Improved integrated A/O sewage treatment equipment

A kind of sewage treatment equipment and equipment technology, applied in the field of water treatment, can solve the problems of lack of efficient, economical and practical complete set of sewage treatment technology, lagging construction and operation of sewage treatment facilities, limited development and research, etc., to facilitate management and operation , save infrastructure costs, and have a strong ability to resist changes in water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

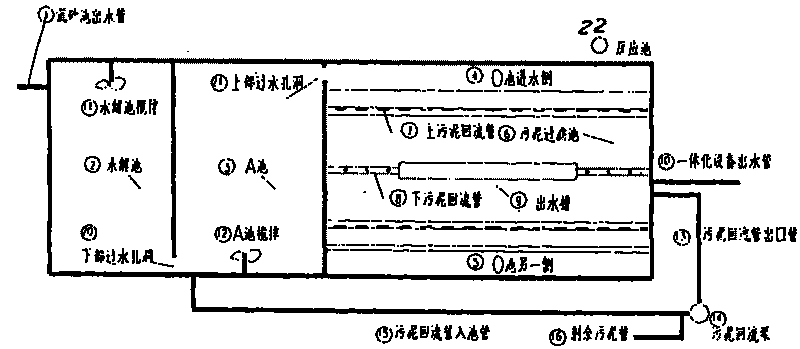

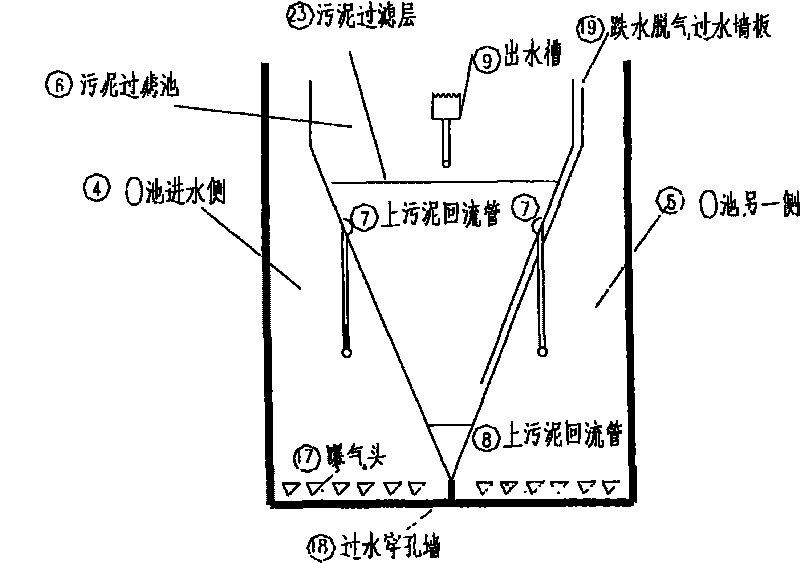

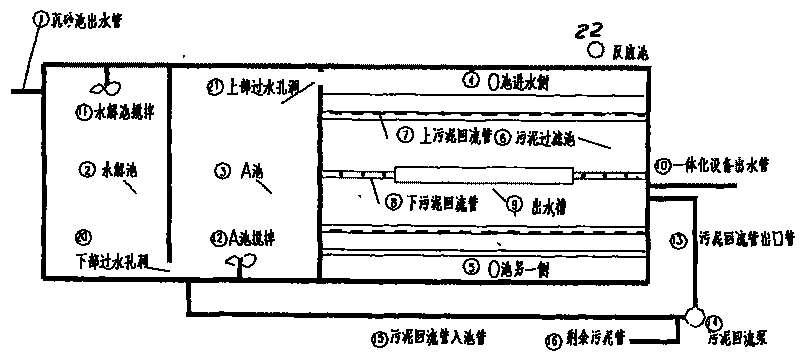

[0016] Example 1: Combining figure 1 , figure 2 , the integrated AO improved sewage treatment equipment of the present invention, it is made up of hydrolysis pond (2), A pond (3), reaction pond (22) and sludge return pump (14), and hydrolysis pond (2) connects A pond (3), pool A (3) is connected to the reaction tank (22) and the sludge return pump (14).

[0017] The present invention also has the following technical characteristics:

[0018] The hydrolysis tank (2) includes a grit chamber outlet pipe (1), a hydrolysis tank agitator (11) and a lower water passage hole (20), and the grit chamber outlet pipe (1) is located on the side of the hydrolysis tank (2) In the upper part, the hydrolysis tank agitator (11) is arranged inside the hydrolysis tank (2), and the lower part of the water passing hole (20) is located at the lower side inside the hydrolysis tank (2).

[0019] The A pool (3) includes an upper water hole (21), an A tank agitator (12) and a sludge return pipe into...

Embodiment 2

[0024] Example 2: Combining figure 1 , figure 2 , the integrated AO improved sewage treatment equipment of the present invention operates like this: the sewage enters the grit chamber outlet pipe (1) after the grit chamber, enters the overall reaction tank by the grit chamber outlet pipe (1), and the overall reaction pool is hydrolyzed Pool (2), A pool (3), O pool inlet side (4), O pool other side (5) and sludge filter pool (6). Sewage enters the hydrolysis tank (2) through the outlet pipe (1) of the grit chamber, is mixed by the hydrolysis tank agitator (11), and then enters the A pool (3) through the lower water hole (20). In pool A (3), because the sludge return pipe into the pool pipe (15) flows into the sludge, the mixed solution becomes a sludge mixed solution with a concentration of 3500-4500 mg / L, and part of the sludge solution will pass through the lower water-passing cavity (20 ) to the hydrolysis tank (2), thereby maintaining a higher sludge concentration in the...

Embodiment 3

[0025] Example 3: Binding figure 1 , figure 2 , the integrated A / O improved sewage treatment equipment of the present invention, the design idea is as follows:

[0026] 1) Omit the initial sedimentation tank and change it to a hydrolysis tank

[0027] The A / O process is the abbreviation of Anoxic / Oxic (Anoxic / Oxic), and it is a simple and practical urban sewage treatment technology with many researches and practical engineering applications. The traditional AO sewage treatment process is usually: thick and fine grid → grit chamber → primary sedimentation tank → AO biological reaction tank → secondary sedimentation tank. The O tank in the biological reaction tank is oxygenated, the A tank is mixed, the mixed solution of the effluent from the O tank is returned to the A tank, and the muddy water mixture is returned to the O tank after the secondary sedimentation. Pool A mainly completes denitrification and denitrification, pool O mainly completes COD removal and nitrificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com