Advanced treatment method and device of coking wastewater

A technology for coking wastewater and advanced treatment, which is applied in special compound water treatment, reflux water treatment, multi-stage water treatment, etc. It can solve the problems of low technical risk, difficulty in reaching the standard of effluent, and membrane pollution of coking wastewater, and achieve stable process operation, The effect of improved water recovery and good biochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

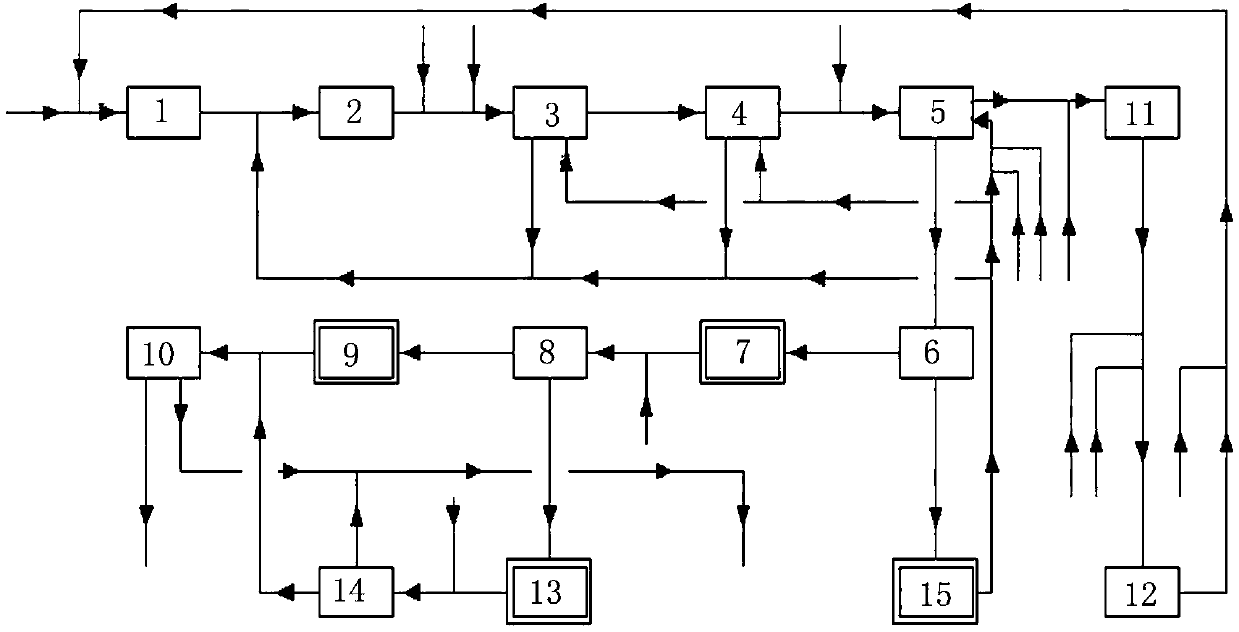

[0032] 300m 3 / h Coking wastewater advanced treatment process: biochemical effluent, high-efficiency coagulation, filtration, renewable filler adsorption / desorption liquid micro-electrolysis Fenton reflux biochemical, membrane separation system (ultrafiltration + nanofiltration + reverse osmosis); figure 1 Completed in the device shown, including sequentially connected biochemical unit 1, sedimentation tank 2, medium-speed filter 3, multimedia filter 4, resin adsorption tower 5, ultrafiltration unit 6, ultrafiltration pool 7, nanofiltration unit 8 , nanofiltration pool 9, reverse osmosis unit 10; wherein the resin adsorption tower 5 is also connected to the micro-electrolysis system 11, the Fenton system 12, and the Fenton system 12 is connected to the biochemical unit 1 to form a cycle; the nanofiltration unit 8 is also connected sequentially There are nanofiltration concentrated water tank 13, nanofiltration concentrated water unit 14, and described nanofiltration concentrat...

Embodiment 2

[0044] 300m 3 / h coking wastewater advanced treatment process: biochemical effluent, high-efficiency coagulation, filtration, renewable filler adsorption / desorption liquid micro-electrolysis Fenton reflux biochemical, membrane separation system (ultrafiltration + nanofiltration + reverse osmosis). figure 1 Completed in the device shown, including sequentially connected biochemical unit 1, sedimentation tank 2, medium-speed filter 3, multimedia filter 4, resin adsorption tower 5, ultrafiltration unit 6, ultrafiltration pool 7, nanofiltration unit 8 , nanofiltration pool 9, reverse osmosis unit 10; wherein the resin adsorption tower 5 is also connected to the micro-electrolysis system 11, the Fenton system 12, and the Fenton system 12 is connected to the biochemical unit 1 to form a cycle; the nanofiltration unit 8 is also connected sequentially There are nanofiltration concentrated water tank 13, nanofiltration concentrated water unit 14, and described nanofiltration concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com