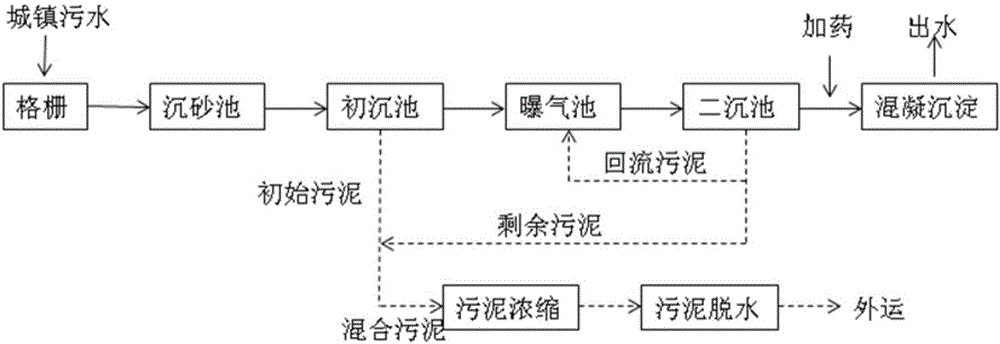

Sludge hydrothermal oxidization reaction system and method with function of product reflux pretreatment

A hydrothermal oxidation and reaction system technology, applied in the oxidation treatment of sludge, chemical instruments and methods, special compound water treatment, etc., can solve the problem of insufficient heat, increased investment in heating equipment, system complexity, liquid phase product dissolved oxygen corrosion, etc. problems, to achieve the effect of reducing sludge viscosity, shortening time, and strengthening dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following non-limiting examples illustrate the invention.

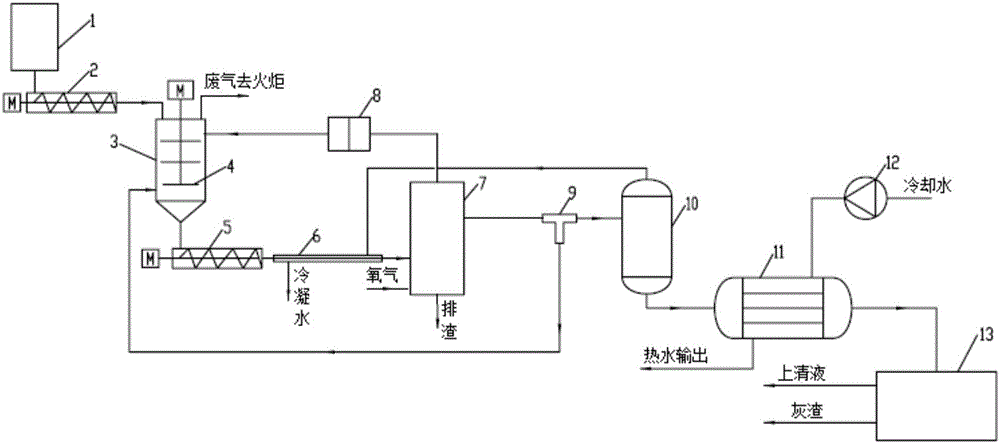

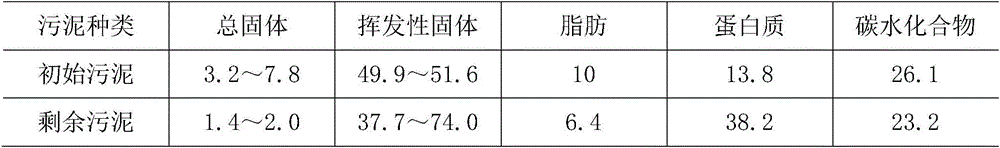

[0043] refer to figure 2 As shown, the sludge hydrothermal oxidation system with product reflux includes: sludge pretreatment device (sludge pretreatment tank 3), agitator 4, booster pump 5, hydrothermal oxidation reactor 7, gas phase oxygen removal device 8. Splitter 9 and flash tank 10, as well as heat exchanger 11, feed water pump 12, settling tank 13, etc. The specific plan is as follows:

[0044] (1) Sludge transportation: use the screw pump 2 to transfer the sludge with a water content of about 80% by mass from the sludge silo 1 to the sludge pretreatment tank 3 .

[0045] (2) Sludge pretreatment: The sludge pretreatment tank 3 is equipped with an agitator 4 and a scraper, which scrapes off the sludge sticking to the inner wall of the tank while stirring the sludge to provide shear force; the hydrothermal oxidation reactor 7. The gas phase products generated by the reaction and part of the liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com