Biological absorbent for treating hydrocarbon organic waste gas and preparation method thereof

A technology for biological absorption and organic waste gas, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems affecting the treatment capacity of organic waste gas, low concentration of organic waste gas, and restriction of mass transfer rate, etc., and achieves great popularization and application value. , Improve impact resistance, solve the effect of easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

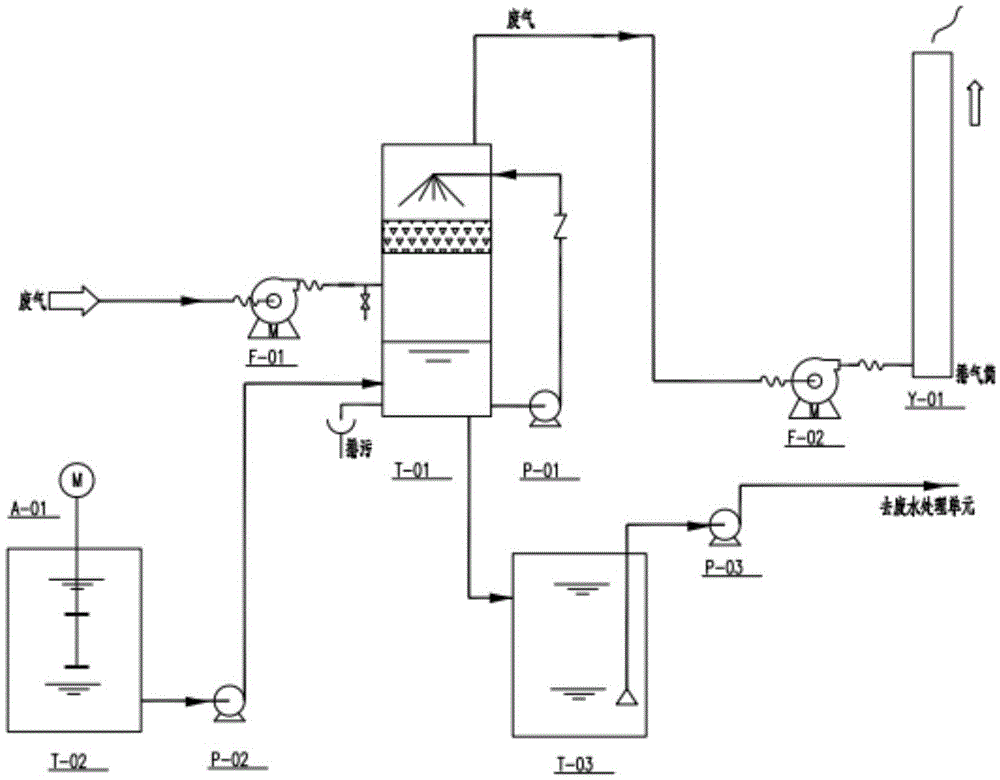

Image

Examples

Embodiment 1

[0031] A bioabsorbent for treating hydrocarbon organic waste gas described in Example 1 of the present invention is made of the following components: 2kg of 25g / l rhamnolipid aqueous solution, 0.3kg of sodium oleate, 2kg of biodiesel, bacteria thick 10 10 -10 11 91kg of functional bacteria aqueous solution and 0.5kg of sodium citrate.

[0032] The preparation method of the above-mentioned bioabsorbent for treating hydrocarbon organic waste gas comprises the following steps:

[0033] (1) biodiesel and sodium oleate are mixed with the rhamnolipid fermentation liquid, stirred to obtain an emulsion, and the emulsion is sterilized;

[0034] (2) Make the bacteria concentration 10 10 -10 11 The functional bacteria aqueous solution of each / ml is added to the sterilized emulsion in step (2), stirred at 25°C, the stirring intensity is 72 rpm, and the stirring time is 30 minutes; and

[0035] (3) Put the nutrient salt into the mixed solution prepared in step (3), mix and stir to obt...

Embodiment 2

[0037] A bioabsorbent for treating hydrocarbon organic waste gas described in Example 1 of the present invention is made of the following components: 25g / l rhamnolipid fermentation broth 4kg, sodium oleate 0.4kg, biodiesel 2% , bacterial concentration 10 10 -10 11 93kg of functional bacteria aqueous solution and 0.5kg of potassium sulfate per ml.

Embodiment 3

[0039] A bioabsorbent for treating hydrocarbon organic waste gas described in Example 1 of the present invention is made of the following components: 6 kg of 25 g / l rhamnolipid fermentation broth, 0.5 kg of sodium oleate, 2 kg of biodiesel, Bacterial concentration 10 10 -10 11 95kg of functional bacteria aqueous solution of each / ml, and 0.25kg of sodium citrate and 0.25kg of ammonium phosphate.

[0040] Main raw material characteristics and absorption process principle, parameters of the embodiment of the present invention

[0041] (1) Main raw materials: biodiesel, rhamnolipid fermentation broth, hydrocarbon degrading bacteria (brevibacterium, laboratory screening)

[0042] Biodiesel: It has good safety performance and is a kind of green diesel. The flash point is higher than that of petrochemical diesel. It is not a dangerous fuel and has obvious advantages in transportation, storage and use. It is an organic liquid mainly made from oil crops such as soybean and rapeseed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com