Graphene aerogel and hybrid composite material thereof as well as preparation method and application of graphene aerogel

A graphene airgel, graphene technology, applied in the field of airgel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

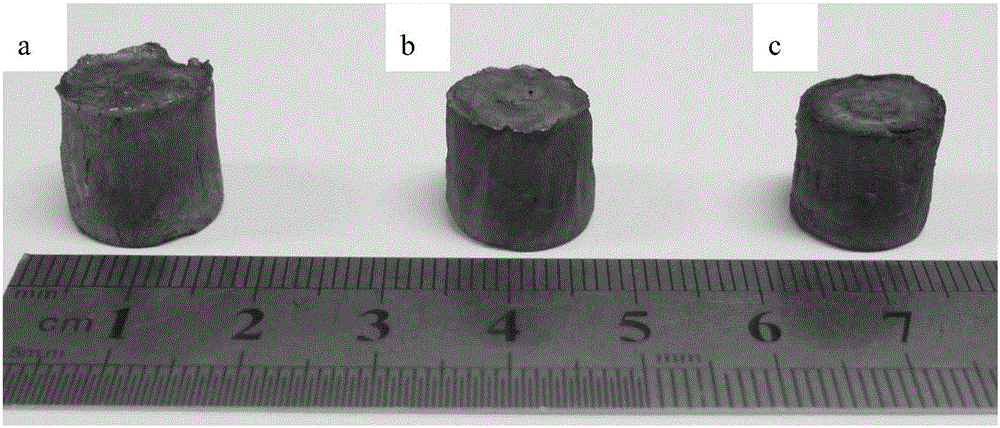

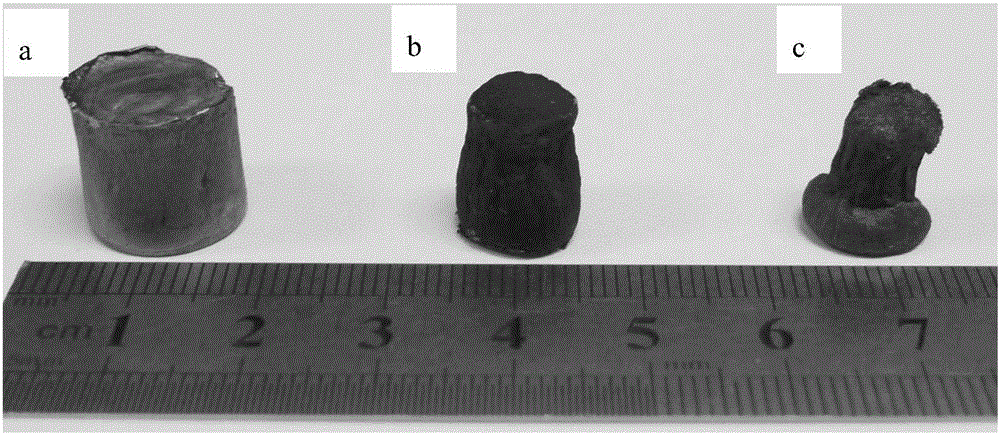

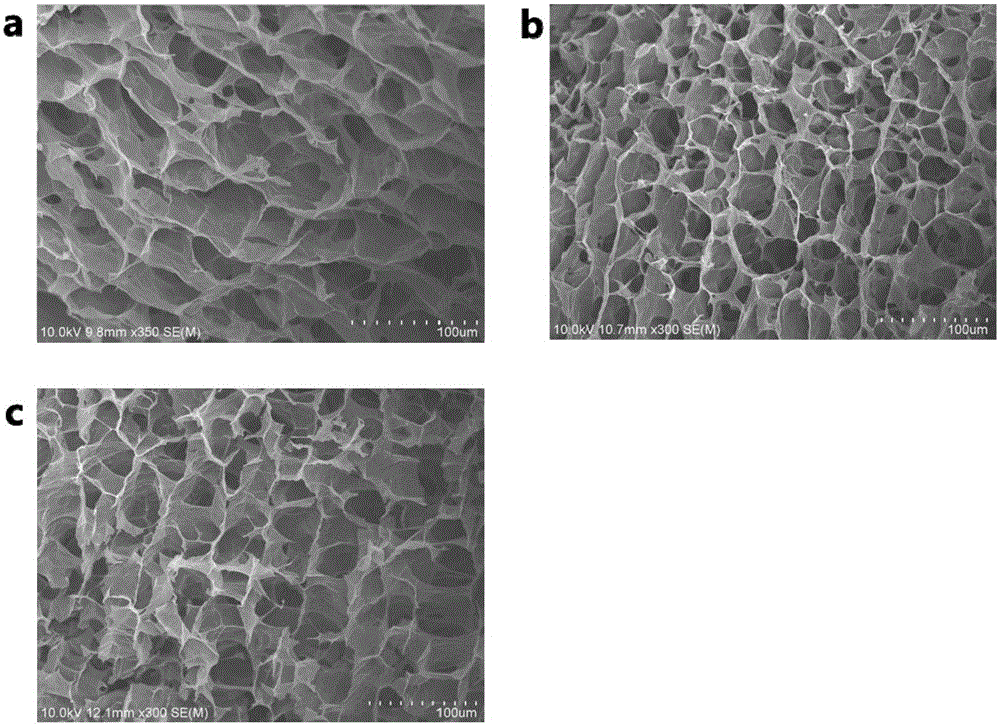

Embodiment 1

[0084] Embodiment 1, prepare graphene airgel:

[0085] 1) Add 75mg of acrylamide, 3.3mg of N,N-methylenebisacrylamide, 0.6 mg potassium persulfate and 150 mg ascorbic acid were stirred at 10°C for 60 min to obtain a mixed solution;

[0086] 2) Heat the mixed solution in an oil bath at 70°C for 20 minutes to obtain a partially reduced graphene oxide / polyacrylamide hydrogel;

[0087] 3) Pre-freeze the partially reduced graphene / polyacrylamide hydrogel at -75°C for 30 minutes, and after melting at room temperature, heat the gel in an oil bath at 80°C for 18 hours to obtain graphene / polyacrylamide hydrogel gel;

[0088] 4) Put the graphene / polyacrylamide hydrogel in a dialysis bag with a molecular weight cut-off of 16,000, then place the dialysis bag in deionized water for replacement, replace the deionized water regularly, and obtain graphene hydrogel after 2 days of dialysis. glue;

[0089]5) Graphene hydrogel is directly freeze-dried to obtain graphene airgel, the freezing ...

Embodiment 2

[0110] Embodiment 2, prepare graphene airgel:

[0111] 1) Add 37.5 mg of acrylamide, 1.6 mg of N,N-methylenebisacrylamide, 0.3mg potassium persulfate and 150mg ascorbic acid were stirred at 20°C for 60min to obtain a mixed solution;

[0112] 2) Heat the mixed solution in an oil bath at 90°C for 10 minutes to obtain a partially reduced graphene oxide / polyacrylamide hydrogel;

