Modified chitosan/nanocellulose composite aerogel and preparation method and application thereof

A technology of nano-cellulose and composite airgel, which is applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problem of low removal rate of heavy metal ions, and achieve sustainable development of the environment and biocompatibility Good performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

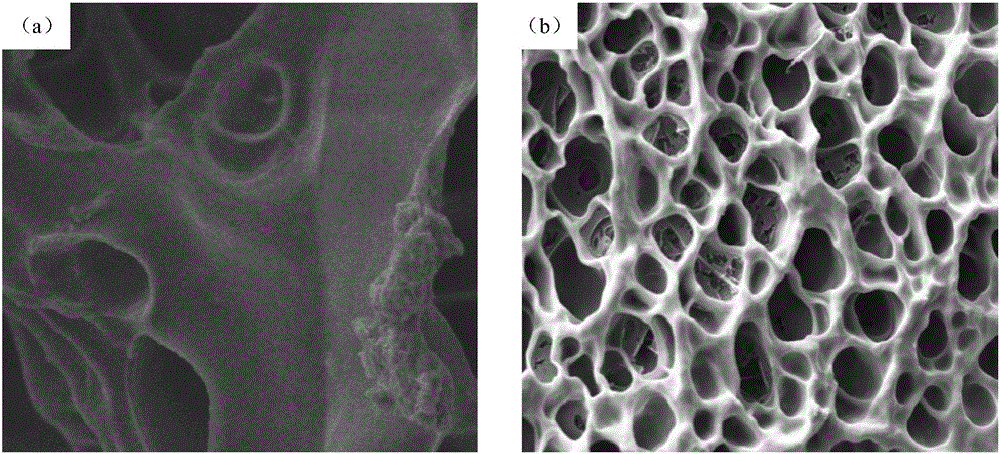

Image

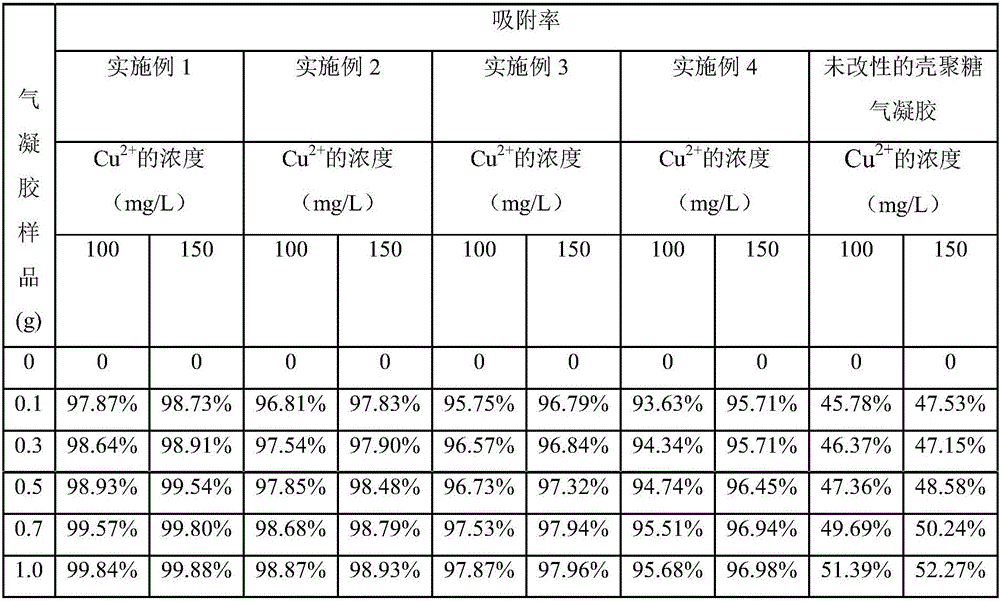

Examples

Embodiment 1

[0030] A preparation method of sulfur-containing modified chitosan airgel, comprising the following steps:

[0031] (1) take by weighing 10.0g chitosan in the glacial acetic acid solution of 2% in 500mL mass fraction, the chitosan solution is carried out suction filtration, then wash with dehydrated alcohol, obtain the chitosan after the pretreatment; In 500mL In the round bottom flask, respectively add 5 g of the above-mentioned pretreated chitosan and 30 mL of hydrochloric acid solution with a mass fraction of 6%, and control the reaction temperature at 0° C. Dimethyl dipropionate 25g; after the dropwise addition, remove the ice-water bath, and continue to react at room temperature for 10 hours to obtain a light yellow viscous substance; after standing, precipitate, and suction filter to obtain a milky white solid, dry it with absolute ethanol to re- Crystallization obtains sulfur-containing modified chitosan;

[0032] (2) getting the modified chitosan 3g that step (1) make...

Embodiment 2

[0035] A preparation method of sulfur-containing modified chitosan airgel, comprising the following steps:

[0036](1) taking by weighing 8.0g chitosan and being dissolved in 400mL mass fraction is in the glacial acetic acid solution of 3%, the chitosan solution is carried out suction filtration, then washes with dehydrated alcohol, obtains the chitosan after pretreatment; In a 500mL round-bottomed flask, add 5g of the above-mentioned pretreated chitosan and 28mL of hydrochloric acid solution with a mass fraction of 5%, control the reaction temperature at 1°C, and add disulfide disulfide dropwise at a rate of 2mL / min under stirring. Substituting dimethyl dipropionate 20g; after the dropwise addition, remove the ice-water bath, and continue to react at room temperature for 9h to obtain a light yellow viscous substance; after standing, precipitate, and suction filter to obtain a milky white solid, dry it with absolute ethanol Recrystallization obtains sulfur-containing modified ...

Embodiment 3

[0039] A preparation method of sulfur-containing modified chitosan airgel, comprising the following steps:

[0040] (1) taking by weighing 10.0g chitosan and being dissolved in 500mL mass fraction is in the glacial acetic acid solution of 1%, the chitosan solution is carried out suction filtration, then washes with dehydrated alcohol, obtains the chitosan after pretreatment; In a 500mL round-bottomed flask, add 5g of the pretreated chitosan and 24mL of 4% hydrochloric acid solution respectively, control the reaction temperature at 3°C, and add disulfide disulfide dropwise at a rate of 3mL / min under stirring. Substituting dimethyl dipropionate 15g; After the dropwise addition, remove the ice-water bath, and continue to react at room temperature for 8h to obtain a light yellow viscous substance; after standing, precipitate, and suction filter to obtain a milky white solid, dry it with absolute ethanol Recrystallization obtains sulfur-containing modified chitosan;

[0041] (2) g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com