Patents

Literature

79results about How to "Reduce separation and purification steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

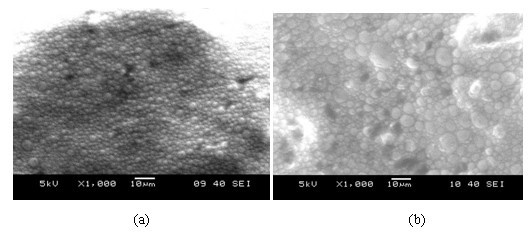

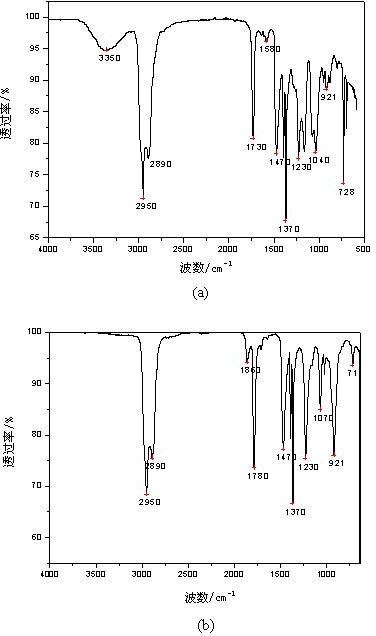

Synthesis method of emulsifier for emulsion explosive

InactiveCN102558409AReduce separation and purification stepsThe synthesis method is simpleTransportation and packagingMixingSynthesis methodsEmulsion explosive

The invention relates to a novel emulsifier for emulsion explosives, which is product of reaction of PIBSA (polyisobutylene succinic anhydride) and triethanolamine. The method has the advantages that no catalyst is needed for reaction, changes in the reaction acid value can be followed during the reaction process, and the ending of reaction can be determined according to the acid value. The emulsifier synthesized in the method has high emulsion capacity, and the prepared emulsion explosive has high stability for storage and excellent explosive performance. The emulsifier can also be used as adispersing agent in lubricants to effectively disperse oil sludge.

Owner:NANJING UNIV OF SCI & TECH

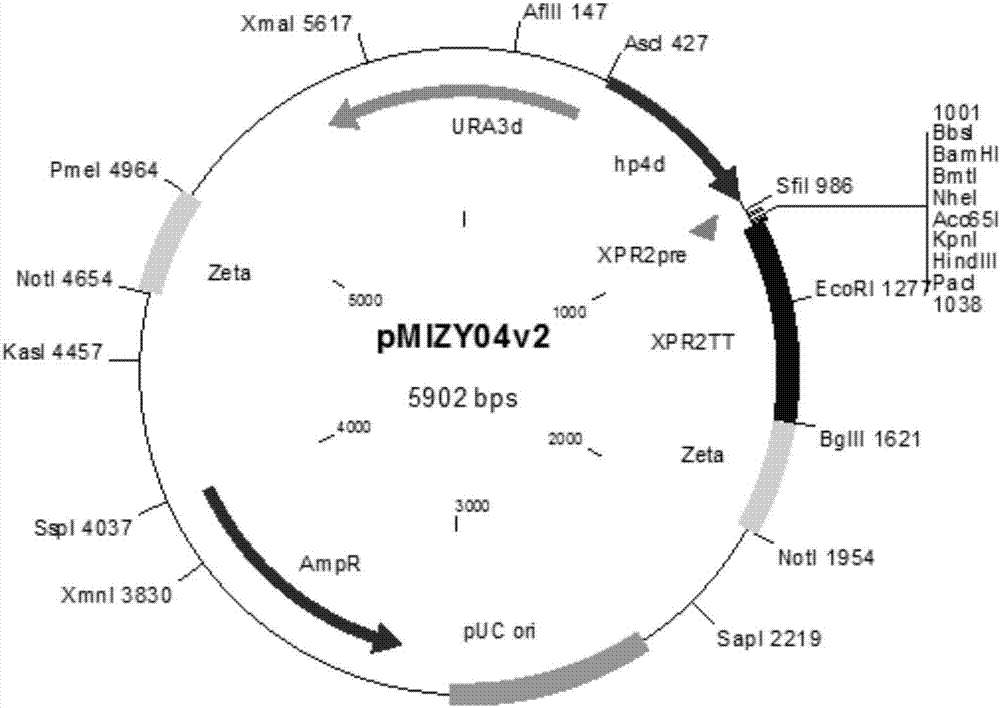

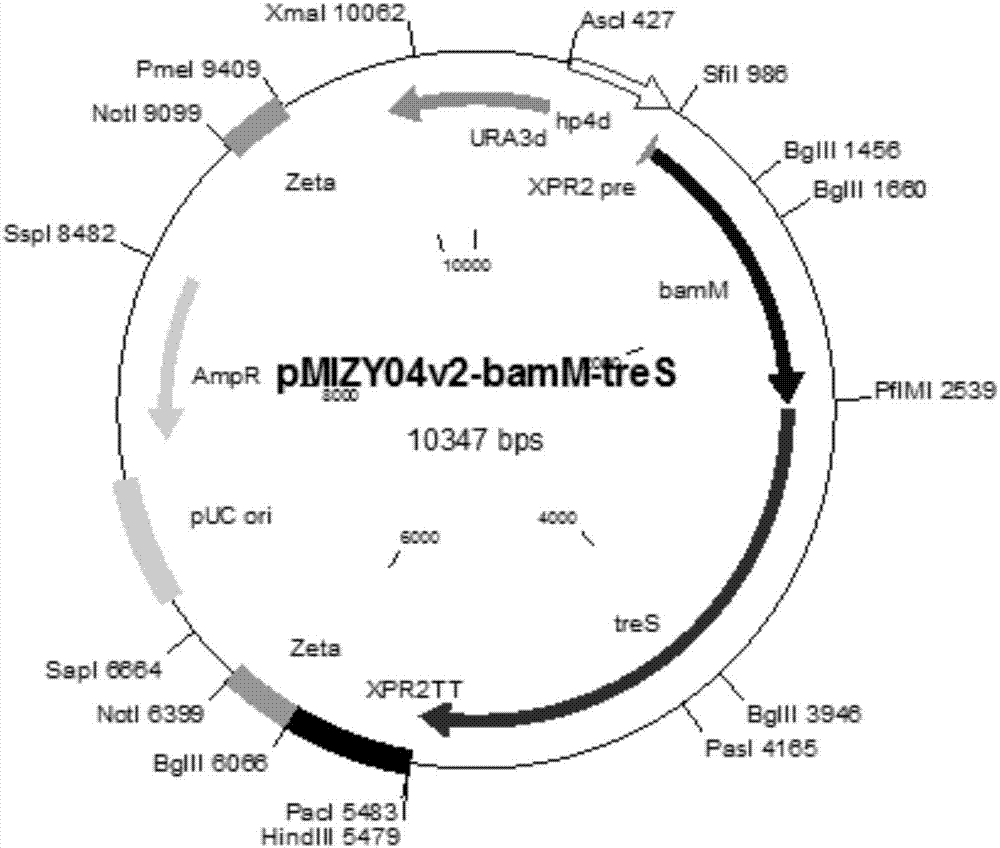

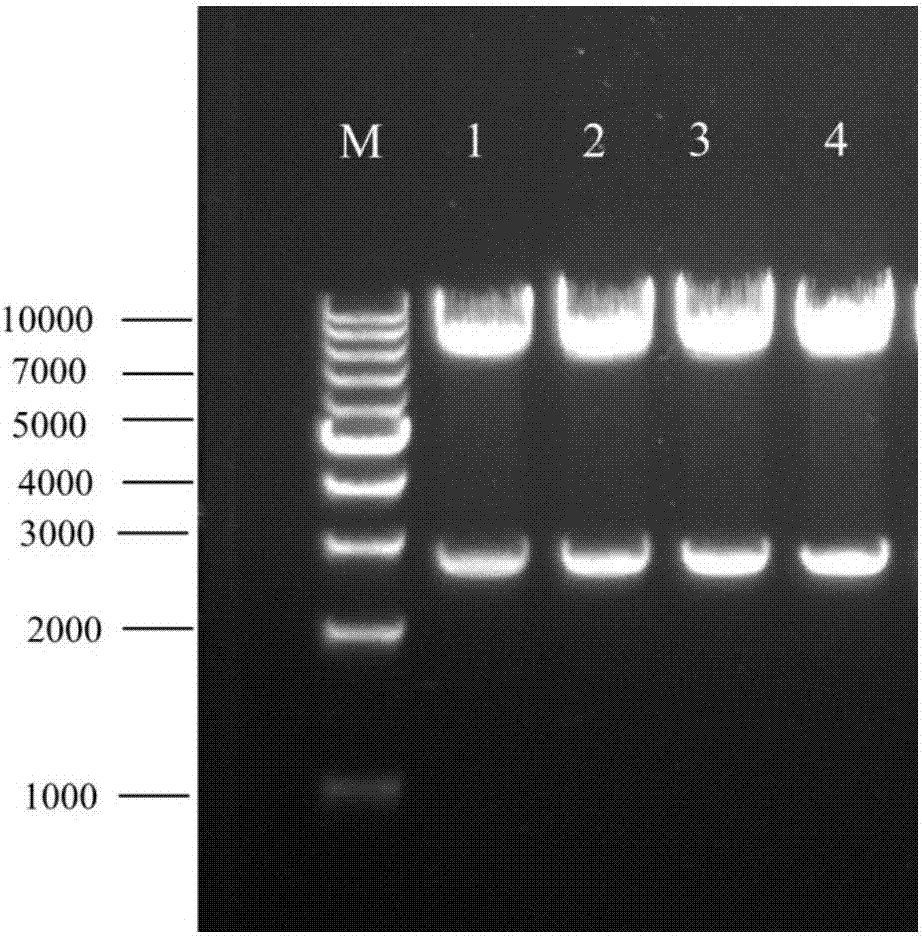

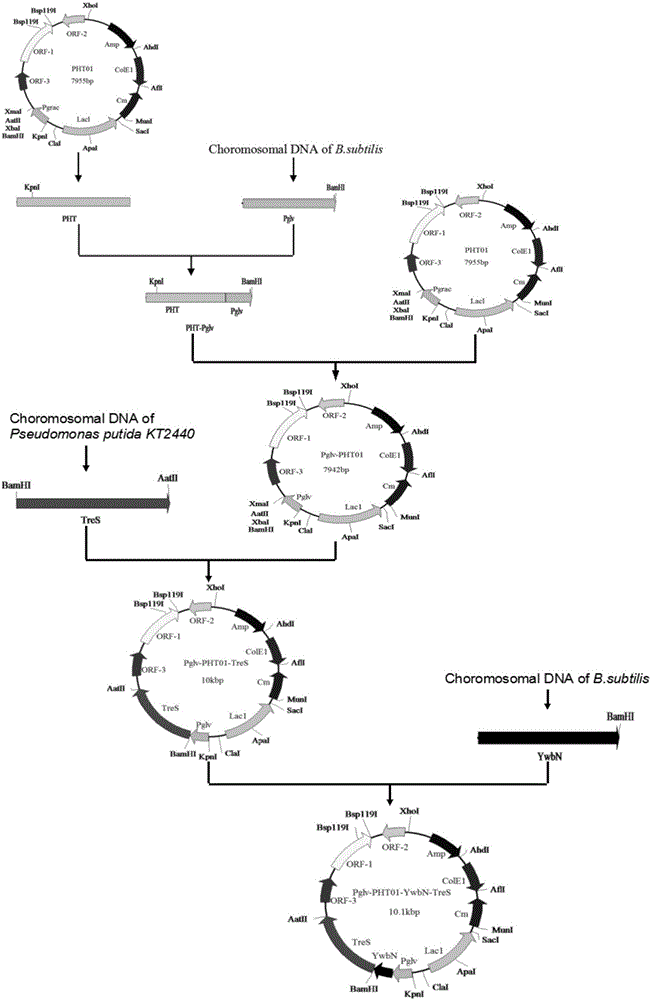

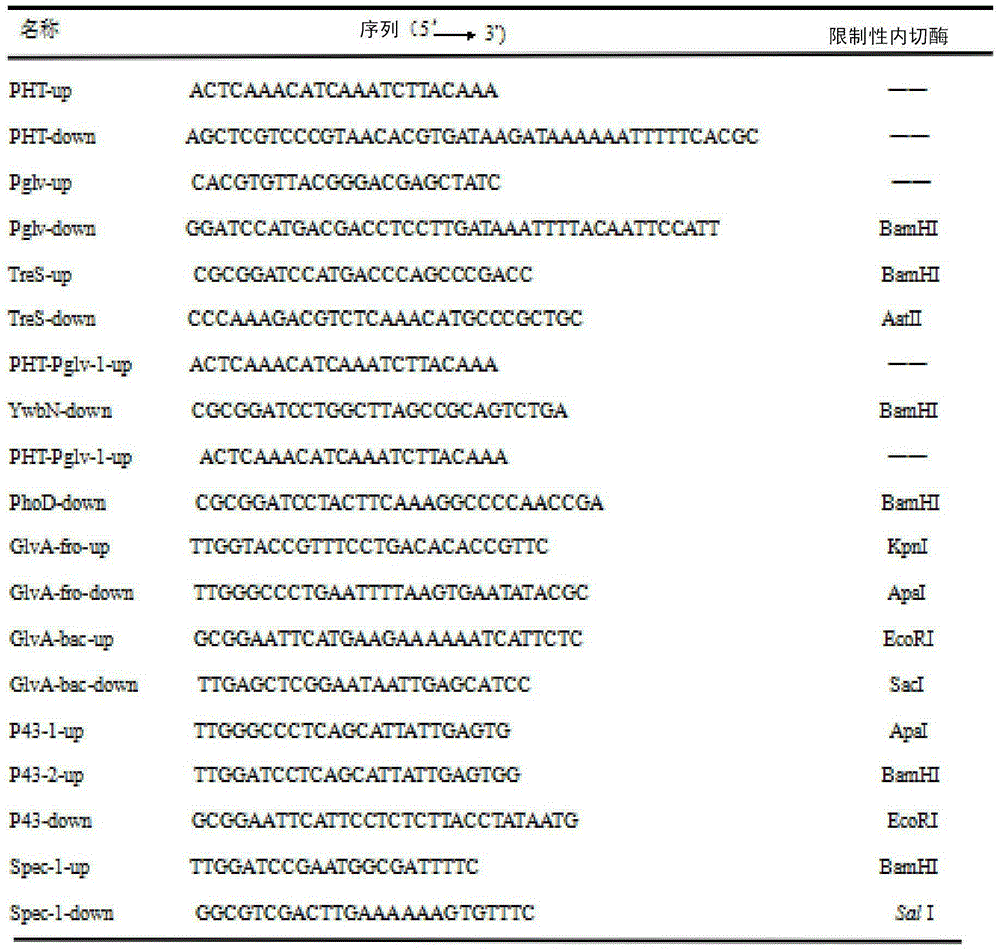

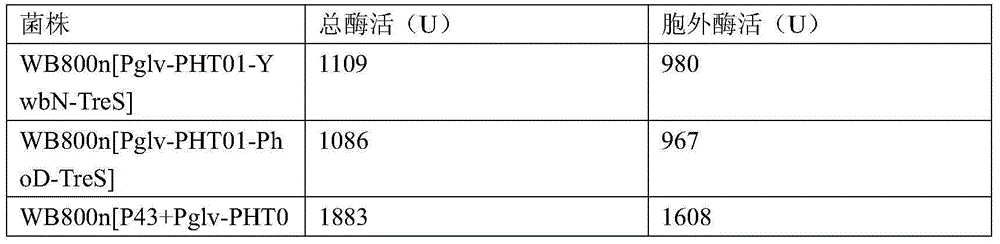

Maltose inducible trehalose synthase synthesis engineering bacterium, method for preparing same and application

The invention relates to a maltose inducible trehalose synthase synthesis engineering bacterium, a method for preparing the same and application. The maltose inducible trehalose synthase synthesis engineering bacterium is characterized in that maltose inducible promoters are inserted in the fronts of BamHI cleavage sites of PHT01 plasmids of recombinant plasmid vectors instead of Pgrac promoters on the PHT01 plasmids, expression genes of Tat type signal peptides are inserted in the fronts of the BamHI cleavage sites, and expression genes of trehalose synthase are inserted in the rears of the BamHI cleavage sites. The maltose inducible trehalose synthase synthesis engineering bacterium, the method and the application have the advantage that expression effects realized after the maltose inducible promoters and the trehalose synthase are fused with one another are obviously superior to other inducible expression effects.

Owner:山东开盾生物科技有限公司

Gene for coding glutamine dipeptide biosynthetic enzyme and application thereof

ActiveCN106754985AImprove conversion efficiencyResolve separabilityBacteriaMicroorganism based processesEscherichia coliDipeptide

The invention discloses a gene for coding a glutamine dipeptide biosynthetic enzyme and application thereof. The nucleotide sequence of the gene is shown as SEQ ID NO.1. The invention further discloses an amino acid sequence coded by the gene, and provides a recombinant vector containing the gene, recombinant escherichia coli, and a method for performing biotransformation to synthesize the glutamine dipeptide by using the gene. The gene and the application of a recombinant bacterial strain of the gene have the advantages of high mol conversion rate, high reaction speed, easy separation, low cost and the like. In the synthesis method, the maximum mol conversion rate of the glutamine dipeptide can reach 83.3 percent; meanwhile, the thalli can be applied to the catalytic synthesis of the glutamine dipeptide again after the circulation recovery; in addition, the catalytic activity is stable. Therefore high market competitive power and application values are realized; a foundation is laid for the industrial production of the glutamine dipeptide.

