Pre-acidification anaerobic UASB treatment device and method for sewage

A treatment device and acidification treatment technology, which is applied in anaerobic digestion treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. Due to the limited improvement capacity, the effect of simple operation process, increased volume load, and improved anaerobic COD removal rate can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The specific operation steps are as follows:

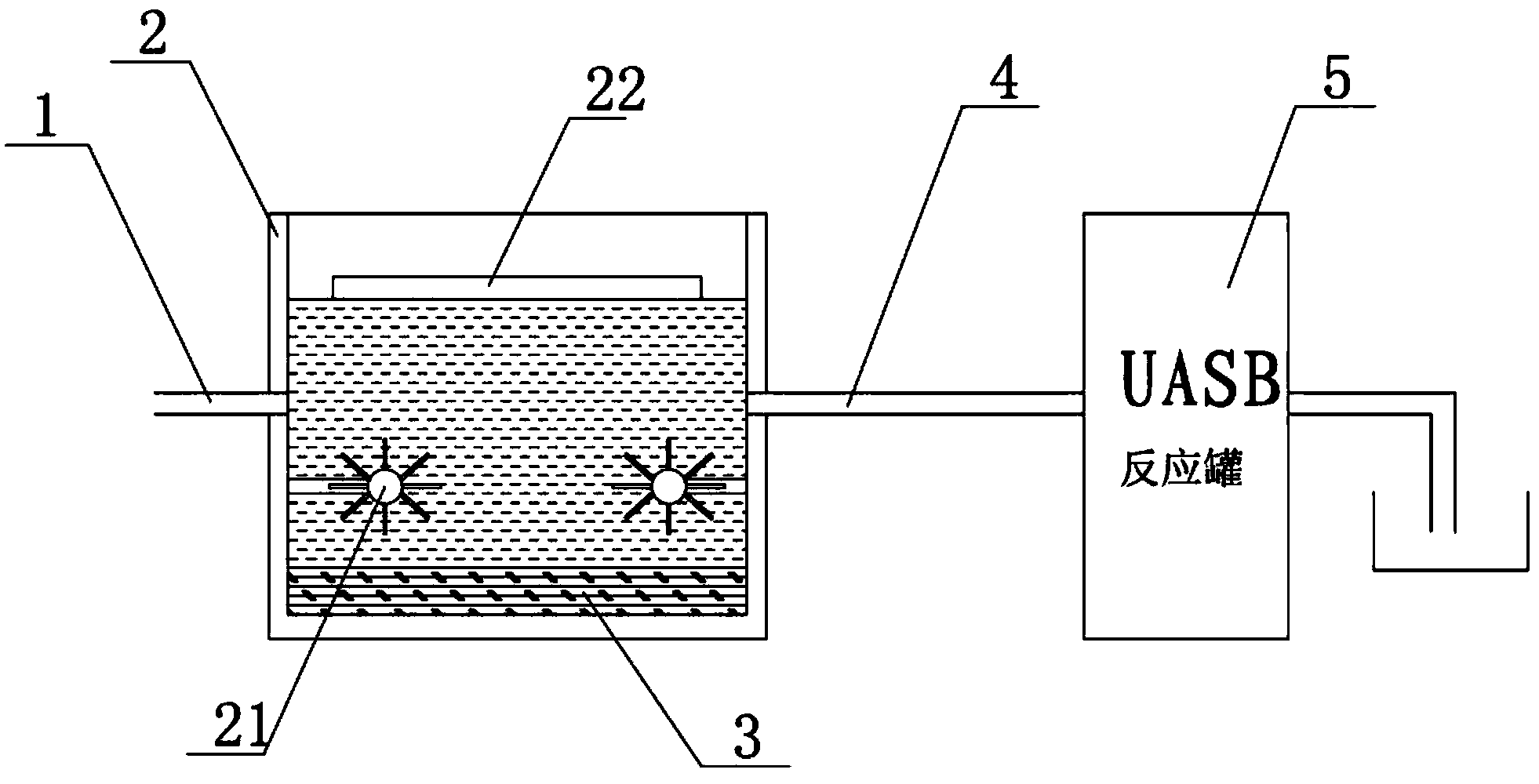

[0025] (a) Spread a certain amount of concentrated sludge 3 on the bottom of the regulating tank 2, and then add a certain amount of nutrient salt to the concentrated sludge 3. The concentration of the concentrated sludge 3 is controlled at 2500 mg / L, and the nutrient salt C:N:P=150:3:1;

[0026] (b) After the domestication of the acidifying bacteria in the concentrated sludge 3 is completed, the sewage is injected into the regulating tank 2 through the water inlet pipe 1;

[0027] (c) Start the agitator 21 on both sides to agitate the sewage to speed up the acidification process of the sewage. The rotation speed of the agitator 21 is 25 rpm, and the gas collecting hood 22 collects the biogas generated;

[0028] (d) When the water level of the sewage reaches the position of the overflow pipe 4, the acidified sewage enters the UASB reaction tank 5 through the overflow pipe 4 for the next step of treatment, ensuring that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com