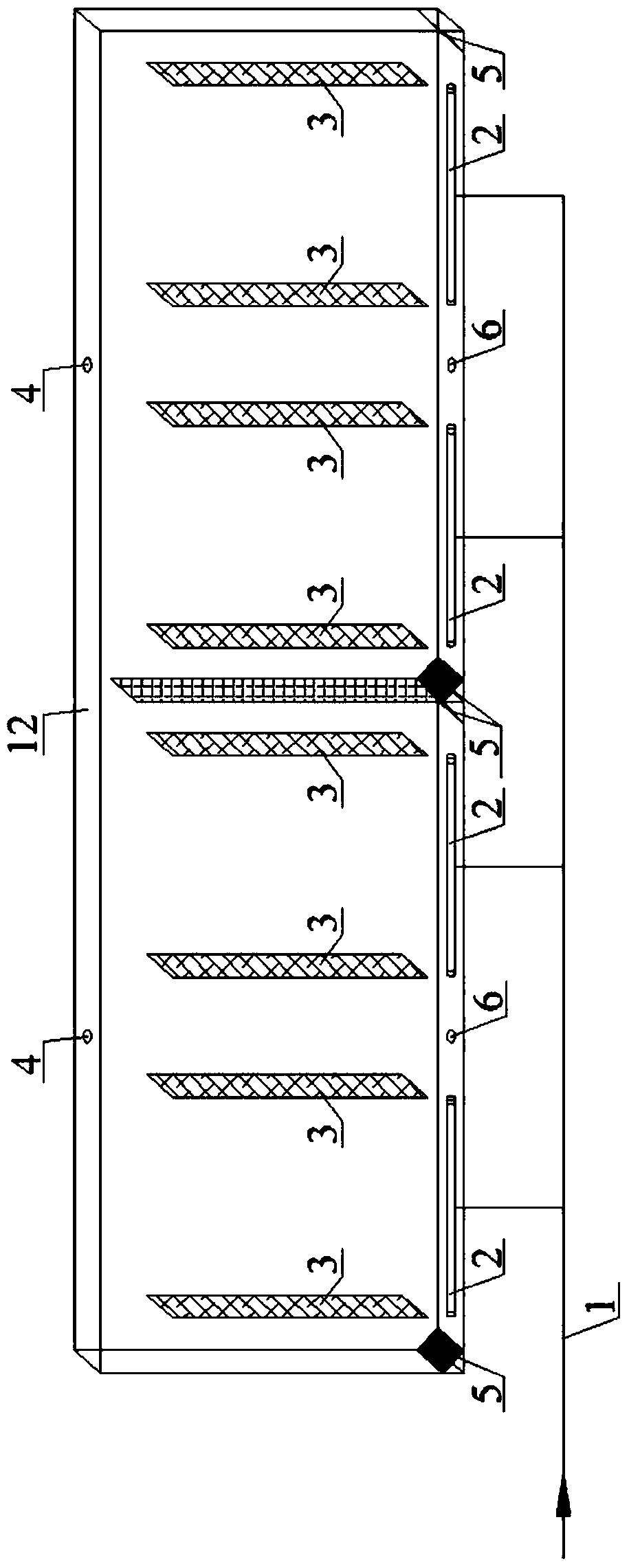

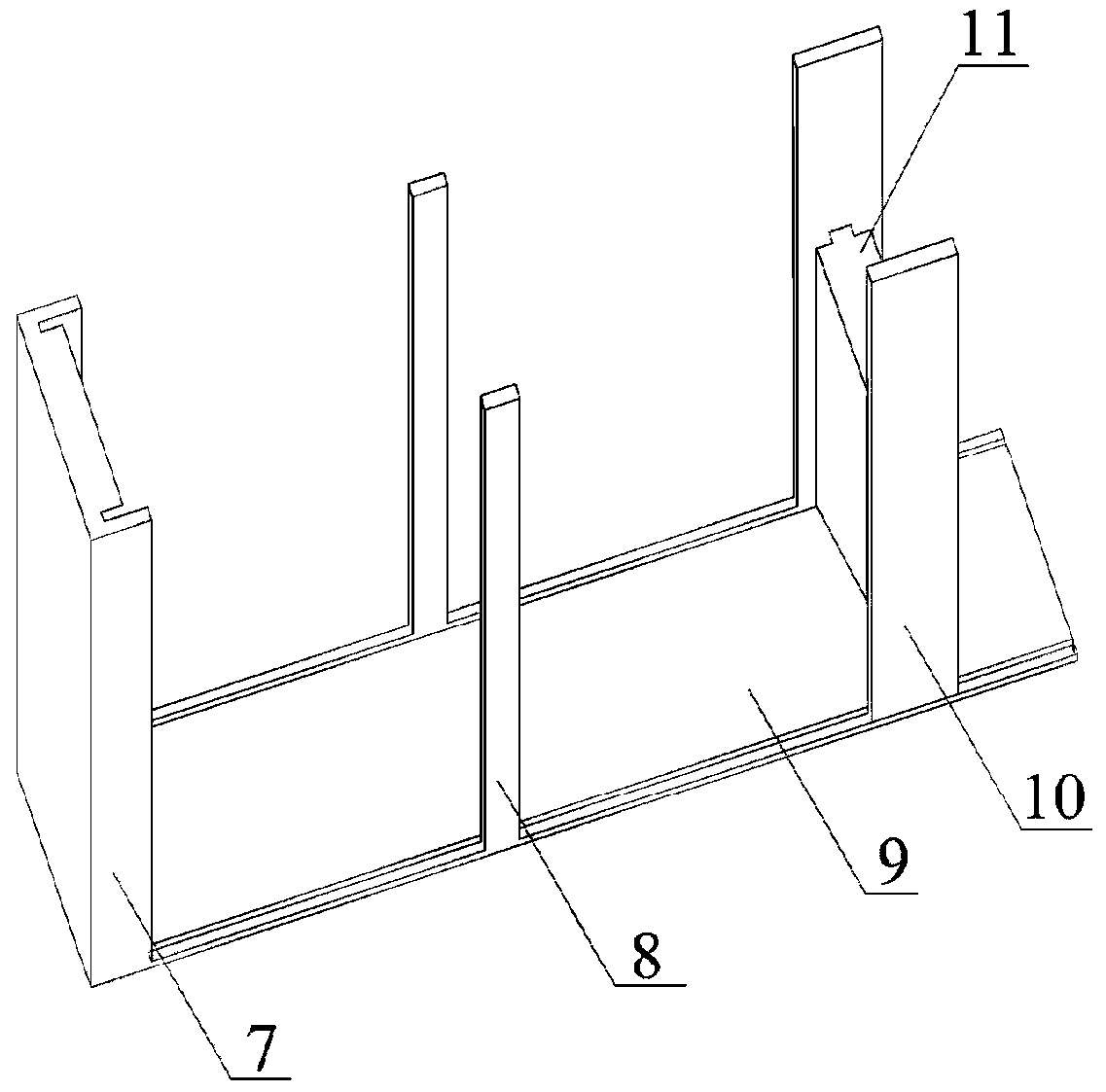

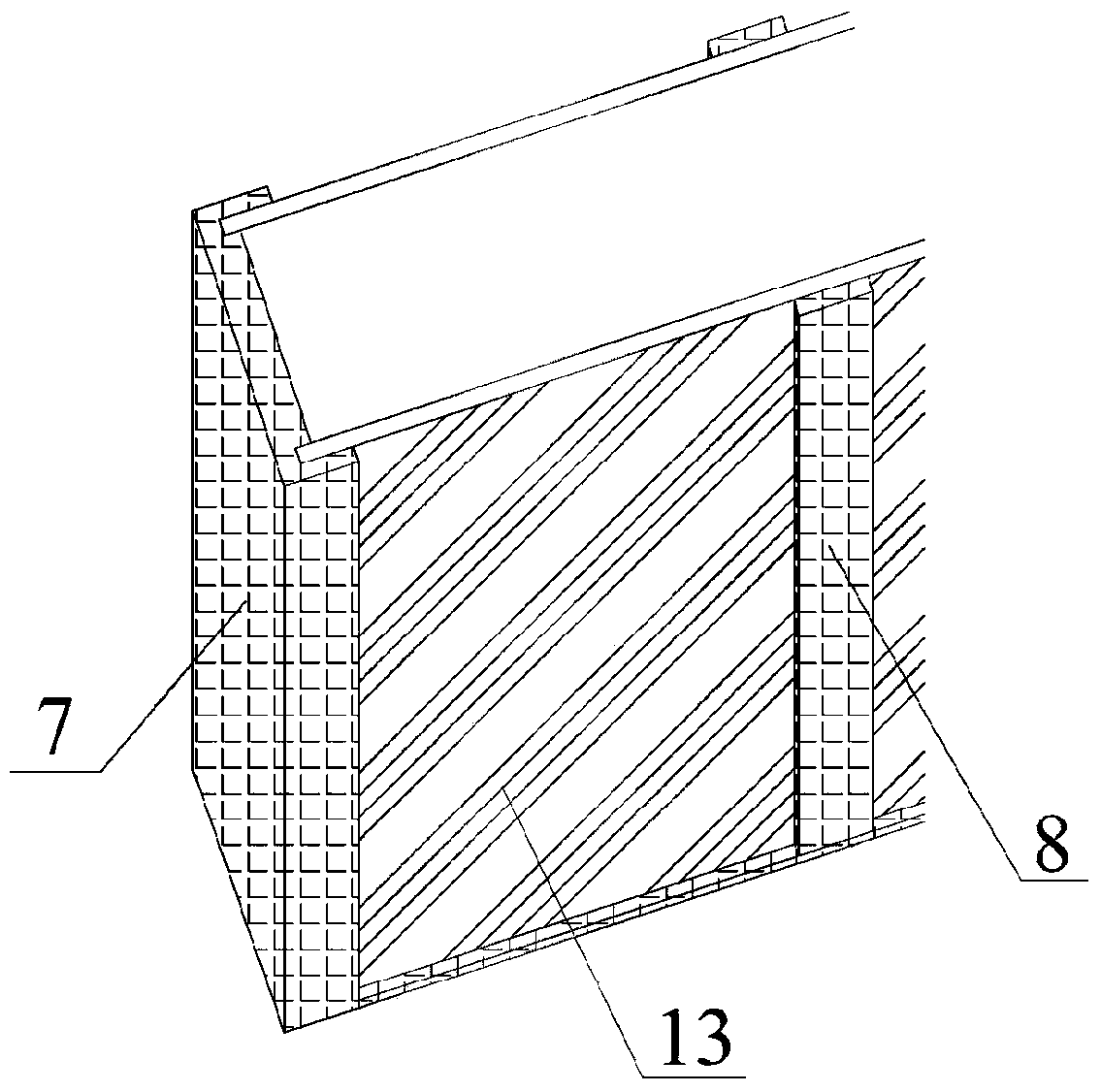

A flat air-lift circulation type photosynthetic microorganism cultivation device

A technology of photosynthetic microorganisms and airlift circulation, applied in enzymology/microbiology equipment, biochemical cleaning equipment, photobioreactors, etc. Problems such as irregular flow of internal algae liquid, to avoid algae cell deposition and wall attachment, convenient mechanical or manual cleaning, good mixing and mass transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0042] Take the cultivation of chlorella as an example. Before the cultivation, fill the reactor with clean water, add about 200mL of sodium hypochlorite solution, and use an air compressor to continuously feed air into the reactor through the inlet pipe 1 and aeration pipe 2, and soak for 24 hours. Sterilization. Open the liquid discharge port 6 to discharge the sodium hypochlorite solution, rinse the reactor repeatedly with clear water for 3 to 5 times, and then inject the chlorella culture medium, algae liquid and clear water to a liquid holding height of 900 mm. Use an air compressor and a gas cylinder to feed a mixture of 2% carbon dioxide and air at an aeration rate of 0.05vvm, and regularly check the pH, dissolved oxygen concentration, dissolved carbon dioxide concentration, and volume per unit volume of the reactor during the cultivation process. Algal cell dry weight and other parameters. After the cultivation is over, use the drain port at the bottom of each reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com