Owner:INNOBIO CORP LTD

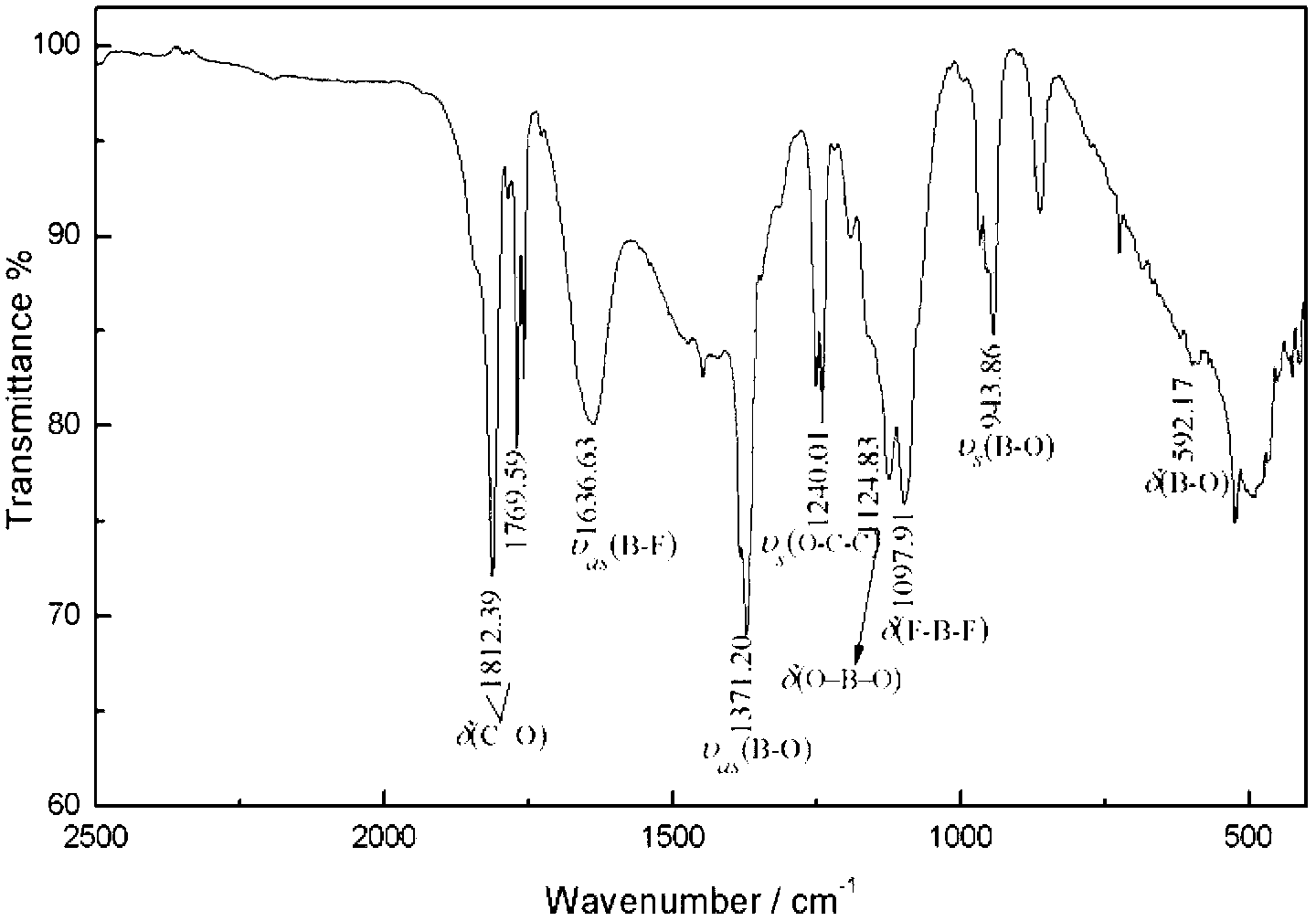

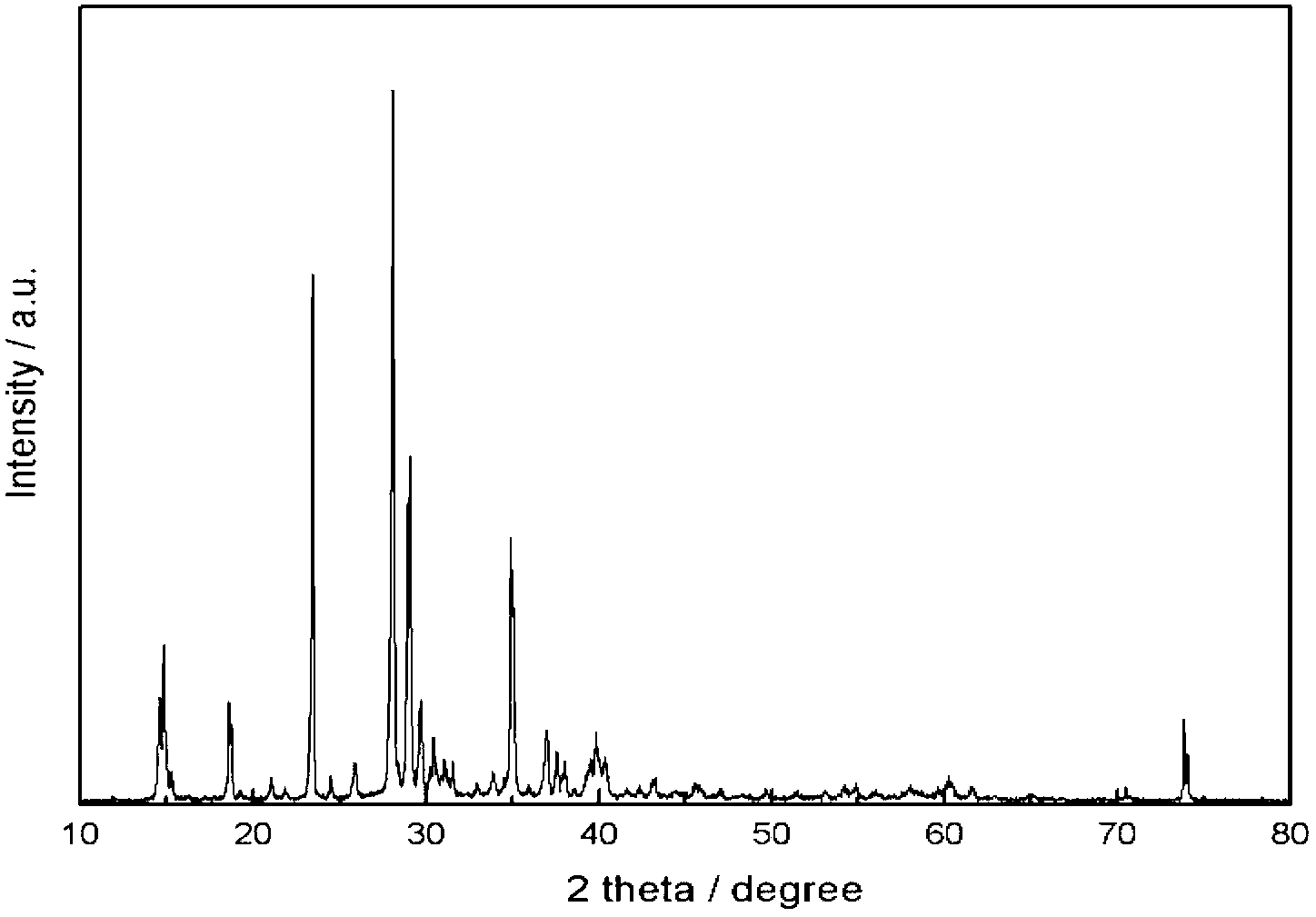

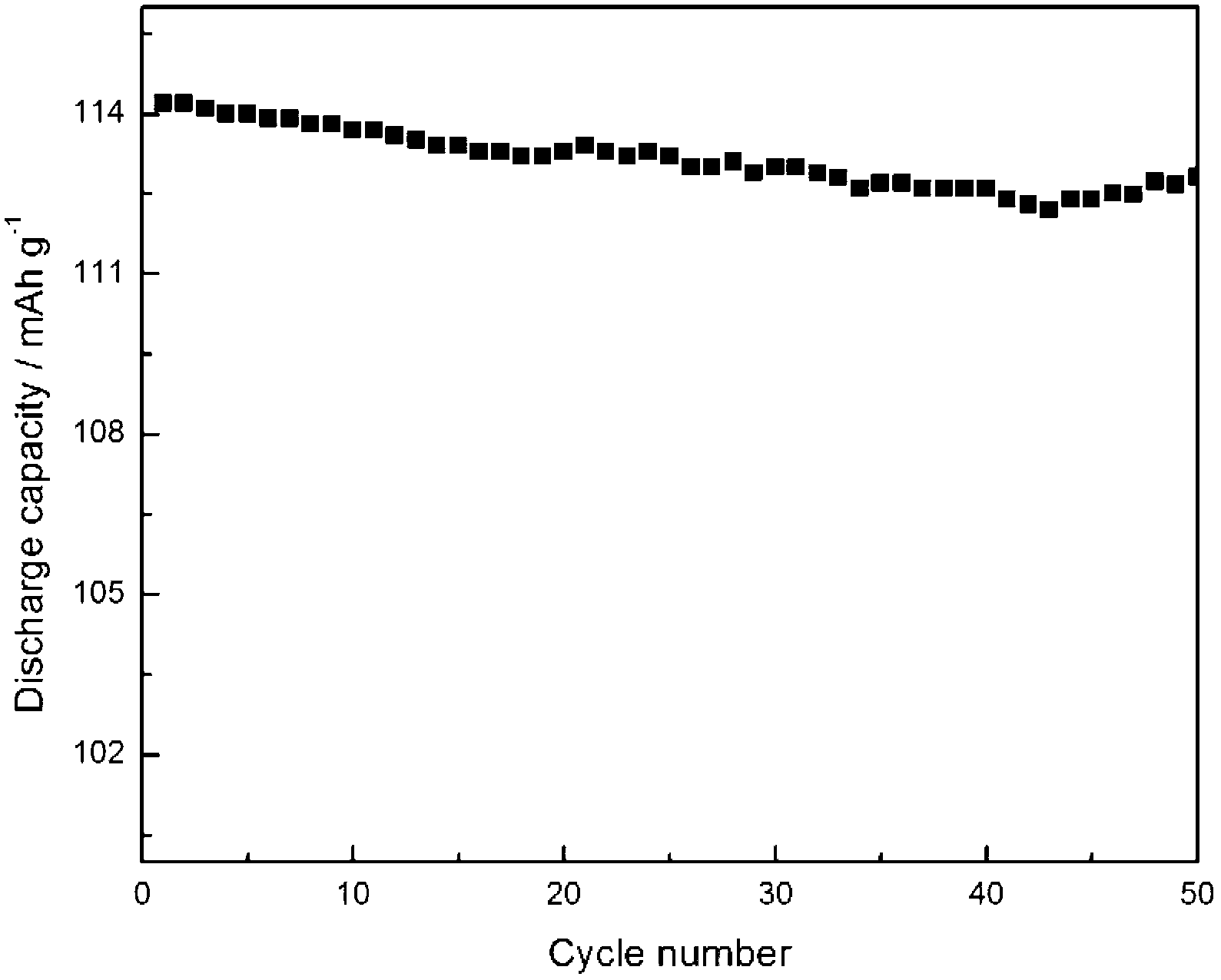

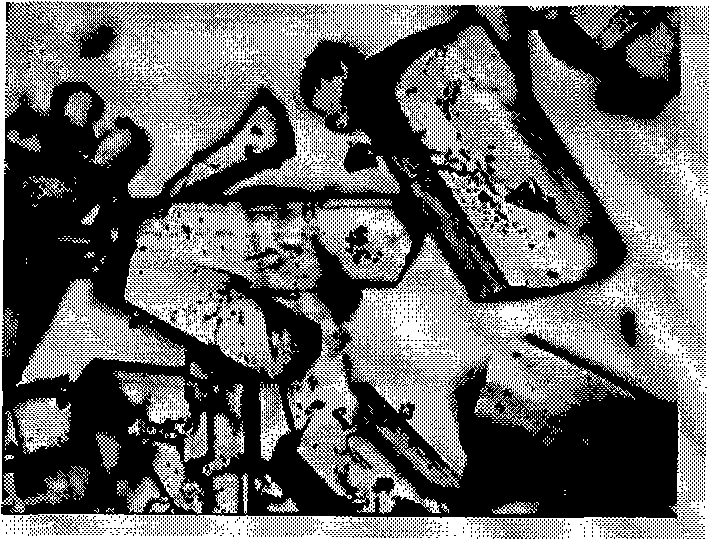

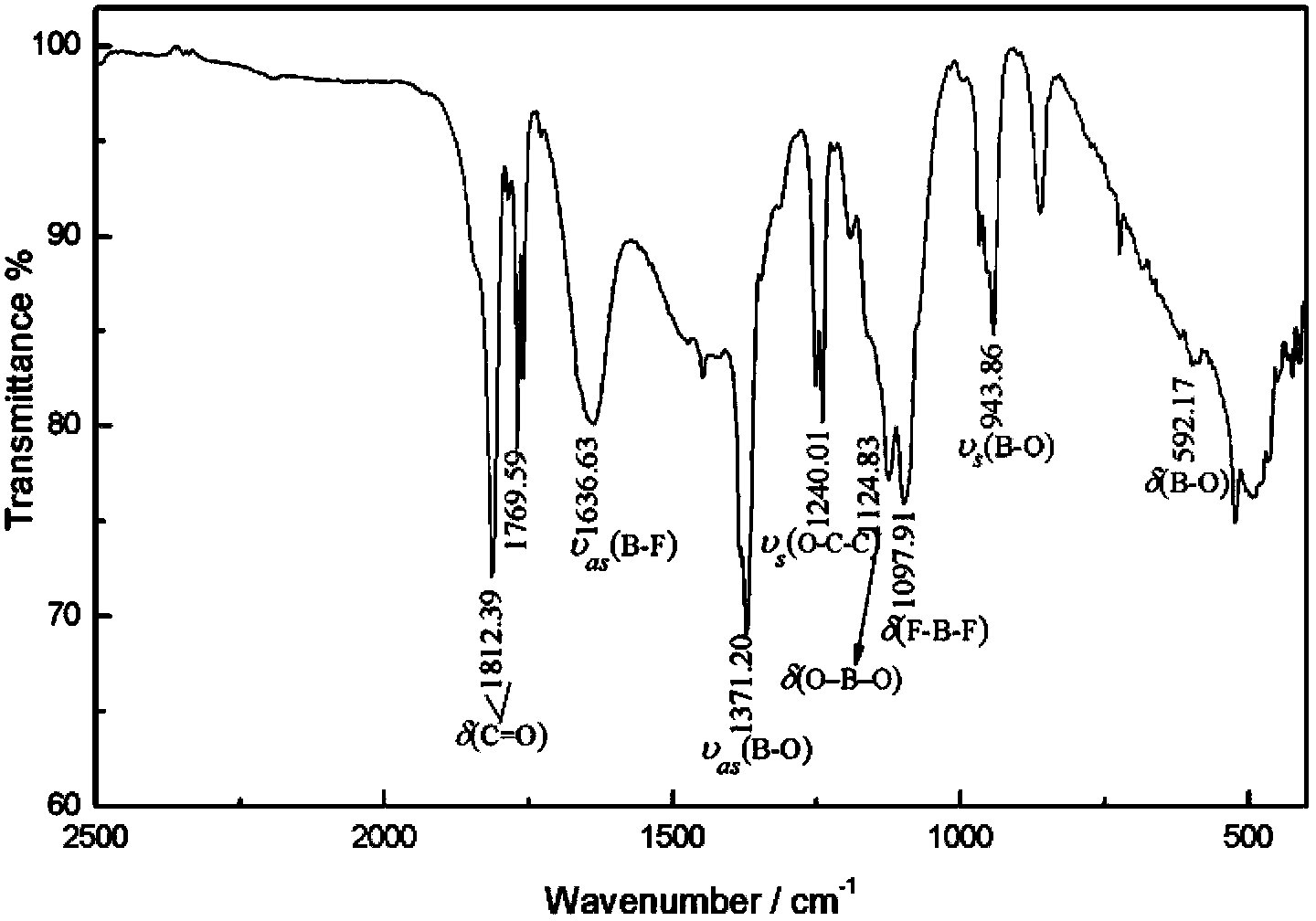

Method for preparation and purifying lithium difluoroborate

ActiveCN102702243AEasy to industrializeReduce usageSecondary cellsGroup 3/13 element organic compoundsPower batteryPurification methods

The invention relates to a novel method for preparation and purifying an electrolyte lithium salt LiDFOB for a lithium ion battery, which belongs to the technical fields of novel energy materials and preparation. The method comprises the following specific steps of: (1) dissolving anhydrous dry NaBF4 and LiCl into an organic solvent; (2) adding a catalyst, heating, stirring and reflowing at the temperature of 30-80 DEG C, and fully reacting for 4-12 hours; (3) filtering, separating a solid from a liquid to obtain an organic solution of LiBF4, adding H2C2O4 and a catalyst in an inertial atmosphere, performing a magnetic stirring reaction at the temperature of 30-120 DEG C for 4-12 hours till no gas is generated, and ending reaction; and (4), filtering, evaporating a filtrate with a rotary evaporimeter till white solid particles are just formed, adding a non-polar solvent into the white solid particles, recrystallizing at a low temperature, filtering, and drying in vacuum at the temperature of 60 DEG C to obtain a high-purity LiDFOB product. The LiDFOB synthesizing method is simple, used raw materials are safe and nontoxic, an intermediate, i.e., LiBF4 is not required to be separated from a solvent, and the process flow is simplified. The LiDFOB prepared by using the process has superior performance, has a good application prospect in the field of power batteries, and is convenient to industrialize.

Owner:CENT SOUTH UNIV

Separation and purification technology of trehalose by one-step method

InactiveCN101538292AReduce separation and purification stepsReduce manufacturing costSugar derivativesDisaccharidesYeastPurification methods

The invention relates to an extraction, separation and purification method of trehalose, in particular to a separation and purification method of trehalose by one-step. The method comprises the steps of: after extracting dry yeast by using water, adding a flocculating agent to adjust the pH value; and then filtering to obtain clear filtrate, and directly concentrating and crystallizing to obtain trehalose crystals. The method has simple separation and purification steps, convenience and feasibility, low cost and good effect, and provides conditions for the trehalose to be widely used in the fields of medicine, cosmetics, food preservation and the like.

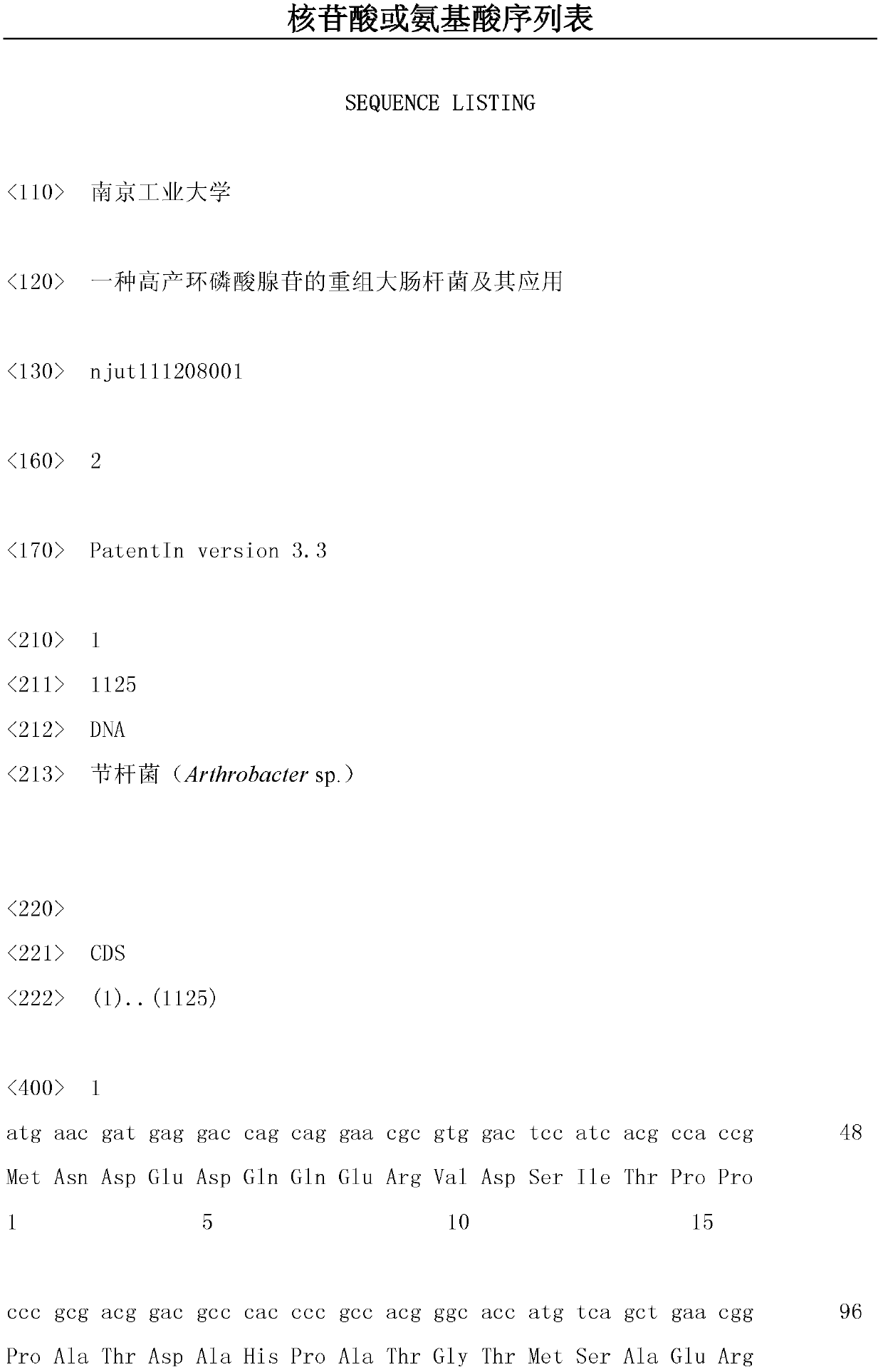

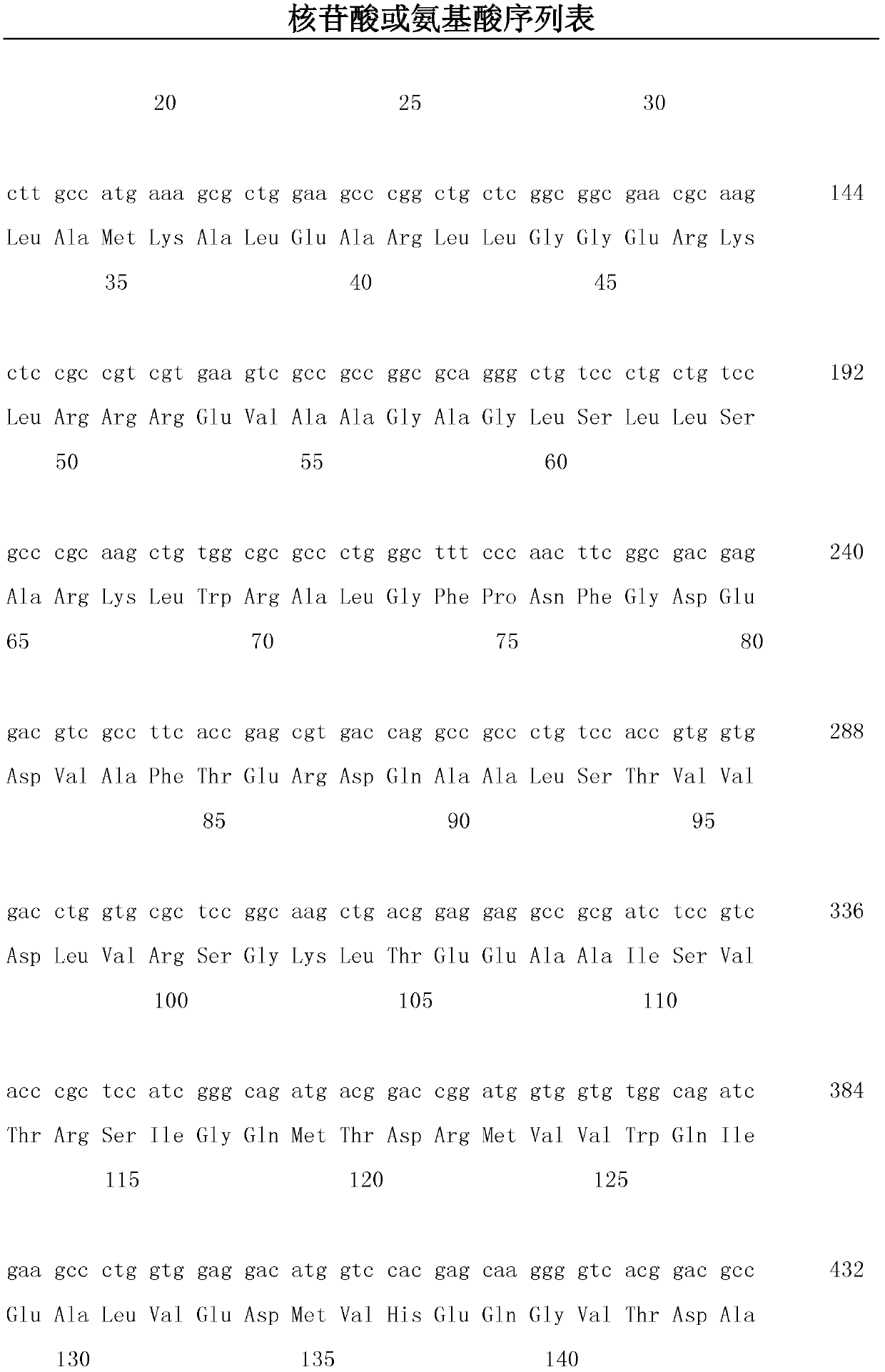

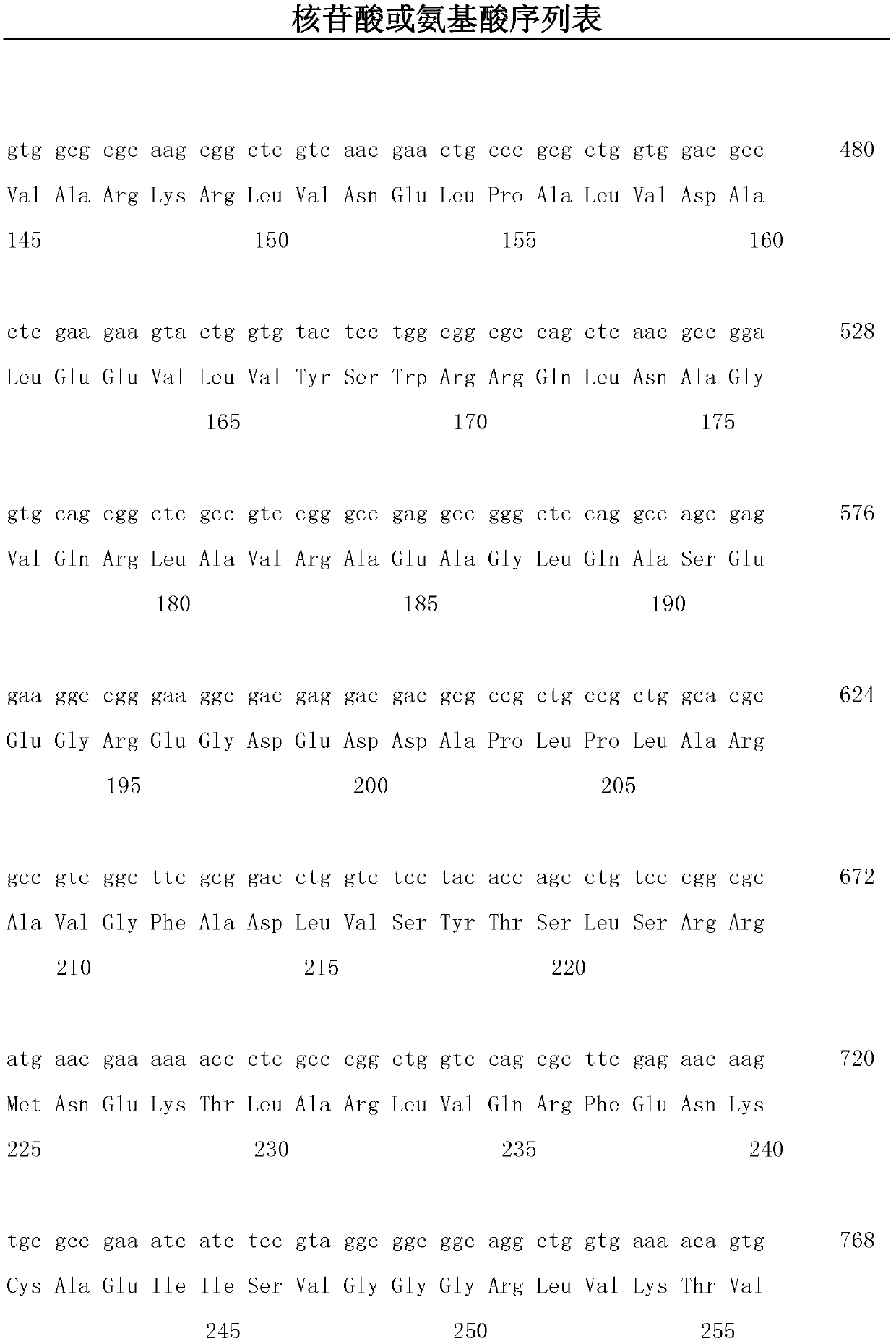

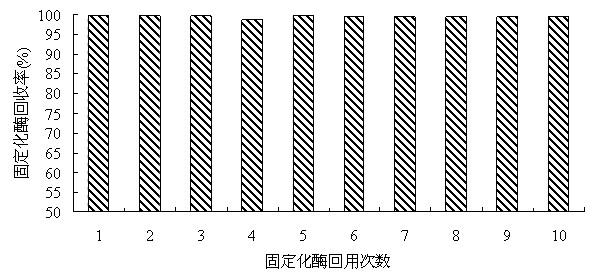

Recombinant Escherichia coli capable of highly producing cyclic adenosine monophosphate and application of recombinant Escherichia coli

ActiveCN102433292AHigh catalytic activityImprove catalytic stabilityBacteriaMicroorganism based processesEscherichia coliRecombinant escherichia coli

The invention discloses recombinant Escherichia coli capable of highly producing cyclic adenosine monophosphate. The systematic nomenclature is Escherichia coli; and the collection number is CGMCC No.4706. The invention also discloses application of the recombinant Escherichia coli capable of highly producing the cyclic adenosine monophosphate to the production of the cyclic adenosine monophosphate. In the invention, an adenylate cyclase gene which is obtained by cloning a cAMP producing strain shows high catalytic activity and stability in the whole-cell catalysis process of recombinant bacteria, and ensures that the conversion rate of a substrate, namely adenosine triphosphate (ATP) reaches over 90 percent; and the reaction system is simple, conditions are mild, the period is short, few byproducts are generated, and the method is clean and pollution-free and is a simple, quick and efficient production way.

