Pt-Fe/C catalyst as well as preparation method and application thereof

A catalyst, pt-fe technology, applied in the field of precious metal catalyst preparation, can solve the problems of unfavorable industrialization and high production cost of carbon nanotubes, and achieve the effects of narrow distribution, reduction of product separation and purification steps, and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

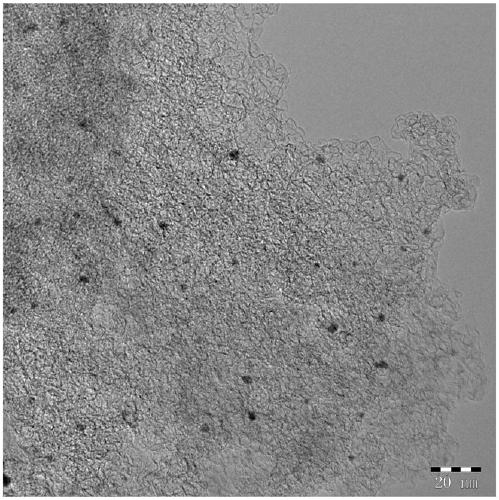

Image

Examples

Embodiment 1

[0032] 1. Activated carbon was treated with 10wt% hydrogen peroxide for 1 hour, and the solid-to-liquid ratio (g / mL) was 1:10, washed and dried as a carrier for subsequent use;

[0033] 2. Dissolve chloroplatinic acid containing 0.1g of platinum and 0.96g of ferric chloride hexahydrate in 16mL of ethylene glycol solvent, add 1.0g of oleic acid as a carrier modifier, stir for 30min, and prepare the active component impregnation solution;

[0034] 3. Add the active component impregnation solution to 9.7g of hydrogen peroxide-treated activated carbon, stir and absorb, and let stand for 16 hours to obtain a carbon carrier loaded with platinum and iron;

[0035] 4. Add 0.5g of formaldehyde solution into 80mL of ethylene glycol solvent, stir evenly and add it into the carrier of platinum and iron in step (3), stir and disperse for 30min, add 10wt% NaOH solution dropwise to adjust the pH of the system to 12~ 13. Raise the temperature to 80°C, keep it warm for 1.5h, add 80mL ethanol a...

Embodiment 2

[0037] 1. Activated carbon was treated with 10wt% hydrogen peroxide for 1 hour, and the solid-to-liquid ratio was 1:10, washed and dried for later use;

[0038] 2. Dissolve chloroplatinic acid containing 0.2g of platinum and 1.94g of ferric chloride hexahydrate in 32mL of ethylene glycol, add 2.0g of oleic acid, stir for 30min, and prepare the active component impregnation solution;

[0039] 3. Add the active component impregnating solution to 19.4 g of oxidized activated carbon, stir and absorb, and let it stand for 16 hours to obtain a carbon carrier loaded with platinum and iron;

[0040] 4. Dissolve 0.8g of sodium formate in 150mL of ethylene glycol, stir evenly and add it into the carrier of platinum and iron in step (3), stir and disperse for 30min, add 10wt% NaOH solution dropwise to adjust the system pH=12~13, Raise the temperature to 80°C, keep it warm for 1.5h, add 150mL ethanol aqueous solution with a volume ratio of 1:1 to dilute, let it stand for aging, filter, wa...

Embodiment 3

[0042]Same as Example 1, except that the amount of ferric chloride hexahydrate is 0.49g, and the obtained catalyst is a 1%Pt-1%Fe / C catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com