Industrial oily wastewater treatment system

A wastewater treatment system and industrial technology, applied in multi-stage water treatment, water/sewage treatment, flotation water/sewage treatment, etc., can solve problems such as unsatisfactory treatment effects, reduce floor space and improve treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

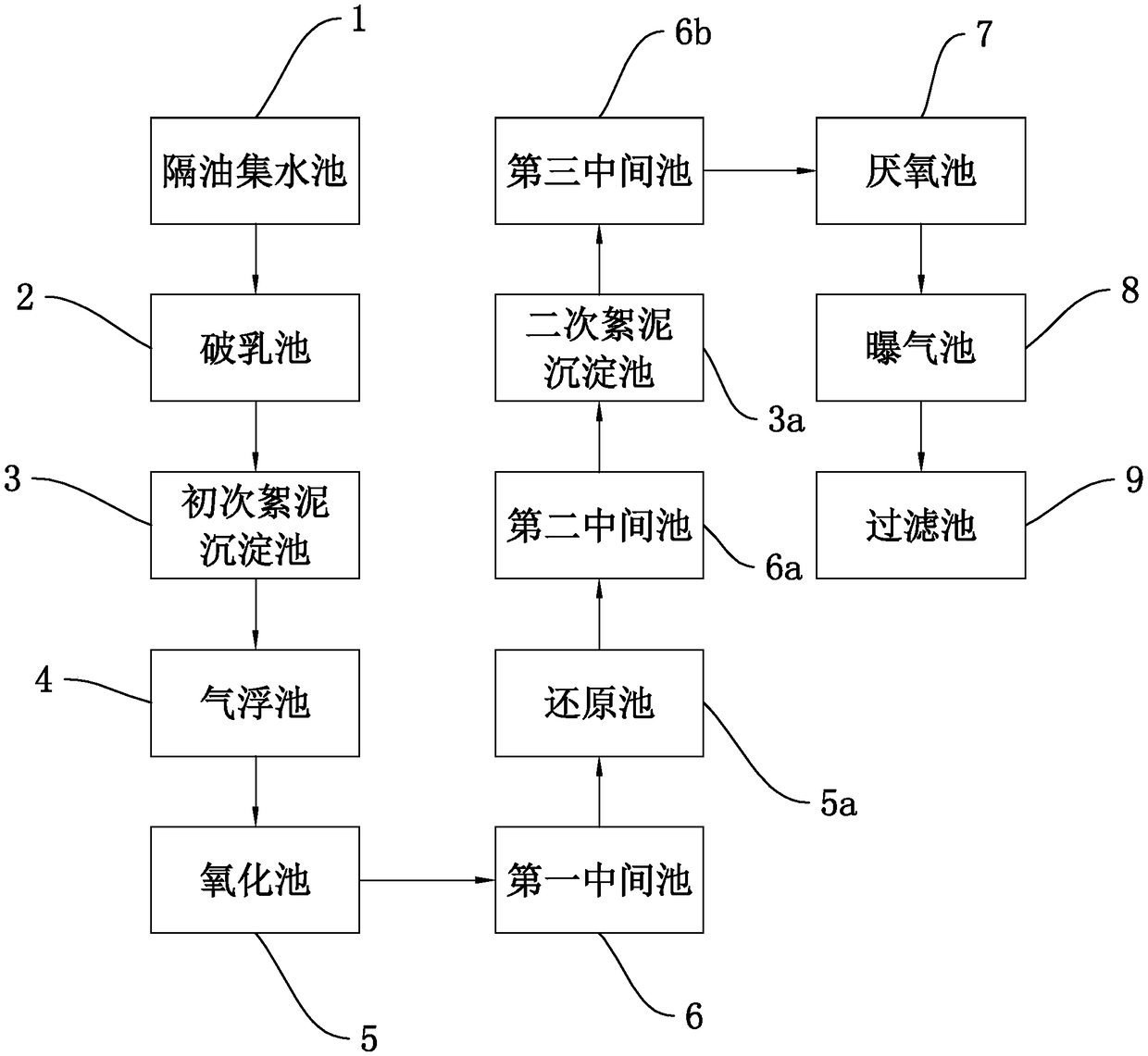

[0052] as attached figure 1 As shown, an industrial oily wastewater treatment system includes sequentially connected oil separation pool 1, demulsification tank 2, primary floc sedimentation tank 3, air flotation tank 4, oxidation tank 5, reduction tank 5a, secondary floc sedimentation pool 3a, anaerobic pool 7, aeration pool 8 and filter pool 9. A first intermediate pond 6 is arranged between the oxidation pond 5 and the reduction pond 5a, and a second intermediate pond 6a is arranged between the reduction pond 5a and the secondary floc sedimentation pond 3a; the secondary floc sedimentation pond 3a and the anaerobic pond 7 There is a third intermediate pool 6b between them.