Owner:NANJING UNIV OF TECH

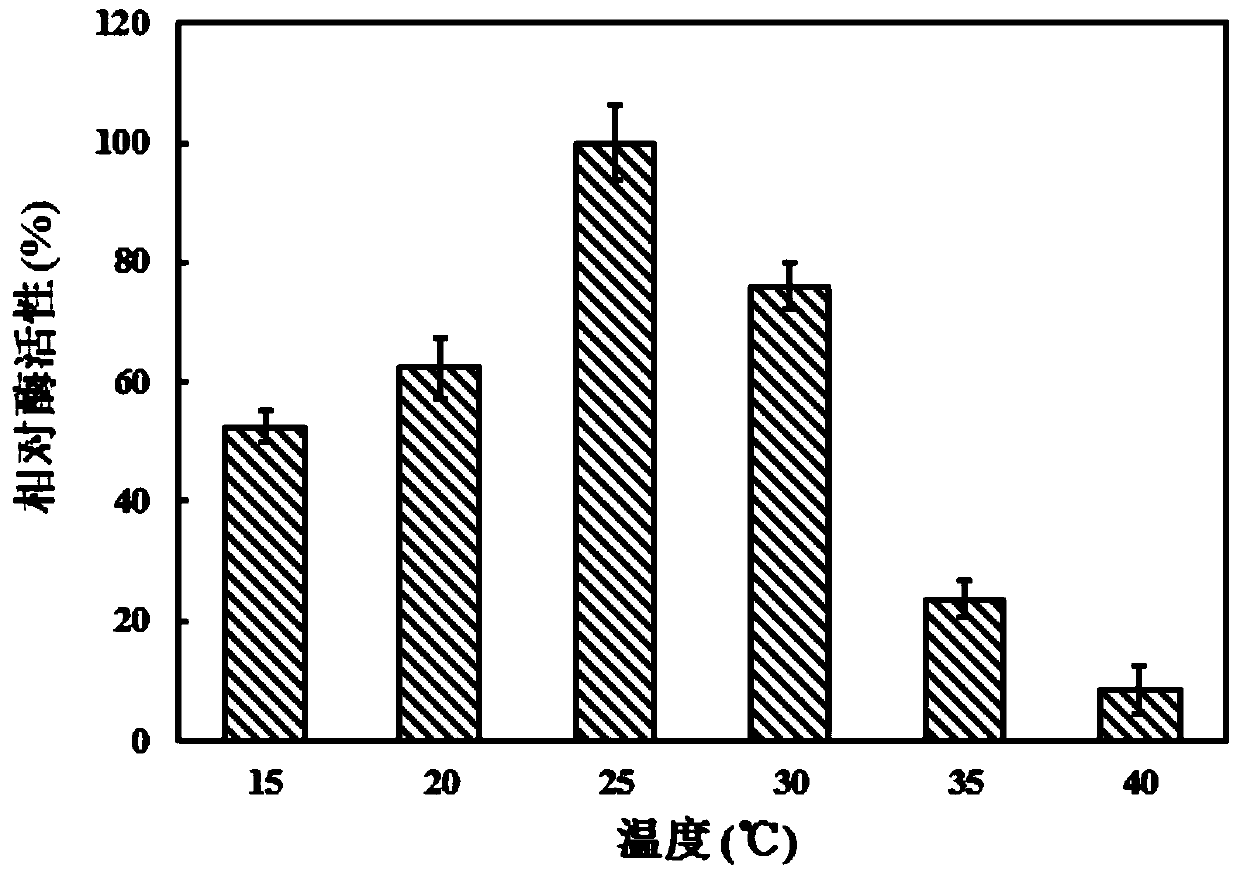

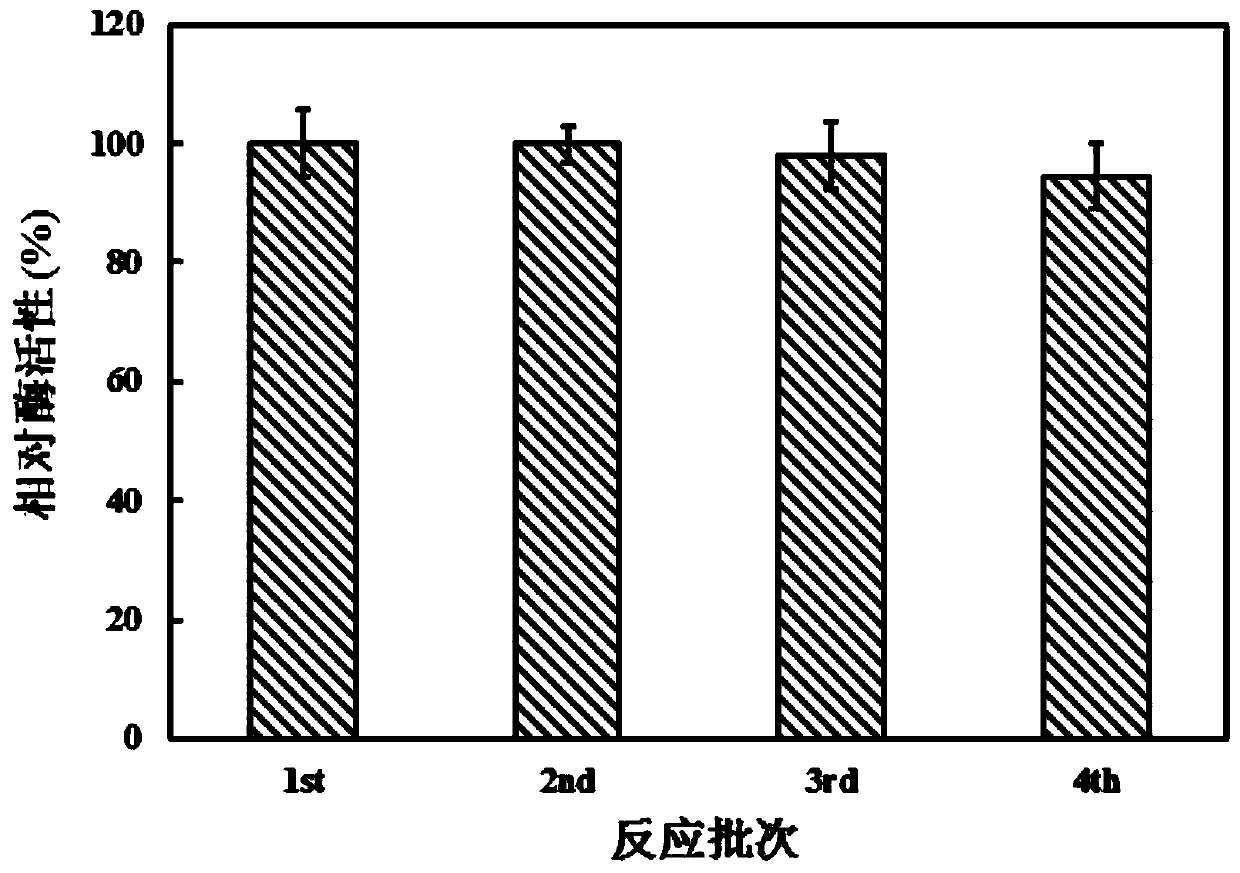

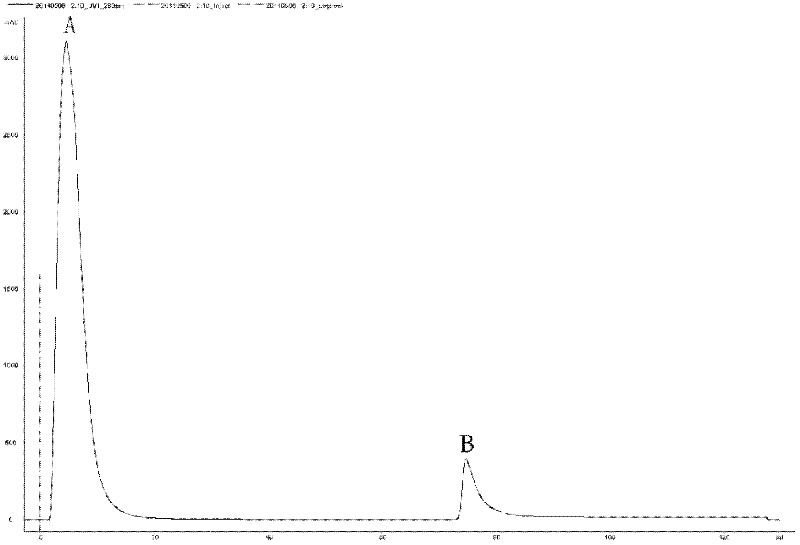

Method for producing L-2-aminobutyric acid by double immobilized multi-enzyme systems

InactiveCN102517351AImprove recycling ratesImprove regeneration efficiencyChemical industryFermentationEnzyme systemOxidative enzyme

The invention discloses a method for producing L-2-aminobutyric acid by double immobilized multi-enzyme systems. The method provided by the invention comprises the following steps that 1, threonine dehydrogenase and leucine dehydrogenase are fixed on reversely-dissoluble pH-sensitive polymer carriers so that a co-immobilized multi-enzyme system is obtained; and 2, alcohol oxidase, formaldehyde dehydrogenase and formate dehydrogenlyase are fixed on reversely-dissoluble pH-sensitive polymer carriers so that a co-immobilized coenzyme regeneration system is obtained. The method for producing L-2-aminobutyric acid by the double immobilized multi-enzyme systems utilizes dissolution reversibility of co-immobilized enzymes, realizes effective separation of the co-immobilized enzymes and products, improves accessibility between the co-immobilized enzymes and reactants, improves recovery and utilization rates of threonine dehydrogenase, leucine dehydrogenase, alcohol oxidase, formaldehyde dehydrogenase and formate dehydrogenlyase, improves coenzyme regeneration efficiency, reduces follow-up separation purification processes, simplifies a process flow and reduces a production cost.

Owner:李鑫

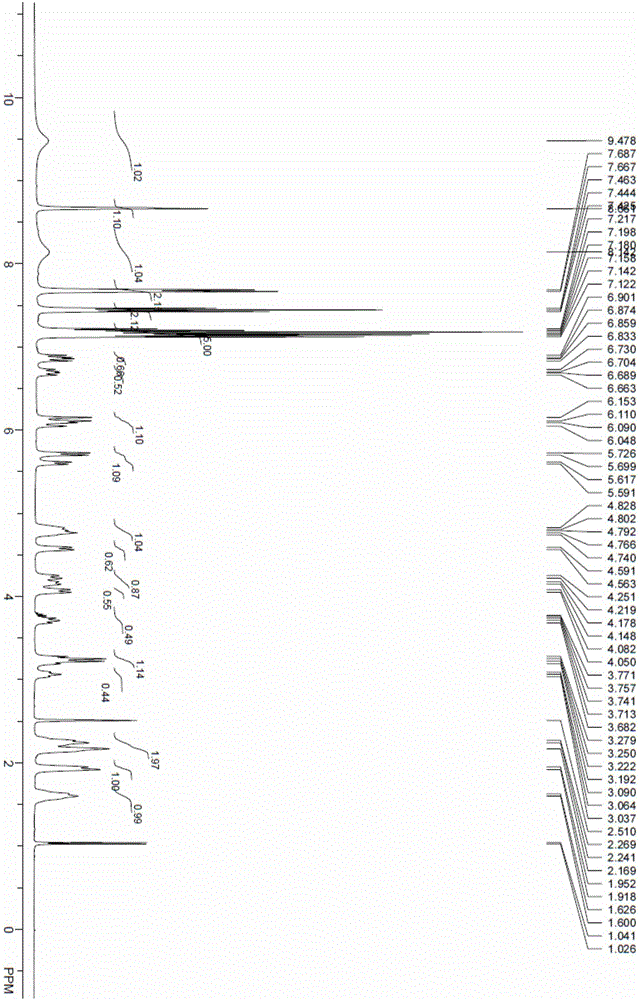

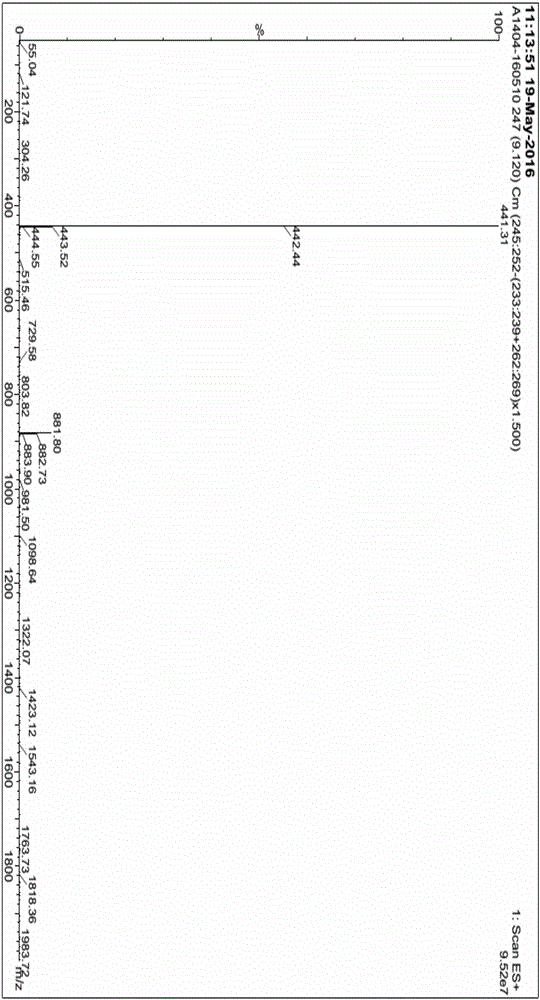

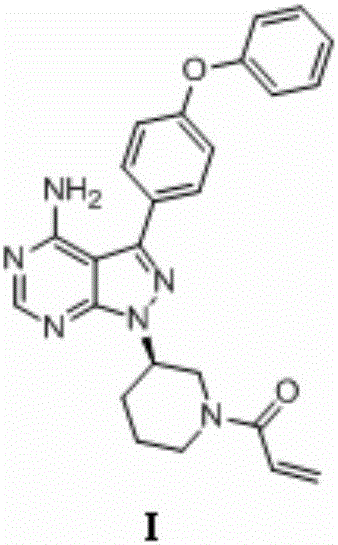

Preparation method of ibrutinib

ActiveCN106008526AHigh yieldQuality improvementOrganic chemistryBulk chemical productionTert-Butyloxycarbonyl protecting groupMitsunobu reaction

The invention relates to the technical field of medicine, in particular to a preparation method of ibrutinib. The preparation method of ibrutinib comprises the following steps that 4-amino-3-(4-phenoxy phenyl)-1H-pyrazol[3,4-d]pyrimidine and S-1-tert-butyloxycarbonyl-3-hydroxyl piperidine are prepared into a compound shown in the formula IV (please see the formula in the description) through a Mitsunobu reaction, and a Boc protecting group of the compound shown in the formula IV is removed to prepare a compound shown in the formula V (please see the formula in the description); the compound shown in the formula V and acrylic ester are prepared into a compound shown in the formula I (please see the formula in the description) in the presence of a catalyst and an activating agent. According to the preparation method, the reaction process is mild in condition, few reaction steps are needed, high temperature and copious cooling are not needed, no high-toxicity reagent is adopted, and the whole synthesizing process is stable and controllable; ibrutinib prepared through the method is high in yield and quality and has the advantages of being good in stability, high in purity, convenient to store and the like.

