Comprehensive wastewater reuse treatment method for waste incineration power plant

A waste incineration and treatment method technology, applied in water/sewage treatment, biological water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of imbalanced ratio of carbon, nitrogen and phosphorus, high frequency of chemical cleaning, affecting treatment effect, etc. , to achieve the effect of reducing COD, prolonging the frequency of chemical cleaning, and saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

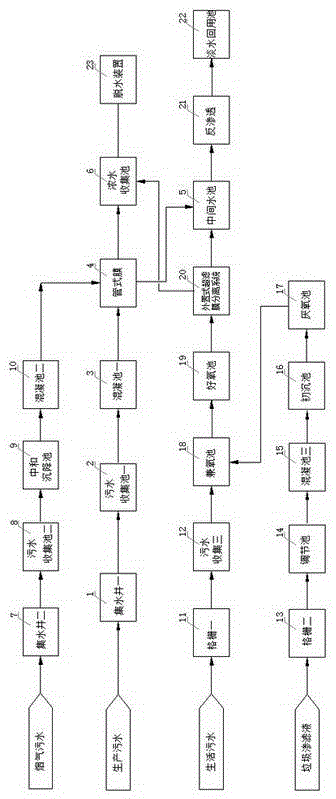

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0050] like figure 1 As shown, the main facilities and equipment adopted in the present invention include: sewage collection tank one 2, sewage collection tank two 8, sewage collection tank three 12, coagulation tank one 3, coagulation tank two 10, tubular membrane 4, middle Pool 5, landfill leachate regulating tank 14, upflow anaerobic biological (UASB) reactor, facultative oxygen tank 18 (section A), membrane bioreactor (MBR), reverse osmosis advanced treatment system 21 (RO) and pressure filter device, etc. Among them, sewage collection tank 1 2, sewage collection tank 2 8, sewage collection tank 3 12, coagulation tank 1 3, coagulation tank 2 10, intermediate pool 5, landfill leachate adjustment tank 14, upflow anaerobic bioreactor (UASB), facultative pool 18, and aerobic pool 19 adopt reinforced concrete structure, the outside of the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com