Dry method recovery process of re-integrated waste industrial catalyst and device thereof

A dry recovery and catalyst technology, which is applied to the improvement of process efficiency, chemical instruments and methods, solid separation, etc., can solve the problems of inability to effectively separate sponge and sintered magnetic beads, difficult to control sorting, and low sorting efficiency. , to avoid secondary pollution, reduce energy consumption and improve sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

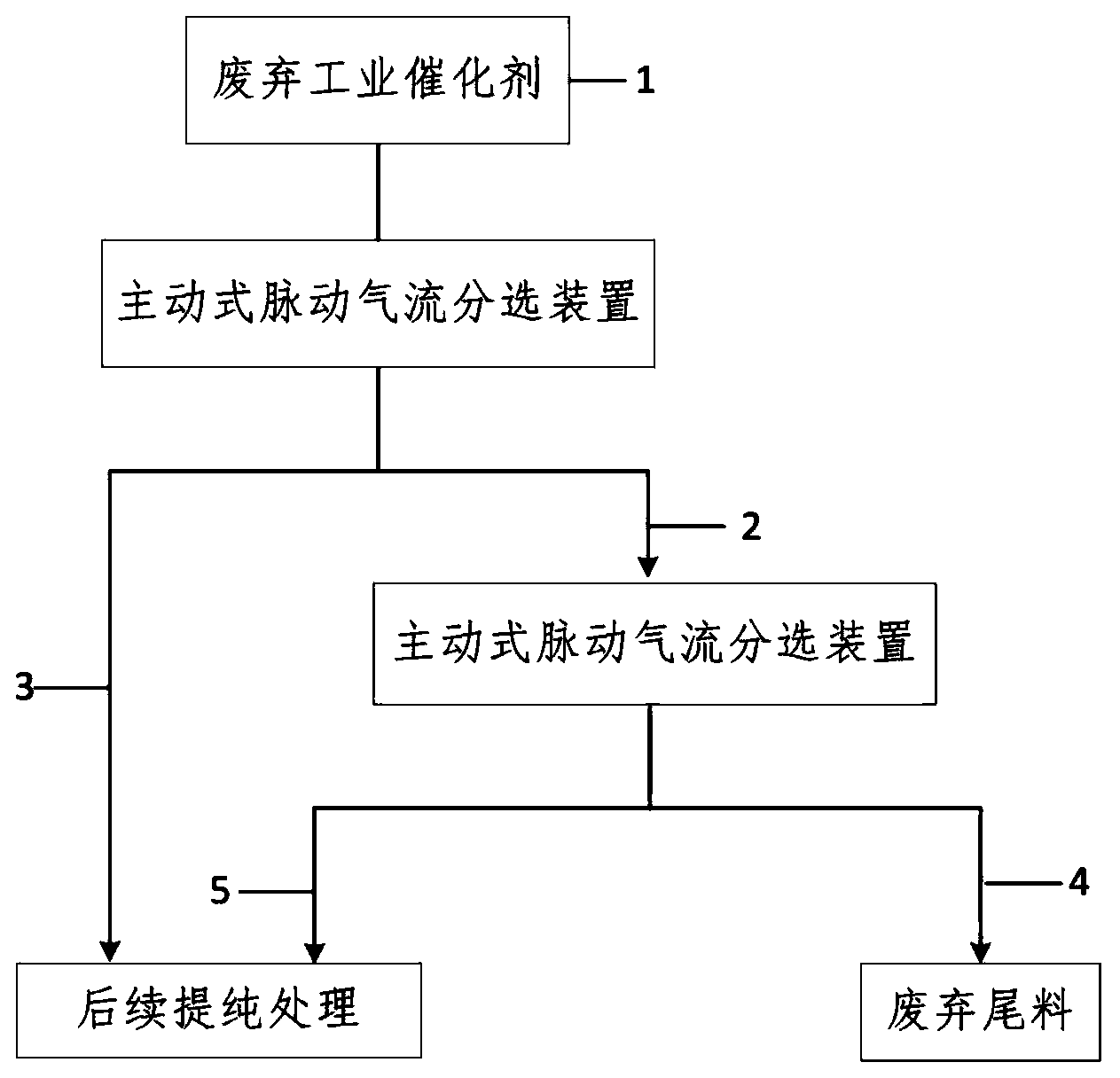

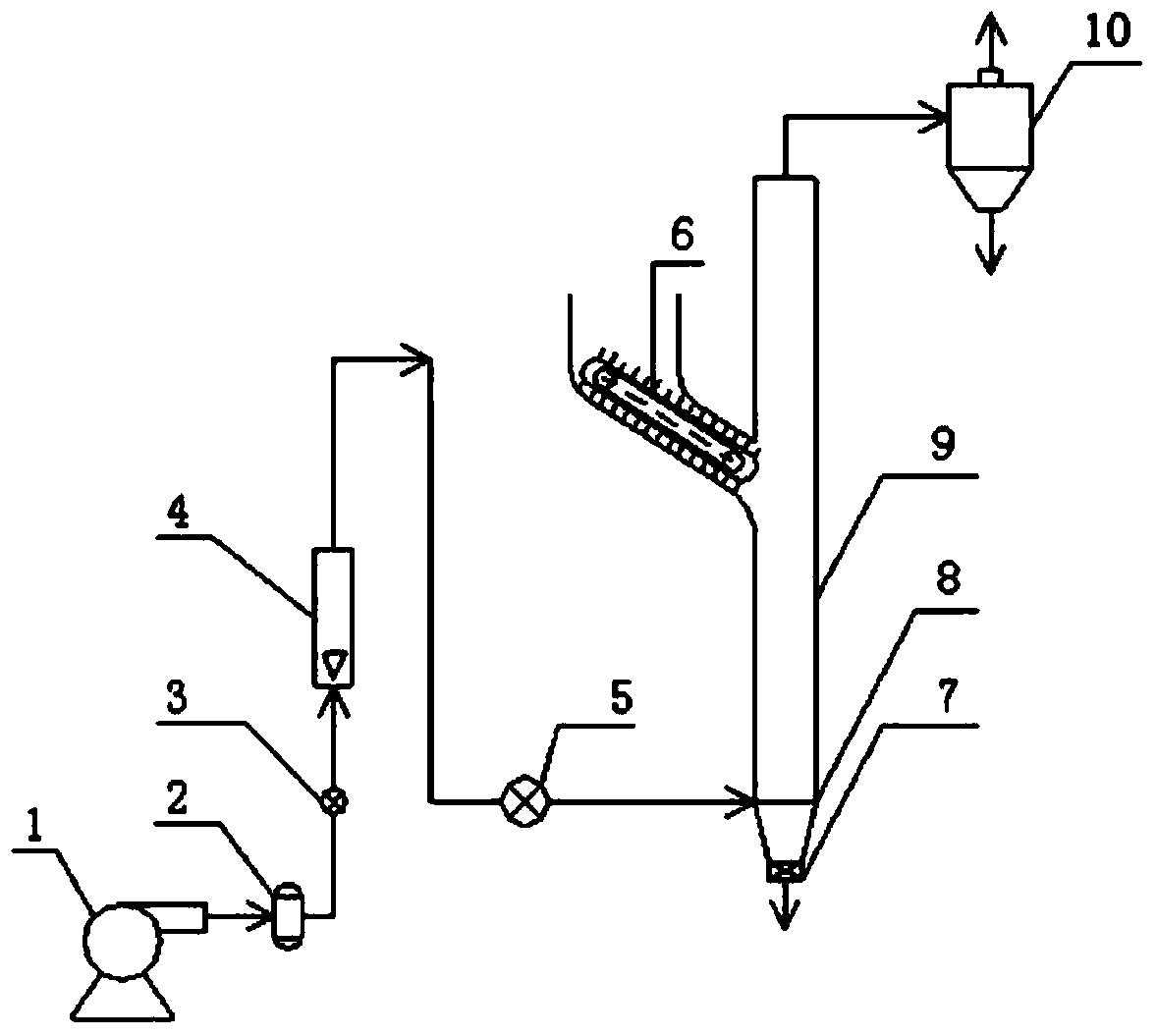

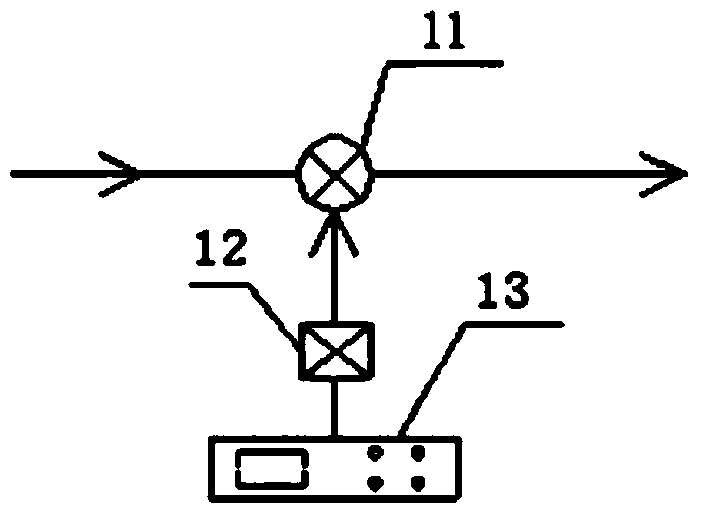

[0027] Embodiment 1: The dry recovery process of reintegrating waste industrial catalysts is realized in this way, and the concrete steps are:

[0028] Step 1: Put the reintegrated waste industrial catalyst into the feeding device of the first set of active pulsating airflow separation device, and transport it to the sorting column for rough separation. By adjusting the feeding frequency, pulsation frequency and air volume, different The acceleration and deceleration states of the particles of density are different, so as to realize the effective separation of the sponge body rich in precious metals and the sintered magnetic beads. The heavy product, namely most of the sintered magnetic The sponge that collects precious metals is collected by the cyclone dust collector on the top of the sorting column;

[0029] Step 2: The rough-selected materials are processed as follows:

[0030] (1) Feed the heavy product obtained by roughing into the feeding device of the second set of ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com