Owner:BIOCOMPOUNDS PHARMACEUTICAL INC +1

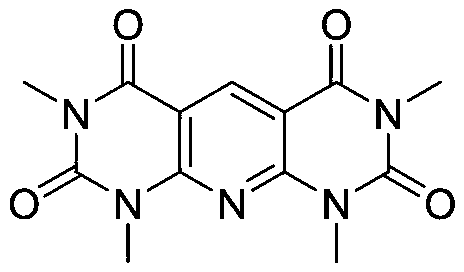

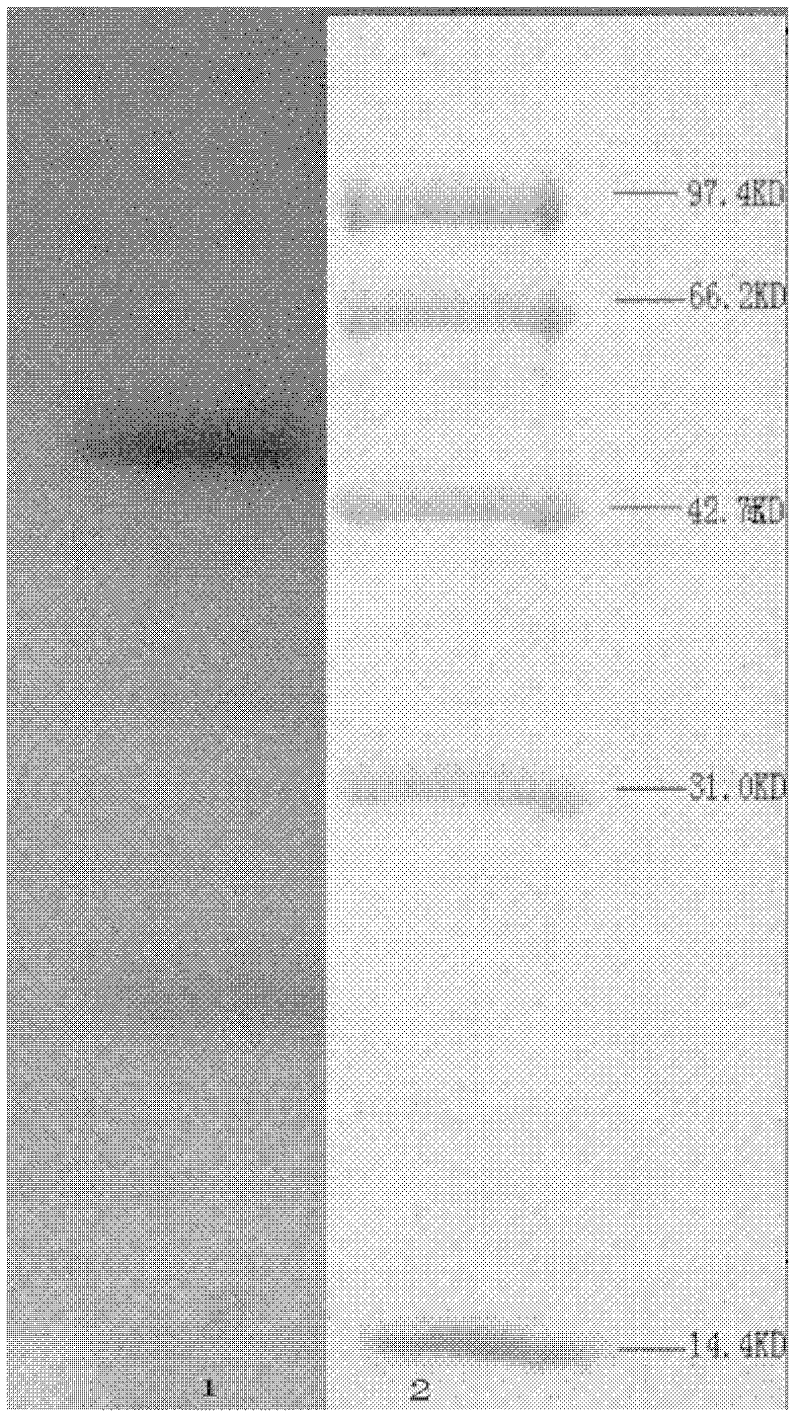

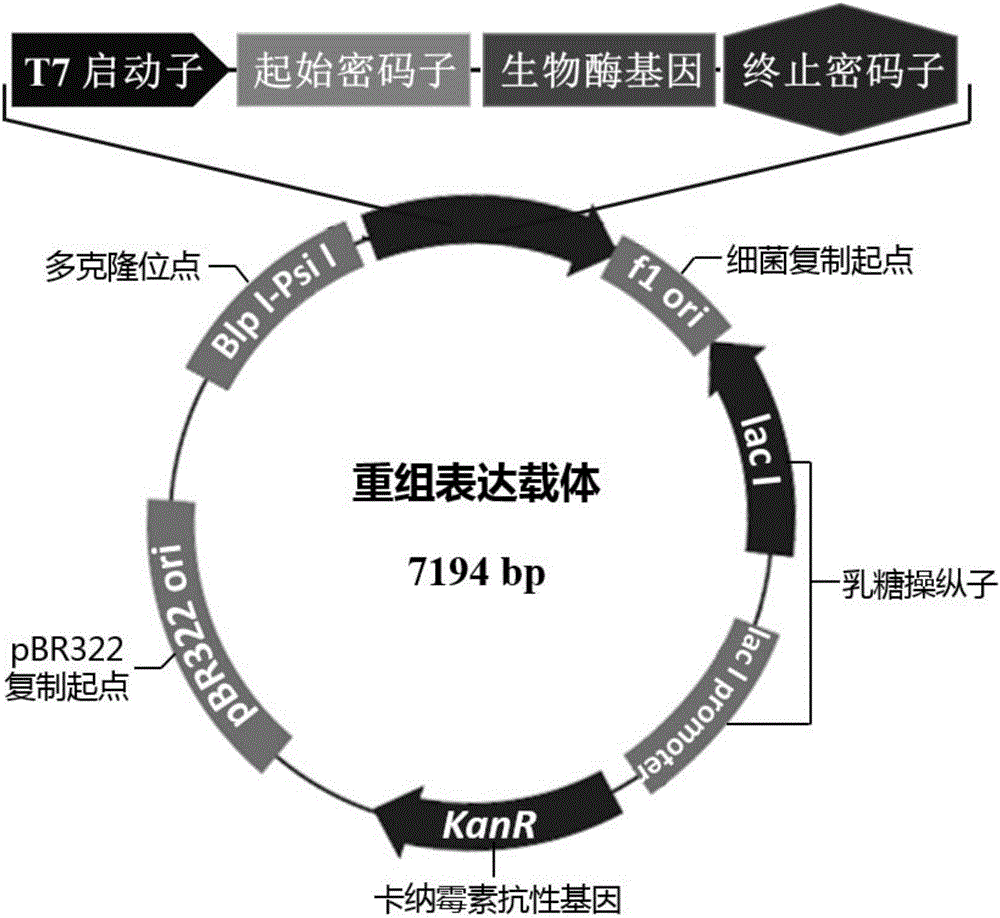

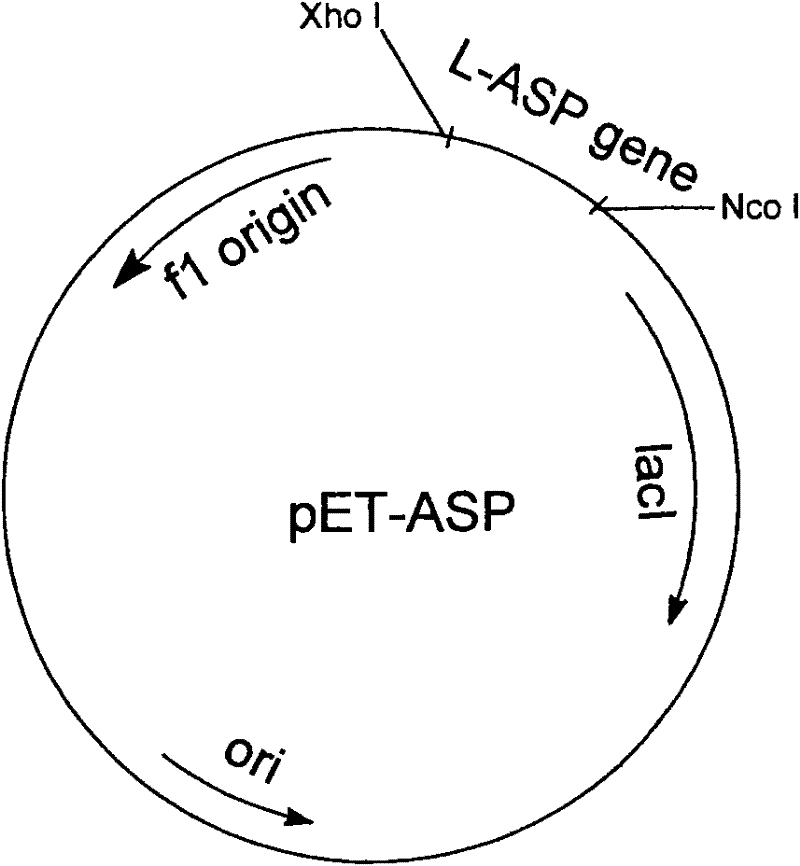

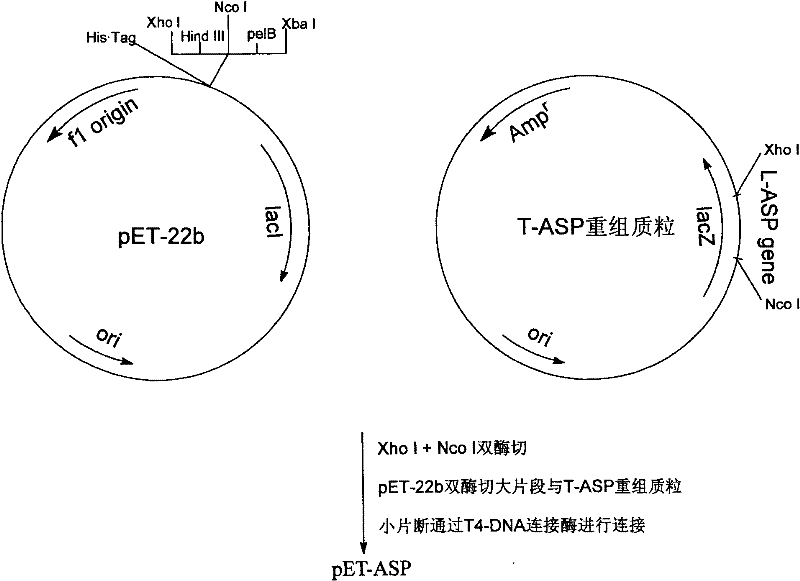

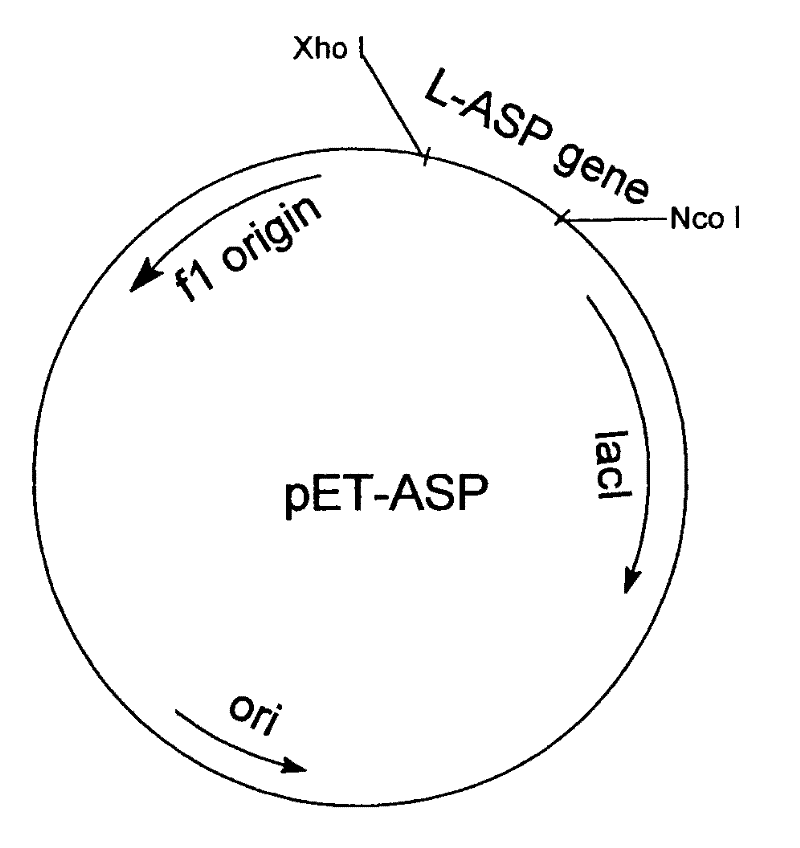

Engineering bacteria for producing L-asparaginase II and construction method and applications thereof

InactiveCN101748094AWide variety of sourcesLow costBacteriaHydrolasesEscherichia coliCompanion animal

The invention relates to novel engineering bacteria for producing L-asparaginaseII. An extracellular expression product of the engineering bacteria has L-asparaginaseIIprotein activity. The invention also discloses a construction method and fermentation culture conditions of the engineering bacteria, wherein recombinant plasmids pET-ASP invert colon bacillus BL21 to obtain the engineering bacteria; and the structure of the recombinant plasmids pET-ASP is shown in figure 1. The recombinant engineering bacteria are obtained by connecting the L-asparaginase II genes on expression plasmids pET22b to obtain the recombinant plasmids pET-ASP and then using the recombinant plasmids pET-ASP to invert the colon bacillus BL21. The L-asparaginase II can be produced massively by carrying out fermentation culture on the engineering bacteria. And the engineering bacteria has wide raw material source, low cost, and few separation and purification steps and high yield of the products in the fermentation liquor.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

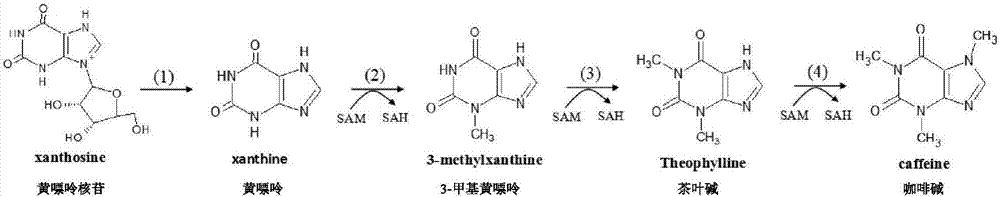

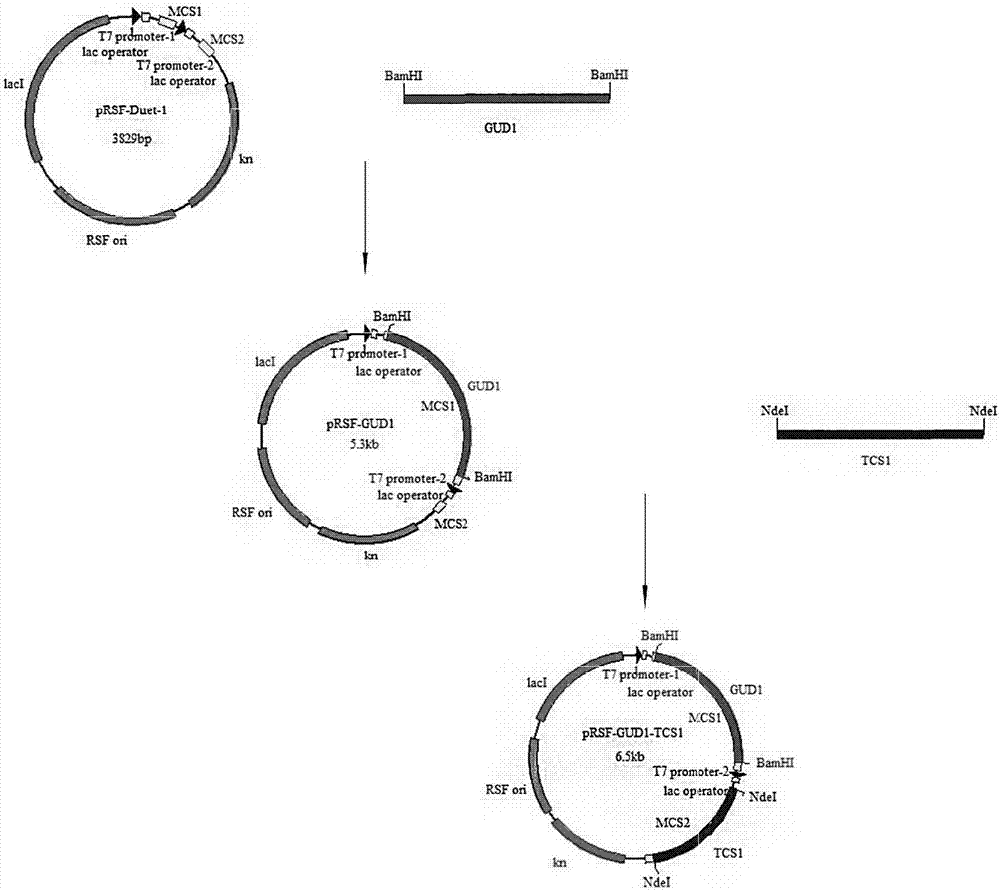

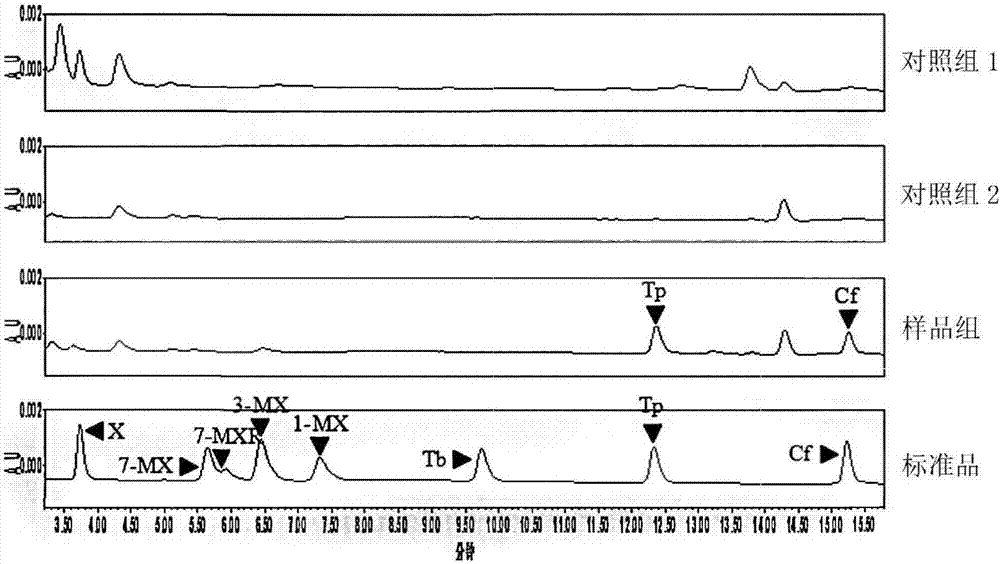

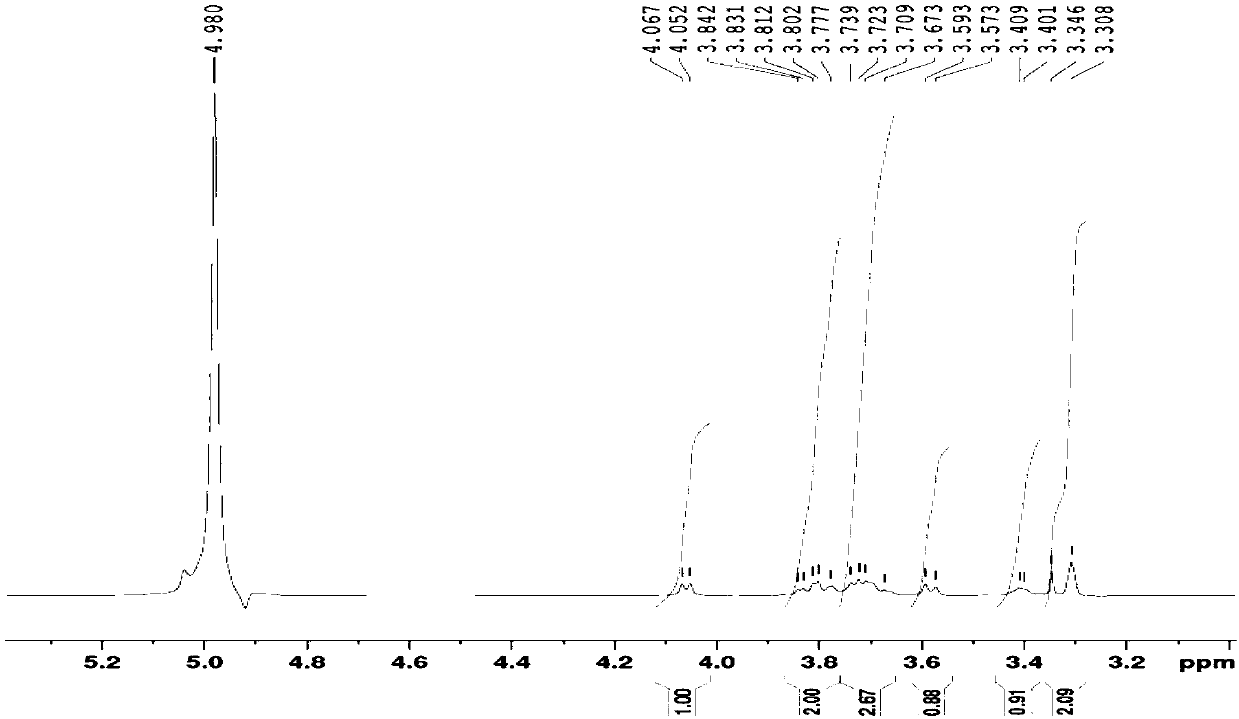

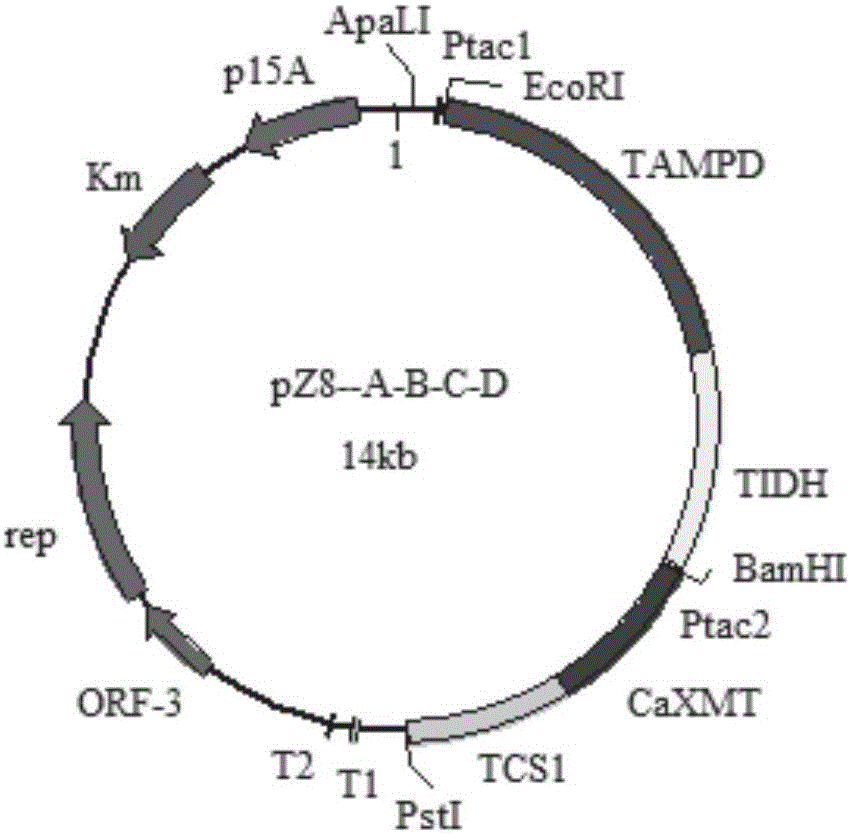

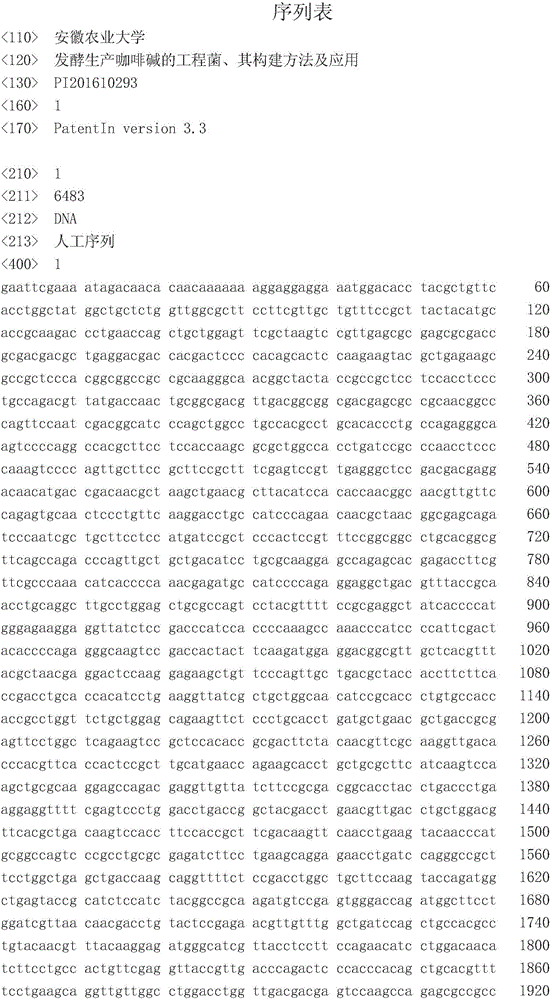

Engineering bacterium for producing caffeine by fermentation, and establishment method and application thereof

ActiveCN105861408AHigh yieldReduce separation and purification stepsBacteriaHydrolasesCorynebacterium efficiensEnzyme Gene

The invention provides an engineering bacterium for producing caffeine by fermentation. The engineering bacterium is a recombinant corynebacterium glutamicum which is established by guiding a key enzyme gene in a caffeine biosynthetic pathway into a corynebacterium glutamicum. The key enzyme gene in the caffeine biosynthetic pathway is over-expressed, so that the corynebacterium glutamicum is capable of producing the caffeine; and moreover, a large number of caffeine as products can be secreted out of cells, separation and purification steps are few, yield of the caffeine is high, and a flask fermentation result shows that the yield of the caffeine reaches 3.75 mg / L, so that the recombinant engineering bacterium has a good industrial application prospect, and lays a theoretical foundation for producing food safety-level caffeine by fermentation by using the corynebacterium glutamicum.

