Method for clathrating tributyrin by enzyme method

A technology for combining tributyrin and tributyrin, which is applied in the field of enzymatic inclusion of tributyrin, can solve the problems of poor fluidity, low oil content, poor solubility, etc. The effect of storage period and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

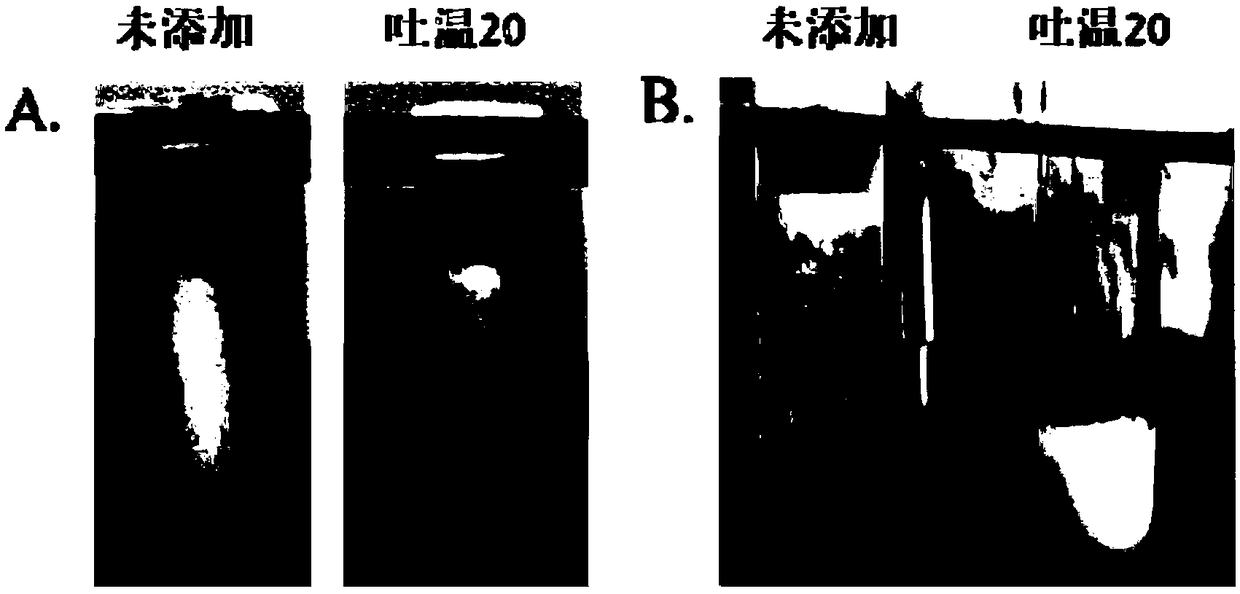

[0030] Example 1 Comparison of cyclodextrin inclusion tributyrin and enzymatic method inclusion tributyrin

[0031] The process of directly inclusion tributyrin with cyclodextrin is as follows:

[0032] Glyceryl tributyrate is mixed with ethanol in advance (mass ratio of glyceryl tributyrate and ethanol is 1:1), 4% β-cyclodextrin is heated and dissolved, and after cooling to 50°C, the ethanol solution of tributyrin is slowly It is added to the above solution, wherein the mass ratio of tributyrin added to β-cyclodextrin is (0.1-0.5):1. Thoroughly shake and mix, and sonicate at 50°C for 30min. After the reaction is finished, freeze-drying is carried out to obtain dryness and sealed storage.

[0033] The preparation process of enzymatic inclusion tributyrin is carried out as follows:

[0034] (1) Using cornstarch solution with a mass concentration of 20% as a substrate, add CGTase to liquefy at 90°C for 60 minutes, wherein the amount of CGTase added is 2U / (g starch wet basis);...

