Printing and dyeing wastewater treatment device

A treatment device, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high cost of chemical treatment, secondary pollution, and large consumption of chemical treatment agents, etc., to achieve Good filtering effect, saving energy and avoiding the use of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

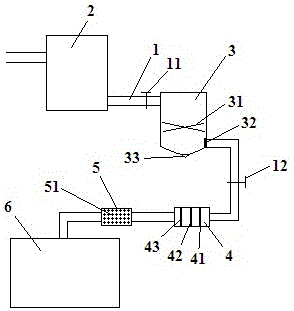

[0014] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 The printing and dyeing wastewater treatment device shown includes a wastewater pool 2, an adsorption clarifier 3, a secondary filter 4, a tertiary filter 5, and a reservoir 6 connected in sequence through a drain pipe 1, and the printing and dyeing wastewater is stored in the wastewater pool 2 Among them, the waste water tank 2 is placed above the adsorption clarifier 3, the secondary filter device 4, the tertiary filter device 5 and the reservoir 6, and the waste water in the waste water tank 2 passes through the adsorption clarifier 3 under the action of the water pressure of its own weight. , After the secondary filtering device 4 and the tertiary filtering device 5 are purified and filtered, the purified water is discharged into the reservoir 6 .

[0015] Further, a stirring device 31 is provided in the adsorption clarification tank 3, and a filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com