Novel method and device for coupling utilization of sludge and urban garbage energy resources

A technology of municipal waste and new method, applied in the field of comprehensive utilization of solid waste resources, can solve problems such as easy generation of polluting gas, insufficient combustion process, unsatisfactory incinerator temperature, etc., to achieve economic and environmental benefits, Dioxin reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention firstly provides a new method for coupled utilization of sludge and urban waste energy resources, including:

[0037] (1) Mix the sludge and pulverized coal at a weight ratio of 1:1, and incinerate in a cyclone furnace; mix the municipal waste with pulverized coal at a weight ratio of 1:1, and incinerate in a grate furnace; Set the furnace temperature of the cyclone furnace and the grate furnace to 1400°C; generate heat and slag I and slag II, and use the heat for power generation;

[0038] (2) Burn the unburned mixed fuel again in the secondary incinerator, set the furnace temperature of the secondary incinerator to 1500°C, generate heat and slag 3, use the heat for power generation, and use the slag III It is mixed evenly with slag I and slag II and then subjected to quenching and tempering treatment to prepare glass-ceramics.

[0039]The calorific value of mixed fuel per ton of sludge, urban waste and coal powder is 4421Kcal / Kg (k is lowercase)...

Embodiment 2

[0041] The present invention firstly provides a new method for coupled utilization of sludge and urban waste energy resources, including:

[0042] (1) Mix the sludge and pulverized coal in a weight ratio of 1:2, and incinerate in a cyclone furnace; mix the municipal waste and pulverized coal in a weight ratio of 1:2, and incinerate in a grate furnace; Set the furnace temperature of the cyclone furnace and the grate furnace to 1400°C; generate heat and slag I and slag II, and use the heat for power generation;

[0043] (2) Burn the unburned mixed fuel again in the secondary incinerator, set the furnace temperature of the secondary incinerator to 1400°C, generate heat and slag 3, use the heat for power generation, and use the slag III It is mixed evenly with slag I and slag II and then subjected to quenching and tempering treatment to prepare glass-ceramics.

[0044] The calorific value of mixed fuel per ton of sludge, municipal waste and coal powder is 5280Kcal / Kg, the amount ...

Embodiment 4

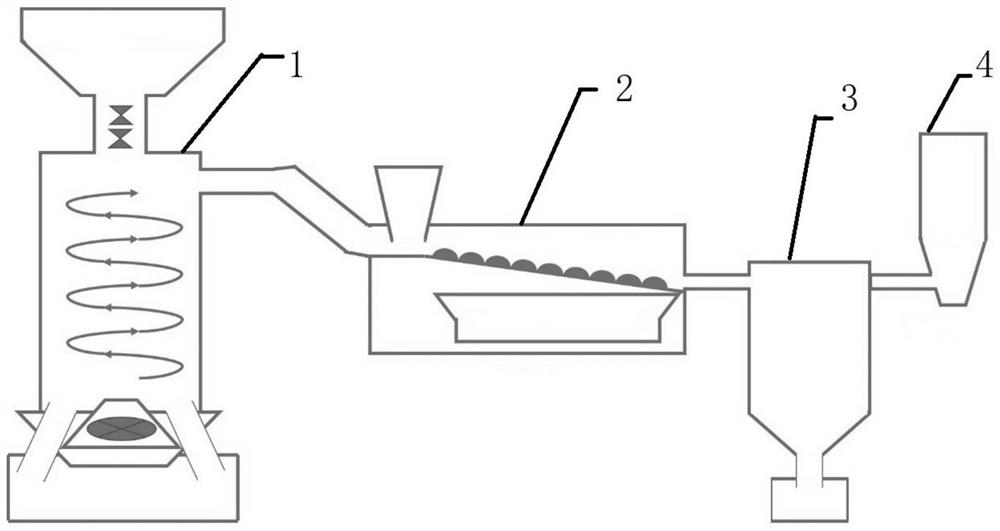

[0046] This embodiment provides a device for implementing the methods described in Embodiments 1-2 (a fluid-solid coupling combustion device, see figure 1 ), including garbage sorting unit, cyclone furnace 1, grate furnace 2, secondary incinerator 3, flue gas purification unit 4, power generation unit, glass-ceramic preparation unit,

[0047] The garbage sorting unit sorts the garbage according to the density difference, and the discharge port is respectively connected to the feed inlet of the cyclone furnace 1 and the grate furnace 2;

[0048] A heat communication pipe is provided between the cyclone furnace 1 and the grate furnace 2, and the unburned fuel outlets of the cyclone furnace 1 and the grate furnace 2 are connected to the feed of the secondary incinerator 3 mouth,

[0049] The heat outlets of the cyclone furnace 1, the grate furnace 2 and the secondary incinerator 3 are connected to power generation units; the slag discharge ports of the cyclone furnace 1, the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com