Method for biochemical treatment and standard discharge of sewage of coal chemical industry

A technology of biochemical treatment and coal chemical industry, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as unstable operation, high operating costs, and difficulty in reaching the standard for effluent. , to achieve the effects of saving investment and operating costs, high process volume load, and easy main biochemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

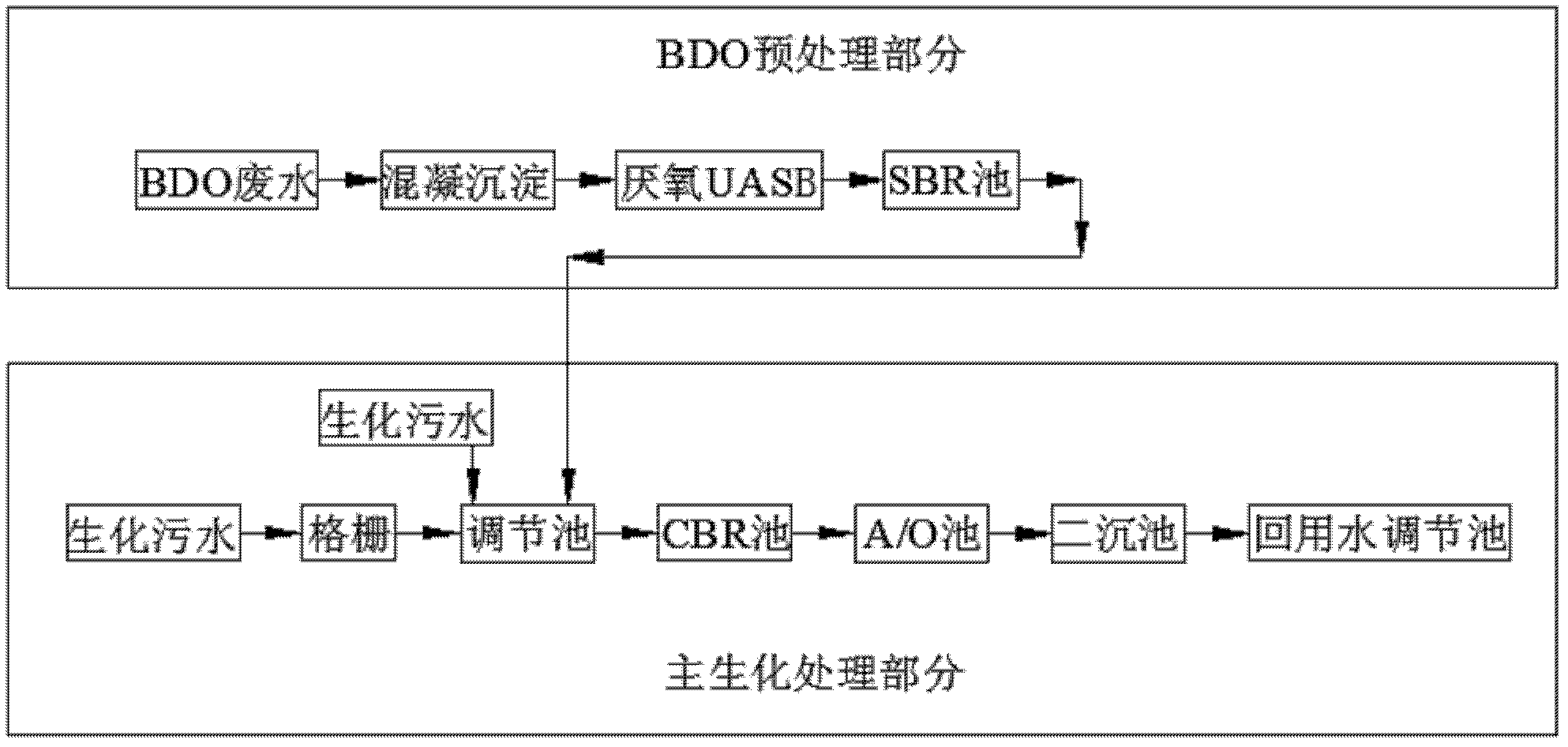

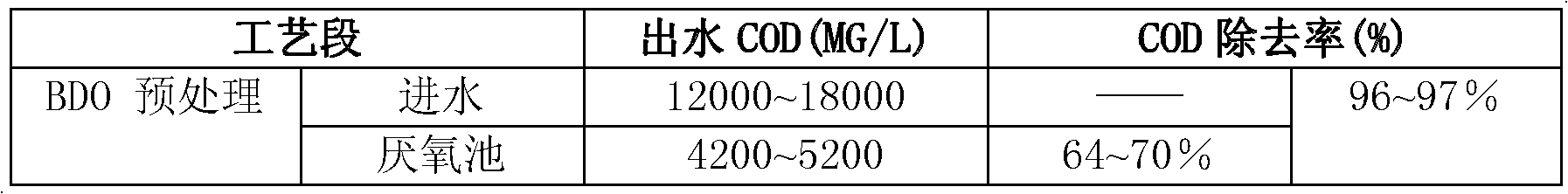

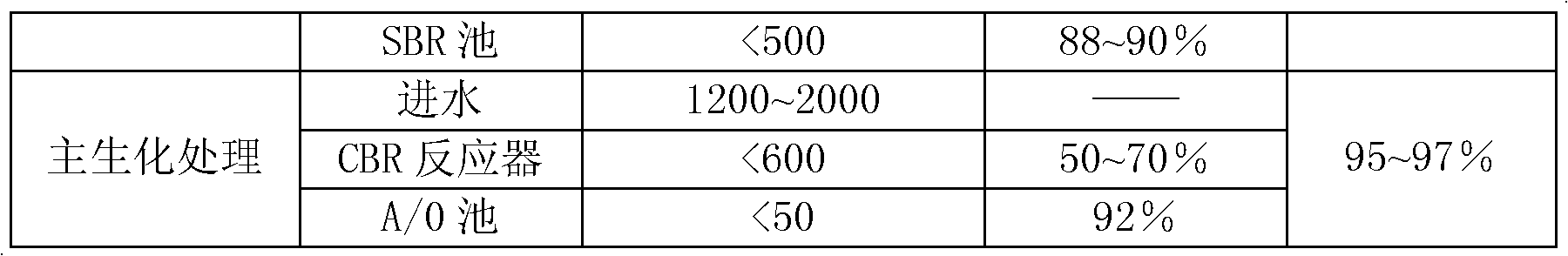

[0019] The invention relates to coal chemical sewage treatment technology, in particular to BDO pretreatment and main biochemical treatment technology of coal chemical sewage. The combined process of "coagulation sedimentation tank-anaerobic tank-SBR tank, aerobic carrier fluidized bed reactor-pre-denitrification tank-aerobic activated sludge tank-secondary sedimentation tank" is mainly used to treat coal chemical sewage, providing a A safe and reliable coal chemical wastewater biochemical treatment technology.

[0020] Coal chemical sewage COD fluctuates greatly, generally around 5000mg / l, some only around 1000mg / l, and some can reach tens of thousands of milligrams per liter, or even higher. Therefore, the patent of the present invention adopts the process of "coagulation sedimentation tank-anaerobic tank-SBR tank, aerobic carrier fluidized bed reactor-pre-denitrification tank-aerobic activated sludge tank-secondary sedimentation tank", the specific process flow is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com