Method for preparing taurine by adopting sulfonation of ammonium sulfite

A technology of ammonium sulfite and taurine, which is applied to the preparation of sulfonic acid, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as non-process route, highly toxic boiling point of ethyleneimine, low volatility, etc. , to achieve the effect of simple operation process, easy separation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

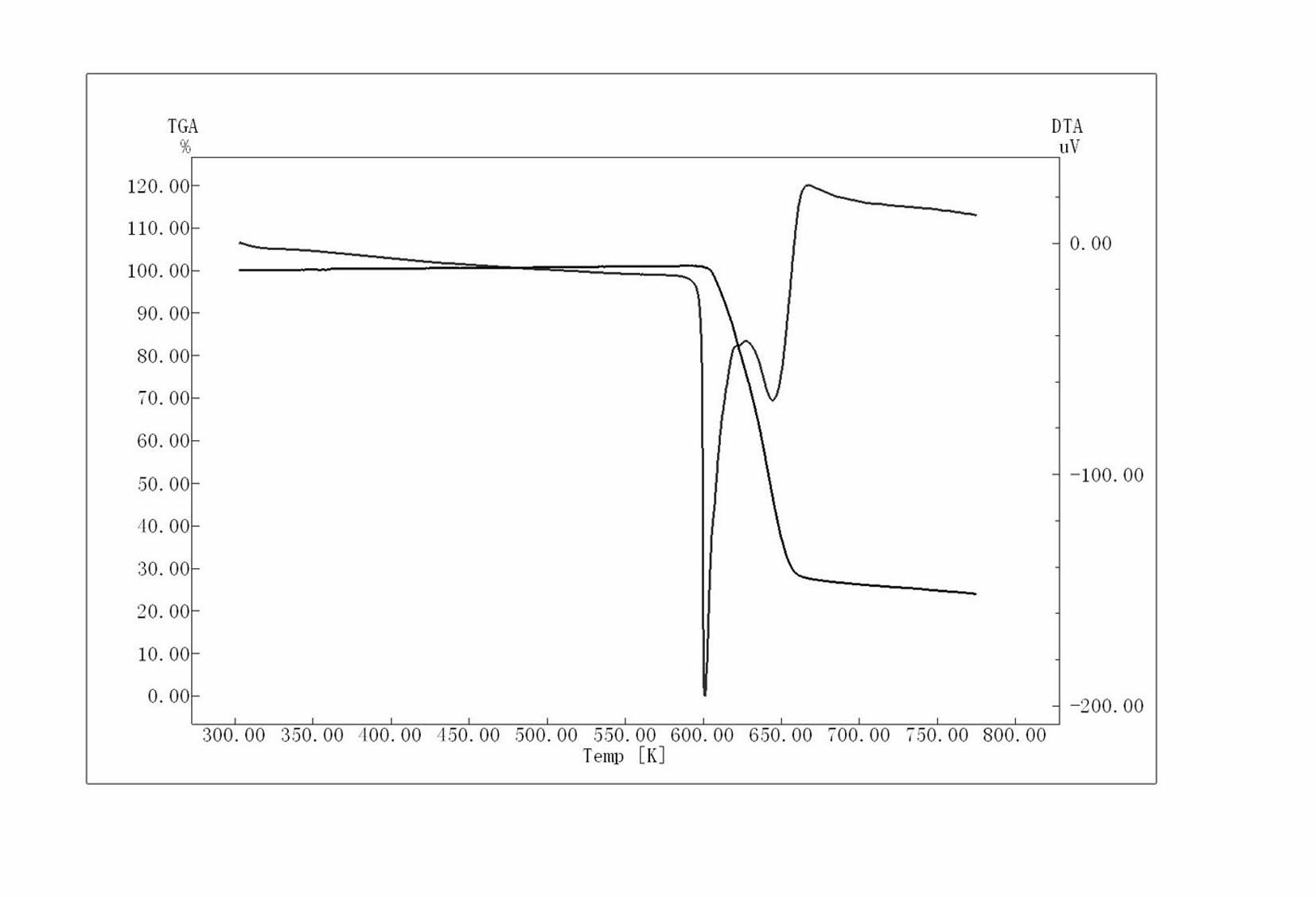

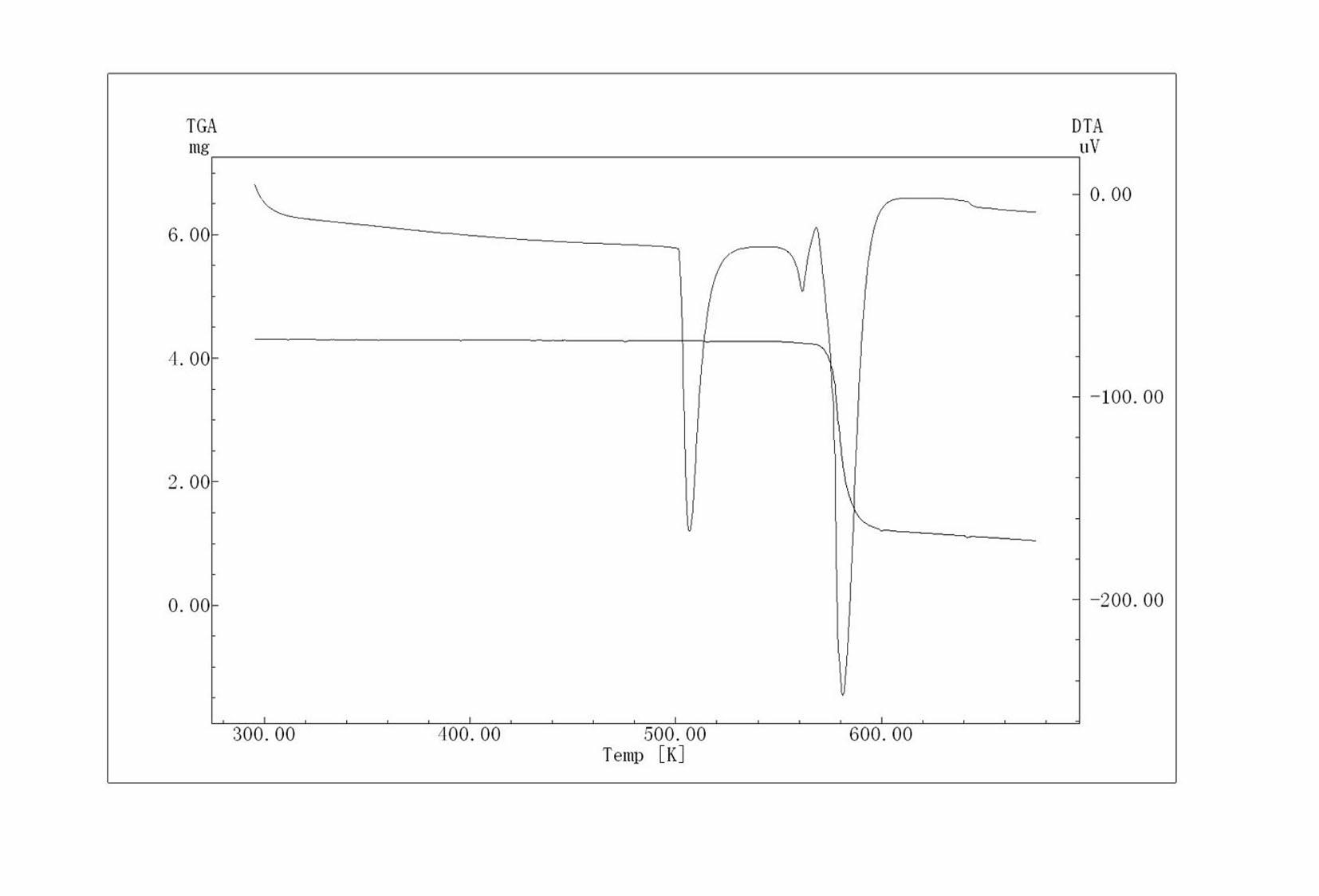

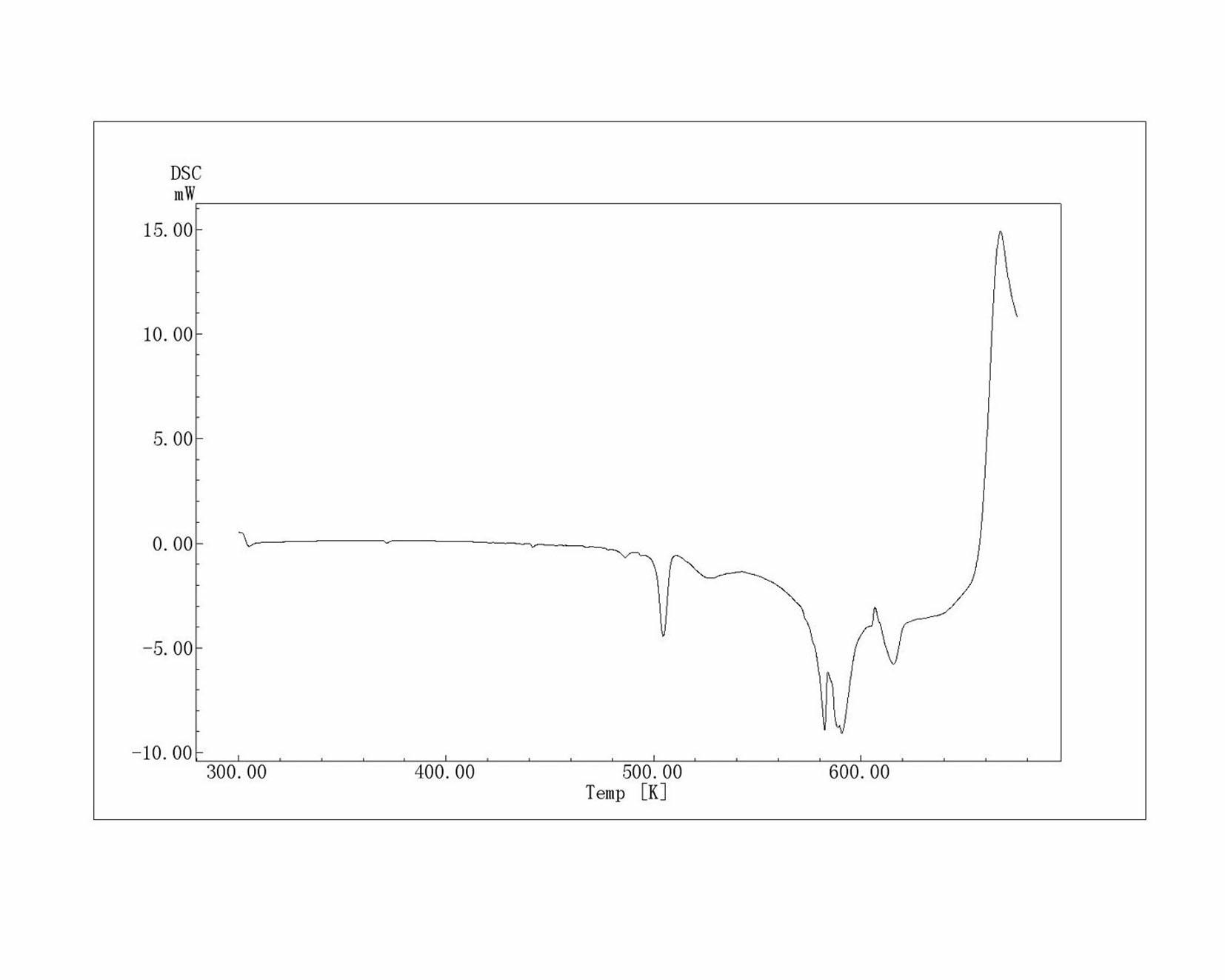

Image

Examples

Embodiment 1

[0054] b, sulfonation reaction: feed ammonia gas into the reaction vessel 5 minutes before the start of the reaction (the purpose of feeding ammonia gas is to protect the system, make the system alkaline, inhibit the hydrolysis of 2-aminoethanol sulfate, and in the step Recycling and reuse in c), the flow rate of ammonia gas is 15mL·min -1 ; First add the intermediate 2-aminoethanol sulfate synthesized by step a, then add ammonium sulfite, the mol ratio of the amount added between the ammonium sulfite and 2-aminoethanol sulfate is 1.55:1, start to carry out For sulfonation reaction, control the sulfonation