Anaerobic-micro-aerobic membrane bioreactor and operation method thereof

A technology of membrane bioreactor and anaerobic reaction zone, which is applied in anaerobic digestion treatment, aerobic and anaerobic process treatment, waste fuel, etc., can solve the problems of high cost and high safety requirements, and achieve light membrane pollution, Effects of reducing pollution load and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

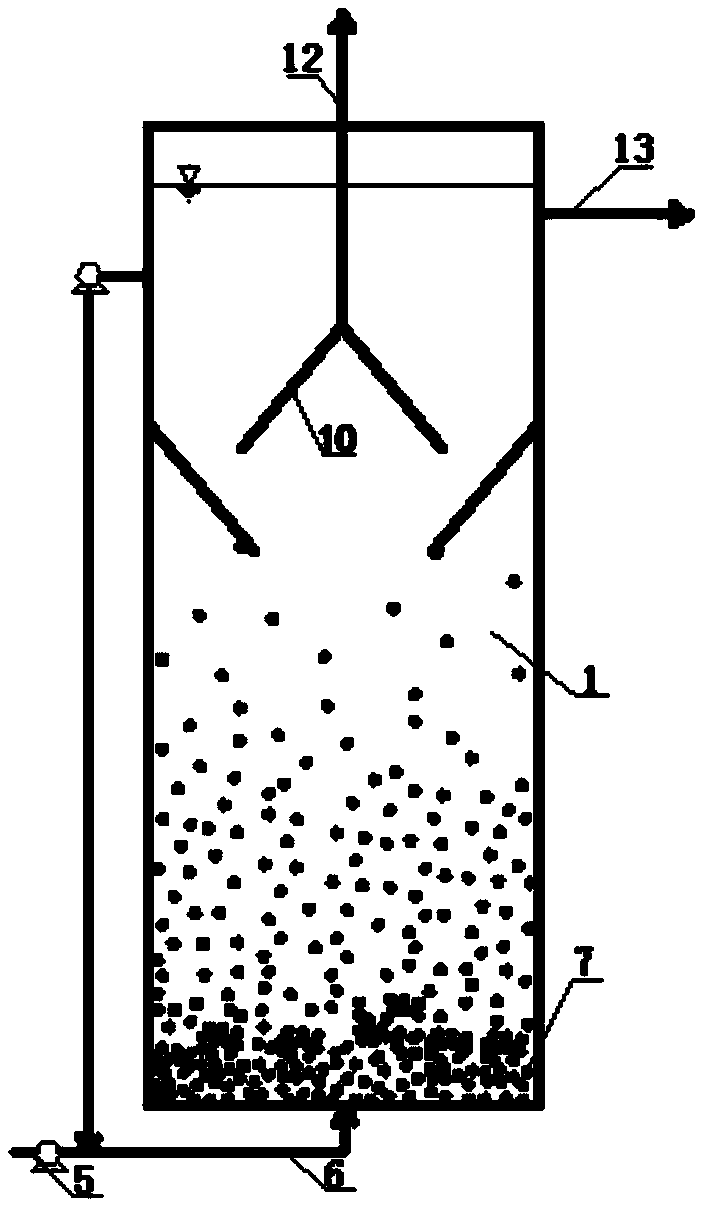

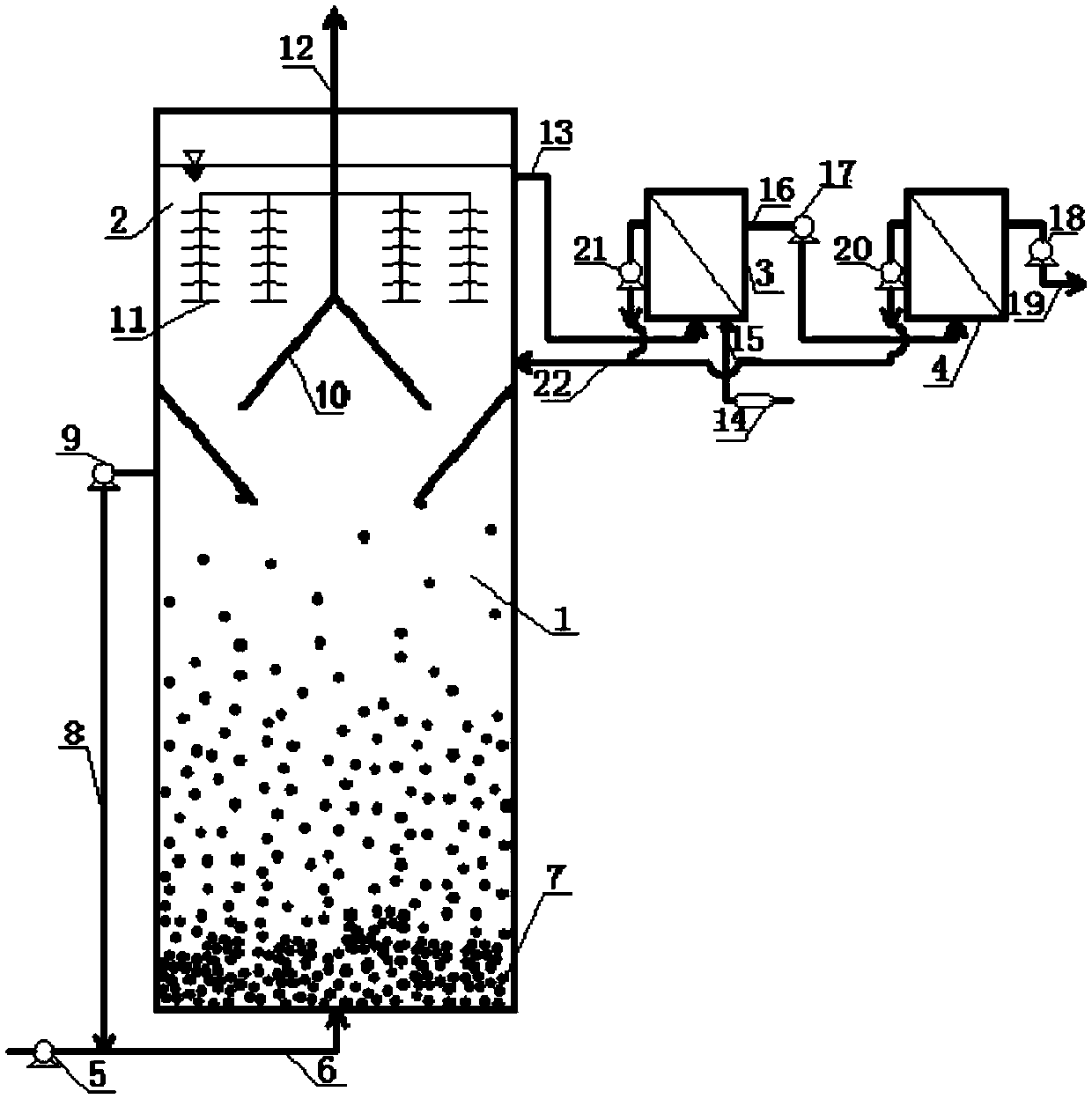

[0023] The structure, principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

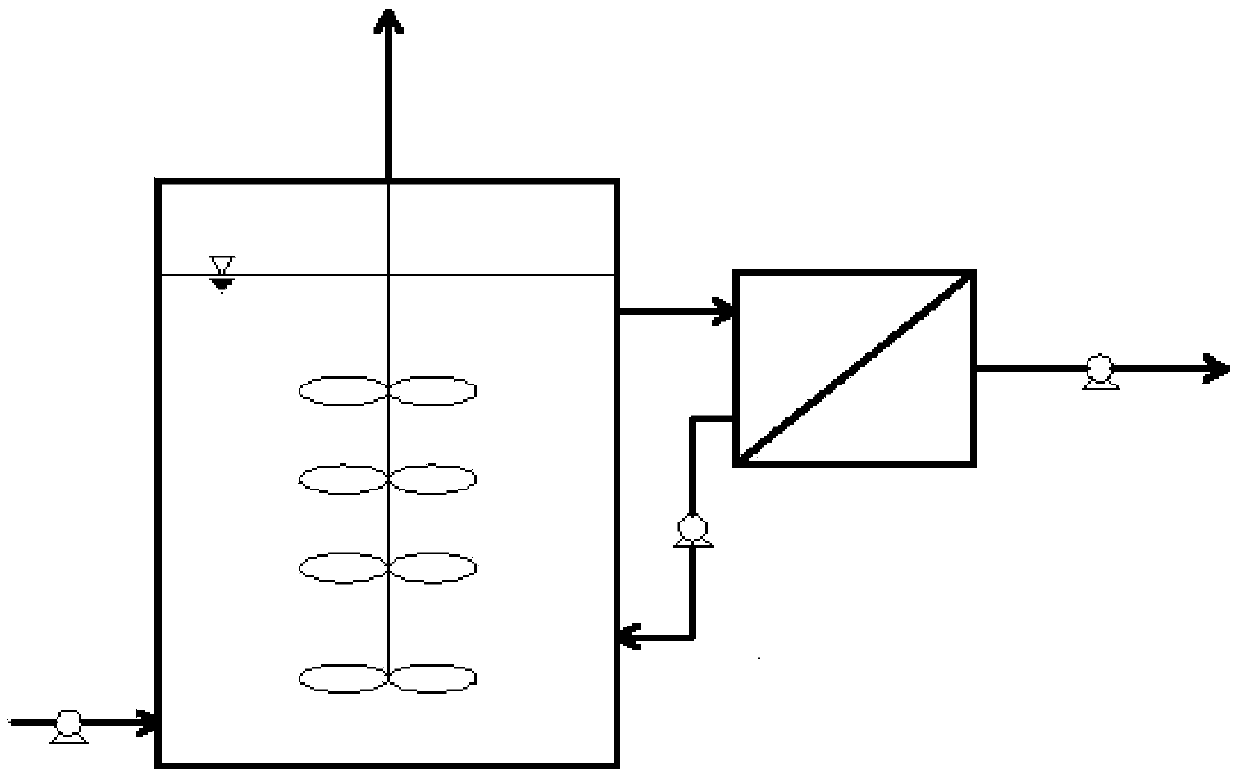

[0024] The anaerobic-microoxygen membrane bioreactor provided by the present invention is proposed on the concept of combining high-efficiency anaerobic reactors such as UASB and membrane separation technology, and its structure is as follows image 3 As shown, the reactor contains the main part of an upflow anaerobic sludge bed reactor, and the main part contains a granular sludge anaerobic reaction zone 1, a three-phase separator 10, a precipitation zone 2 and a biogas collection system 12; The anaerobic-microoxygen membrane bioreactor also includes external membrane modules, which include ultrafiltration membrane module 3 and nanofiltration membrane module 4. The ultrafiltration membrane is a hollow fiber membrane or a flat membrane with a pore size of 0.04 to 0.4 μm; the nanofiltration membrane has a pore size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com