Pipe gas phase biological filtering device

A technology of biological filtration and biological filter, which is used in air quality improvement, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large bed height, large packing layer height, low volume load, etc., and achieves a simple and compact structure. , Small filler thickness, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

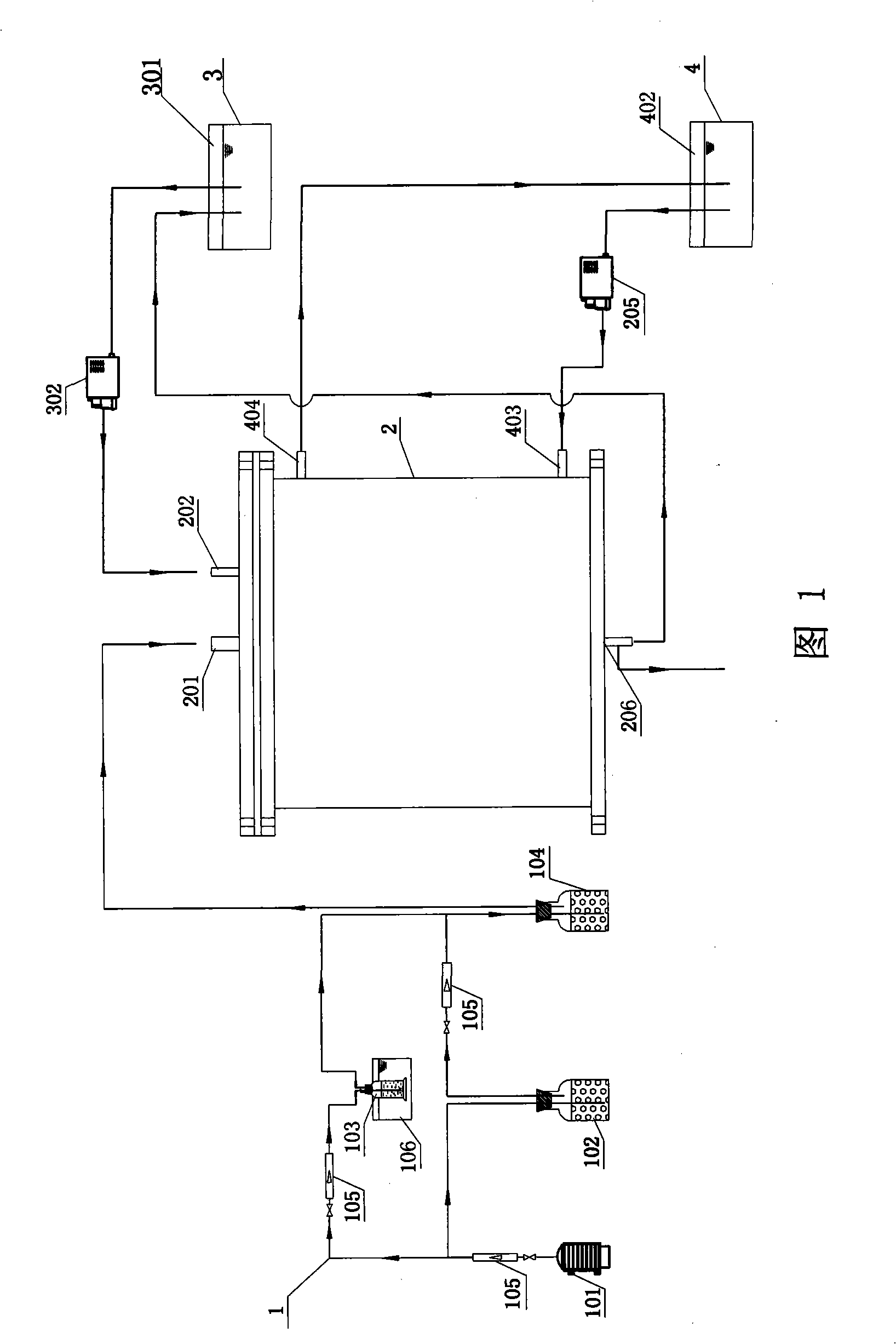

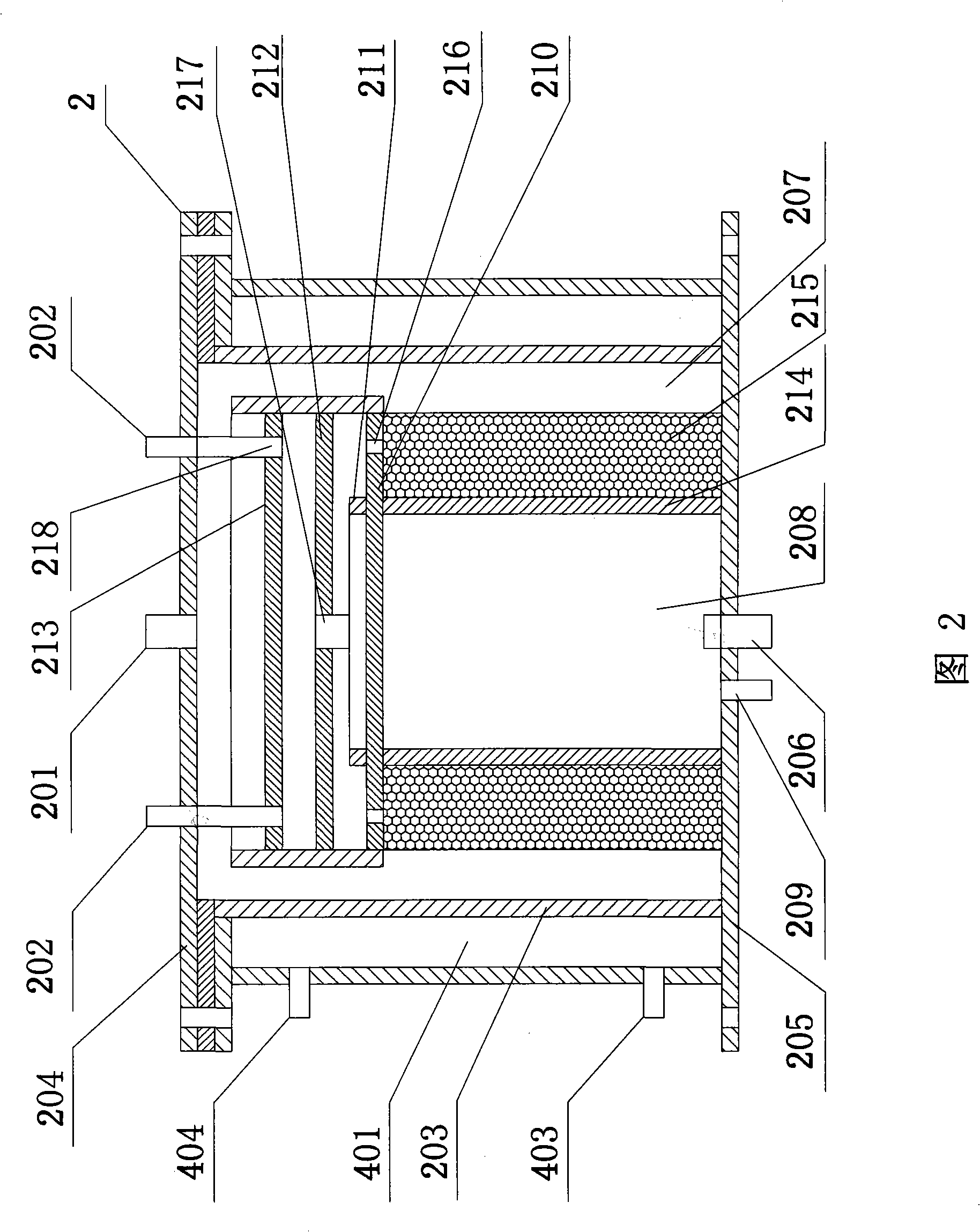

[0036]As shown in Fig. 1 and Fig. 2, a kind of tubular gas-phase biological filtration device of the present invention, it comprises waste gas supply device 1, biofilter 2 and nutrient solution supply device 3, and biofilter 2 comprises cylindrical housing 203, top The cover plate 204, the base plate 205 and the tubular packing device installed in the inner cavity of the cylindrical shell 203, the top cover plate 204 is provided with an air inlet 201 and the nutrient solution inlet 202, and the base plate 205 is provided with a waste liquid discharge port 206 and Exhaust port 209, an annular gas channel 207 is formed between the tubular packing device and the inner wall of the cylindrical shell 203, and the central cavity of the tubular packing device forms an air chamber 208 in the pipe. One end of the air chamber 208 in the pipe comm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com