Owner:ANHUI AGRICULTURAL UNIVERSITY

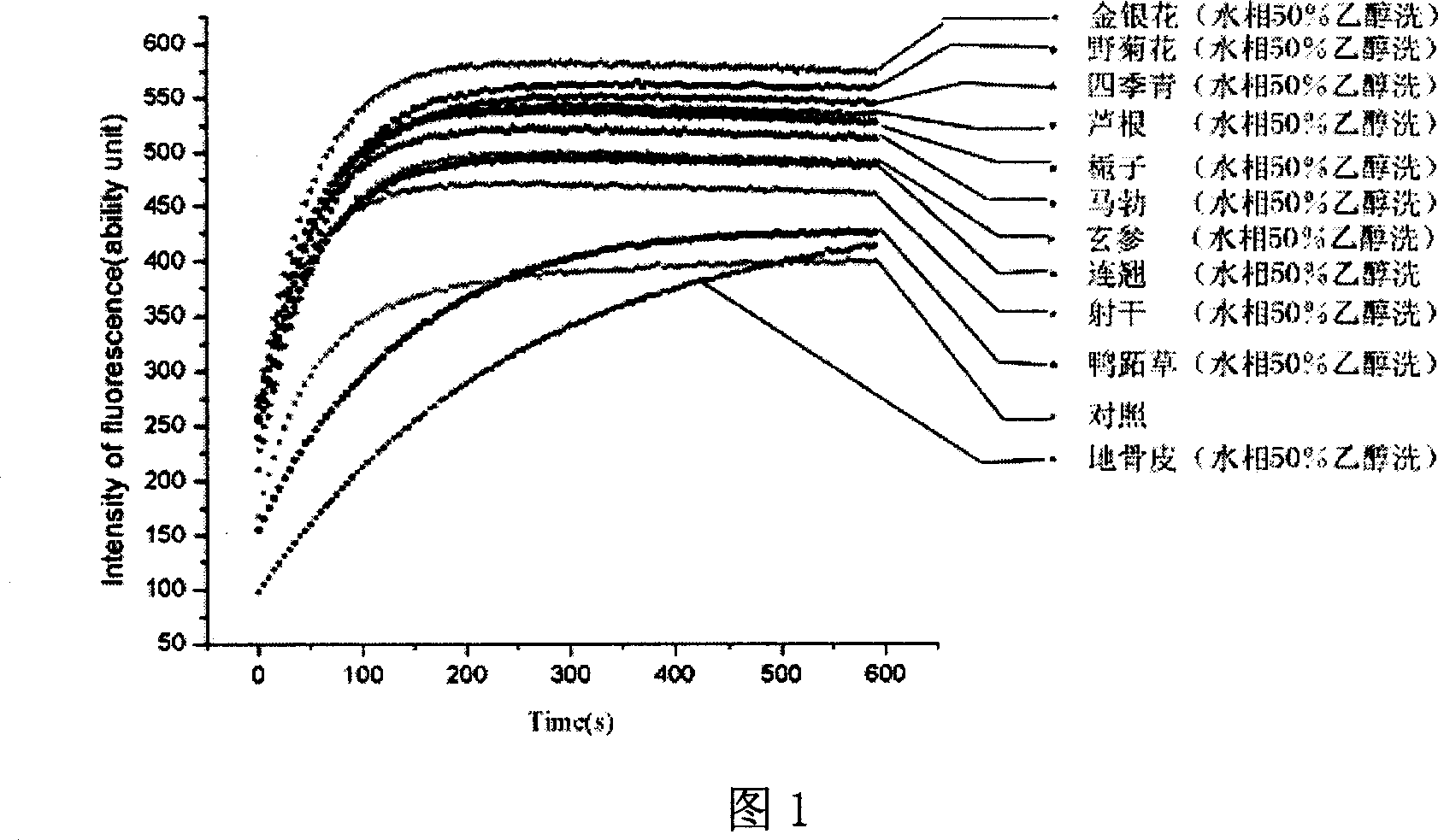

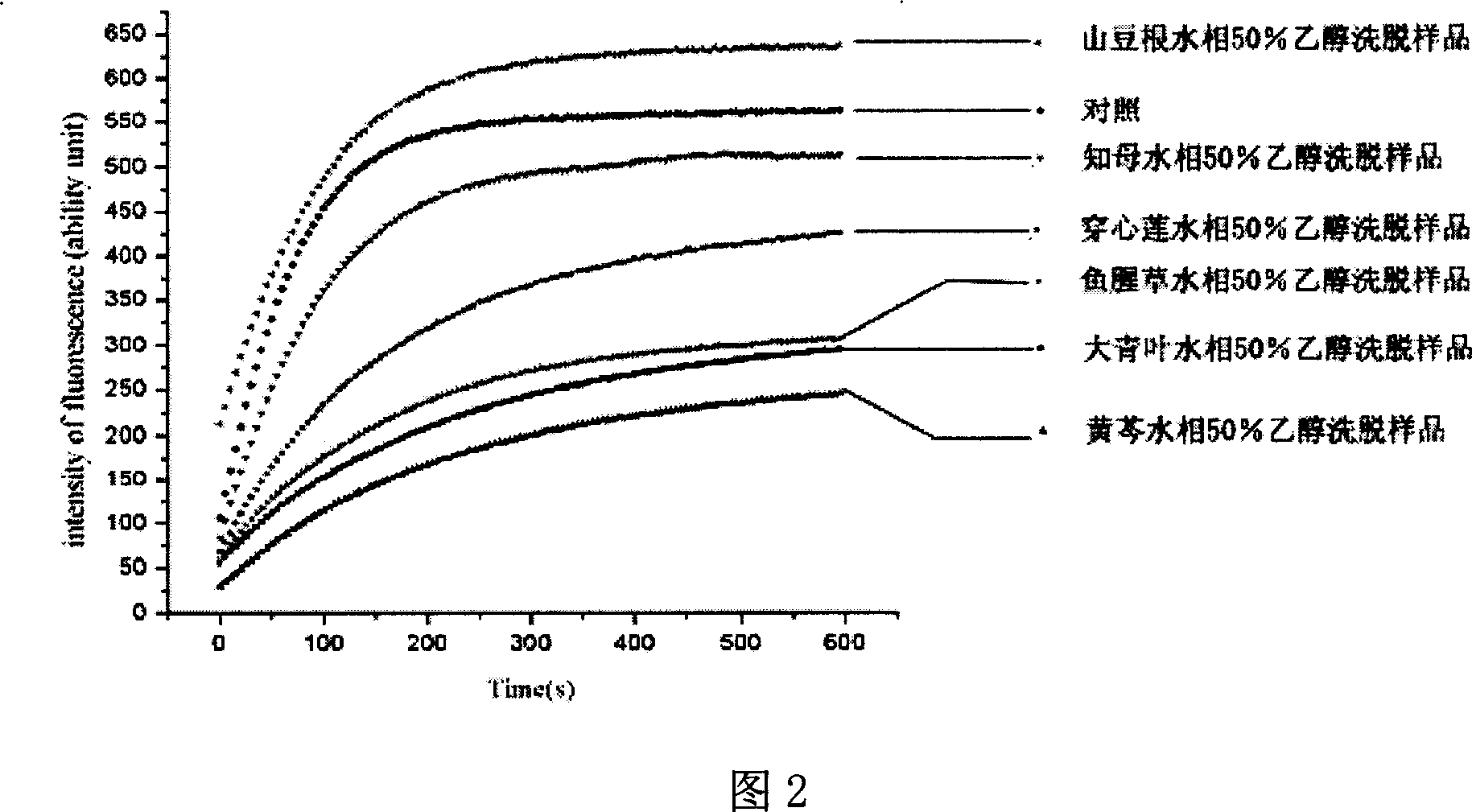

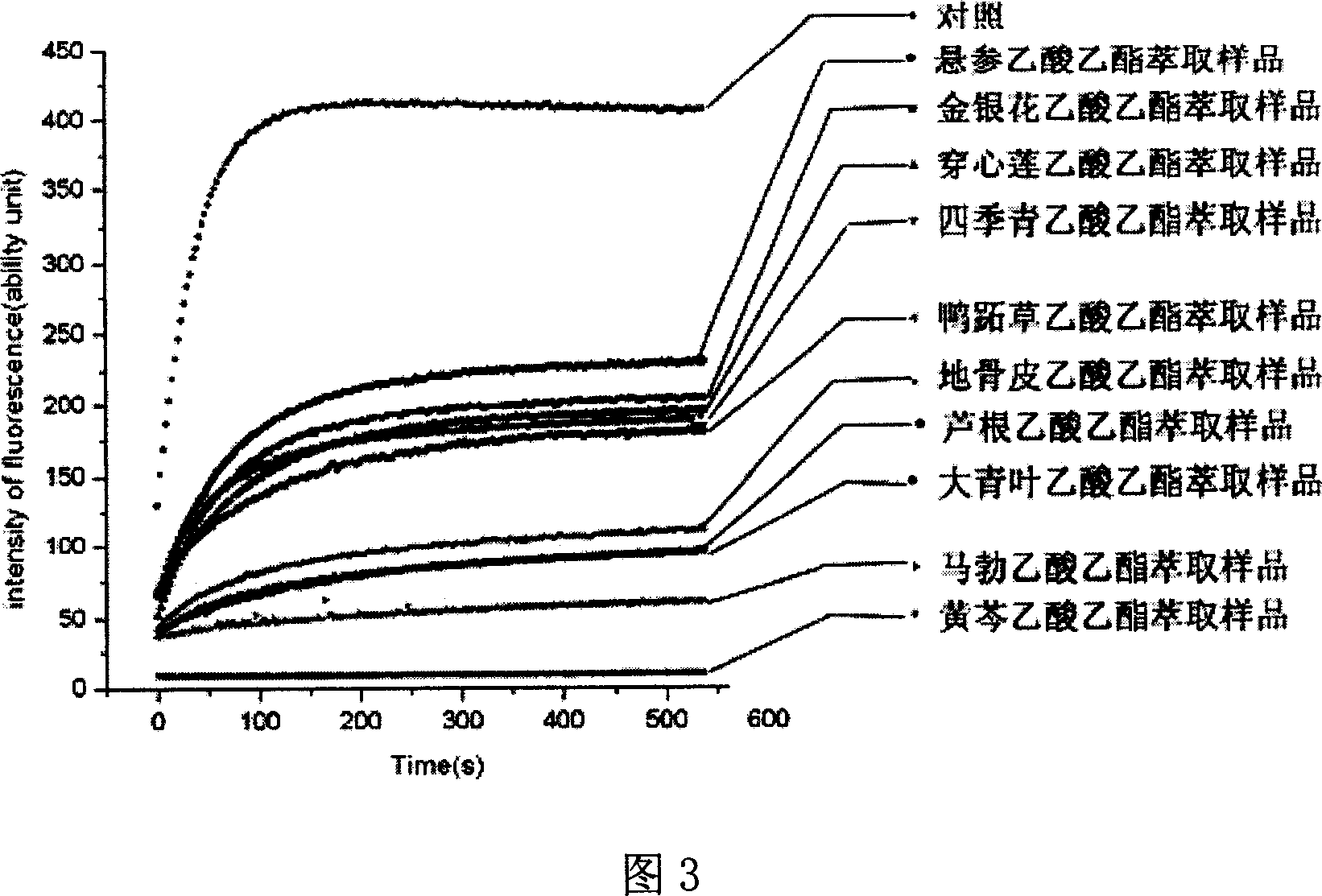

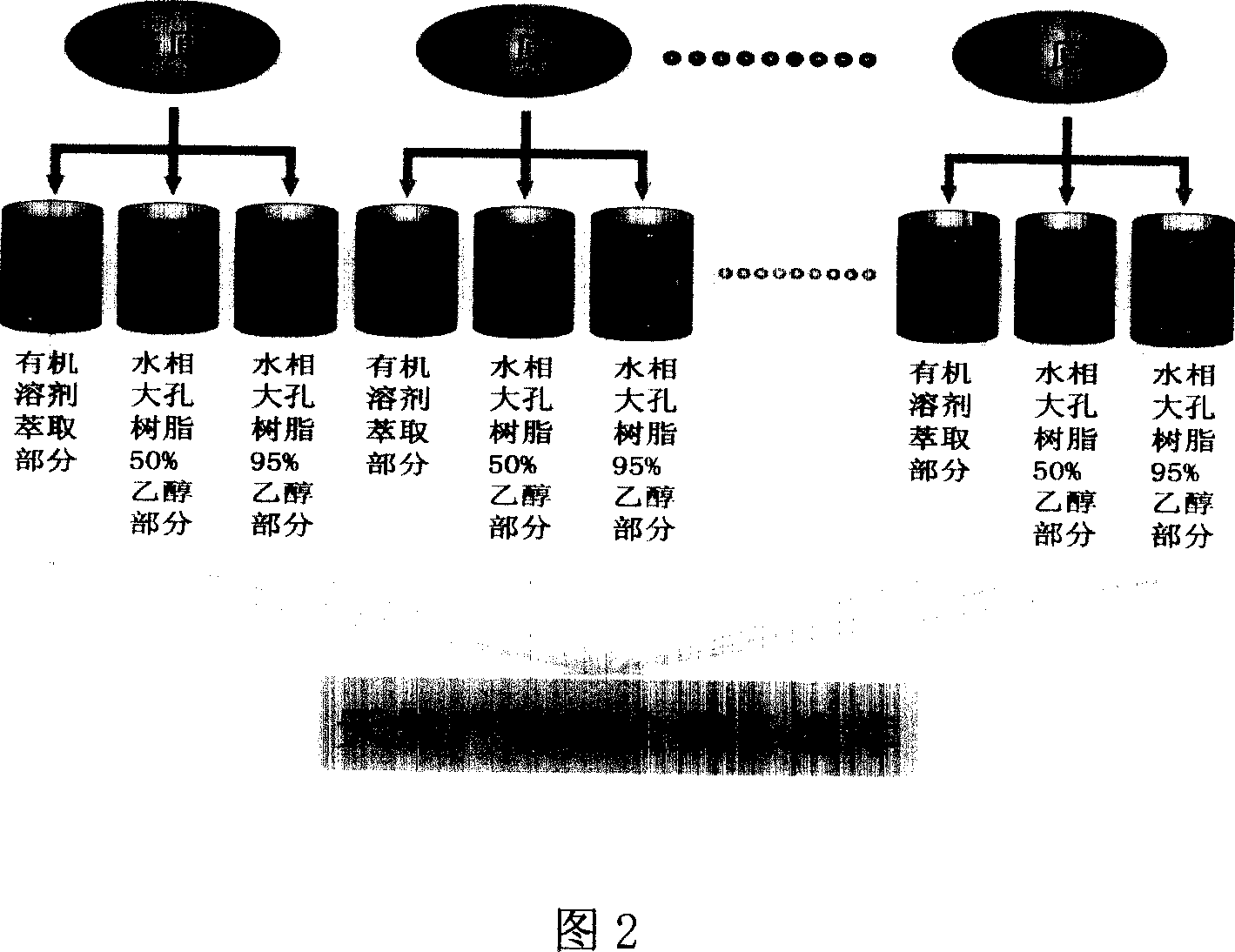

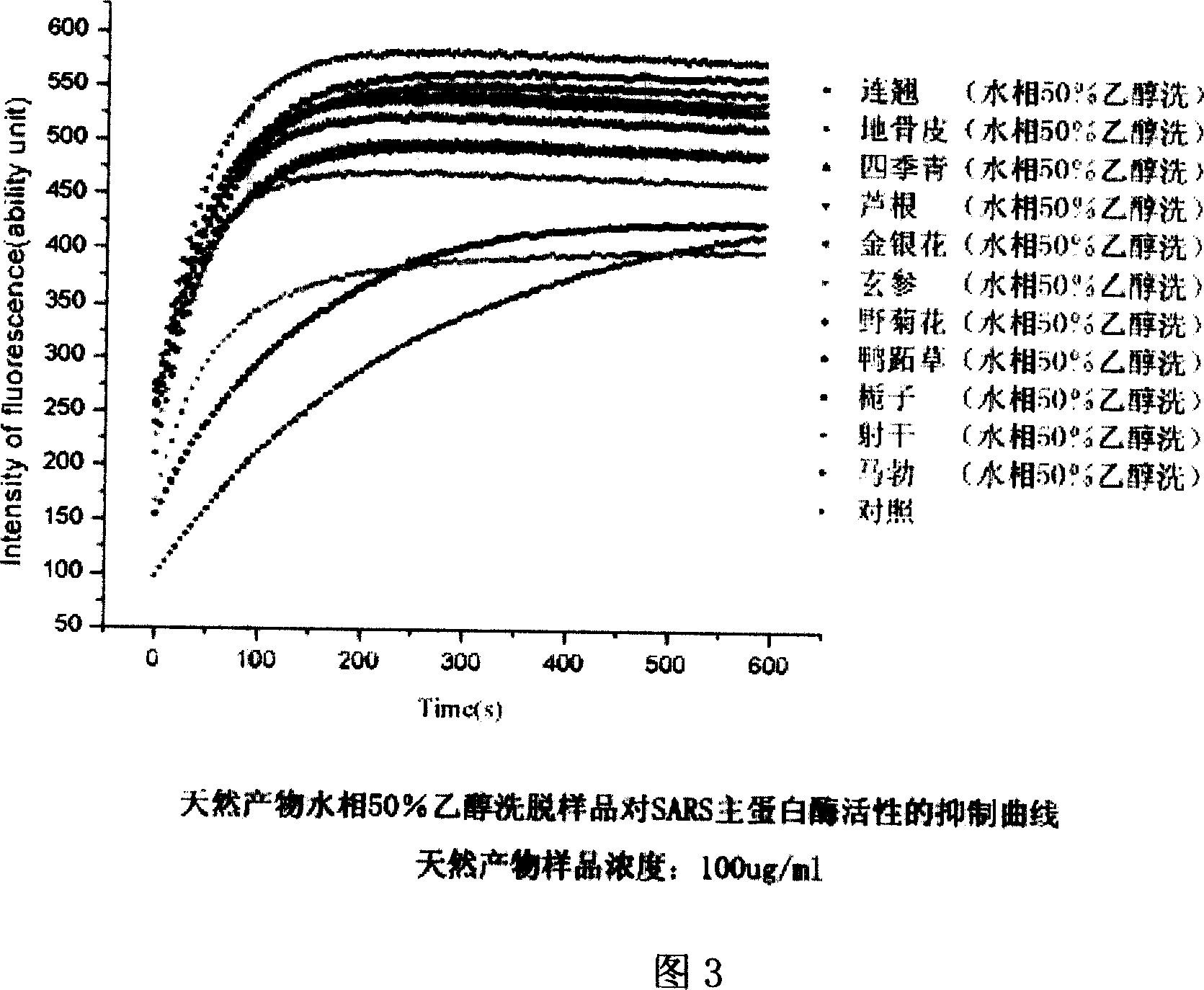

Method for screening SARS coronaviruses main Protease inhibitors from natural product such as Chinese medicinal materials mixture prepared storeroom

ActiveCN101063234AReduce separation and purification stepsReduce workloadLibrary screeningMaterial analysisDiseaseVirus inhibitors

The invention discloses a method to sieve SARS coronavirus main prolease depressor from natural products mixture optional warehouse, which comprises the following steps: touching crystal of SARS coronavirus main prolease with 'sample with inhibited active'; getting electron density of small molecule depressant combined with SARS coronavirus main prolease; appraising the small molecule depressant based on electron density; getting fine three-dimensional structure of SARS coronavirus main prolease and small molecule depressant; getting small molecule depressant Sichuan scented sea vegetable ala factor. This Sichuan scented sea vegetable ala factor can inhibit coronavirus main prolease activator effectively, which can cure or prevent SARS coronavirus and infectivity gastrointestinal disease virus.

Owner:NANKAI UNIV +2

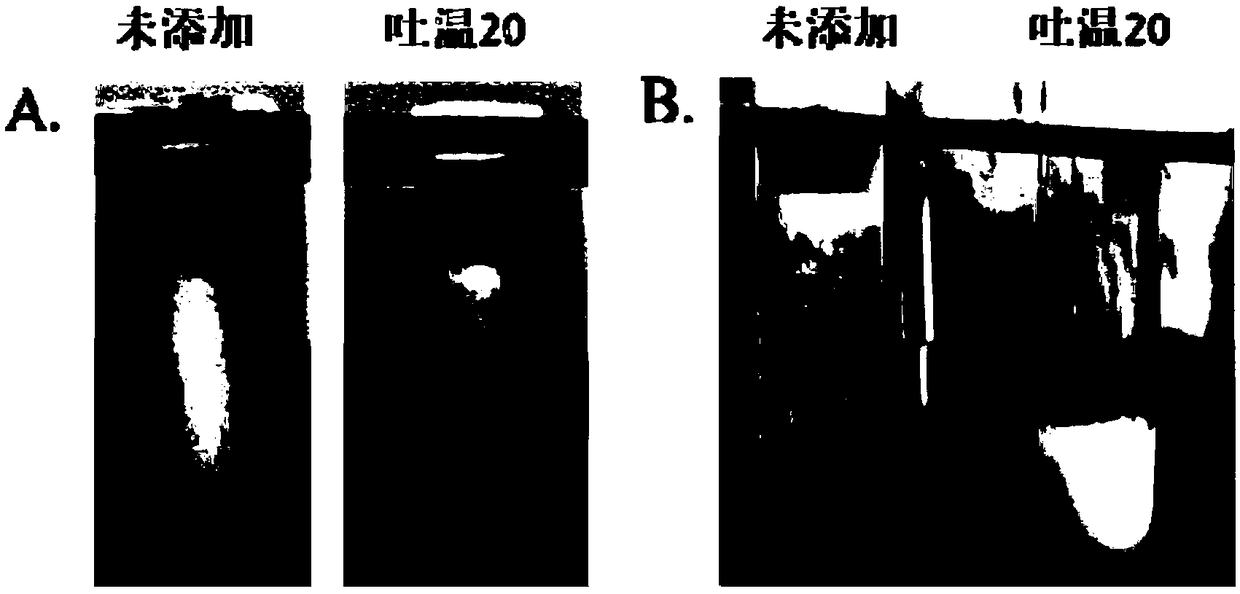

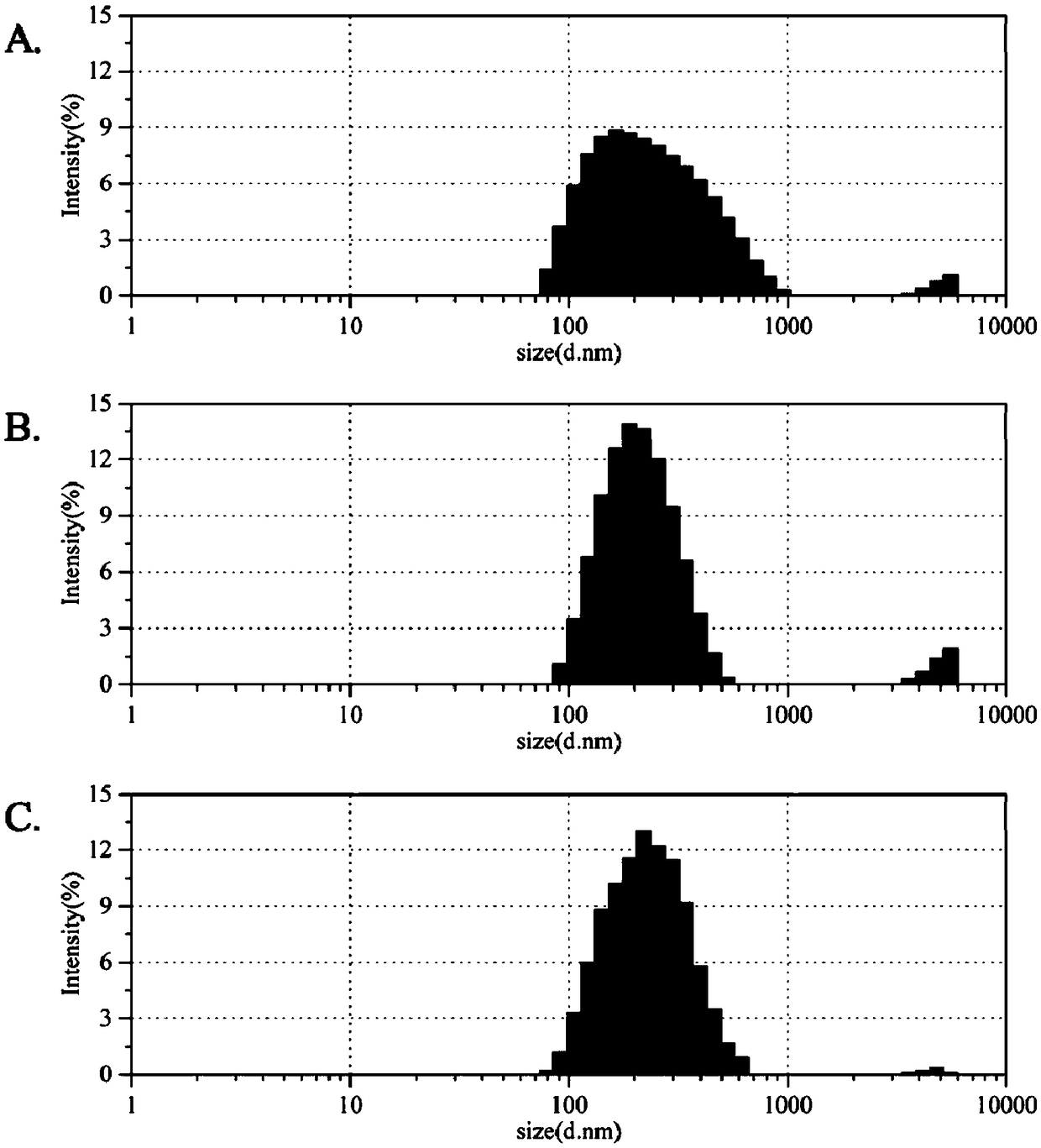

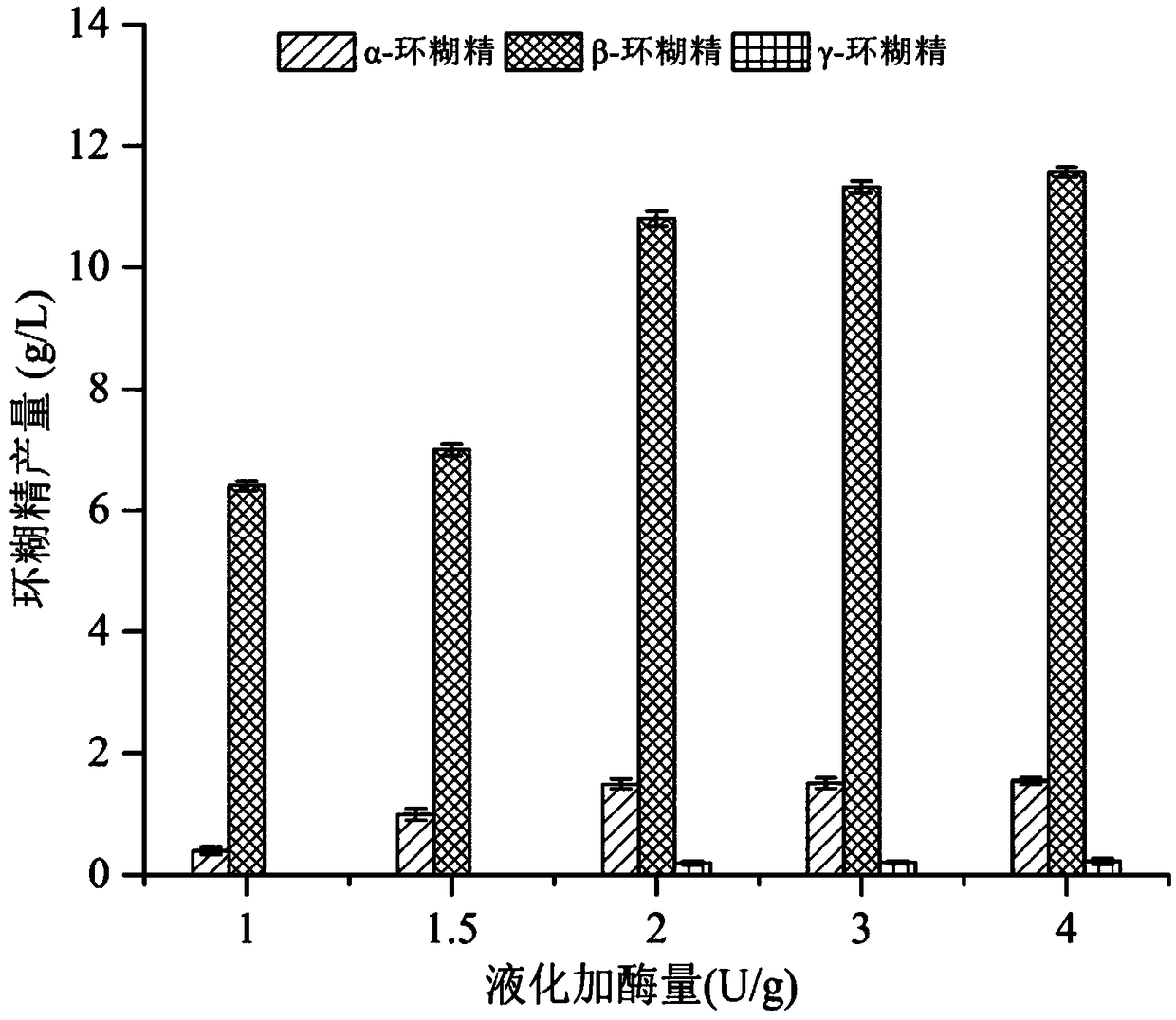

Method for clathrating tributyrin by enzyme method

ActiveCN108642105AReduce separation and purification stepsSimple processAnimal feeding stuffAccessory food factorsCyclodextrinTributyrin

The invention discloses a method for clathrating tributyrin by an enzyme method, and belongs to the technical field of grease microencapsulation. According to the method, cyclodextrin synthesized by the enzyme method and tributyrin clathrated by cyclodextrin are combined. The method comprises the step of preparing the cyclodextrin by the enzyme method using CGT enzymes; the tributyrin is added inthe preparation process; after the reaction, Tween is added; and homogenizing and spray drying are performed. The effect of the finally obtained tributyrin powder is much better than the single cyclodextrin clathration effect. The method provided by the invention has the advantages that the process is simple; the cost is low; the operation is convenient; non-toxic harmless and pollution-free effects are achieved in the reaction process; no toxic reagent is remained; the clathration effect is obvious; and the better utilization of a nutritive additive of the tributyrin in the practical production is facilitated.