reaction temperature to 98°C, the reaction time is 11h, and the raw material ammonium sulfite is fed 4 times. After the sulfonation reaction is completed, the temperature of the reaction solution is lowered. , measure and calculate the yield of gained taurine with sodium thiosulfate back titration method;

[0055] c, the reaction solution obtained in step b is down to room ...

Embodiment 2

[0061] In step d: first use phosphate buffer to adjust the pH value of the filtrate to 6, and gradually lower the temperature at a rate of 4°C / min, and crystallize when the crystallization temperature is 14°C, and the crystallization time is 6h (cooling, crystallization process The stirring rate of the medium magnetic stirrer is 400r / min), the obtained crystals are suction filtered, and then dried to constant weight (the drying temperature is 80°C).

[0062] Product analysis results: In the sulfonation reaction, the conversion rate of 2-aminoethanol sulfate is 67.41%, and the desalination rate is 99.18% by sodium thiosulfate back titration. After the crystallization, the primary yield of taurine was 52.47%, and the purity reached 95%.

[0063] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0064] In step b: the flow rate of ammonia gas is 10mL min -1 , the molar ratio of the addition amount between the ammonium sulfite and 2-aminoethanol sulfate is 1....

Embodiment 3

[0065] In step d: first use phosphate buffer to adjust the pH value of the filtrate to 6, and gradually lower the temperature at a rate of 3°C / min, and crystallize when the crystallization temperature is 14°C, and the crystallization time is 10h (cooling, crystallization process The stirring rate of the magnetic stirrer is 600r / min), the obtained crystals are suction filtered, and then dried to constant weight (the drying temperature is 80°C).

[0066] Product analysis results: the conversion rate of 2-aminoethanol sulfate was 70.43% and the desalination rate was 99.24% in the sulfonation reaction determined by sodium thiosulfate back titration. After the crystallization, the primary yield of taurine was 65.32%, and the purity reached 95%.

[0067] Embodiment 4: basically the same as Embodiment 1, the difference is:

[0068] In step b: the ammonia flow rate is 18mL min -1 , the molar ratio of the added amount between the ammonium sulfite and 2-aminoethanol sulfate is 1.75:1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com