High-strength temporary blocking agent and preparation method thereof

A temporary plugging agent, high-strength technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of inability to use temporary plugging operations, cannot adapt to temporary plugging operations in medium and low temperature reservoirs, and achieve excellent plugging. performance, improve fracturing effect, save operation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

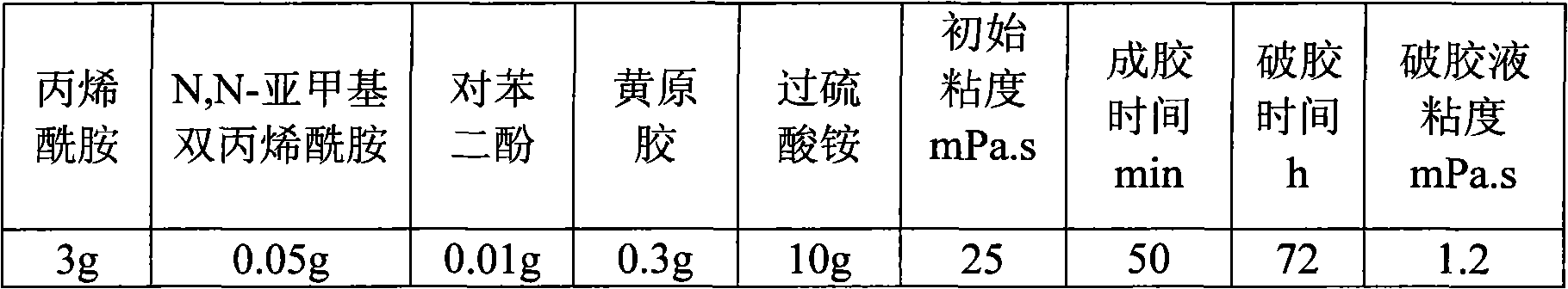

[0020] At room temperature, weigh 80g of water into a beaker, then sequentially add 3g of acrylamide, 0.05g of methylene bisacrylamide, 0.01g of hydroquinone and stir until completely dissolved, then add 0.3g of xanthan gum and stir After it is completely dissolved, add 10g of ammonium persulfate and water to a total weight of 100g, and stir until it is completely dissolved to obtain a temporary blocking agent. With a Brookfield viscometer at 170s -1 After measuring the initial viscosity of the prepared temporary blocking agent under the following conditions, put the temporary blocking agent into a 45°C oven to polymerize into a gel, and observe the time for the polymerization to become a jelly (gelation time) and the time for the gel to be broken into a clear liquid (gelation time). time), and measure the breaker at 170s -1 under the viscosity. The results are shown in Table 1.

[0021] Table 1 Formula and performance of temporary plugging agent with xanthan gum as viscosi...

Embodiment 2

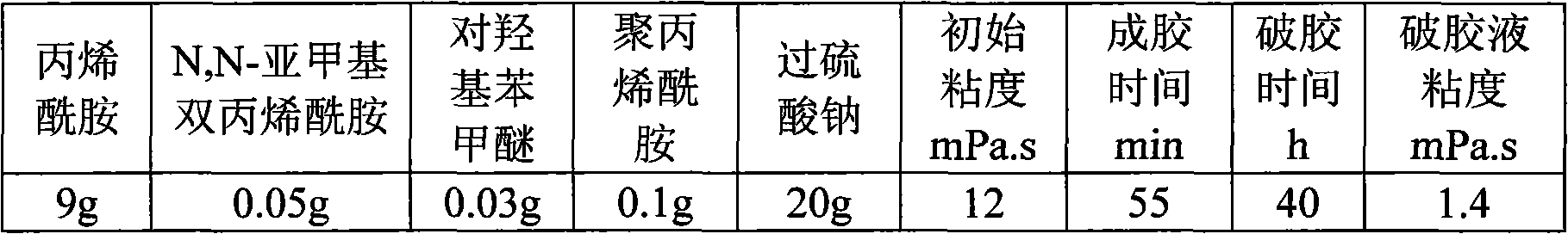

[0024] At room temperature, weigh 65g of water into a beaker, then sequentially add 9g of acrylamide, 0.05g of methylene bisacrylamide, 0.03g of p-hydroxymethyl anisole and stir until completely dissolved, then add 0.1g of polypropylene Amide, stir until completely dissolved, add 20g of sodium persulfate and water to a total weight of 100g, and stir until completely dissolved to obtain a temporary blocking agent. With a Brookfield viscometer at 170s -1 After measuring the initial viscosity of the prepared temporary blocking agent under the following conditions, put the temporary blocking agent into a 45°C oven to polymerize into a gel, and observe the time for the polymerization to become a jelly (gelation time) and the time for the gel to be broken into a clear liquid (gelation time). time), and measure the breaker at 170s -1 under the viscosity. The results are shown in Table 2.

[0025] Table 2 Formula and performance of temporary plugging agent with polyacrylamide as ta...

Embodiment 3

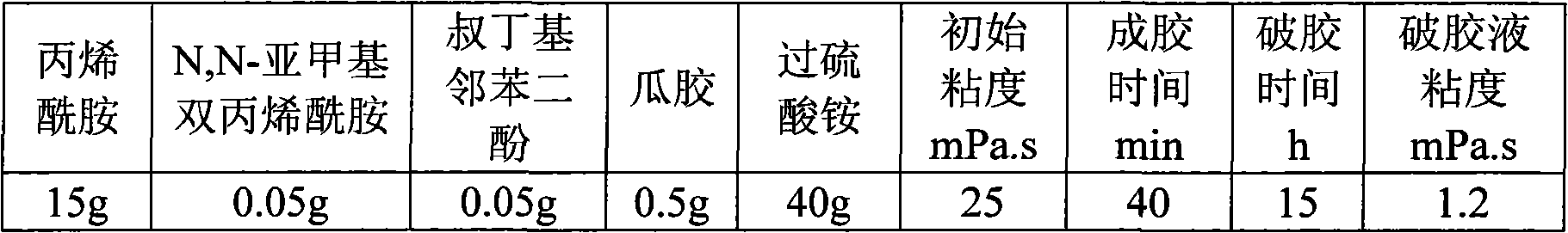

[0028] At room temperature, weigh 40g of water into a beaker, then sequentially add 15g of acrylamide, 0.05g of methylene bisacrylamide, 0.05g of tert-butyl catechol and stir until completely dissolved, then add 0.5g of guar gum After stirring until completely dissolved, add 40g of ammonium persulfate and water to a total weight of 100g, and stir until completely dissolved to obtain a temporary blocking agent. With a Brookfield viscometer at 170s -1 After measuring the initial viscosity of the prepared temporary blocking agent under the following conditions, put the temporary blocking agent into a 60°C oven to polymerize into a gel, and observe the time for the polymerization to become a jelly (gelation time) and the time for the gel to be broken into a clear liquid (gelation time). time), and measure the breaker at 170s -1 under the viscosity. The results are shown in Table 3.

[0029] Table 3 Temporary plugging agent formula and performance of guar gum as a viscosifier (6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com