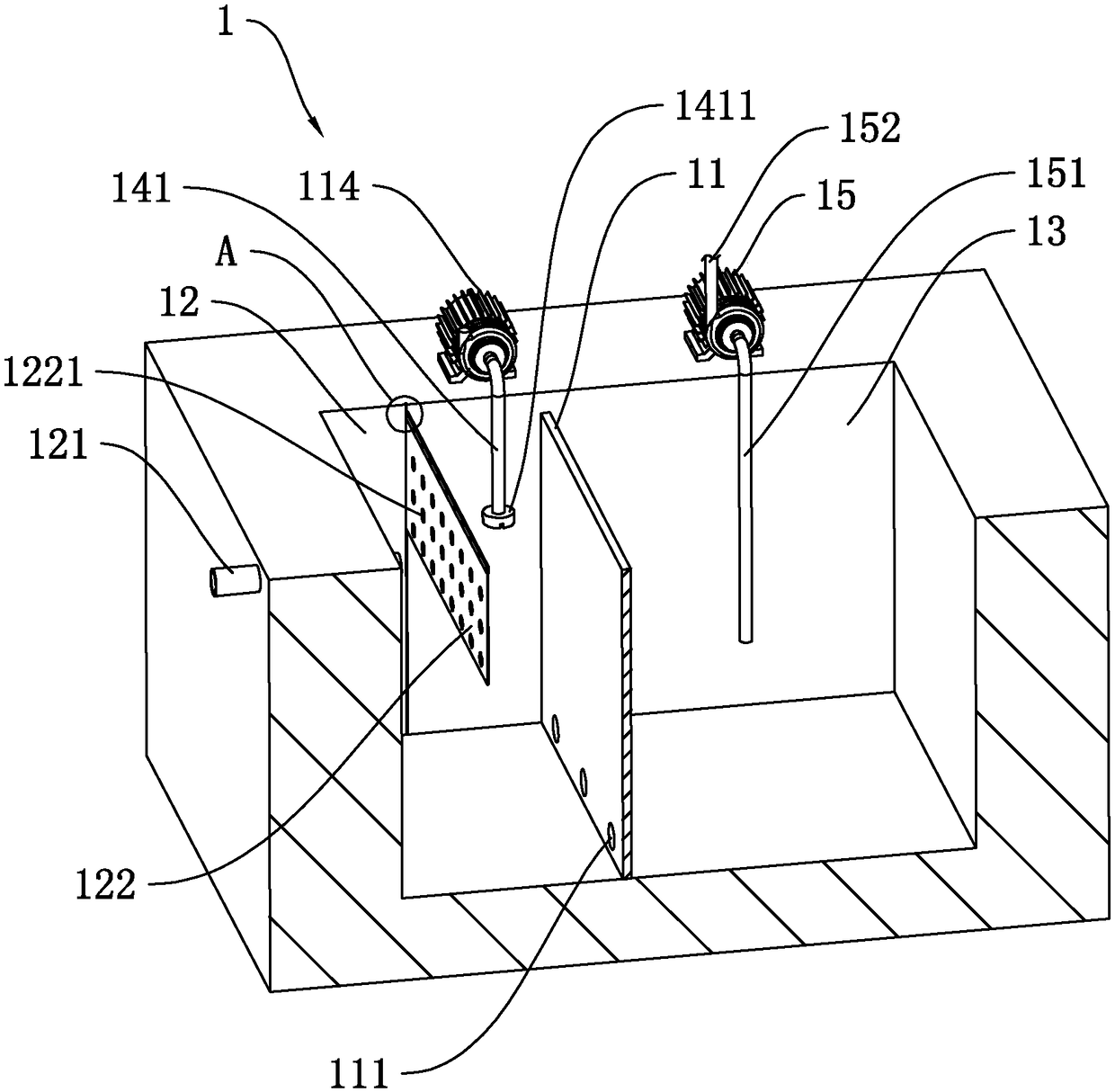

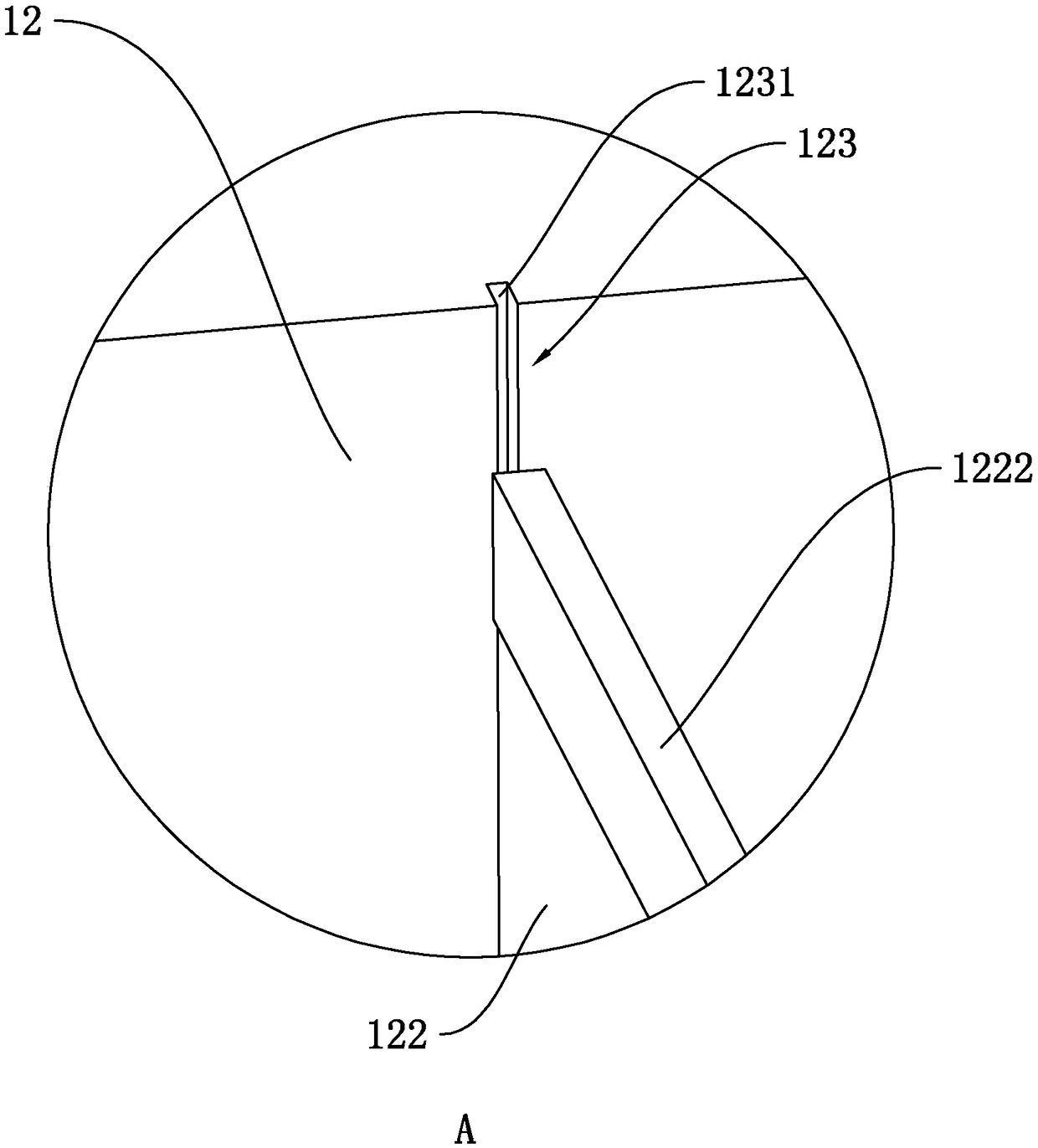

[0053] as attached figure 2 As shown, the shape of the oil separation sump 1 can be determined according to the actual situation, where it is cuboid and open at the top. An oil separator 11 is arranged in the oil separation pool 1 , and both sides and the bottom of the oil barrier 11 are sealed and ...

Embodiment 2

[0089] as attached Figure 18 Shown, a kind of industrial oily wastewater treatment system, it is based on the basis of embodiment 1, and its difference lies in the difference of oil separation sump 1. In the second embodiment, the oil separation pool 1 includes a liquid inlet pool 1a, an oil separation pool 1b, and a water separation pool 1c, which are arranged adjacently and communicate with each other at the upper end. The liquid inlet pool 1a and the oil separation pool 1b are separated by a first partition 1d, and the height of the first partition 1d is h1. The oil separation pool 1b and the water separation pool 1c are separated by a second partition 1e, and the height of the second partition 1e is h2.

[0090] The side wall of the liquid inlet pool 1a is connected with a liquid inlet pipe 121 communicating with oily waste water, and the height of the liquid inlet pipe 121 is lower than that of the first partition 1d. A buffer net 1a1 parallel to the first partition 1d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com