Micropore biofilm carrier filler based on mesh structure

A biofilm carrier and mesh technology, used in biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc. Aeration conditions and other issues to achieve the effect of resisting impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

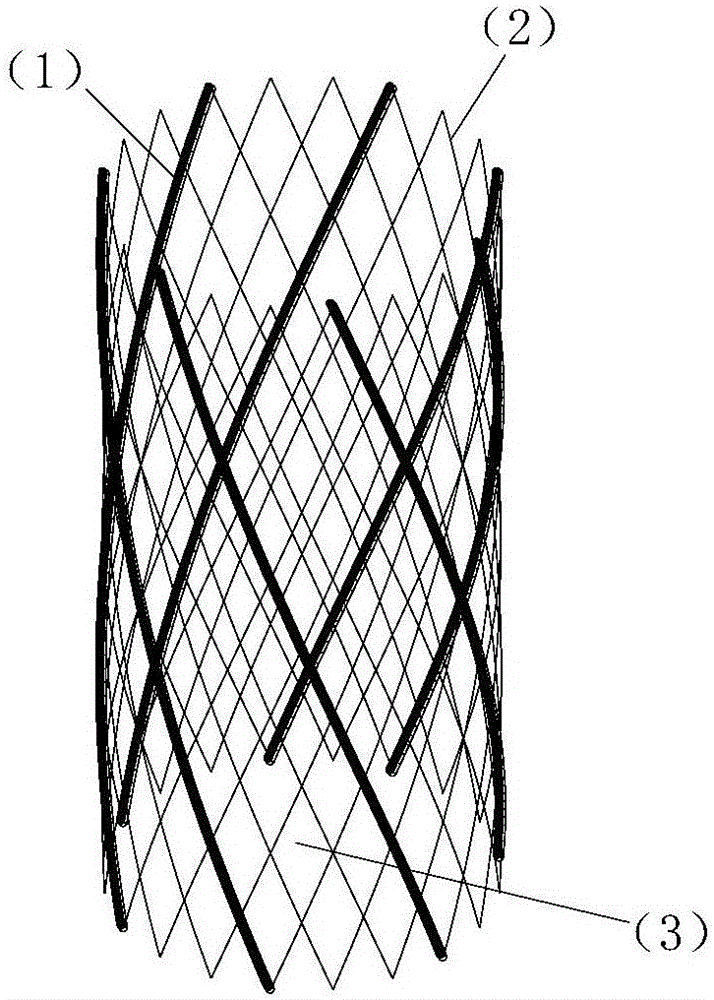

[0023] Microporous biofilm carrier filler based on mesh structure see figure 1 ,preparation

[0024] (1) Mix and granulate with 75% mass fraction of macromolecular polymers such as polyethylene or polypropylene, 10% mass fraction of polyvinyl alcohol and 15% limestone powder of 150-200 meshes as the main material;

[0025] (2) The hot-melt extrusion mesh head is rotated into a cylinder to make a mesh cylinder: the mesh die head of the hot-melt extruder is rotated and extruded, and the mesh is stretched to make the mesh into a uniform diamond shape and foam. After sufficient, it is shaped by water cooling; the high fins are obtained by widening and deepening the corresponding holes according to the model.

[0026] (3) After setting, the mesh cylinder is soaked with 30% sulfuric acid or hydrochloric acid solution, and the soaking time is 1.5h, so that about 80% of the limestone powder is dissolved by acid to form fine voids;

[0027] (4) washing with water and adjusting the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com