Electric microfluidic droplet dispenser

A microfluidic and dispenser technology, applied in the field of experimental equipment, can solve problems such as large errors, and achieve low cost, less waste, and convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

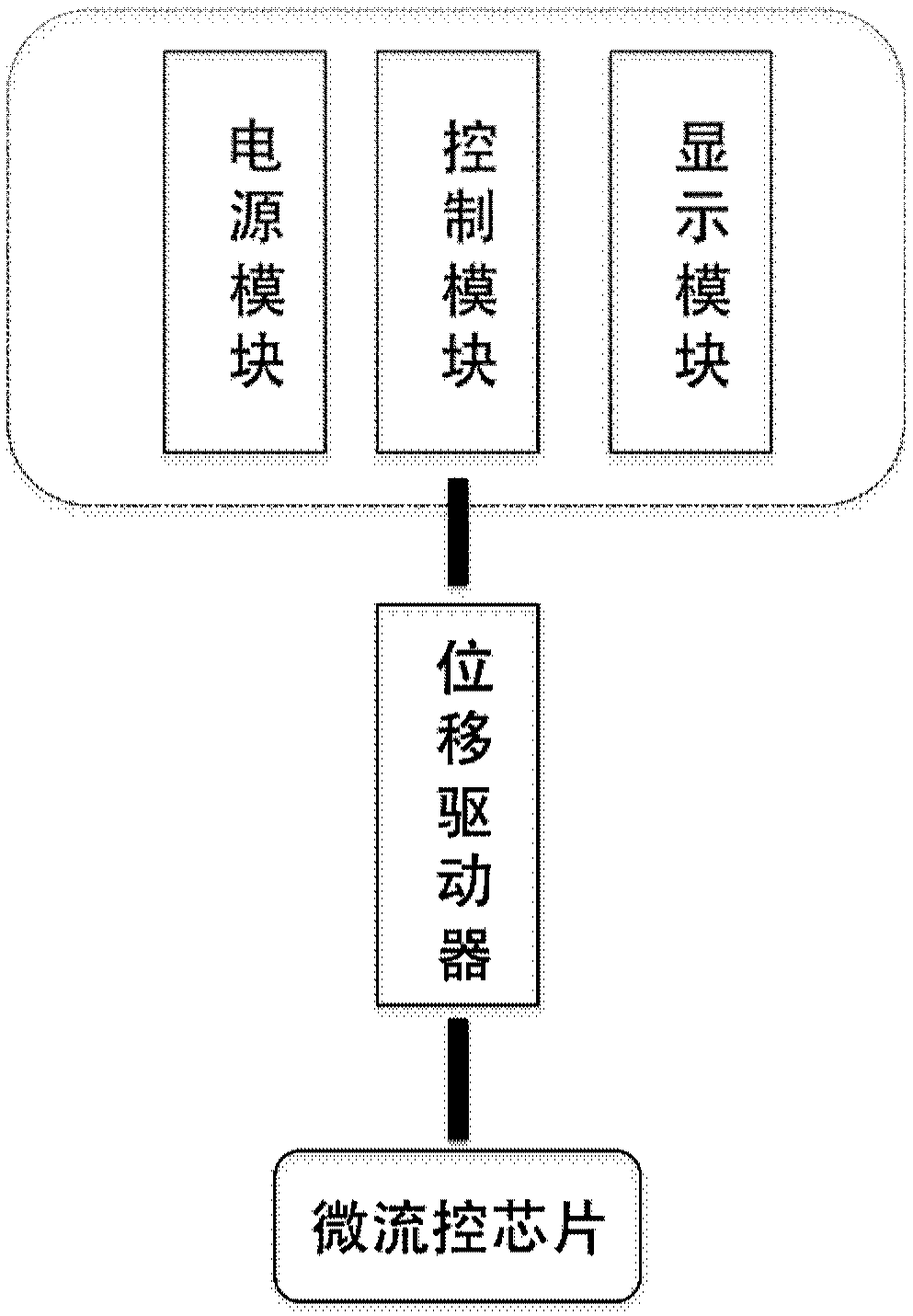

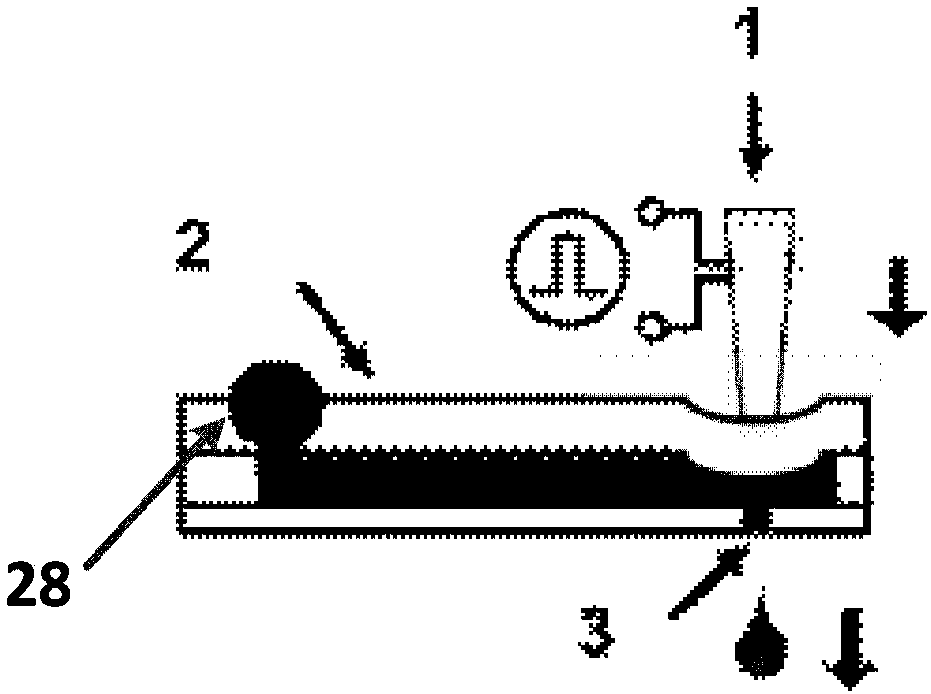

[0044] Such as figure 1 As shown, the electric microfluidic droplet dispenser of an embodiment of the present disclosure, the internal functional area of the droplet dispenser includes three parts: a microfluidic chip as an ink