Method for efficiently recovering active materials of positive poles in waste lithium batteries

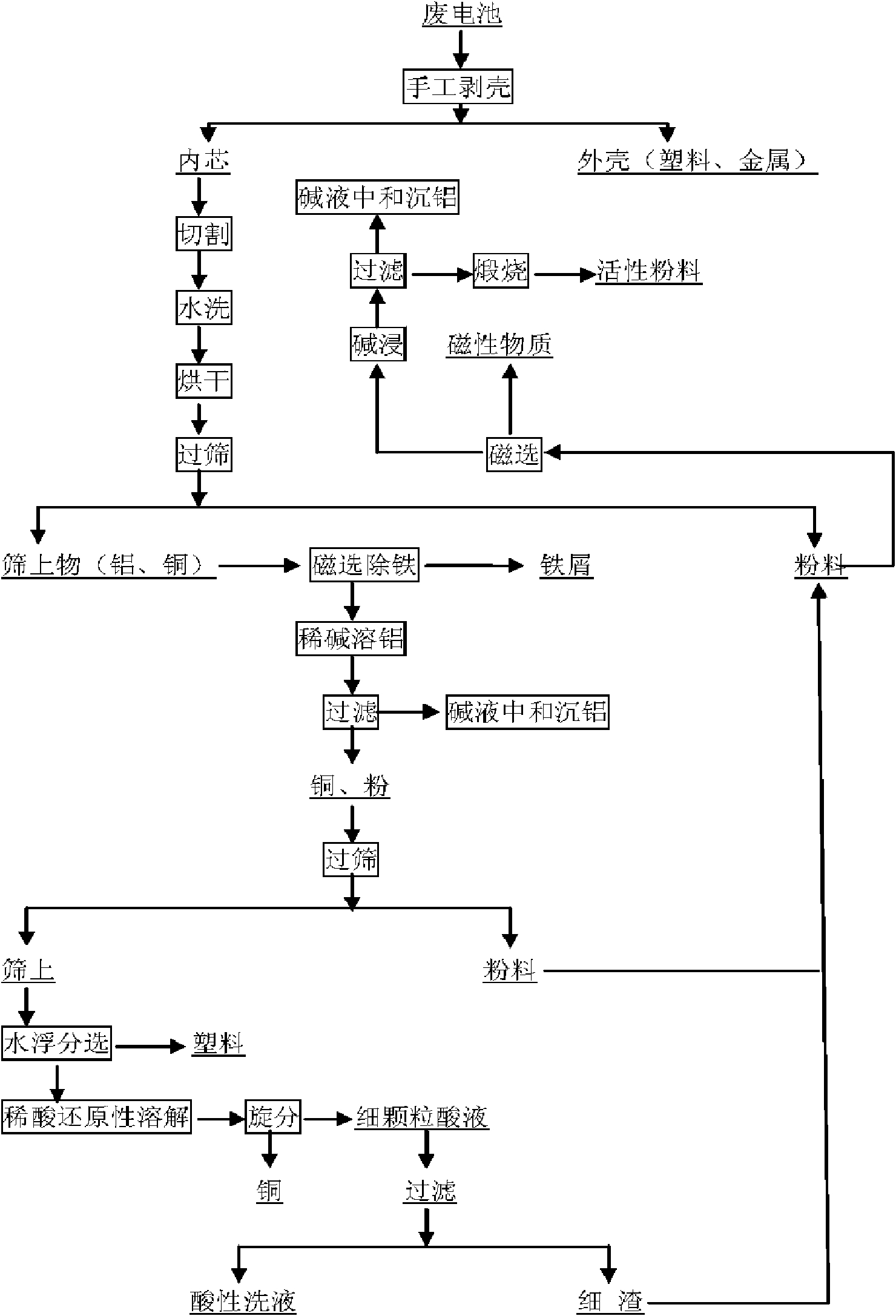

A technology for positive active materials and waste lithium batteries, which is applied in the field of separation and recycling of electrolyte, separator, copper foil, positive active material, battery case, and aluminum foil, which can solve the problems of large environmental pollution, low separation efficiency, and high processing cost. Achieve high separation efficiency, simple process, and solve the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Weigh 500g of broken cell fragments, crush them to 1-5mm, stir in hot water at 80°C for 1 hour, filter and dry, pass through an 80-mesh vibrating sieve, collect the powder material under the sieve, and magnetically separate the part on the sieve After removing iron, use 3% NaOH solution with a mass percentage concentration of 1:10 g / ml according to the solid-to-liquid ratio, stir at 80 ° C for 3 hours, and filter the filtrate after the aluminum foil is completely dissolved. Use 0.2 mol / L dilute sulfuric acid to adjust the pH value to 12 , and then use saturated ammonium bicarbonate to adjust the pH value to 9.5 and age for 1 hour, filter, the aluminum precipitation is complete and the filtration performance is good, the filter residue is dried and passed through an 80-mesh vibrating sieve to collect the powder material under the sieve. The part above the sieve is placed in water for water spinning, and after the upper plastic diaphragm is poured off, the copper sheet is ...

Embodiment 2

[0040] Weigh 500g of broken cell fragments, crush them to 1-5mm, stir in hot water at 80°C for 2 hours, filter and dry, pass through an 80-mesh vibrating sieve, collect the powder material under the sieve, and magnetically separate the part on the sieve After iron removal, use 3% NaOH solution with a mass percentage concentration of 1:10 g / ml according to the solid-to-liquid ratio, and stir for 5 hours at about 80°C. After the aluminum foil is completely dissolved, filter it, and adjust the pH of the filtrate with 0.2mol / L dilute sulfuric acid. The value is 12, and then adjust the pH value to 8.5 with saturated ammonium bicarbonate to age for 1 hour, filter, and the aluminum precipitation is complete and the filter performance is good. After the filter residue is dried, pass through an 80-mesh vibrating sieve to collect the powder material under the sieve. The part above the sieve is placed in water for water spinning, and after the upper plastic diaphragm is poured off, the c...

Embodiment 3

[0042] Weigh 500g of broken cell fragments, crush them to 1-5mm, stir in hot water at 90°C for 2 hours, filter and dry, pass through an 80-mesh vibrating sieve, collect the powder material under the sieve, and magnetically separate the part on the sieve After removing iron, use 5% NaOH solution with a mass percentage concentration of 1:6g / ml according to the solid-to-liquid ratio, and stir for 5 hours at about 60°C. After the aluminum foil is completely dissolved, filter it, and adjust the pH of the filtrate with 0.5mol / L dilute sulfuric acid. The value is 12, and then adjust the pH value to 8.5 with saturated ammonium bicarbonate to age for 2 hours, filter, and the aluminum precipitation is complete and the filtration performance is good. After the filter residue is dried, pass through an 80-mesh vibrating sieve to collect the powder material under the sieve. The part above the sieve is placed in water for water spinning, and after the upper plastic diaphragm is poured off, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com