New medical solid waste utilization method and device

A new method and medical technology, applied in the field of medical solid waste utilization, can solve the problems of increasing the cost and pressure of gas treatment, poor use of heat, and easy generation of polluting gases, etc., to achieve economic and environmental benefits, The effect of reducing the generation of polluting gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A new method of medical solid waste utilization, including:

[0032] (1) After mixing the medical solid waste and coal powder at a weight ratio of 1:1, put them into a fluid-solid coupling combustion device for incineration treatment, generate heat and slag I, and use the heat for power generation;

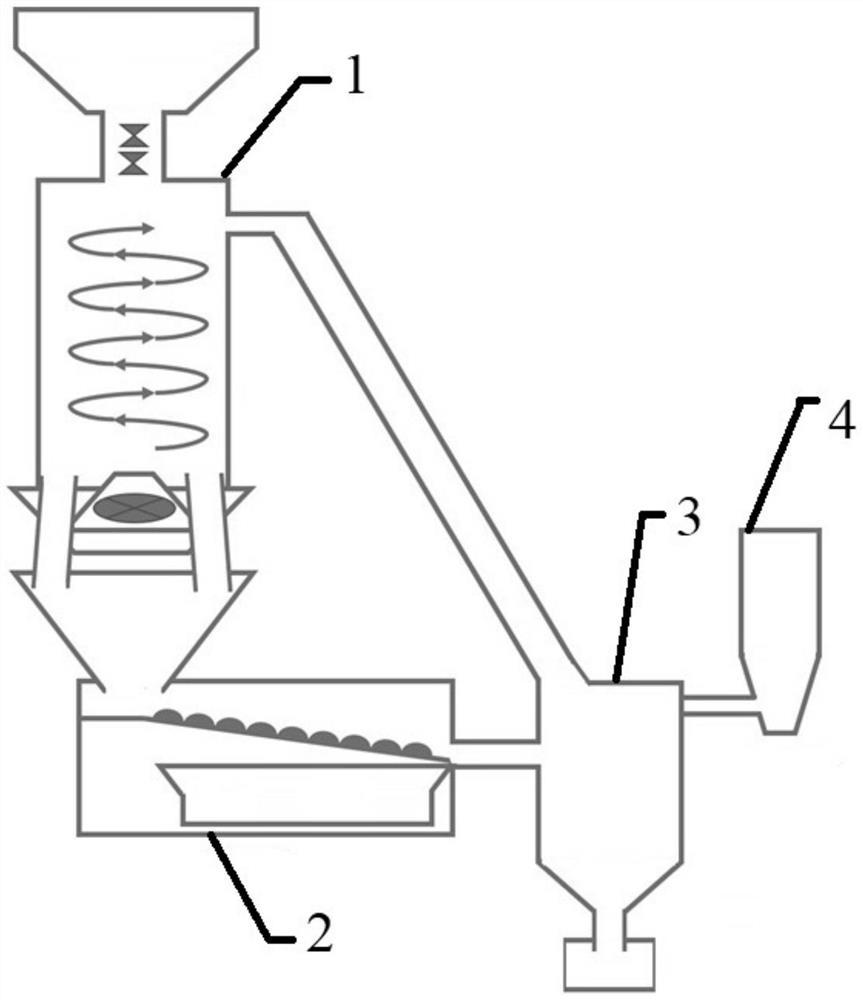

[0033] The fluid-solid coupling combustion device includes a cyclone furnace and a grate furnace arranged from top to bottom, and a channel for the medical solid waste to pass is provided between the bottom of the cyclone furnace and the feed port of the grate furnace ;

[0034] Setting the furnace temperature of the cyclone furnace and the grate furnace to be 1400°C;

[0035] (2) The unburned solid waste and pulverized coal are burned again in the secondary incinerator, and the furnace temperature of the secondary incinerator is set to be 1400° C. to generate heat and slag II, and the heat is used for power generation, and the Slag I and Slag II are mixed for the prepara...

Embodiment 2

[0038] A new method of medical solid waste utilization, including:

[0039] (1) After mixing the medical solid waste and coal powder at a weight ratio of 2:1, put them into a fluid-solid coupling combustion device for incineration treatment, generate heat and slag I, and use the heat for power generation;

[0040] The fluid-solid coupling combustion device includes a cyclone furnace and a grate furnace arranged from top to bottom, and a channel for the medical solid waste to pass is provided between the bottom of the cyclone furnace and the feed port of the grate furnace ;

[0041] Setting the furnace temperature of the cyclone furnace and the grate furnace to be 1400°C;

[0042] (2) The unburned solid waste and pulverized coal are burned again in the secondary incinerator, and the furnace temperature of the secondary incinerator is set to be 1400° C. to generate heat and slag II, and the heat is used for power generation, and the Slag I and Slag II are mixed for the prepara...

Embodiment 3

[0045] A new method of medical solid waste utilization, including:

[0046] (1) After mixing the medical solid waste and coal powder at a weight ratio of 3:1, put them into a fluid-solid coupling combustion device for incineration treatment, generate heat and slag I, and use the heat for power generation;

[0047] The fluid-solid coupling combustion device includes a cyclone furnace and a grate furnace arranged from top to bottom, and a channel for the medical solid waste to pass is provided between the bottom of the cyclone furnace and the feed port of the grate furnace ;

[0048] Setting the furnace temperature of the cyclone furnace and the grate furnace to be 1400°C;

[0049] (2) The unburned solid waste and pulverized coal are burned again in the secondary incinerator, and the furnace temperature of the secondary incinerator is set to be 1400° C. to generate heat and slag II, and the heat is used for power generation, and the Slag I and Slag II are mixed for the prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com