[0113] 3) The partially reduced graphene oxide / polyacrylamide hydrogel was pre-frozen in liquid nitrogen for 10 minutes, and after melting at room temperature, the gel was heated in an oil bath at 70°C for 24 hours to obtain graphene / polyacrylamide hydrogel gel;

[0114] 4) Dialyzing the graphene / polyacrylamide hydrogel in deionized water for 2 days to obtain a graphene hydrogel;

[0115] 5) Graphene hydrogel is directly freeze-dried to obtain graphene aerogel. The freezing temperature is -75°C, the freezing time is 30min, the drying temperature is -15-30°C, the drying temperature rises from -15°C to ...

Embodiment 3

[0122] Embodiment 3, prepare graphene airgel:

[0123] 1) Add 375 mg of acrylamide, 16.5 mg of N,N-methylenebisacrylamide, 3.0 mg of graphene oxide solution (wherein the molar ratio of carbon to oxygen in graphene oxide is 2) in 10 ml, 7.5 mg / ml of graphene oxide solution mg potassium persulfate and 150 mg ascorbic acid were stirred at 20°C for 60 min to obtain a mixed solution;

[0124]2) Heat the mixed solution in an oil bath at 100°C for 3 minutes to obtain a partially reduced graphene oxide / polyacrylamide hydrogel;

[0125] 3) Pre-freeze the reduced graphene oxide / polyacrylamide hydrogel at -50°C for 60 minutes, and after melting at room temperature, heat the gel in an oil bath at 100°C for 8 hours to obtain graphene / polyacrylamide hydrogel gel;

[0126] 4) Dialyzing the graphene / polyacrylamide hydrogel in deionized water for 2 days to obtain a graphene hydrogel;

[0127] 5) Graphene hydrogel is directly freeze-dried to obtain graphene aerogel. The freezing temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com