Patents

Literature

35 results about "N,N-Methylenebisacrylamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N,N'-Methylenebisacrylamide (MBAm or MBAA) is a cross-linking agent used during the formation of polymers such as polyacrylamide. Its molecular formula is C₇H₁₀N₂O₂. Bisacrylamide is used in biochemistry as it is one of the compounds of the polyacrylamide gel (used for SDS-PAGE). Bisacrylamide polymerizes with acrylamide and is capable of creating cross-links between polyacrylamide chains, thus creating a network of polyacrylamide rather than unconnected linear chains of polyacrylamide.

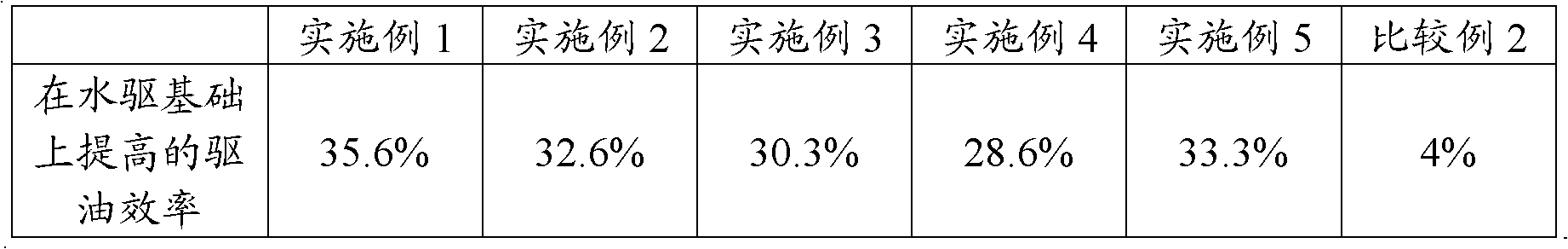

Polyacrylamide microgel as well as preparation method and application thereof

ActiveCN102127189AImprove stabilityPrevent implosionDrilling compositionN,N-MethylenebisacrylamideMethylene bisacrylamide