Embodiment 2

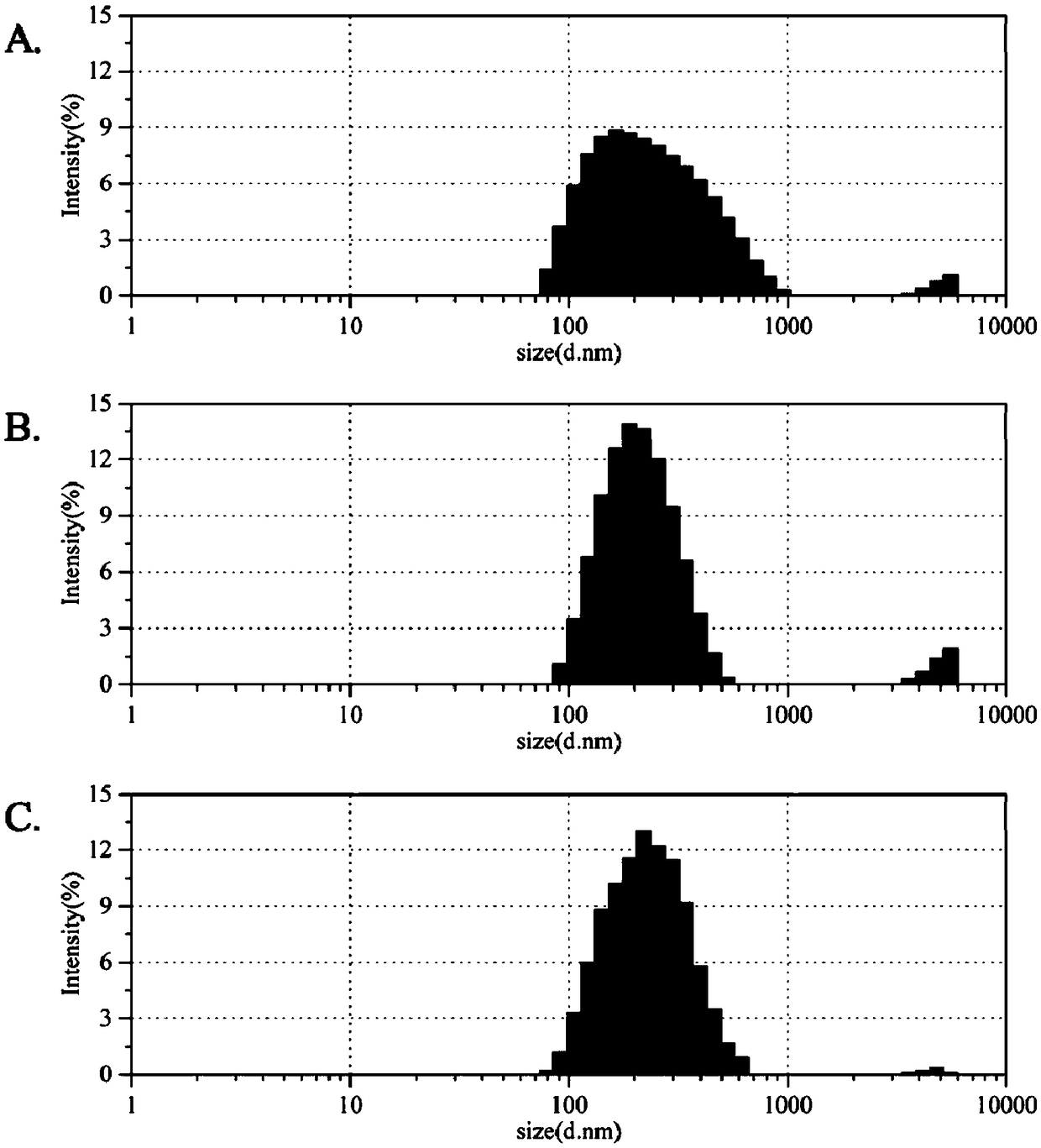

[0044] Example 2 Preparation of tributyrin embedding material with different substrates

[0045] The preparation process of tributyrin powder oil is carried out as follows:

[0046] (1) Using cornstarch, potato starch or maltodextrin (DE=10) with a mass concentration of 20% as substrates, add 2U / (g starch or maltodextrin wet basis) CGTase to liquefy at 90°C for 60min;

[0047] (2) Cool to 45°C, add 2U / (g starch or malt paste wet base) CGT enzyme to carry out cyclization reaction for 12 hours, after the end, add tributyrin, tributyrin and starch or malt paste to the system The ratio of fine to raw material is 0.30:1 (mass ratio);

[0048] (3) Add Tween-20 emulsifier to the above solution and mix well. The ratio of emulsifier to starch or maltodextrin is 0.2:1 (mass ratio)

[0049] (4) High-speed shearing machine 8000~2000rpm under high-speed shearing above-mentioned solution 2~5min;

[0050] (5) Homogenize the emulsion obtained in (4) to obtain a uniform and stable emulsion,...

