Polluted and waste water front-end physical treatment method

A water and moisture technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of reduced filtration capacity, high slag yield, complex structure, etc., to ensure minimum damage, prolong service life, and achieve cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

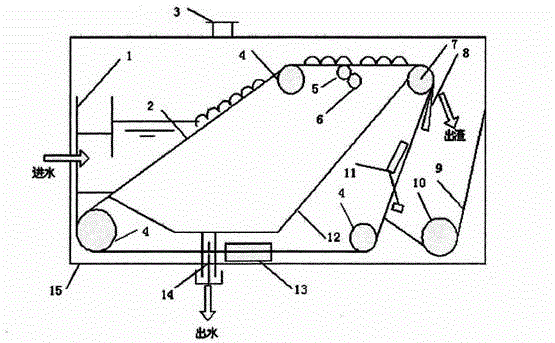

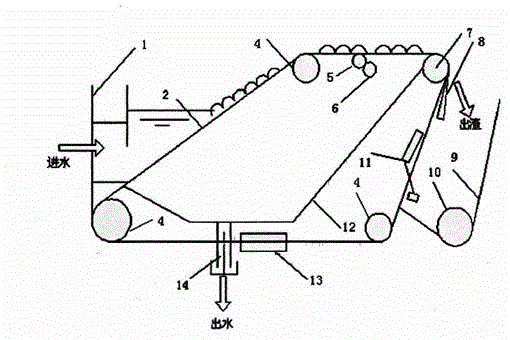

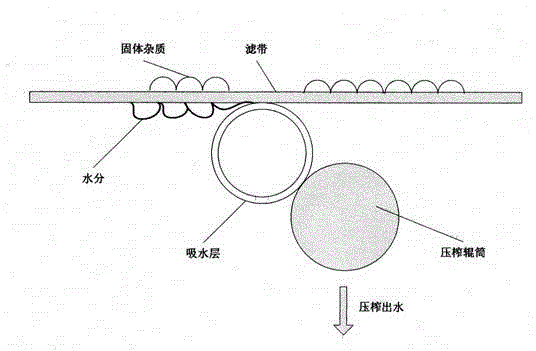

Method used

Image

Examples

Embodiment 1

[0083] Embodiment 1: solid impurity removal in nursery ground water body

[0084] The device for removing solid impurities in the water body of the present invention is used to remove the solid impurities in the water body of nursery farms in fish farming.

[0085] The water body of the nursery field refers to the environmental raw water used for seedling cultivation. It is necessary to remove suspended solids and colloidal impurities in the environmental raw water to reduce its turbidity.

[0086] After the environmental raw water enters the water distributor, it can be used as the water body of the nursery after intercepting and removing the solid impurities in it. After a series of cleaning, the filter belt recovers its interception capacity. Because the solid impurity concentration in the environmental raw water is low, the filter belt The traveling speed can be correspondingly accelerated, that is, the processing capacity of the same device can be greatly increased. At th...

Embodiment 2

[0091] Embodiment 2: removal of solid impurities in slaughter wastewater

[0092] The solid impurities in the slaughter wastewater were removed by the same method as in the above-mentioned Example 1.

[0093] Slaughter wastewater is mainly produced in the slaughtering, scalding, processing and other slaughtering processes of animals, which has the characteristics of many impurities and suspended solids, and high oil content.

[0094] After the slaughter wastewater enters the water distributor, it is intercepted by the filter belt, and the solid impurities and grease and oil stains contained in it are intercepted on the surface of the filter belt, and the intercepted and filtered water enters the next step of treatment. Due to the presence of solid impurities and grease and oil, the filter belt is more likely to be blocked. Therefore, this device needs to increase the blowing intensity of the high-speed air curtain accordingly, and at the same time increase the cleaning intensi...

Embodiment 3

[0098] Example 3: Treatment of Solid Impurities in Feedwater of Domestic Sewage Treatment Plants

[0099] The solid impurities in the influent of the domestic sewage treatment plant were removed by the same method as in the above-mentioned Example 1.

[0100] Domestic sewage contains a relatively high concentration of solid impurities, especially hair, floating matter and fibers, etc., relatively speaking, it contains a small amount of oily substances, and because domestic sewage stays in the drainage network for a long time, it has a strong The odor has a great impact on the working environment.

[0101] The domestic sewage is lifted by the pump and enters the water inlet distributor. The domestic sewage is intercepted by the filter belt, and the solid impurities contained in it are intercepted on the surface of the filter belt. The intercepted and filtered domestic sewage enters the subsequent biochemical treatment process. Because it contains a large amount of hair, floati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com