Synthesis method of emulsifier for emulsion explosive

A technique of emulsified explosives and synthetic methods, which is applied in the direction of non-explosive/non-thermal agent components, chemical instruments and methods, explosives, etc., can solve the problems of cumbersome synthesis process, complex emulsifier structure, unclear reaction end mark, etc., and reduce the Aggregation, reducing the steps of separation and purification, and the effect of simple and easy synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

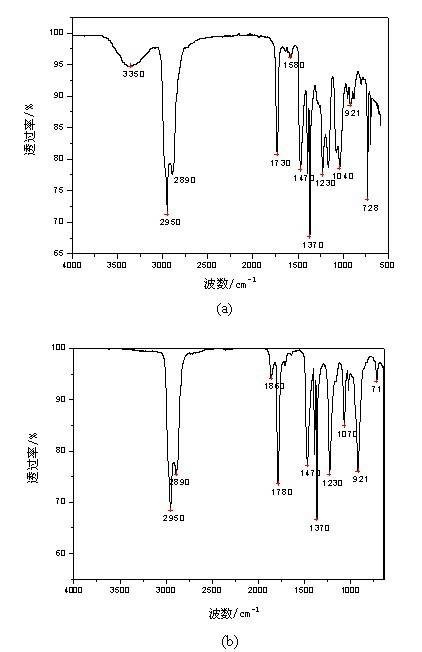

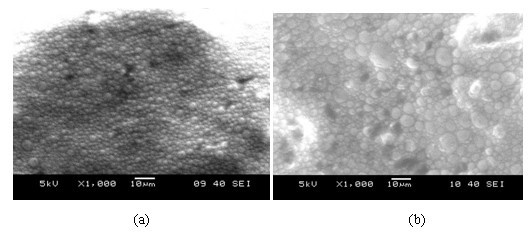

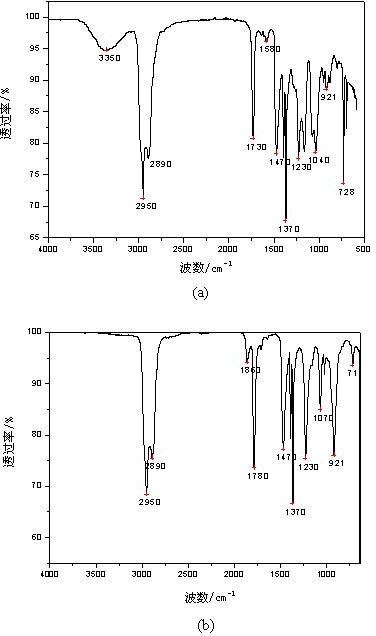

[0025] Dissolve 16.0 g of PIBSA (polyisobutylene chain molecular weight of 1000) in xylene, add it into a 250 mL four-neck flask, and weigh triethanolamine in a constant pressure dropping funnel according to the molar ratio of PIBSA:triethanolamine of 1:2. Put constant pressure dropping funnel, thermometer, N 2 Introduce the tube, put the mechanical stirring device on the four-necked flask, start stirring, and feed N 2 , the temperature was raised to 60°C, and triethanolamine was slowly added dropwise. After the dropwise addition, the temperature was raised to 140°C, and the reaction was terminated when the acid value decreased to 5 mgKOH / g, and the product emulsifier A was obtained by extraction with saturated saline. Analyze the effective groups contained in the product by infrared spectroscopy (such as figure 1 Shown), measure the hydroxyl value of product (as shown in table 1); Prepare emulsified explosive with product emulsifier A as emulsifier, observe the particle morp...

Embodiment 2

[0027] Dissolve 15.4 g of PIBSA (polyisobutylene chain molecular weight of 1000) in 150SN base oil, add it into a 250 mL four-necked flask, and weigh triethanolamine in a constant pressure dropping funnel according to the molar ratio of PIBSA:triethanolamine 1:1.5. Put constant pressure dropping funnel, thermometer, N 2 Introduce the tube, put the mechanical stirring device on the four-necked flask, start stirring, and feed N 2 , the temperature was raised to 40°C, and triethanolamine was slowly added dropwise. After the dropwise addition, the temperature was raised to 140°C, and the reaction was terminated when the acid value decreased to 8 mgKOH / g, and the product emulsifier B was obtained by extraction with saturated saline. The hydroxyl value of the product was measured; the emulsifier B was used as the emulsifier to prepare the emulsified explosive, and the stability of the emulsified explosive was tested by high and low temperature cycle experiments, and the detonation v...

Embodiment 3

[0029] Dissolve 15.8 g of PIBSA (polyisobutylene chain molecular weight: 1300) in xylene, add it into a 250 mL four-necked flask, and weigh triethanolamine in a constant pressure dropping funnel according to the molar ratio of PIBSA:triethanolamine of 1:2.5. Put constant pressure dropping funnel, thermometer, N 2 Introduce the tube, put the mechanical stirring device on the four-necked flask, start stirring, and feed N 2 , the temperature was raised to 60°C, and triethanolamine was slowly added dropwise. After the dropwise addition, the temperature was raised to 140°C, and the reaction was terminated when the acid value decreased to 10 mgKOH / g, and the product emulsifier C was obtained by extraction with saturated saline. The hydroxyl value of the product was measured; the product emulsifier C was used as an emulsifier to prepare an emulsion explosive, and the stability of the emulsion explosive was tested by high and low temperature cycle experiments, and the detonation veloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com