Owner:JIANGNAN UNIV

Method for preparation and purifying lithium difluoroborate

ActiveCN102702243BEasy to industrializeReduce usageSecondary cellsGroup 3/13 element organic compoundsPurification methodsRotary evaporator

Owner:CENT SOUTH UNIV

Method for preparing fatty glyceride

InactiveCN107338274AShort reaction timeImprove efficiencyFermentationGlycerolFatty acid glycerol esters

The invention discloses a method for preparing fatty glyceride. The method comprises steps as follows: (1) glycerinum and free fatty acid in the mass ratio being (1-5):1 are mixed, free lipase accounting for 0.1%-2% of the total mass of a reactant and water accounting for 1%-6% of the total mass of the reactant are added, and the mixture is stirred to react at the temperature of 30-60 DEG C for 2-4 h; (2) an oil phase and a glycerinum phase in the reaction are subjected to centrifugal separation, the glycerinum phase is retained to be recycled, and the oil phase is dehydrated; (3) immobilized lipase accounting for 1%-5% of the total mass of the oil phase is added to the dehydrated oil phase, the mixture is subjected to a high-vacuum reaction at the temperature of 45-65 DEG C for 4-8 h, and fatty glyceride is obtained. Fatty glyceride is esterified and synthesized with a two-step method, the conversion rate of fatty acid in the final product is 98% or higher, the conversion rate of the fatty acid is increased, the separation and purification steps are omitted, and the method has good economic value and environmental protection value.

Owner:SOUTH CHINA UNIV OF TECH

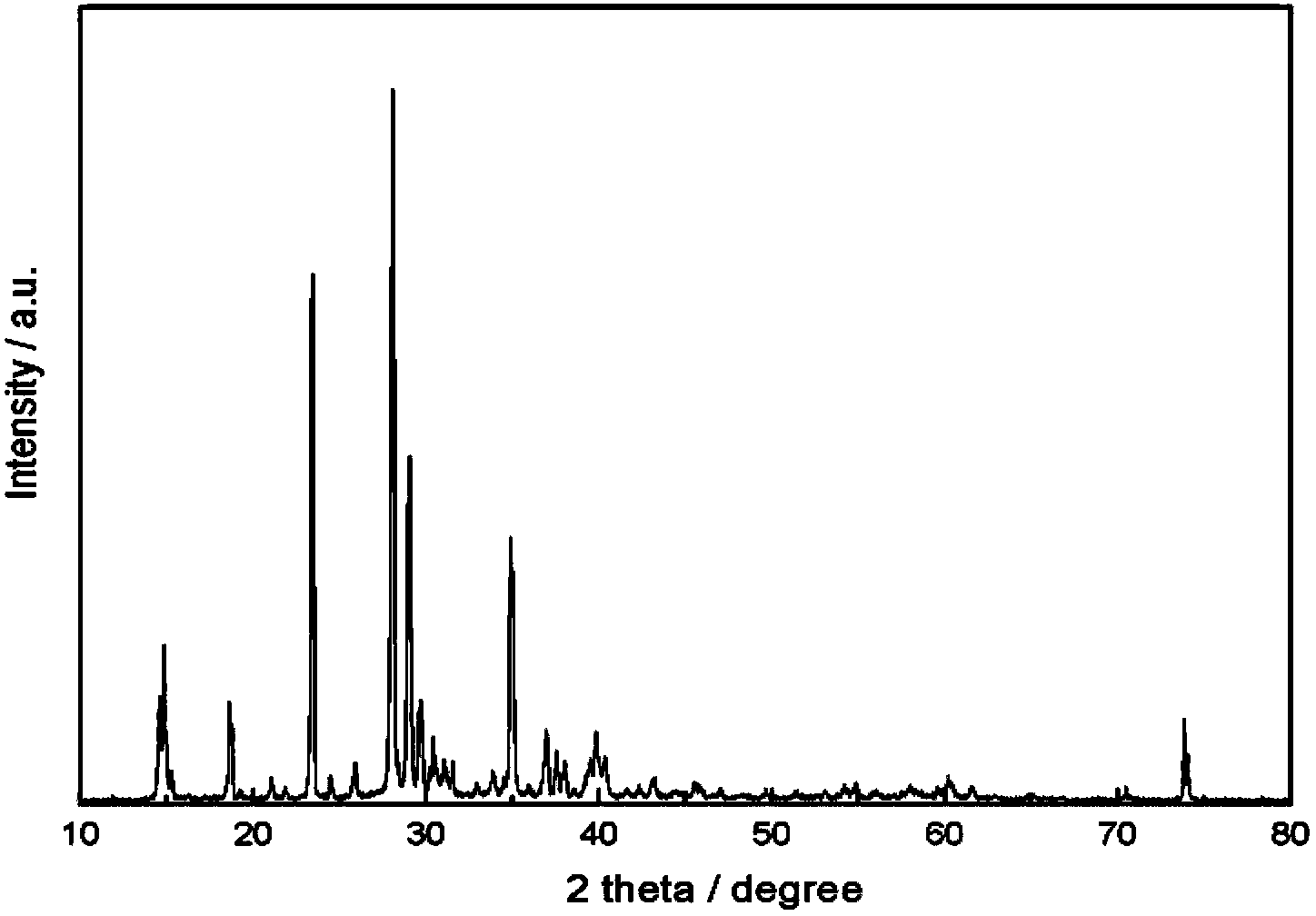

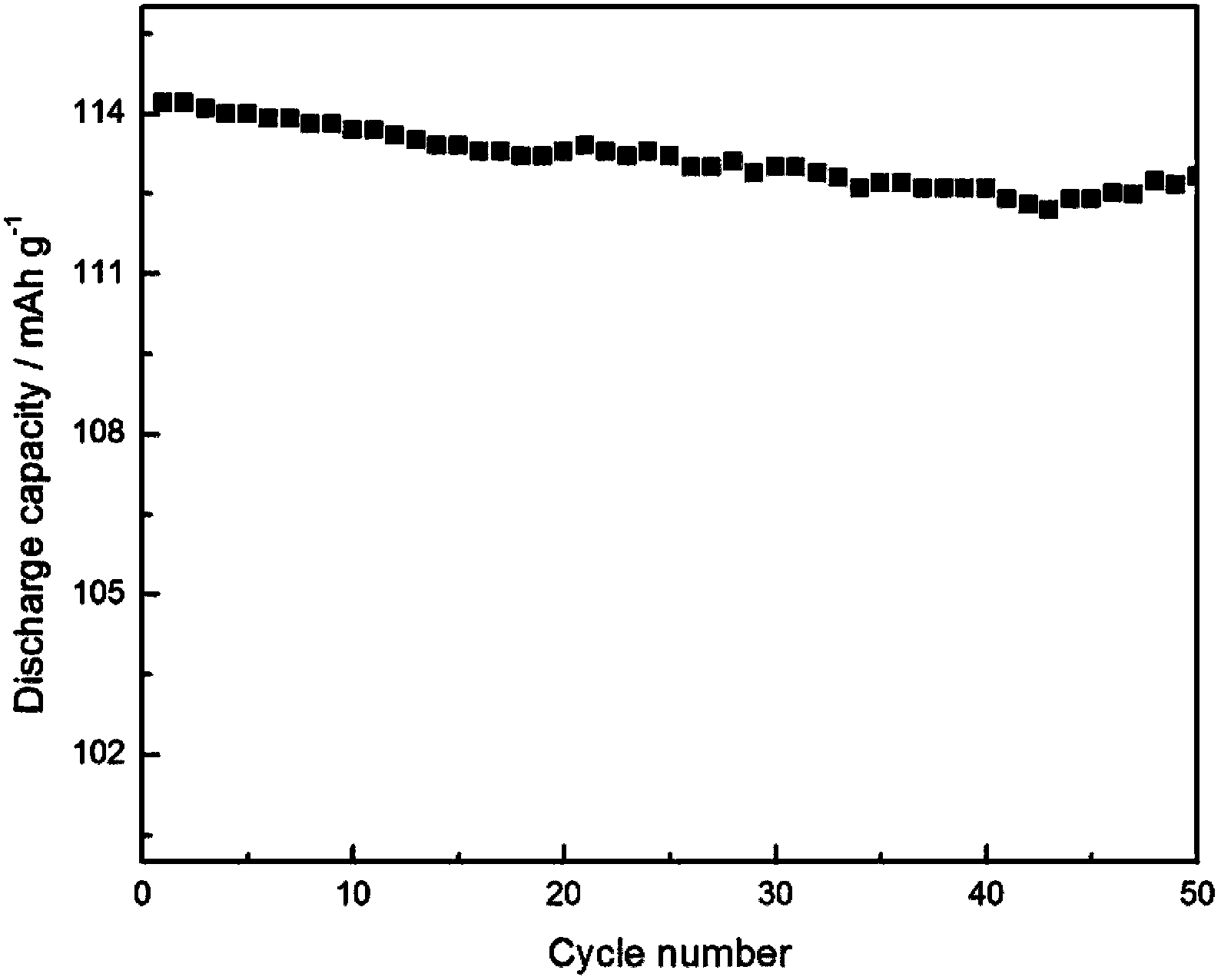

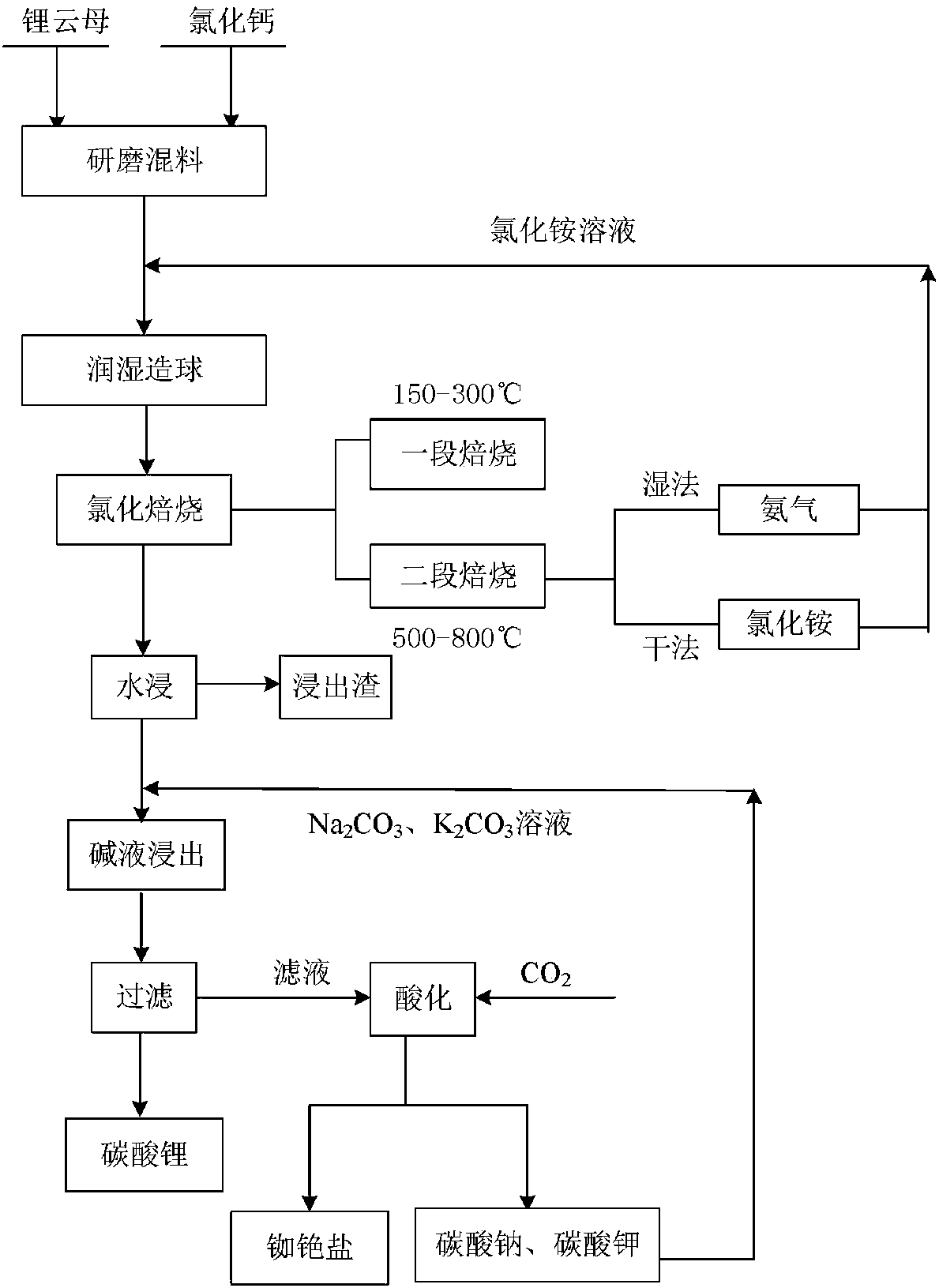

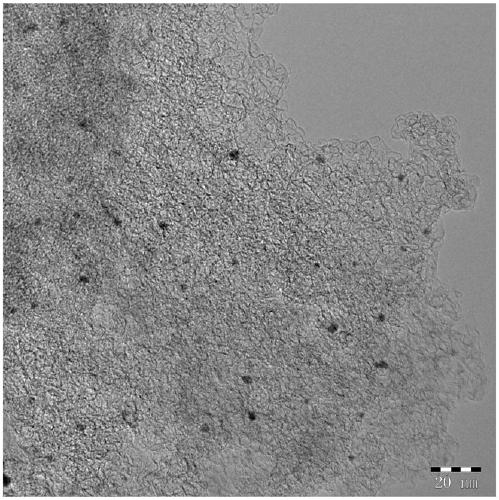

Method for preparing lithium carbonate by extracting lithium from lepidolite by adopting two-stage chloridizing roasting and alkali liquor leaching method

ActiveCN108118143ALow melting pointImprove reaction kineticsProcess efficiency improvementPregnant leach solutionLithium carbonate

The invention discloses a method for preparing lithium carbonate by extracting lithium from lepidolite by adopting two-stage chloridizing roasting and an alkali liquor leaching method. The method disclosed by the invention comprises the following steps: (1) levigating the lepidolite and calcium chloride, adding the levigated lepidolite and calcium chloride into ammonium chloride solution, uniformly blending and pelletizing, so as to obtain green balls; (2) performing first-stage roasting on the green balls obtained in step (1) at the temperature of 150-300 DEG C and performing second-stage roasting on the green balls at the temperature of 500-800 DEG C, so as to obtain clinkers; (3) leaching the clinkers obtained in step (2) with water, and filtering to obtain leaching solution; (4) addingcarbonate solution into the leaching solution obtained in step (3), stirring and filtering to obtain mother solution and filter residues, and collecting the filter residues, so as to obtain the lithium carbonate. In the method disclosed by the invention, all the steps are cooperated, and a process of preparing the lithium carbonate by extracting the lithium from the lepidolite is environmentallyfriendly, low in energy consumption, low in cost and high in extracting efficiency. Therefore, the method disclosed by the invention has a broad industrial application prospect.

Owner:CENT SOUTH UNIV

Pt-Fe/C catalyst as well as preparation method and application thereof

PendingCN109225258ASimple preparation stepsEvenly dispersedOrganic compound preparationAmino compound preparationReaction temperatureSolvent

The invention discloses a Pt-Fe / C catalyst as well as a preparation method and application thereof. The catalyst is composed of an active component and a carrier, wherein the active component is platinum, iron and oxide of iron; the carrier is active carbon; Pt accounts for 0.5-3% of the total mass of the catalyst, and a Fe / Pt mass ratio is (0.5 to 4) : 1. The preparation method of the catalyst comprises the following preparation steps: preparing a platinum-iron active component impregnation solution, performing equal-volume loading, performing in-situ reduction, washing and drying. The catalyst is used for preparing chloroaniline by chloronitrobenzene hydrogenation though a no-solvent method; dechloridation can be effectively restrained in case of not adding a dehalogenation inhibitor, and the advantages of good reaction activity and high selectivity are achieved. Under the conditions of no solvent and auxiliaries, the dosage of the catalyst is 0.8% of the mass of chloronitrobenzene,the reaction temperature is 90 DEG C, hydrogenation pressure is 1.0 MPa, reaction can be completed with two hours, and dechlorination amount is less than 0.1%.

Owner:CHENZHOU GAOXIN PLATINUM +1

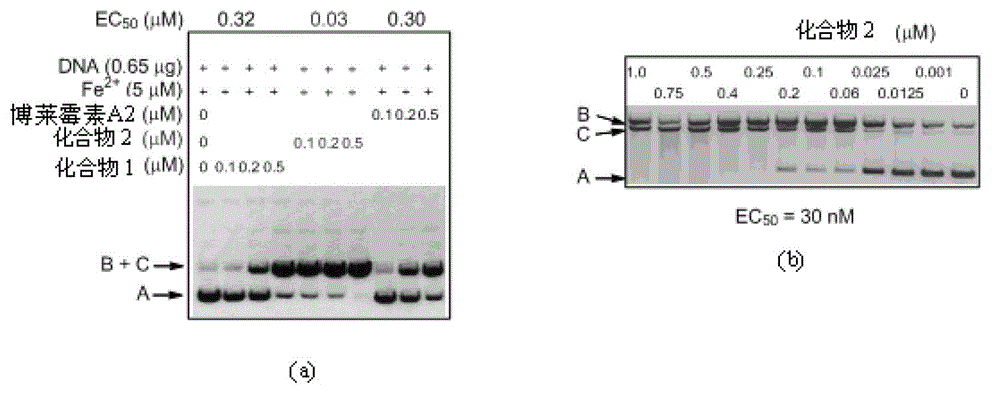

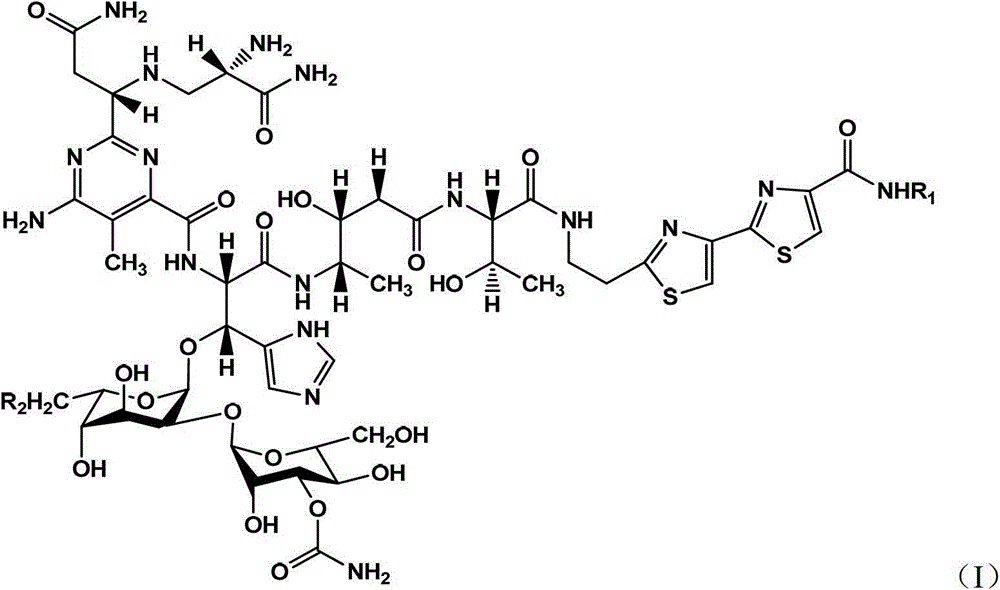

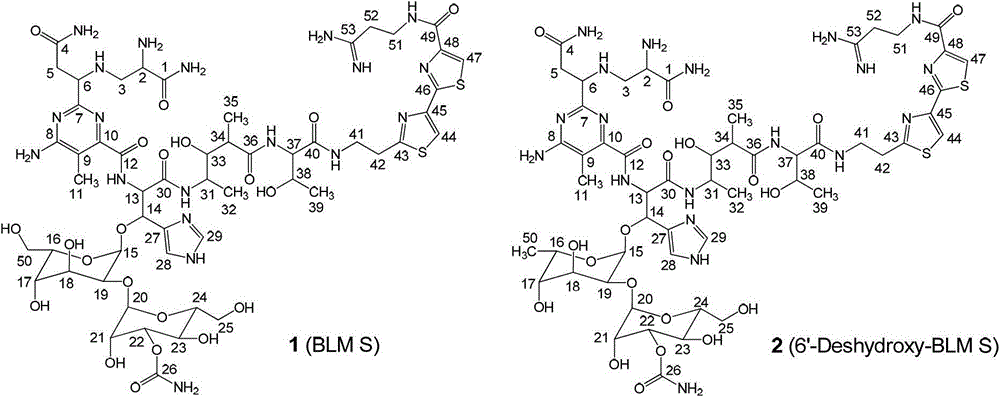

Bleomycin derivative separating and purifying method

ActiveCN104004065AImprove the efficiency of solid-liquid separationImprove serum qualityPeptide preparation methodsChemical structurePurification methods

The invention relates to the technical field of biomedicines, and concretely relates to a method for separating and purifying bleomycin (BLM) derivatives 6'-dehydroxy-BLMs from a recombinant engineering bacterium Streptomyces flavovirens SB9026 (with the preservation number of CCTCC M2011292) fermentation liquid. The method comprises the steps of deposition separation pretreatment, D-113 and Diaion HP-20 resin adsorption elution, Silica Flash column isogradient elution, copper removing refining and the like. The method has the advantages of simplification and reduction of the separating and purifying steps, production cost reduction and recovery rate increase. The chemical structure of the bleomycin derivatives is represented by a general formula shown in the specification.

Owner:CHANGSHA CHARISM BIOSCIENCES CO LTD +2

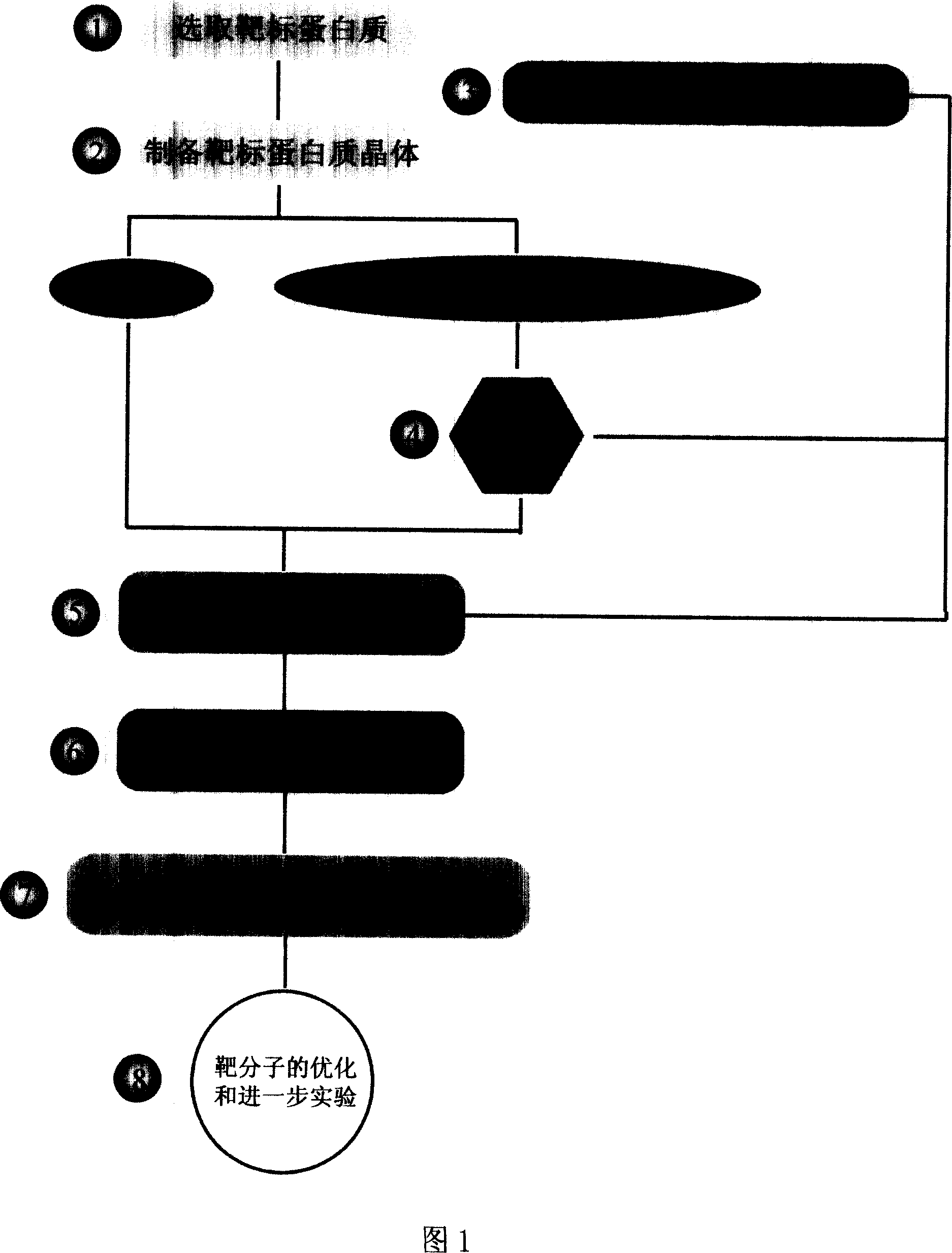

Novel methods for high efficiency and rapid getting fine three dimensional structure of target protein composite body and target molecule target molecule

ActiveCN101063682AReduce separation and purification stepsImprove bindingPreparing sample for investigationMaterial analysis using radiation diffractionNatural productActive component

This invention provides one effective and rapid method to extract target molecule and target compound find three dimensional structure from Chinese medicine product, which uses target protein transistor stricture as base and uses X ray transistor means to filter the product for active component and for study from one new respective.

