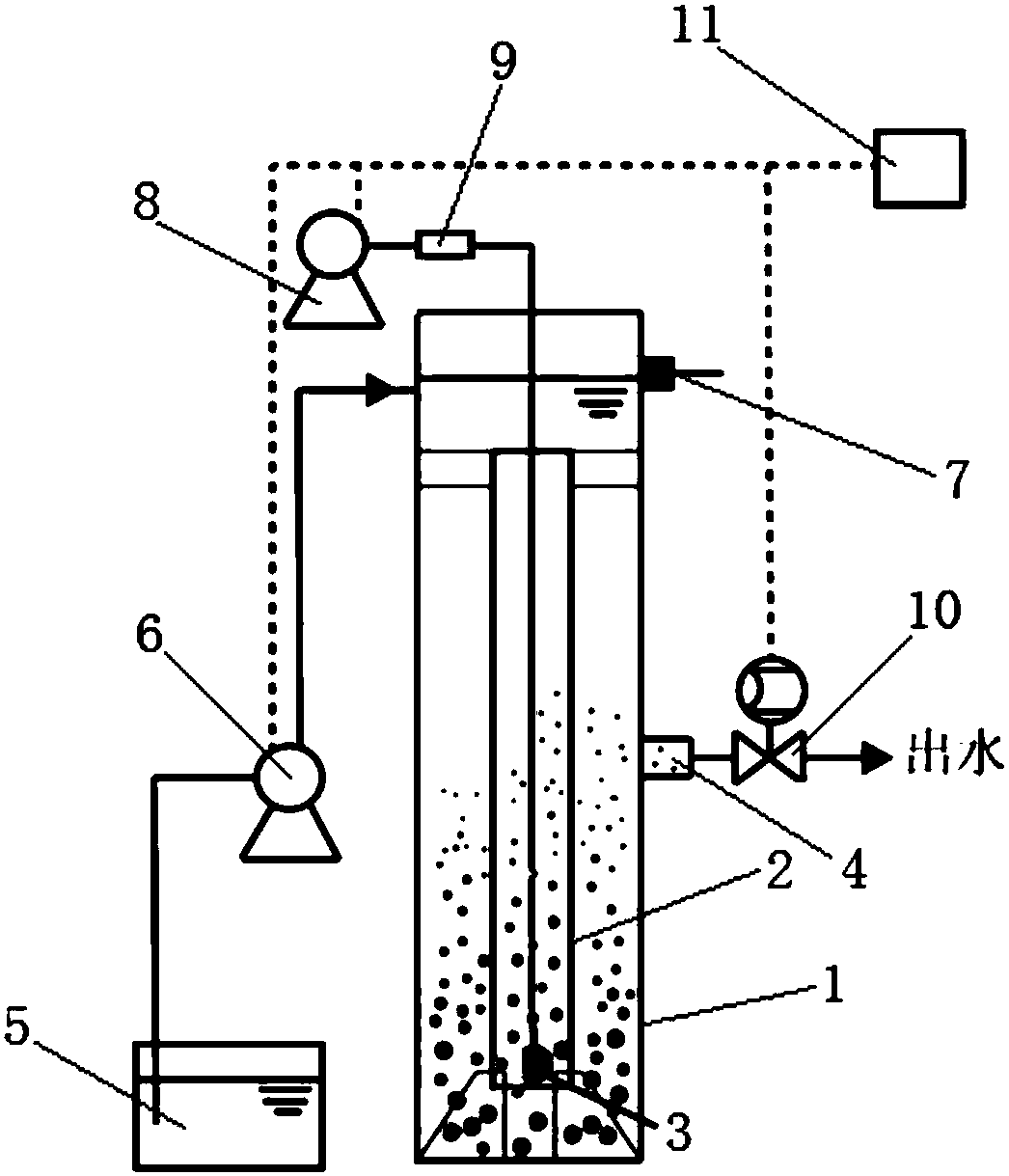

[0066] (1) SBAR reactor such as image 3 As shown, the diameter of the inner pipe 2 is 60mm, the height is 900mm, the diameter of the outer pipe 1 is 110mm, the height is 1100mm, the total volume is 8L, the effective volume is 6L, the height-to-diameter ratio H / D is 10, and the aeration position is set At the bottom of the inner tube 2, the reactor is controlled by a time controller 11 and an overflow device 7;

[0067] (2) The activated sludge inoculated is taken from the return sludge of the secondary settling tank of the municipal sewage treatment plant. It is dark brown, loose in appearance, irregular in shape, and small in floc. 50% of the container volume;

[0068] (3) Using artificial simulated domestic sewage, sucrose, beef extract peptone and potato starch were used as carbon sources, and the peptone and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com