Technology of non-cyanide silver coating

A process method, a cyanide-free silver plating technology, is applied in the field of electrochemical silver plating technology, which can solve the problems of not too ideal brightening effect, poor anti-discoloration ability of the coating, large internal stress of the coating, etc., and achieve strong anti-discoloration, Good wear resistance, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

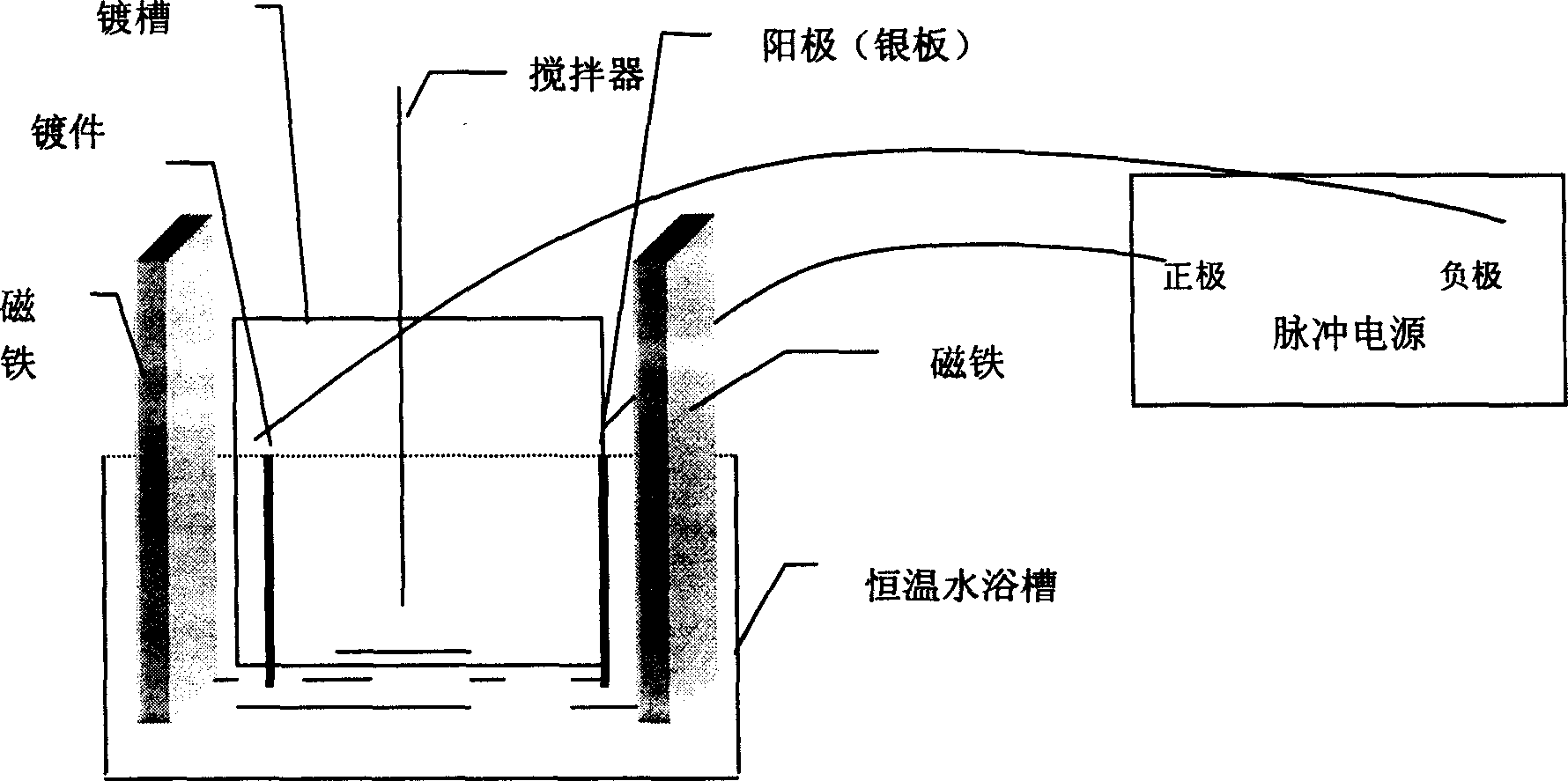

[0018] Embodiment one: see figure 1 , which is a simple schematic diagram of the silver plating device used in the pulse silver plating process of a main process in the process flow of the present invention, which represents a device for silver plating under the action of a magnetic field and a pulse current, where the plated parts are used as cathodes and anodes It is a high-purity 99.99% silver plate. Under the action of electrochemical principles, the plated parts are plated with silver.

[0019] In this embodiment, the flow and process of the entire silver plating process include the following steps: chemical degreasing → water washing → chemical deembroidery → water washing → bright nickel plating → water washing → activation treatment → water washing → silver immersion → water washing → Pulse silver plating→water washing→passivation treatment→drying→finished product.

[0020] The main processes and steps are described in detail as follows:

[0021] a. Chemical degreasi...

Embodiment 2

[0028] Embodiment 2: This embodiment is basically the same as the above-mentioned embodiment 1, the difference is that the main process is the pulse silver plating process, and the composition formula and operating process conditions of the silver plating solution are different. In this embodiment, the process formula of the pulse silver plating solution is: silver nitrate 55g / L, sodium thiosulfate 300g / L, potassium metabisulfite 100g / L, potassium sulfate 25g / L, boric acid 30g / L, brightener 5ml / L; the operating process conditions are: the stirring method is mechanical stirring, the pH value of the plating solution is 4.5, the temperature is 30°C, the silver plating time is 10 minutes, and the average pulse current density is 0.9A / dm 2 , pulse width 0.5ms, duty cycle 15%.

Embodiment 3

[0029] Embodiment 3: This embodiment is basically the same as the above-mentioned embodiment 1, the difference is that the main process is the pulse silver plating process, and the composition formula and operating process conditions of the silver plating solution are different. In this embodiment, the process formula of the pulse silver plating solution is: silver nitrate 60g / L, sodium thiosulfate 350g / L, potassium metabisulfite 110g / L, potassium sulfate 30g / L, boric acid 35g / L, brightener 5ml / L; the operating process conditions are: the stirring method is mechanical stirring, the pH value of the plating solution is 4.8, the temperature is 40°C, the silver plating time is 10 minutes, and the average pulse current density is 1.1A / dm 2 , pulse width 1ms, duty cycle 10%.

[0030] In each of the above-mentioned embodiments, the applied magnetic field mode is: the direction of the magnetic field applied in embodiment 1 is perpendicular to the direction of the electric field; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com