Owner:NANKAI UNIV +2

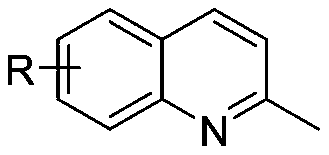

Preparation method of 1,2,3-triazol-[1,5-a] quinoline compound

ActiveCN110105355AThe synthesis method is simpleSave raw materialsOrganic chemistryMethyl benzeneQuinoline

The invention discloses a preparation method of a 1,2,3-triazol-[1,5-a] quinoline compound. The method comprises the steps of making substituted methyl quinoline react with an iodine simple substancein advance, adding a solid potassium phosphate trihydrate after the methyl quinoline disappears, and adding p-methyl benzene sulfonyl hydrazide for continuing a reaction to obtain the 1,2,3-triazol-[1,5-a] quinoline compound. The preparation method has the advantages that the adopted raw materials are cheap and easy to obtain, the operation method is simple, the reaction condition is mild, a one-pot approach can be adopted, the steps are short, the yield is up to 83%, and a feasible method is provided for industrial preparation of the compound.

Owner:YANTAI UNIV

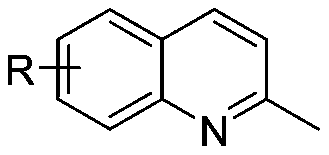

Preparation method of pyridodipyrimidine and pyridodipyrazole derivatives

InactiveCN110790763AReduce consumptionEasy to separateOrganic chemistryMethyl benzeneBiochemical engineering

The invention discloses a preparation method of pyridodipyrimidine and pyridodipyrazole derivatives. The method comprises the following steps: carrying out a contact reaction on substituted methylquinoline derivatives, 6-amino-1,3-dimethylpyrimidine-2,4-dione or 3-methyl-1-phenyl-5-aminopyrazole and an iodine elementary substance to synthesize pyridodipyrimidine compounds, pyridodipyrazole compounds and derivatives thereof in one-pot. According to the preparation method, the adopted raw materials are cheap and easy to obtain, the preparation method is simple, steps are relatively short, the yield is up to 97%, and a feasible method is provided for industrially preparing the compounds.

Owner:YANTAI UNIV

The gene encoding the biosynthetic enzyme of glucodipeptide and its application

ActiveCN106754985BReduce separation and purification stepsEasy to operateBacteriaMicroorganism based processesEscherichia coliDipeptide

The invention discloses a gene for coding a glutamine dipeptide biosynthetic enzyme and application thereof. The nucleotide sequence of the gene is shown as SEQ ID NO.1. The invention further discloses an amino acid sequence coded by the gene, and provides a recombinant vector containing the gene, recombinant escherichia coli, and a method for performing biotransformation to synthesize the glutamine dipeptide by using the gene. The gene and the application of a recombinant bacterial strain of the gene have the advantages of high mol conversion rate, high reaction speed, easy separation, low cost and the like. In the synthesis method, the maximum mol conversion rate of the glutamine dipeptide can reach 83.3 percent; meanwhile, the thalli can be applied to the catalytic synthesis of the glutamine dipeptide again after the circulation recovery; in addition, the catalytic activity is stable. Therefore high market competitive power and application values are realized; a foundation is laid for the industrial production of the glutamine dipeptide.

Owner:INNOBIO CORP LTD

Method for preparing anti-human chorionic gonadotrophin (hCG) monoclonal antibody fragment

The invention discloses a method for preparing an anti-human chorionic gonadotrophin (hCG) monoclonal antibody fragment. The method comprises the following steps of: putting activated immobilized papain into a 0.1mol / L acetic acid buffer solution with pH of 5.0, adding an anti-hCG monoclonal antibody, performing water bath reaction for 4 to 24 hours at the temperature of between 30 and 60 DEG C, and filtering the reaction solution, wherein filter cakes B are immobilized papain and recycled, and filtrate B is a hydrolysate containing the monoclonal antibody fragment; and separating and purifying the hydrolysate containing the monoclonal antibody fragment by adopting weak anion exchange chromatography, and thus obtaining the anti-hCG monoclonal antibody fragment. The method is easy to implement and has a few purification steps, and the obtained antibody fragment has high purity; and the antibody fragment prepared in the method can reach the purity of over 90 percent by one-step purification.

Owner:ZHEJIANG UNIV OF TECH

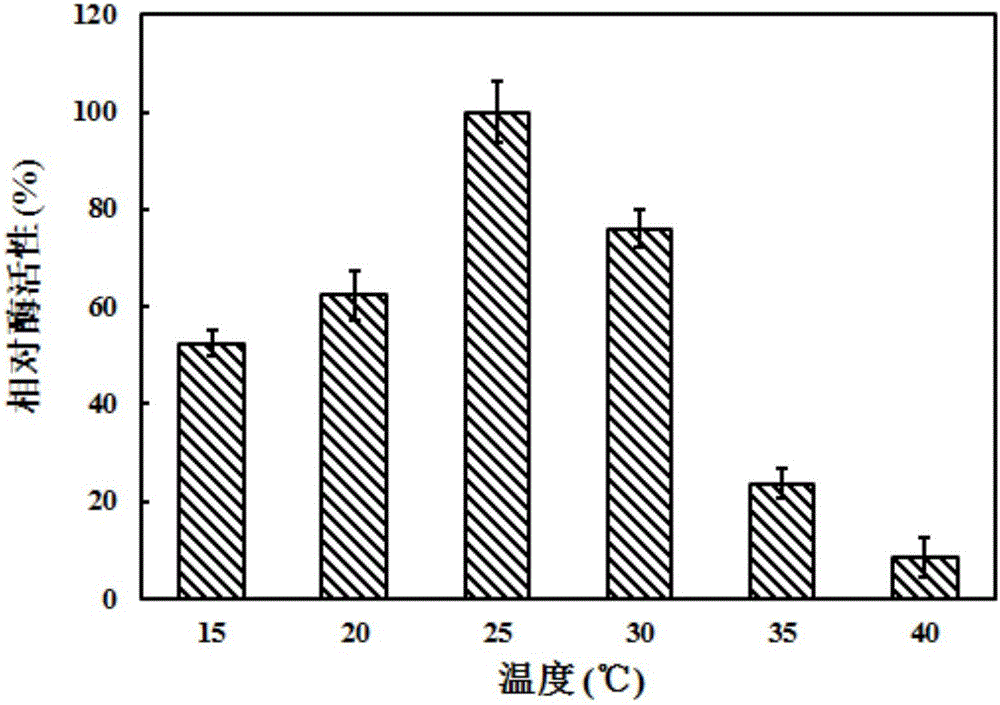

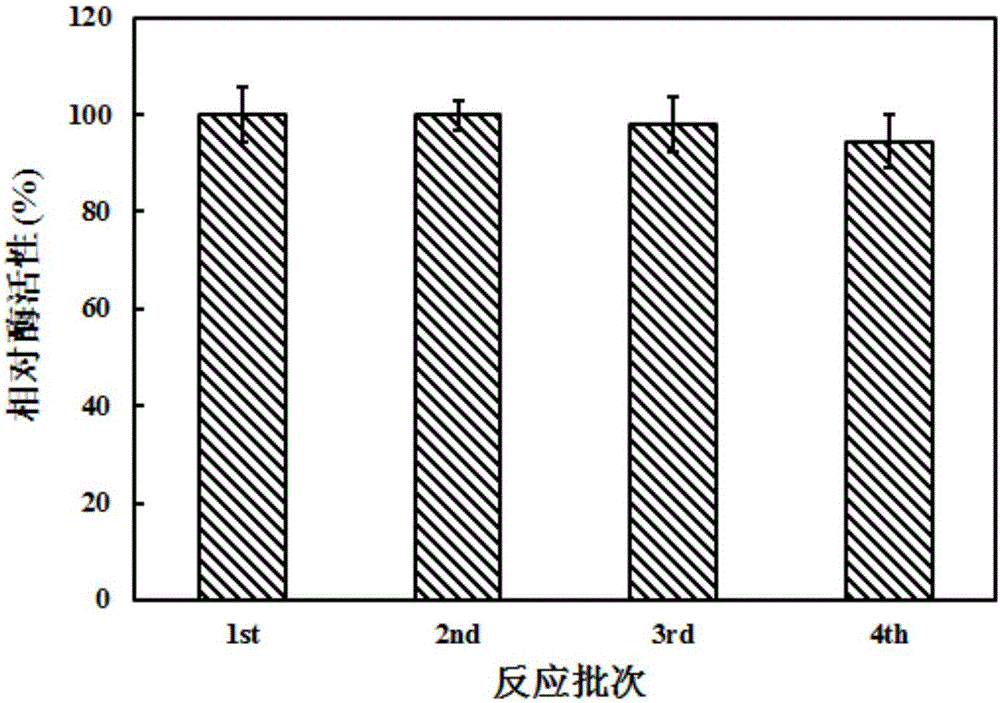

Heat resistant beta-amylase-trehalose synthase fusion enzyme, expression gene of heat resistant beta-amylase-trehalose synthase fusion enzyme, engineering bacterium secreting fusion enzyme, and application

The invention provides a heat resistant beta-amylase-trehalose synthase fusion enzyme, an expression gene of the heat resistant beta-amylase-trehalose synthase fusion enzyme, an engineering bacterium secreting the fusion enzyme and application, and belongs to the technical field of genetic engineering. The heat resistant beta-amylase-trehalose synthase fusion enzyme comprises an amino acid sequence with SEQ ID No.1 and another amino acid sequence, and the similarity of the another amino acid sequence to the amino acid sequence with SEQ ID No.1 is 80%-100%. The expression gene of the heat resistant beta-amylase-trehalose synthase fusion enzyme comprises an amino acid sequence with SEQ ID No.2 and another amino acid sequence, and the similarity of the another amino acid sequence to the amino acid sequence with SEQ ID No.2 is 80%-100%. The obtained beta-amylase-trehalose synthase fusion enzyme has a heat resistant property, directly converts amylose into trehalose at the higher temperature, saves the complicated steps of separating and purifying endoenzyme, simplifies the production process of the trehalose, and reduces the production cost.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

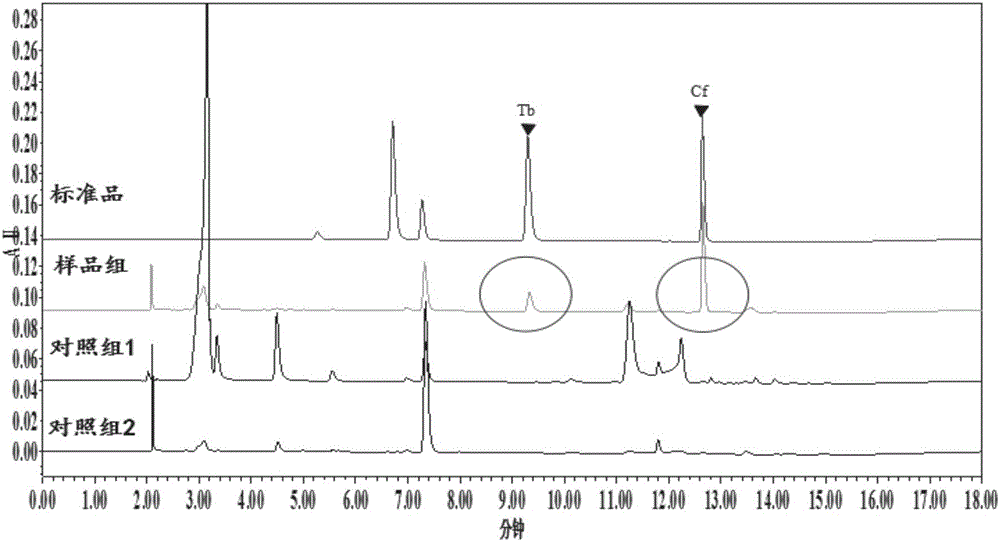

Recombinant gene engineering bacteria producing theophylline and caffeine, and construction method and application of same

The invention belongs to the technical field of gene engineering, and discloses a novel recombinant gene engineering bacteria producing theophylline and caffeine, and a construction method and an application of same. In the invention, a caffeine synthetic and metabolic route with xanthine as a methyl receptor is mainly employed, and a tea tree caffeine synthetase gene TCS1 and a yeast guanine deaminase gene GUD1 are co-introduced into Escherichia coli so as to construct a recombinant Escherichia coli engineering bacteria that can produce the theophylline and caffeine through fermentation in vitro. The engineering bacteria can produce the theophylline and caffeine at high yield at the same time without addition of any substrate, yields of the theophylline and the caffeine respectively reaching 4.17 mg / L and 20.3 mg / L. The products, in a fermentation liquid, are easy to separate and purify. The recombinant gene engineering bacteria has excellent industrial application prospect.

Owner:ANHUI AGRICULTURAL UNIVERSITY

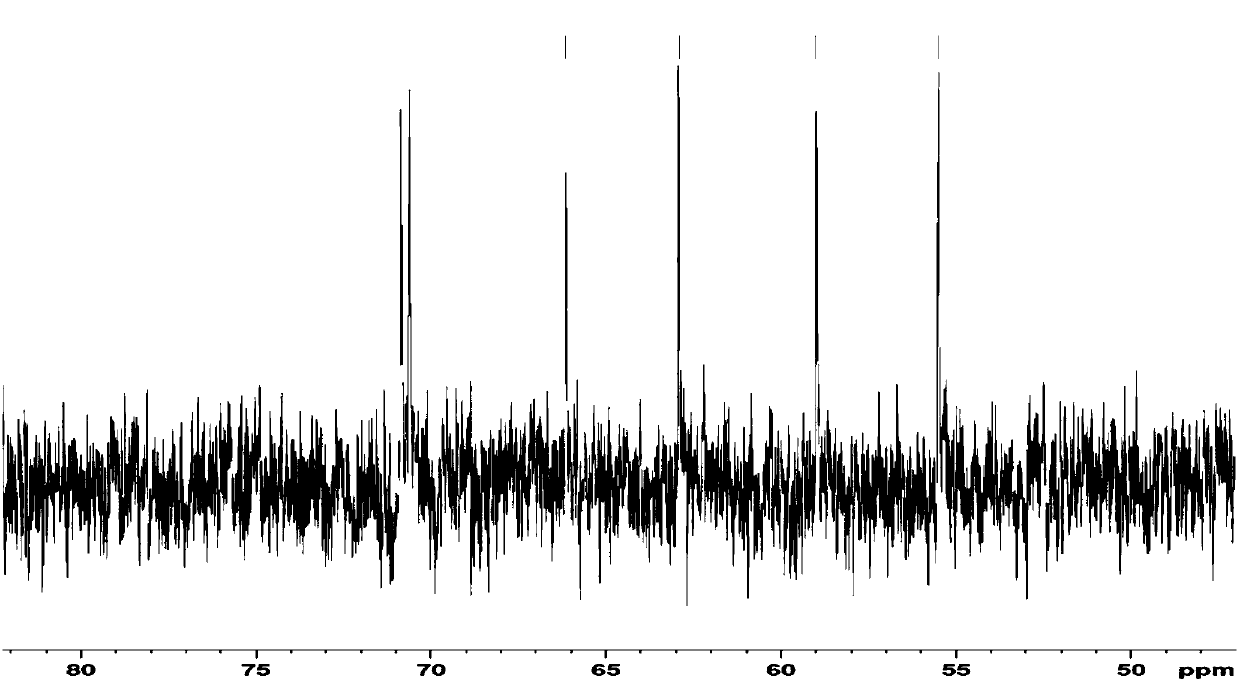

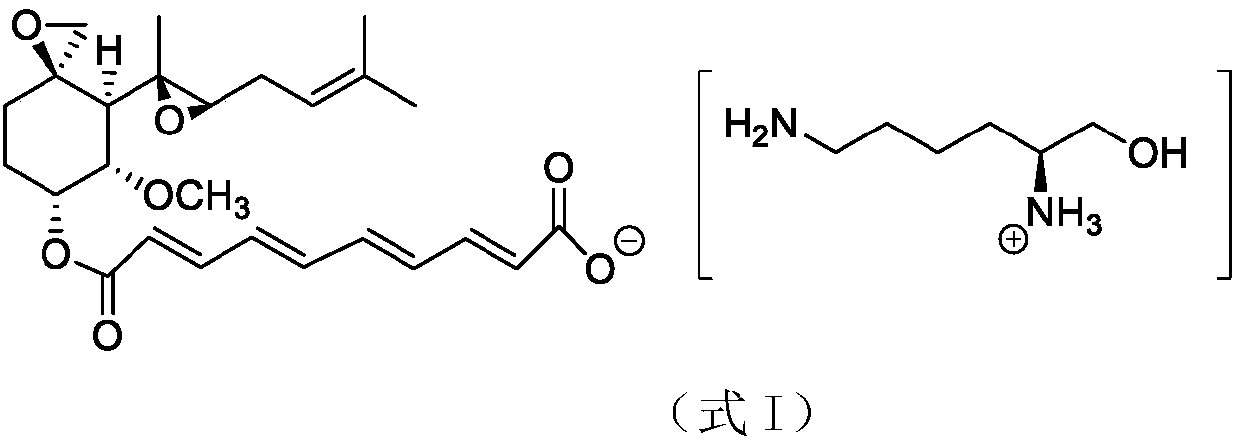

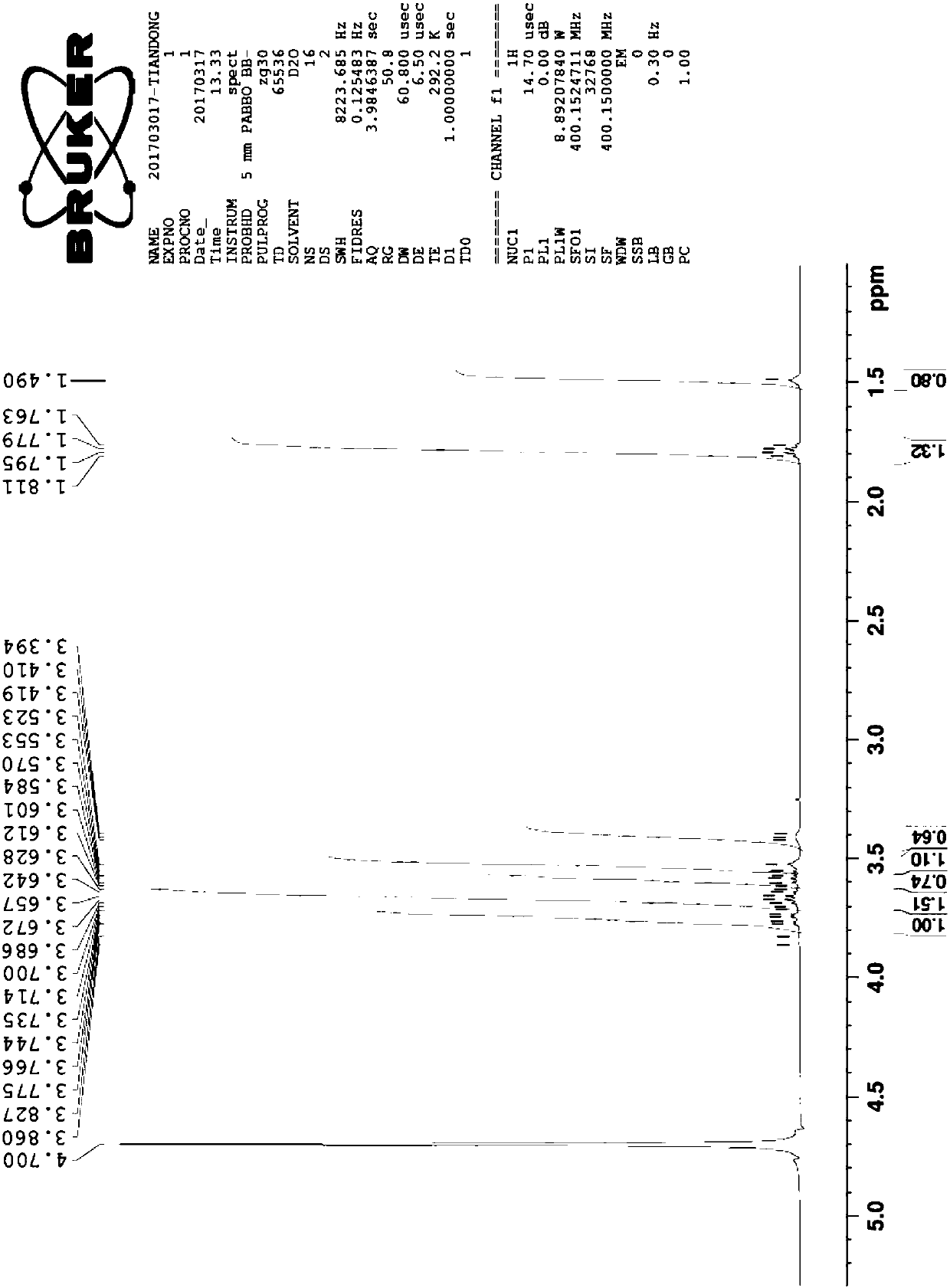

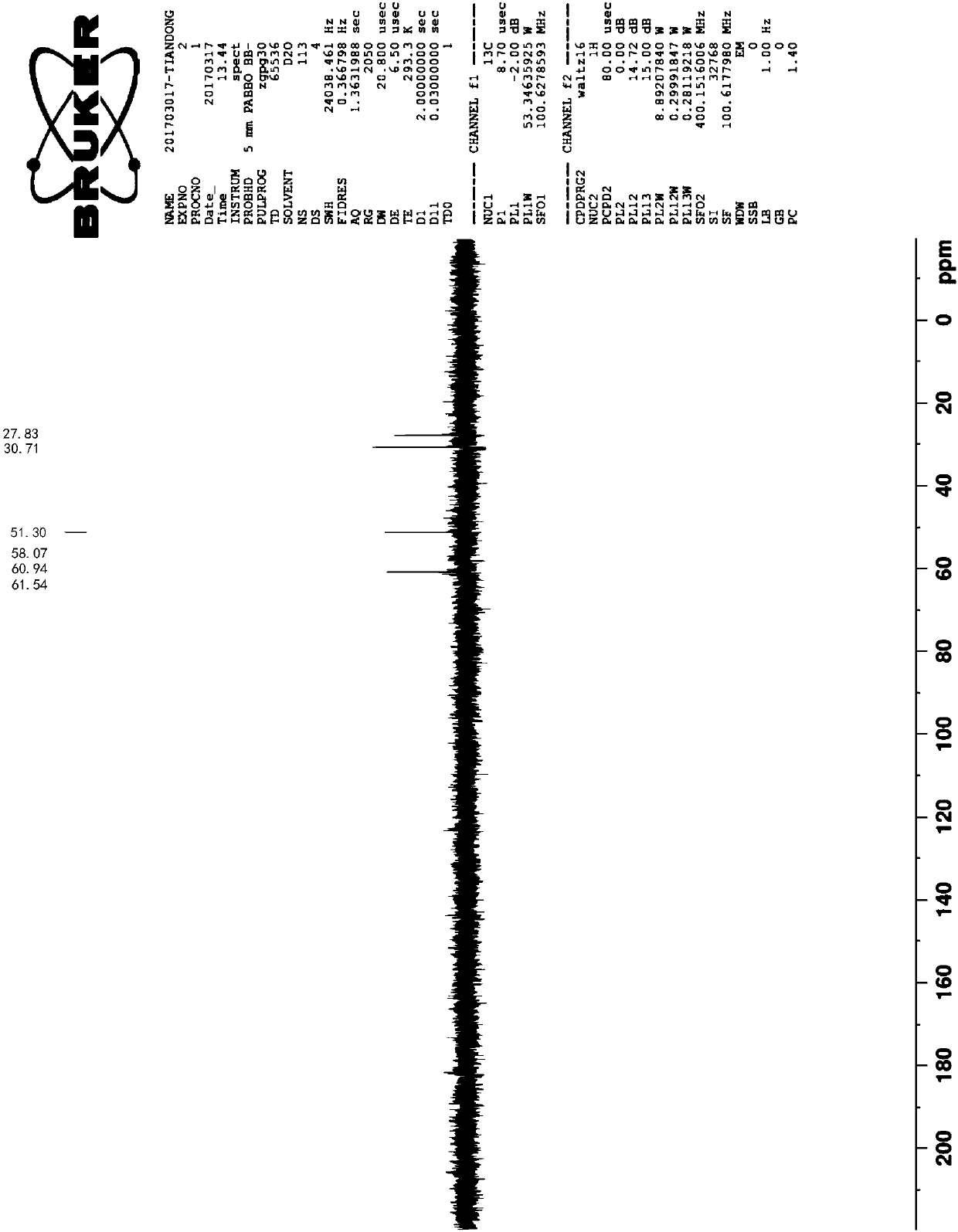

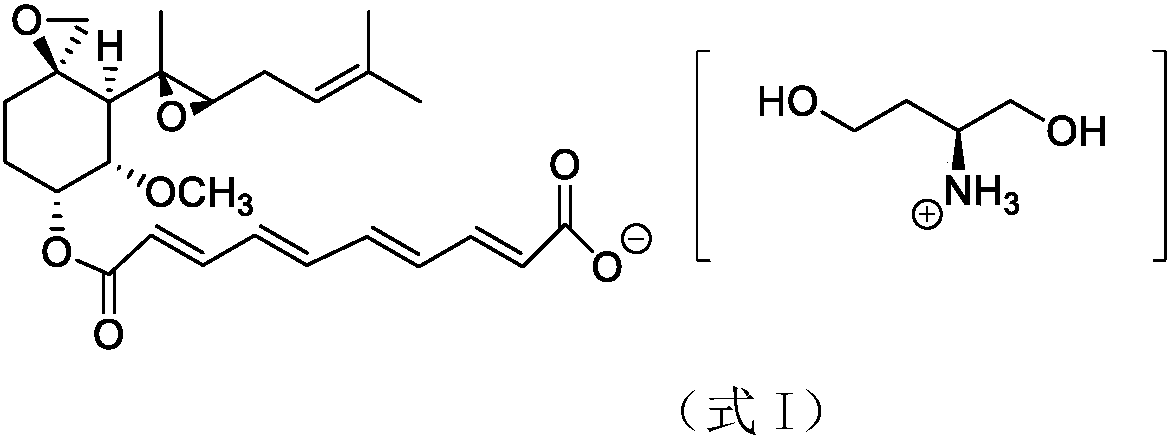

A preparation method of fumagillin amino alcohol

InactiveCN109867637ALow toxicityGood water solubilityOrganic compound preparationAmino-hyroxy compound preparationSolubilityAlcohol

