Diamond recovery method for resin diamond scroll saw

A technology of diamond wire saw and recycling method, applied in the field of diamond recycling of resin diamond wire saw, can solve the problems of polluted environment, unsuitable environmental protection requirements, and high injury to operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

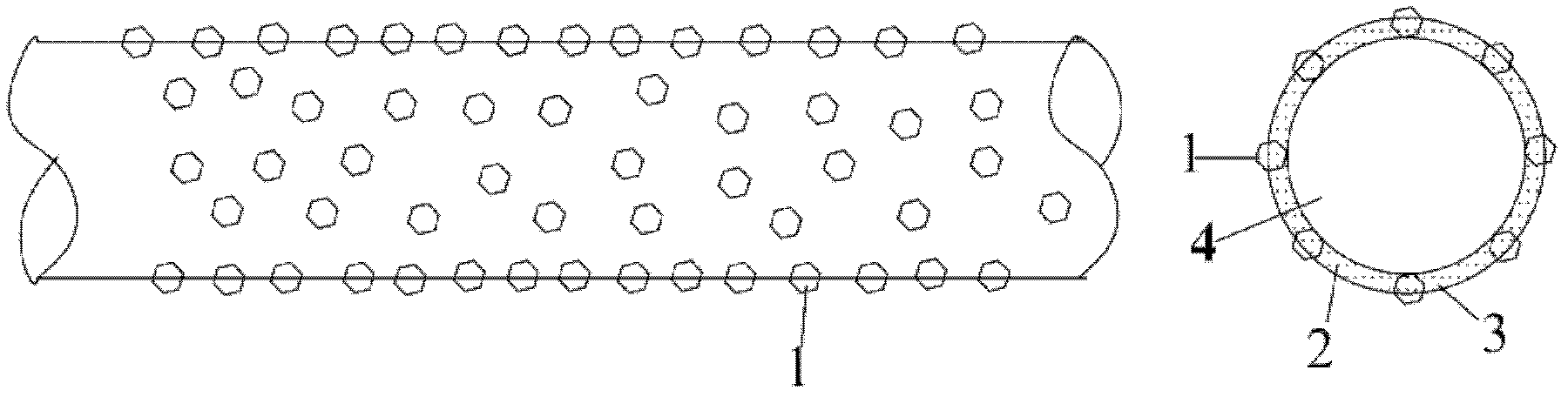

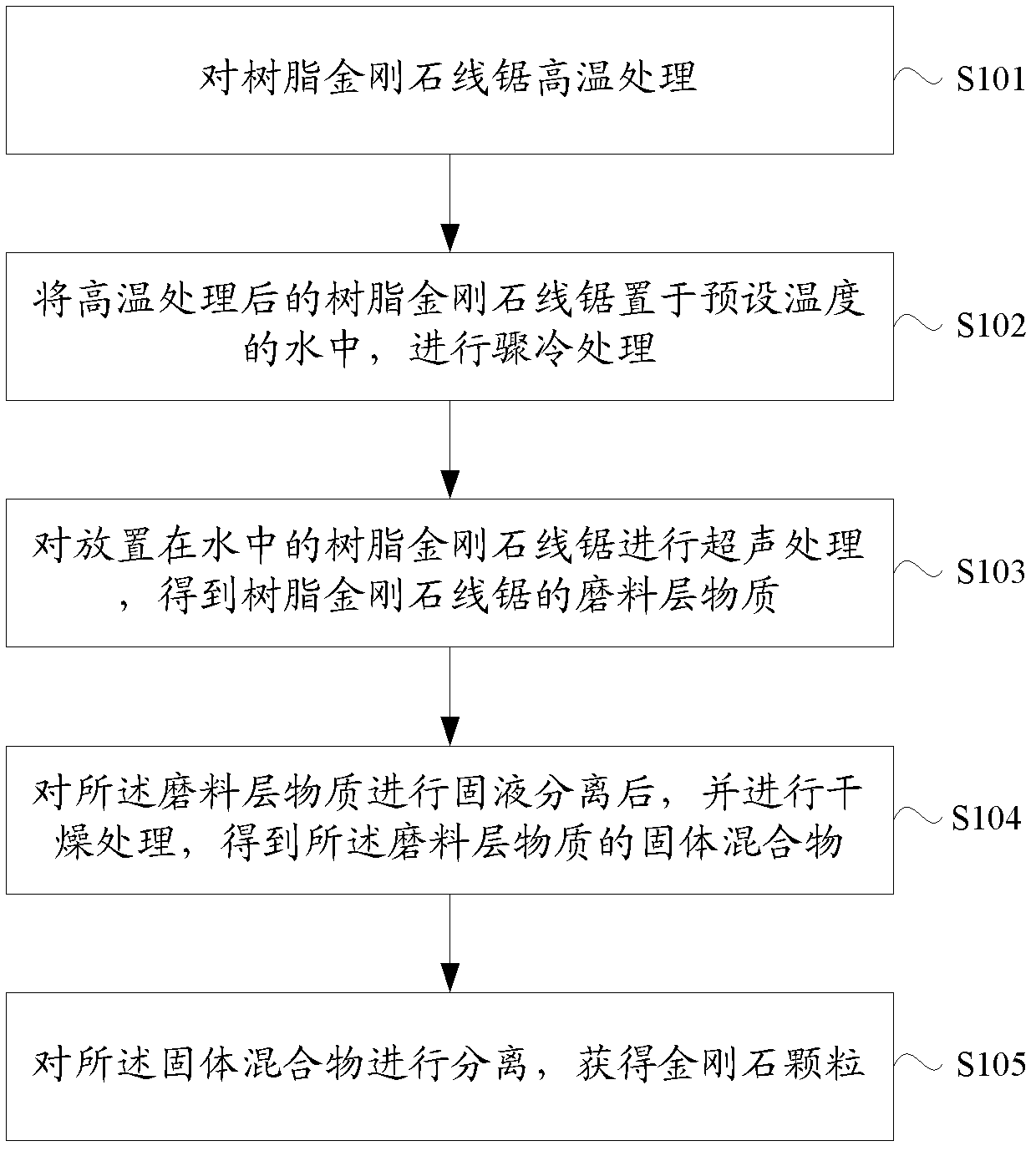

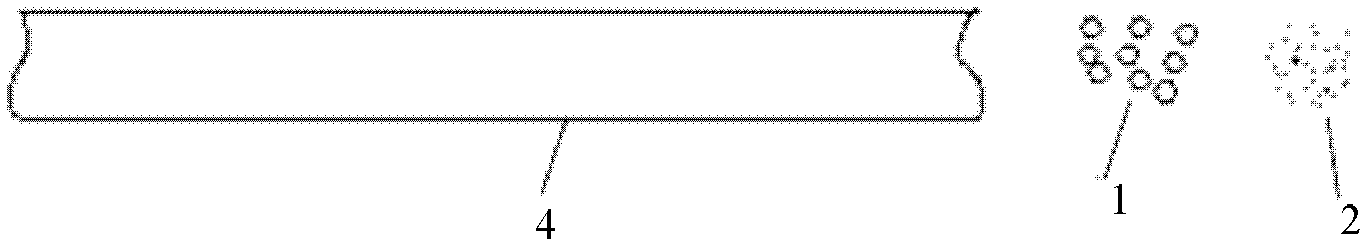

[0017] In the prior art, diamonds from resin diamond wire saws are recovered by means of concentrated acid treatment, which not only causes harm to the operators themselves, but also pollutes the environment. It can be seen that the existing recycling methods cannot meet today's environmental protection needs. The embodiment of the present invention provides a diamond recovery method for resin diamond wire saws, which effectively solves the problems in the prior art by physically recovering diamonds on the wire saws. The method includes:

[0018] High temperature treatment of resin diamond wire saw;

[0019] Place the high temperature treated resin diamond wire saw in water at a preset temperature for quenching treatment;

[0020] Ultrasonic treatment is carried out on the resin diamond wire saw placed in water to obtain the abrasive layer material of the resin diamond wire saw;

[0021] performing solid-liquid separation on the abrasive layer material, and performing dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com