Method for producing L-2-aminobutyric acid by double immobilized multi-enzyme systems

A multi-enzyme system and aminobutyric acid technology, applied in multi-enzyme systems, chemical industry, sustainable manufacturing/processing, etc., to achieve the effects of reducing separation and purification steps, simplifying the process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

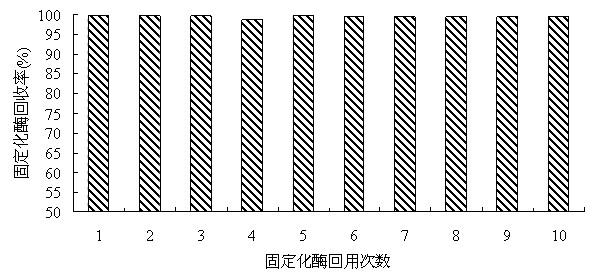

Image

Examples

Embodiment 1

[0031] Example 1: Preparation of co-immobilized multi-enzyme system of threonine deaminase and leucine dehydrogenase.

[0032] Dissolve Eudragit S-100 with 0.05mol / L, pH8.0 phosphate buffer, the concentration of Eudragit S-100 is 20g / L, and deamination with threonine containing 20IU / mL at a volume ratio of 1:1 Enzyme and 50 IU / mL leucine dehydrogenase enzyme solution were thoroughly mixed, and incubated at 25° C. and pH 8.0 for 0.2 hours. After incubation, adjust the pH of the solution to be lower than 6.0 with 0.1 mol / L phosphoric acid solution, let it stand for 2 hours to obtain a suspension, centrifuge at 8000 r / min for 30 minutes, and filter to obtain solid microspheres. According to the mass volume ratio of 1g:5mL, 0.05mol / L, pH6.0 phosphate buffer was added to wash the microspheres, and the suspension was centrifuged at 8000r / min for 30 minutes. The washing process was repeated three times to obtain a co-immobilized multi-enzyme system. Store at 4°C for later use.

Embodiment 2

[0033] Example 2: Preparation of co-immobilized multi-enzyme system of threonine deaminase and leucine dehydrogenase

[0034] Dissolve Eudragit S-100 with 0.05mol / L, pH8.0 phosphate buffer, the concentration of Eudragit S-100 is 20g / L, and deamination with threonine containing 80IU / mL at a volume ratio of 1:5 Enzyme and 90 IU / mL leucine dehydrogenase enzyme solution were thoroughly mixed, and incubated at 25° C. and pH 8.0 for 2 hours. After incubation, adjust the pH of the solution to be lower than 6.0 with 0.1 mol / L phosphoric acid solution, let it stand for 2 hours to obtain a suspension, centrifuge at 8000 r / min for 30 minutes, and filter to obtain solid microspheres. According to the mass volume ratio of 1g:5mL, 0.05mol / L, pH 6.0 phosphate buffer was added to wash the microspheres, and the suspension was centrifuged at 8000r / min for 30 minutes. The washing process was repeated three times to obtain a co-immobilized multi-enzyme system. Store at 4°C for later use.

Embodiment 3

[0035] Example 3: Preparation of co-immobilized multi-enzyme system of threonine deaminase and leucine dehydrogenase

[0036] Dissolve Eudragit S-100 with 0.05mol / L, pH8.0 phosphate buffer, the concentration of Eudragit S-100 is 20g / L, and deamination with threonine containing 200IU / mL at a volume ratio of 1:10 Enzyme and 150 IU / mL leucine dehydrogenase enzyme solution were thoroughly mixed, and incubated at 25° C. and pH 8.0 for 6 hours. After incubation, adjust the pH of the solution to be lower than 6.0 with 0.1 mol / L phosphoric acid solution, let it stand for 2 hours to obtain a suspension, centrifuge at 8000 r / min for 30 minutes, and filter to obtain solid microspheres. According to the mass volume ratio of 1g:5mL, 0.05mol / L, pH6.0 phosphate buffer was added to wash the microspheres, and the suspension was centrifuged at 8000r / min for 30 minutes. The washing process was repeated three times to obtain a co-immobilized multi-enzyme system. Store at 4°C for later use. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com