Floccule self-filtering device and using method thereof

A self-filtration, flocculent technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., to achieve the effects of large processing capacity, long service life, and strong cleaning and recovery ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

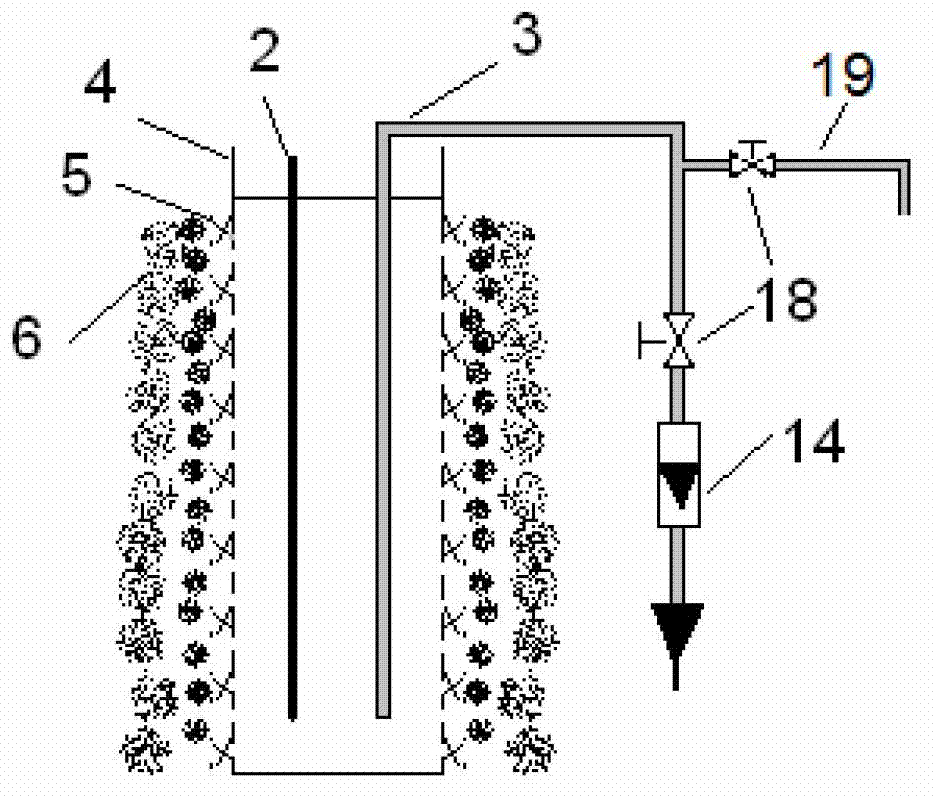

[0047] Adopt the PVC pipe network that length is 3m, inner diameter is 2mm as the supporting structure 4 of self-filtering device, its outer layer wraps aperture and is the non-woven fabric porous filter material layer 5 of 0.8mm, the thickness of non-woven fabric porous filter material layer 5 0.1mm, as a self-filtering unit of the self-filtering device, such 6 self-filtering units are connected in parallel to form a complete self-filtering device, put into the aerobic tank 17, the concentration of the aerobic tank is 1.2g / L, and the aeration Strength is 10m 3 / m 2 *L, through the switch of the pipeline valve, enter the filtered water stage of the self-filtering device, the filtered water flows out from the siphon outlet pipe 3, and set the water output of the self-filtering device at the initial stage to 300L / m by controlling the valve 18 2 *h, after 0.5 min of water outflow, take water samples and observe the water quality of the outflow water, as shown in Table 1. When t...