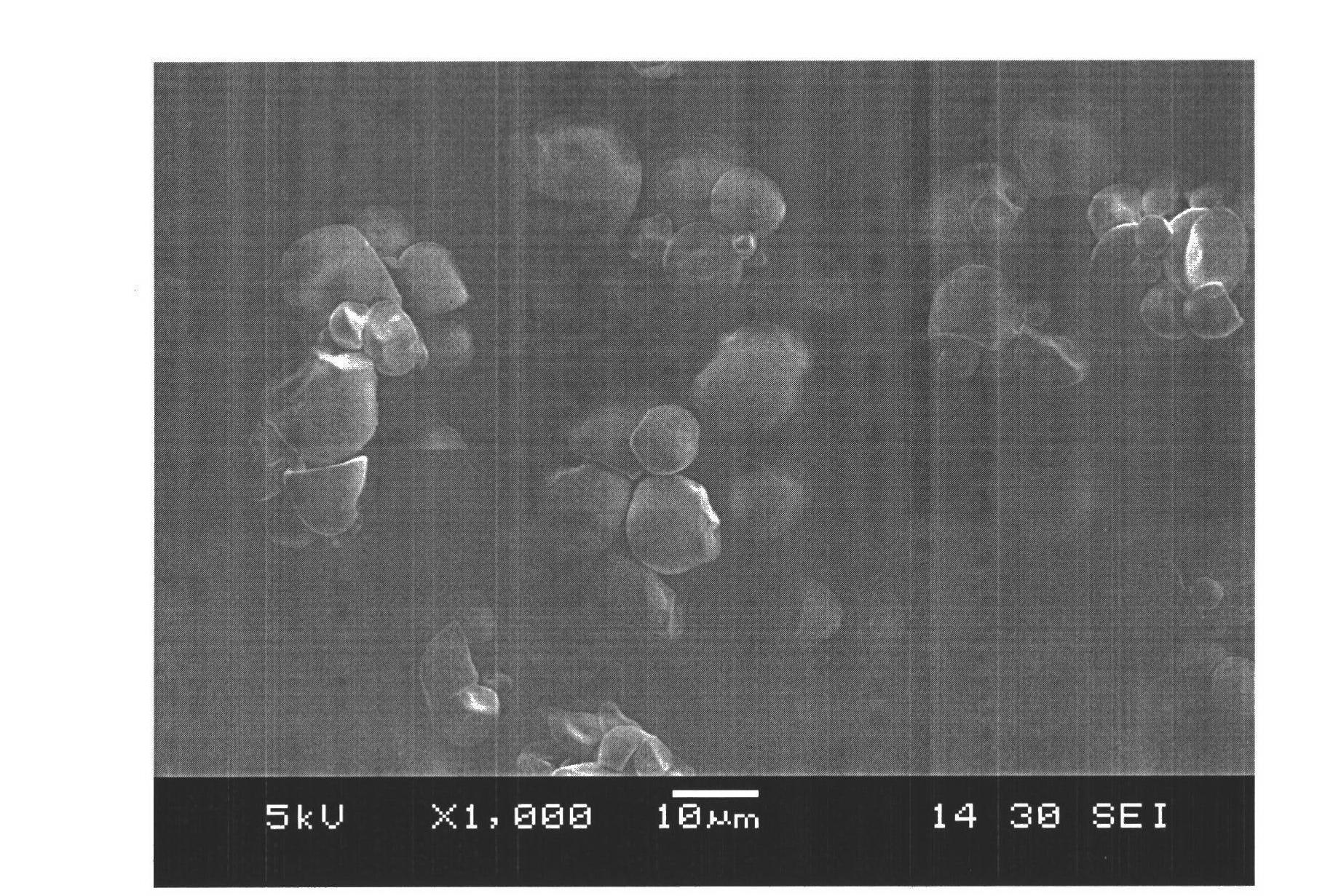

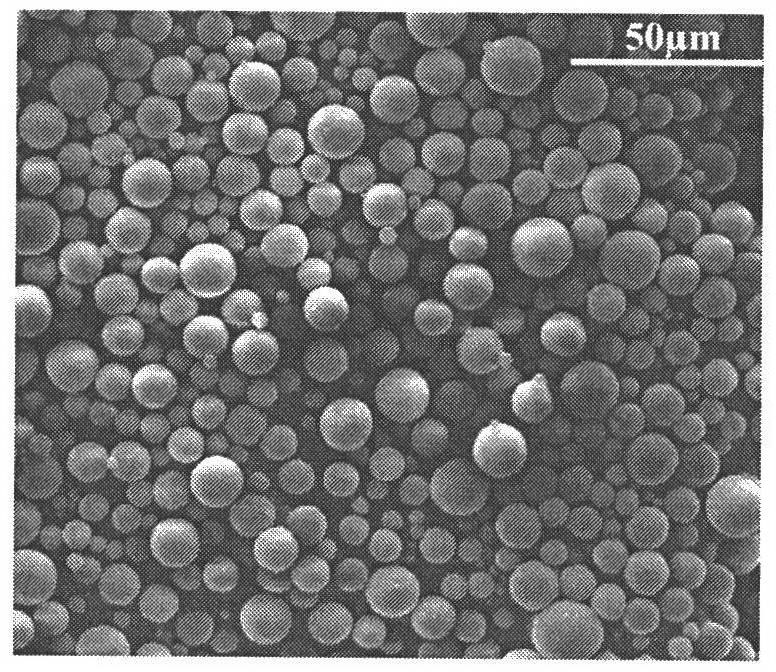

The invention discloses a polyacrylamide microgel as well as a preparation method and application thereof. The particle size of the polyacrylamide microgel is 30-150 micrometers, acrylamide, sodium acrylate, N,N'-bisacrylamide, 2-acrylamide-2-methylpropanesulfonic acid sodium, styrenesulfonate and the like serve as polymerized monomers, white oil and the like serve as disperse phases, and the polymerized monomers and the disperse phases are subjected to thermal initiation suspension polymerization to obtain the polyacrylamide microgel. The polyacrylamide microgel synthetized by the method can be directly injected into an oil layer without being processed and has a good plugging effect.

