Process for producing metal foams having uniform cell structure

a technology of foam and cell structure, applied in the direction of ion implantation coating, chemical vapor deposition coating, liquid/solution decomposition chemical coating, etc., can solve the problems of uneven thickness of nickel, foam conductivity, active mass loading and electrochemical performance of individual battery cells, premature failure of large battery packs, etc., to achieve the effect of increasing the effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

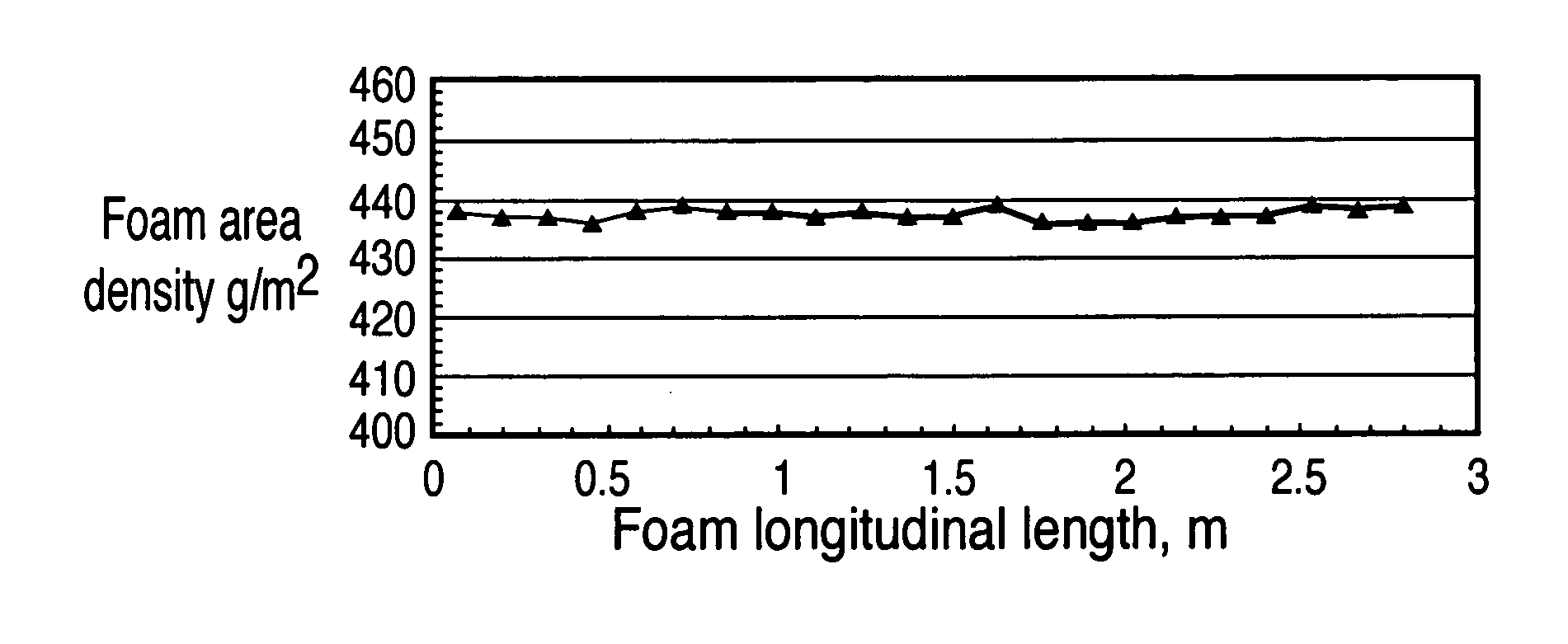

[0030] An object of the present invention is for the production of porous metal plated foam having a uniform cell structure. The metal foam has a consistent distribution of area density, controlled metal strut thickness, and uniform mechanical and electrical properties such as tensile strength, elongation and electrical conductivity.