Embodiment 3

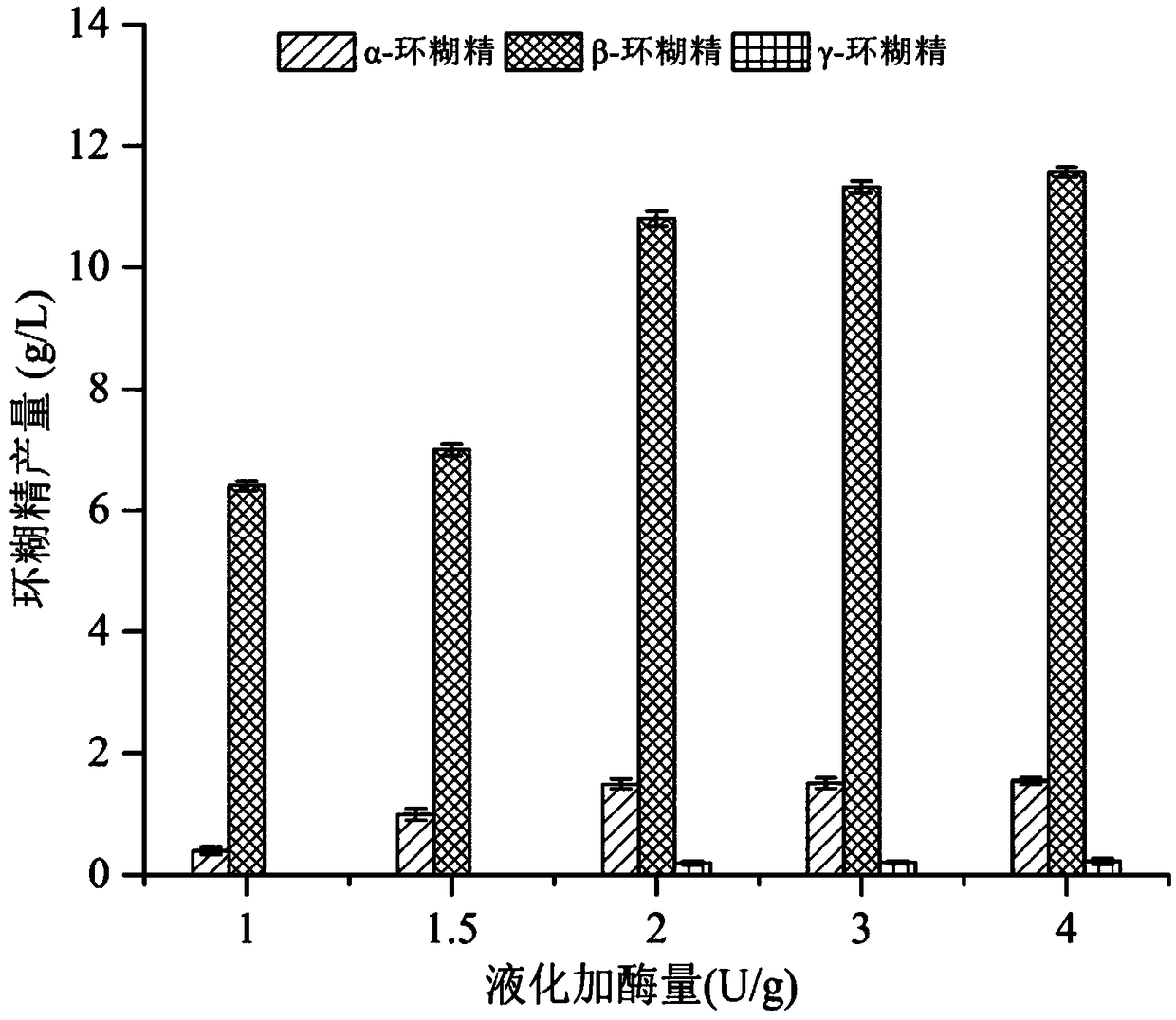

[0052] Example 3 Effect of the amount of liquefaction enzyme added on the emulsion during the preparation of powder tributyrin

[0053] The preparation process of tributyrin powder oil is carried out as follows:

[0054] (1) Using 20% corn starch as a substrate, add CGT enzyme to liquefy at 90°C for 60 minutes, wherein the amount of liquefied enzyme added is 1, 1.5, 2, 3, 4 U / (g starch wet basis);

[0055] (2) Cool to 45°C, add 2U / (g starch) CGT enzyme to carry out cyclization reaction for 12h, add tributyrin to the system after completion, the ratio of tributyrin to starch raw material is 0.30:1 (mass Compare);

[0056] (3) Add Tween-20 emulsifier to the above solution and mix evenly, the ratio of emulsifier to starch is 0.2:1 (mass ratio);

[0057] (4) High-speed shearing machine 8000~2000rpm under high-speed shearing above-mentioned solution 2~5min;

[0058] (5) Homogenize the emulsion obtained in (4) to obtain a uniform and stable emulsion, the homogenization pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com