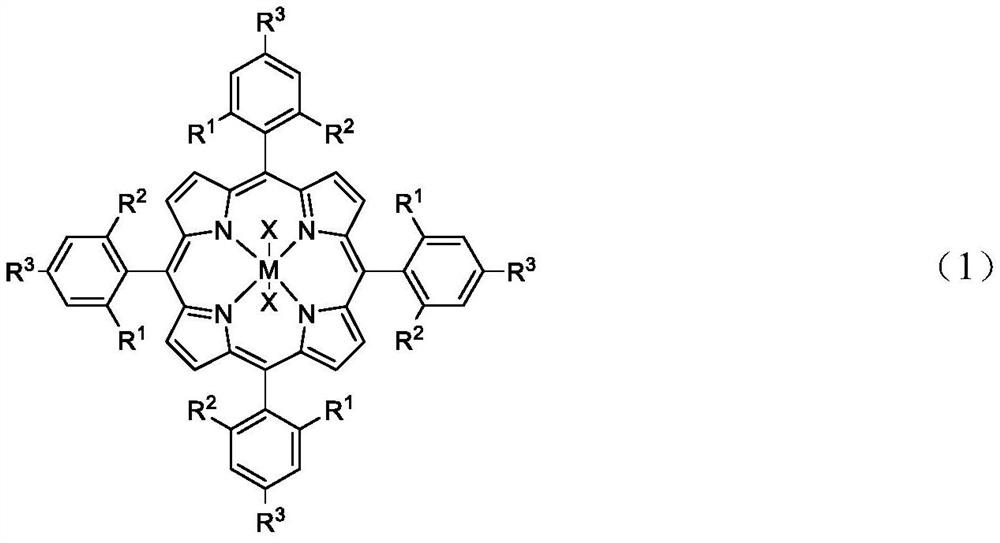

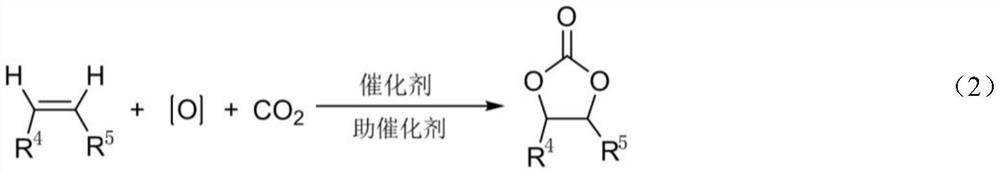

Method for directly synthesizing cyclic carbonate from olefin under catalysis of metalloporphyrin

A technology of porphyrin catalyzing olefins and cyclic carbonates, applied in chemical instruments and methods, catalytic reactions, catalysts for physical/chemical processes, etc., can solve problems such as low yields, etc. The effect of process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

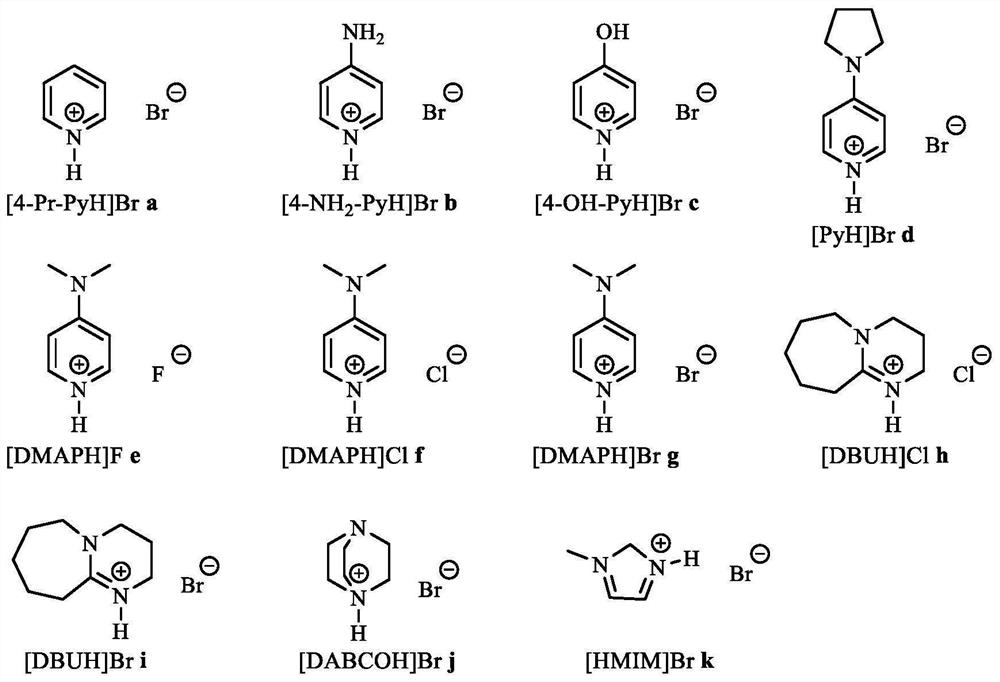

Embodiment 1

[0032] Styrene (1.2g, 10mmol), manganese tetraphenylporphyrin (1.0mg, 0.14%mmol), cocatalyst [4-Pr-PyH]Bra (40mg, 0.25%mol), 0.1MPa oxygen and 1.2MPa carbon dioxide , reacted at 80°C for 8h, stopped the reaction to obtain the corresponding cyclocarbonate, and its yield was 89% by gas phase detection.

Embodiment 2

[0034] Styrene (1.2g, 10mmol), manganese tetraphenylporphyrin (1.0mg, 0.14%mmol), cocatalyst [4-NH 2 -PyH]Br b (44 mg, 0.25% mol), the reactor was closed, and 0.8 MPa oxygen and 1.2 MPa carbon dioxide were introduced. React at 100° C. for 8 h, stop the reaction to obtain the corresponding cyclic carbonate, and its yield is 95% by gas phase detection.

Embodiment 3

[0036] In a 100mL autoclave, add styrene (1.2g, 10mmol), manganese tetraphenylporphyrin (1.0mg, 0.14%mmol), cocatalyst [4-OH-PyH]Br c (44mg, 0.25%mol ), close the reactor, and feed 0.6MPa oxygen and 1.2MPa carbon dioxide. After reacting at 130°C for 8 hours, the reaction was stopped to obtain the corresponding cyclocarbonate, and the yield was 90% by gas phase detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com