The invention discloses a preparation method of fumagillin amino alcohol shown as a formula I in the specification. The method comprises the following steps: (1) reducing amino acid shown in a formulaII to obtain a compound shown in a formula III; and (2) under the heating condition of a methanol solution, carrying out an ammonium salt synthesis reaction on fumagillin and the compound shown in the formula III to obtain fumagillin amino alcohol. The preparation method is short in reaction route and high in synthesis efficiency, the separation and purification steps are reduced, and mass production can be achieved. Meanwhile, the synthesized fumagillin amino alcohol is low in toxicity, can be dissolved and degraded in nature and is good in water solubility.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Method for extracting active alkaloid from lycoris herb

The invention discloses a method for extracting active alkaloid from lycoris plants. The method utilizes the combination of an enzymic method and modern mechanical wall-breaking technique to extract lycoris alkaloid. Lycoris alkaloid is extracted efficiently in excellent yields under mild conditions, other impurities dissolution is lowered and the consistency of extract is decreased for continuing treatment of isolation and purification. Segmental extraction technique is adopted according to the alkalinity of lycoris alkaloid to get a plurality of raw products of lycoris alkaloid. Then highlypurified monomer of lycoris alkaloids (galanthamin, galanthidine, dihydrogalanthamine, sekisamine) are available after column chromatography and repeated recrystallization. The invention has the advantages of simple line, no pollution, short cycle, high yield of products, high safety coefficient, low cost, diversity of outputs, thus raising the comprehensive utilization of lycoris and reducing the manufacturing cost of deep processing and increasing the feasibility of industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A method for preparing fumagillin amino alcohol

InactiveCN109867639ALow toxicityGood water solubilityOrganic compound preparationAmino-hyroxy compound preparationSolubilityAlcohol

The invention discloses a method for preparing fumagillin amino alcohol shown as a formula I in the specification. The method comprises the following steps: (1) reducing amino acid shown in a formulaII to obtain a compound shown in a formula III; and (2) under the heating condition of a methanol solution, carrying out an ammonium salt synthesis reaction on fumagillin and the compound shown in theformula III to obtain fumagillin amino alcohol. The method is short in reaction route and high in synthesis efficiency, the separation and purification steps are reduced, and mass production can be achieved. Meanwhile, the synthesized fumagillin amino alcohol is low in toxicity, can be dissolved and degraded in nature and is good in water solubility.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Method for preparing phloretin from phlorizin through hydrolysis in biphase system

InactiveCN108358769AReduce volumeGuaranteed concentrationCarbonyl compound preparation by hydrolysisCarbonyl compound separation/purificationEnvironmental resistanceOrganic solvent

The invention discloses a preparation method of phloretin. The phloretin is used as raw materials; through two-phase acid hydrolysis, the phloretin pure product with the yield being 95 percent is obtained. Compared with the existing phlorizin semi-preparation production method, the problems of low phloretin conversion rate, many byproducts and low product purity are solved. The whole reaction andseparation purification operation is simple; the conditions are mild; the catalyst can be cyclically used in a water phase; the organic solvents can be recovered and used; green and environment-friendly effects are achieved. The method is suitable for industrial production.

Owner:湖北尧一生物科技有限公司

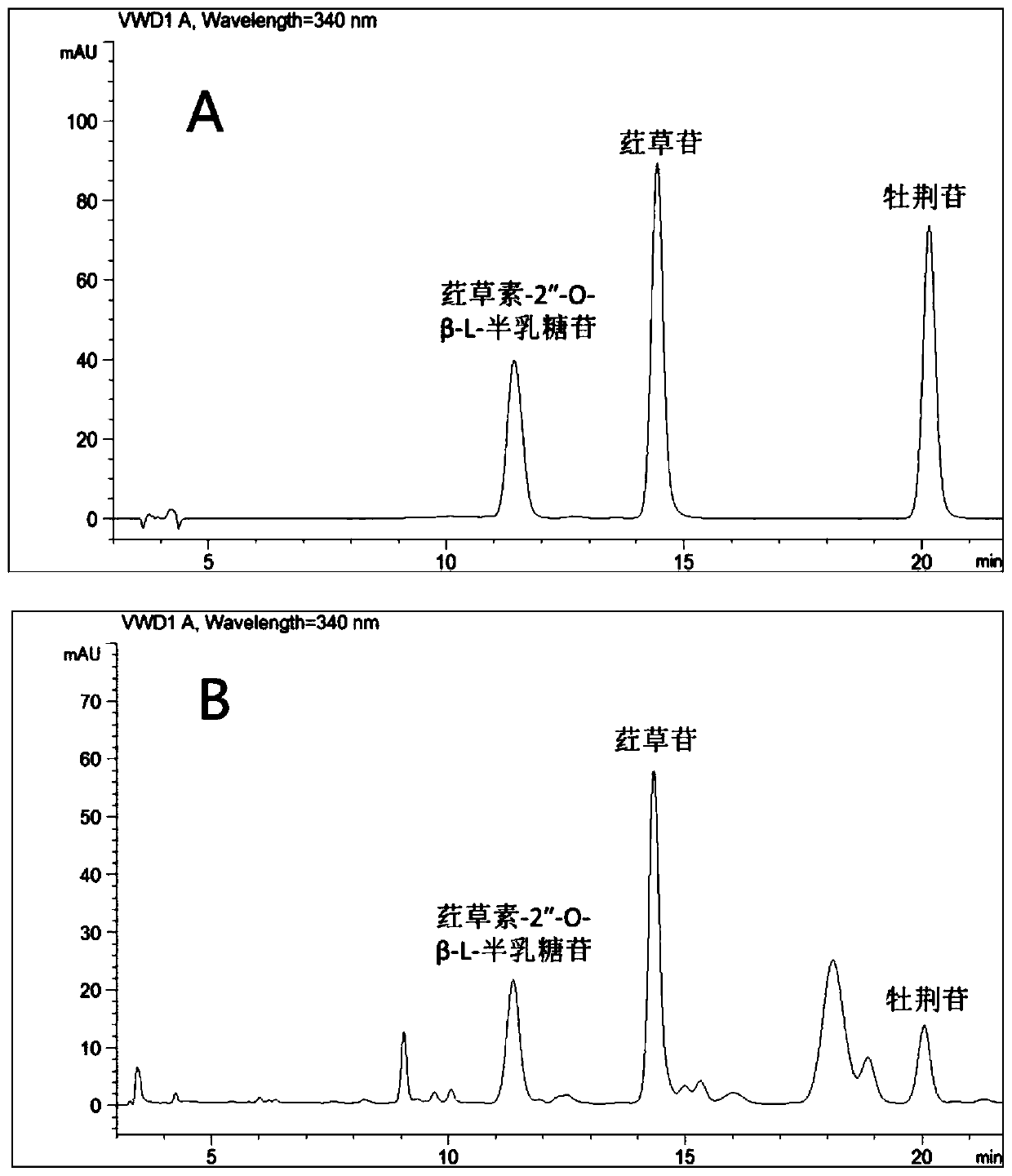

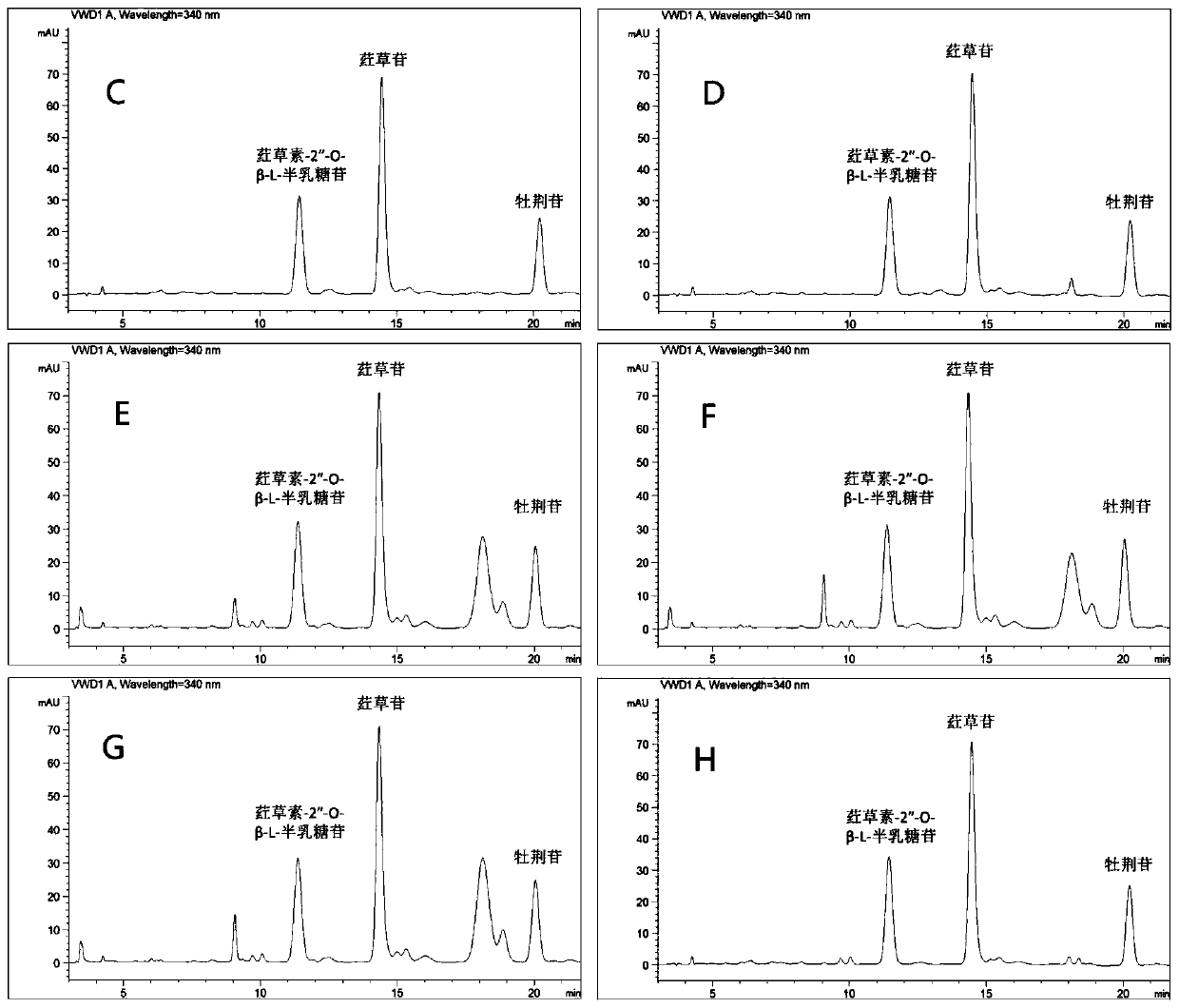

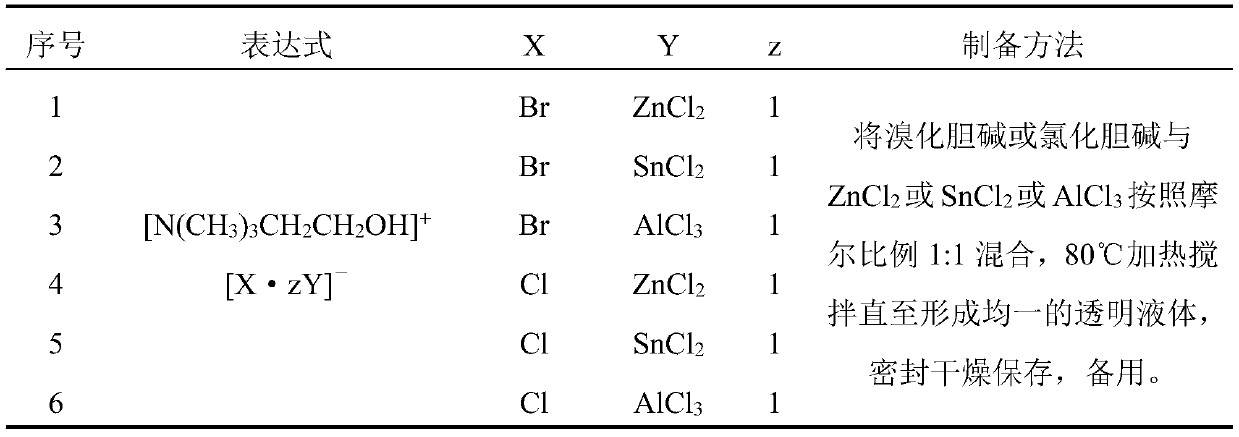

Choline deep eutectic solvent, preparation method and application in extracting flavonoid carbon glycosides of nasturtium

InactiveCN107628959BEfficient extractionHigh extraction rateSugar derivativesOrganic compound preparationC-glycosideSolvent

The invention discloses choline eutectic solvents, a preparation method and an application in extraction of flavone C-glycoside of flos trollii. The choline eutectic solvents have the expression: [N(CH)33CH2CH2OH]+[X.zY]- and is prepared from choline bromide or choline chloride and ZnCl2, SnCl2 or AlCl3 through mixing in a certain mole ratio, wherein when X is Br, Y is ZnCl2 or SnCl2; when X is Cl, Y is AlCl3. By means of the provided choline eutectic solvents, three important flavone C-glycosides, namely, orientin, orientin-2''-O-beta-L-galactoside and vitexin in the flos trollii can be efficiently and selectively extracted; compared with conventional extraction with methanol solvents, the extraction rate of orientin, orientin-2''-O-beta-L-galactoside and vitexin can be improved, few impurities exist in an extract, silica gel columns are not required to be repeatedly used for separation when the extract serving as the raw material is used for preparing monomers of orientin, orientin-2''-O-beta-L-galactoside and vitexin, the separation and purification steps can be greatly reduced, and the separation and purification cost can be reduced.

Owner:HEBEI NORMAL UNIV

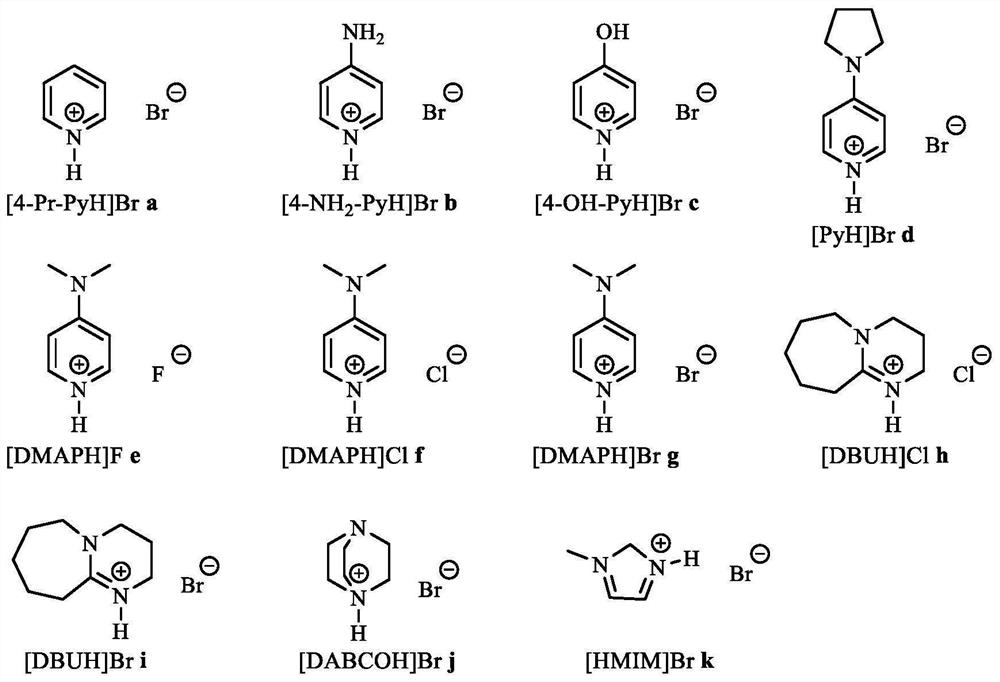

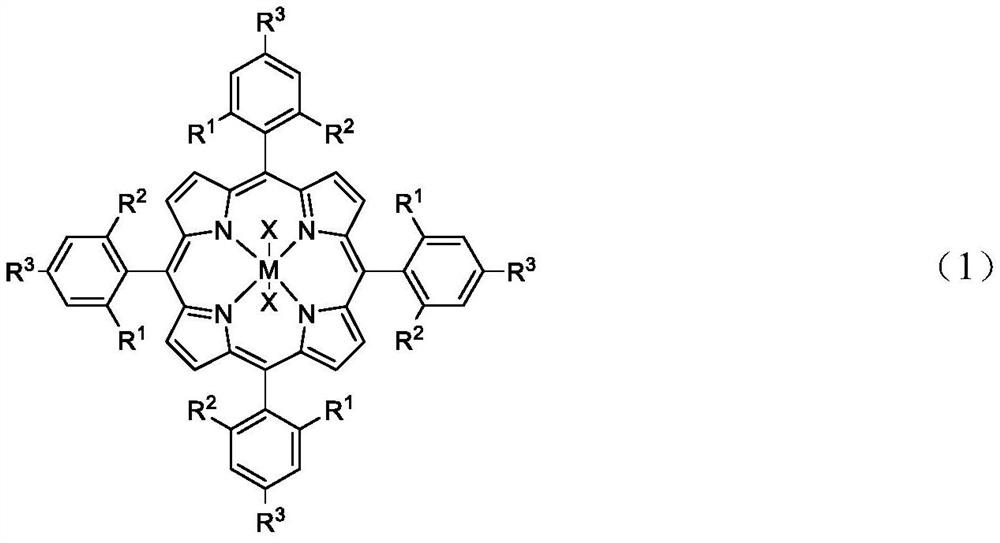

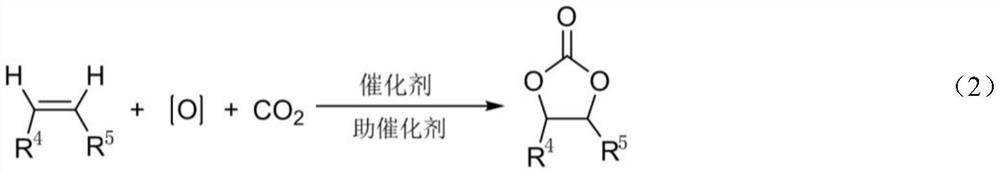

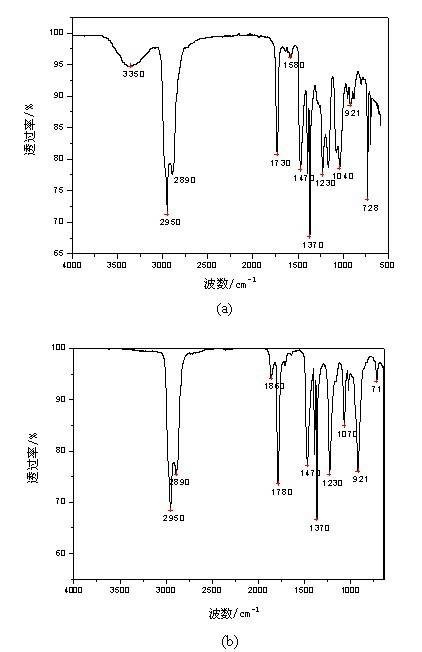

Method for directly synthesizing cyclic carbonate from olefin under catalysis of metalloporphyrin

PendingCN112480059AEasy to manufactureHigh reaction conversion rateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCarbonate ester

The invention discloses a method for directly synthesizing cyclic carbonate from olefin under catalysis of metalloporphyrin, and relates to the technical field of catalytic synthesis. The technical scheme is characterized in that the method comprises the following steps: catalyzing olefin, carbon dioxide and an oxidant to carry out epoxidation carboxylation reaction by taking metalloporphyrin as acatalyst and ionic liquid as a cocatalyst, and preparing cyclic carbonate by a one-pot method. The specific reaction equation is as follows: the reaction conditions are mild, the catalyst preparationis simple and convenient, the catalyst consumption is low, and the target product cyclic carbonate is obtained with high conversion rate and high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 1,2,3-triazol-[1,5-a] quinoline compound Preparation method of 1,2,3-triazol-[1,5-a] quinoline compound](https://images-eureka.patsnap.com/patent_img/8dc3e591-0d7f-469a-b150-14d2d19ae060/1.png)

![Preparation method of 1,2,3-triazol-[1,5-a] quinoline compound Preparation method of 1,2,3-triazol-[1,5-a] quinoline compound](https://images-eureka.patsnap.com/patent_img/8dc3e591-0d7f-469a-b150-14d2d19ae060/FDA0002071350570000011.png)

![Preparation method of 1,2,3-triazol-[1,5-a] quinoline compound Preparation method of 1,2,3-triazol-[1,5-a] quinoline compound](https://images-eureka.patsnap.com/patent_img/8dc3e591-0d7f-469a-b150-14d2d19ae060/BDA0002071350580000011.png)