cartridge for holding liquid, a displacement actuator, and a power supply The control system composed of module, control module and display module, the main functions of the control system are parameter input, result display and signal output.

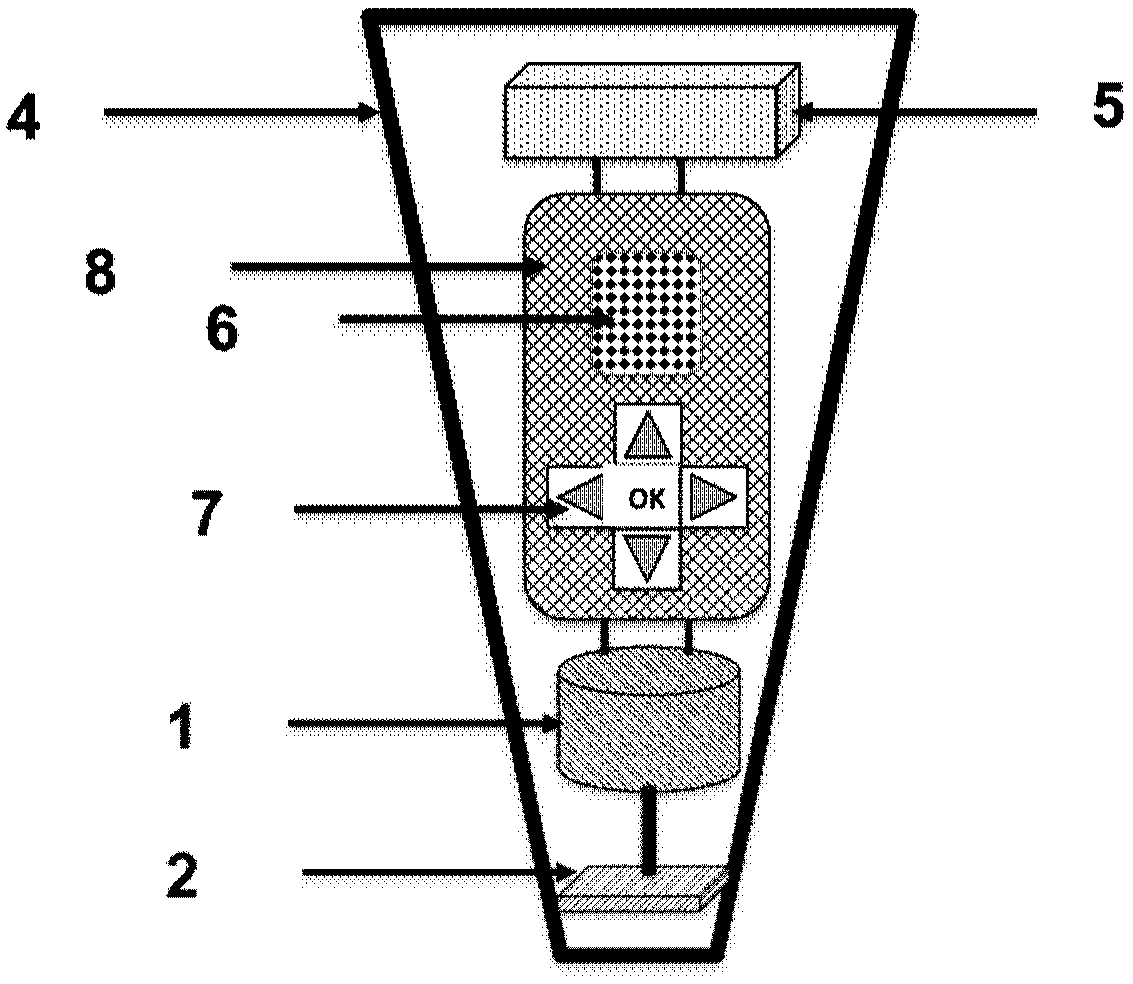

[0045] The droplet dispenser of this embodiment can be hand-held or desktop, and the power module can be either a built-in battery or an external power supply. For an example of a handheld drop dispenser powered by a built-in battery, see figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com