specific example 2

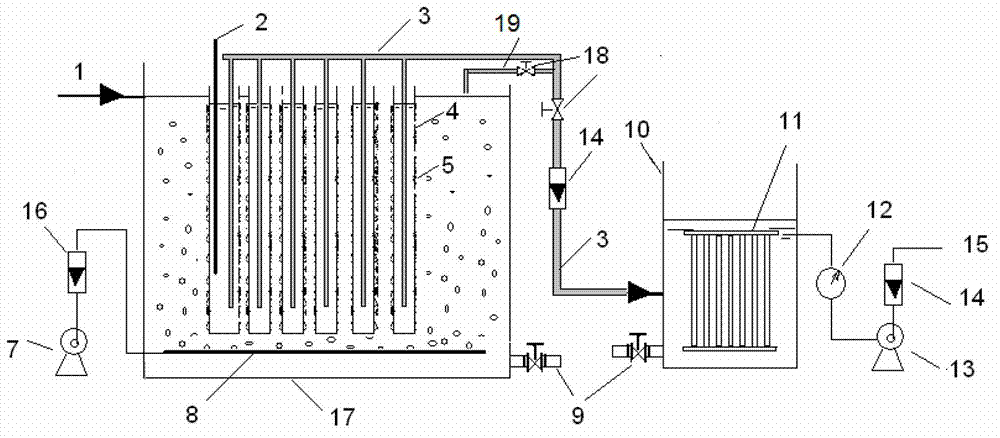

[0053] According to attached figure 1 The described self-filtering unit is placed in the aerobic pool 17 after being connected in parallel, and the untreated sewage enters the aerobic pool 17 from the feed water 1 .

[0054] use The ABS network tube is used as the support structure 4 of the self-filtering unit, and its outer layer is wrapped with a non-woven porous filter material layer 5 made of polypropylene cloth with a pore size of 1 μm. The thickness of the porous filter material layer 5 is 2mm, so six 3m-long The self-filtering units are connected in parallel as a self-filtering device, put into the aerobic tank 17, the concentration of the aerobic tank is 1.0g / L, and the aeration intensity is 50m 3 / m 2 *h, through the switch of the pipeline valve, enter the filtered water stage of the self-filtering device, the filtered water flows out from the siphon outlet pipe 3, and set the water output of the self-filtering device at the initial stage to 500L / m by controlling t...

specific example 3

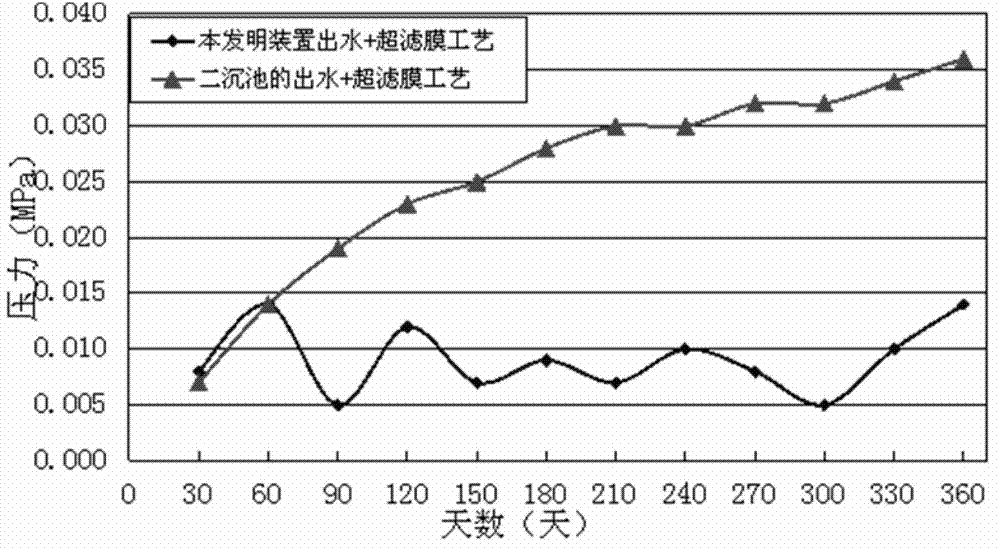

[0059] According to attached figure 2 The described process example of the combined use of the self-filtering device and the fine-pored membrane, the fine-pored membrane in this embodiment specifically adopts the submerged ultrafiltration membrane.

[0060] Stainless steel rods are used as the support structure 4 of the self-filtering device, and a cuboid support structure unit of 500 mm × 10 mm × 2000 mm is made, and its outer layer is wrapped with a pore diameter of 100 μm and a thickness of 0.2 mm. Blended yarn fiber cloth is used as a porous filter material layer 5, Such 6 self-filtering device units are used as a self-filtering device and put into the aerobic pool 17, the concentration of the aerobic pool is 1.0g / L, and the aeration intensity is 20m 3 / m 2 *h, through the switch of the pipeline valve, enter the filtered water stage of the self-filtering device, the filtered water flows out from the siphon outlet pipe 3, and set the water output of the self-filtering dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com