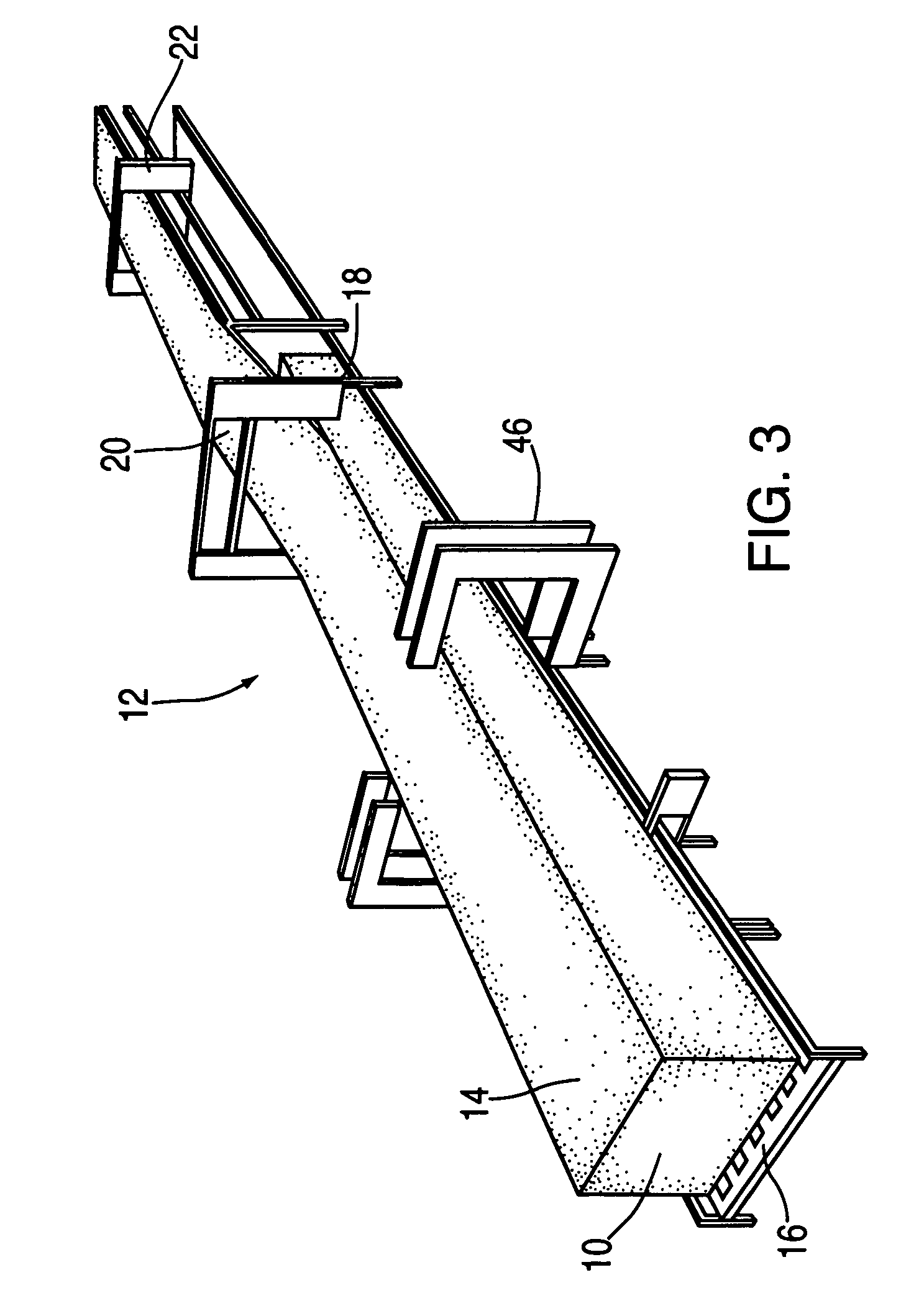

[0031] Turning to FIG. 3, polymeric, preferably polyurethane, foam buns (slabs) 10 of desired length, width and height are slit by a horizontal slitting apparatus 12 along the upper longitudinal bun surface 14.

[0032] The foam bun 10 is repeatedly reciprocated over the slitter bed 16 to cut and raise a planar foam sheet 20 of predetermined thickness from the horizontal longitudinal bun surface 14. Knife 18 slits the bun 10 to generate the foam sheet 20. The foam sheet 20 is transported to a storage section 22 of the apparatus 12. Side trimmer 46 maintains the correct foam slab 10 width. If desired, the foam sheet 20 may be shortened by a blade, heated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com