Processing method of landfill leachate

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment, can solve the problems of many affected factors, high treatment costs, and high input costs, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

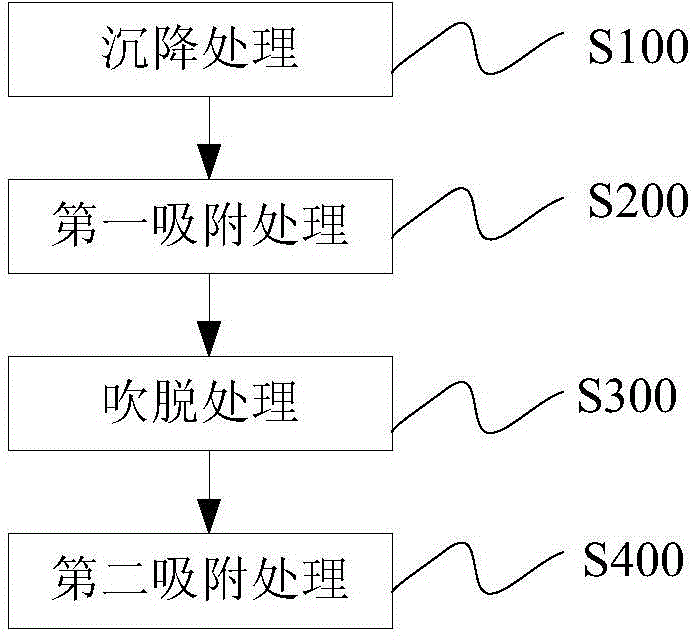

Method used

Image

Examples

Embodiment 1

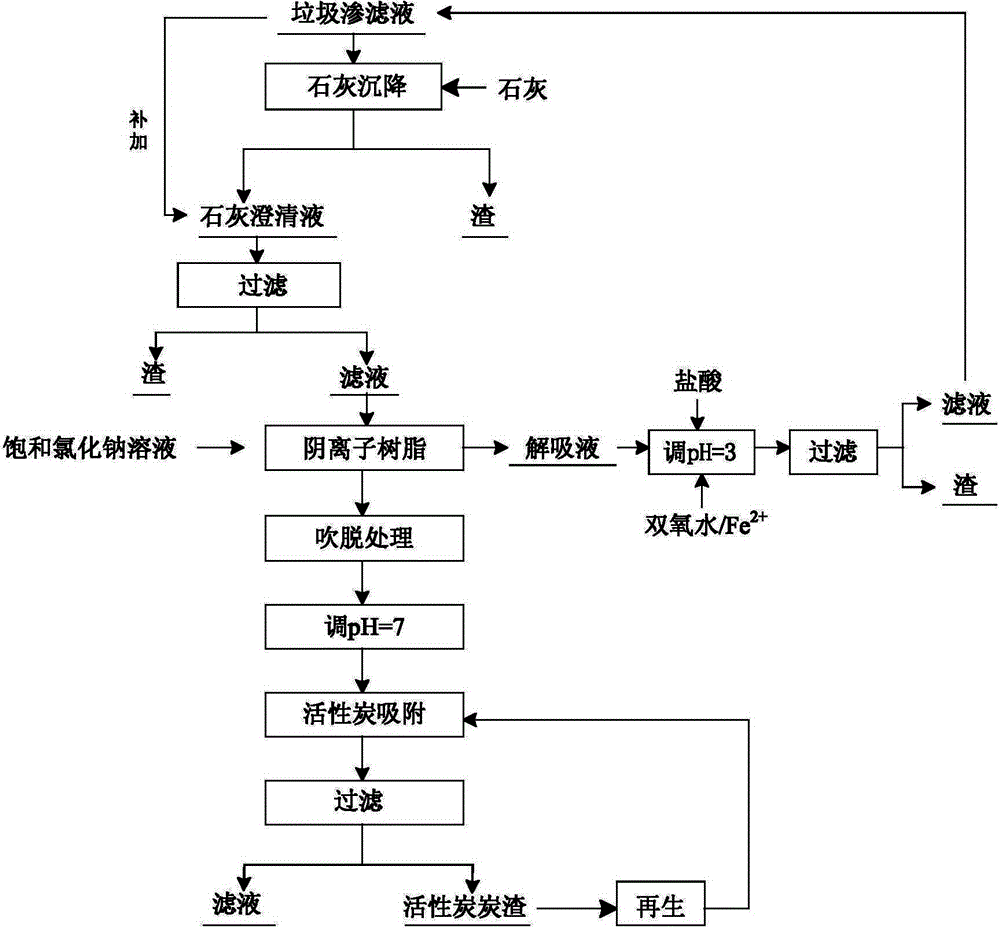

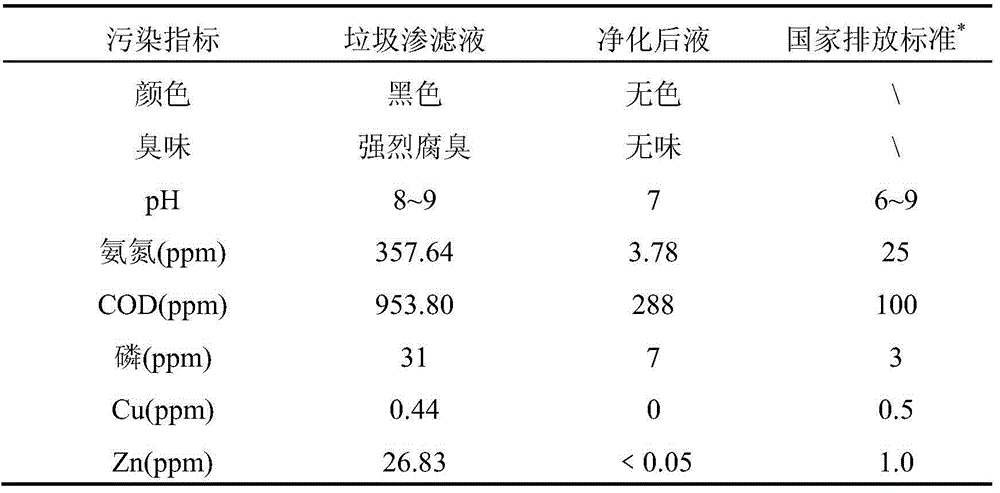

[0042] refer to figure 2 , Take 20L of landfill leachate, add 160g of lime under stirring conditions, control the pH>12, and then let it stand for a while. Take the upper clear liquid and flow through the ion exchange column filled with 100g (wet) 201×7 resin at a linear velocity of 4cm / min, and control the flow velocity to 4-10cm / min. After delivery, the liquid enters the stripping tower for stripping treatment to remove ammonia nitrogen. Adjust the pH to neutral with hydrochloric acid to the stripped liquid after the ammonia nitrogen has been stripped off. Add 16g of activated carbon powder (iodine value 1140, Yalan 13ml), stir for 30min and then filter. Purified liquid and activated carbon residue are obtained. Some pollution indicators of landfill leachate before treatment and purified liquid are shown in Table 1:

[0043] Table 1

[0044]

[0045] * Pollutant Discharge Standard for Urban Sewage Treatment Plants (Level 2) GB18918-2002

[0046] After the resin ads...

Embodiment 2

[0049] Take 40L of landfill leachate, add 320g of lime under stirring conditions, control pH>12, and then let it stand for a while. Take the supernatant liquid and flow through the ion exchange column equipped with 100g (wet) 201×7 resin at a linear velocity of 6cm / min. After delivery, the liquid enters the stripping tower for stripping treatment to remove ammonia nitrogen. Add 16 g of activated carbon powder (860 iodine value, 8 ml of ammonium) to the waste water after blowing off the ammonia nitrogen, stir for 30 min and then filter. Purified liquid and activated carbon residue are obtained. Some pollution indicators of landfill leachate before treatment and purified liquid are shown in Table 2:

[0050] Table 2

[0051]

[0052] * Pollutant Discharge Standard for Urban Sewage Treatment Plants (Level 2) GB18918-2002

[0053] After the resin adsorption exchange is completed, the resin is desorbed with 200 ml of saturated saline, and the flow rate is controlled at 1 cm / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com