Owner:北京石大万嘉新材料科技有限公司

Method for manufacturing high-density and low-cost zinc oxide aluminum sputtering target

ActiveCN102212781ALow resistivityFulfil requirementsVacuum evaporation coatingSputtering coatingCross-linkVolumetric Mass Density

The invention discloses a method for producing a high-density and low-cost zinc oxide aluminum sputtering target. The method comprises the following steps of: selecting ZnO powder and Al2O3 powder as main raw materials; fully dissolving methyl acrylamide monomer and N-N' methylenebisacrylamide in pure water to form premixed solution, adding dispersants such as tetramethyl ammonium hydroxide and the like, adding the powder raw materials, stirring, pulping, regulating the pH value, and performing ball milling for over 6 hours to obtain pulp; adding organic degassing agent and ammonium persulfate initiator into the pulp, vacuumizing, stirring, degassing, and pouring the pulp into a die; heating the die to the temperature of between 50 and 70 DEG C, and initiating cross-linking curing reaction of gel monomer; releasing the cured wet blank from the die, and drying the wet blank to obtain a target biscuit; and performing un-sticking, high-temperature sintering and machining on the biscuit in a circulated air furnace to manufacture the zinc oxide aluminum sputtering target with relative density of over 98 percent and uniform chemical composition and microstructure.

Owner:江苏迪丞光电材料有限公司

Self-reinforced hybrid hydrogel used for artificial muscles and preparation method thereof

InactiveCN103224633AHigh strengthAvoid breakingProsthesisMetal ions in aqueous solutionControllability

The invention relates to a self-reinforced hybrid hydrogel used for artificial muscles and a preparation method thereof. According to the invention, sodium alginate is used as a high-molecular skeleton, acrylamide and derivative thereof are used as polymerizable monomers, divinyl benzene, N,N'-methylene bis acrylamide or ethylene glycol dimethacrylate is used as a chemical cross-linking agent, an aqueous metal salt solution is used as an ion cross-linking agent, and then the hydrogel with high elasticity and high toughness is prepared. During a process of preparing the hydrogel, an organic matter emulsion containing metal ion aqueous solution is added. When the prepared hydrogel is stretched by external forces to a certain extent, the gel deforms to extrude the organic matter emulsion, and metal ions are released and then crosslinked with the sodium alginate in the hybrid gel, thereby substantially improving gel intensity and preventing gel fracture. The preparation method has advantages of good controllability, simple technology and low cost, the obtained hydrogel material can be self-reinforced, and is expected to be applied in fields of artificial cartilage, artificial muscle, flexible robot manufacture, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing double-crosslinking amphoteric tapioca starch

The invention discloses a method for preparing double-crosslinking amphoteric tapioca starch. The method includes: using tapioca starch as main materials, water as solvent, hydroxide 1-butyl-3-methyl imidazole and sodium hydroxide as catalysts for etherification reaction, and N, N'-methylene bisacrylamide as inner-crosslinking agent to enable the starch to be in a meshed form, and preparing double-crosslinking amphoteric tapioca starch by means of outer crosslinking of epichlorohydrin and modification of amphoteric agent such as dimethyl diallyl ammonium chloride cation monomers, monochloro acetic acid and the like to enable the tapioca starch to integrate advantages of crosslinking starch and amphoteric starch. The double-crosslinking amphoteric tapioca starch has high application value in papermaking auxiliaries, cosmetics and the like. Further, since the double-crosslinking amphoteric tapioca starch is swellable in water but insoluble, application of the double-crosslinking amphoteric tapioca starch in sewage treatment is more effective.

Owner:建湖上冈产业园服务有限公司

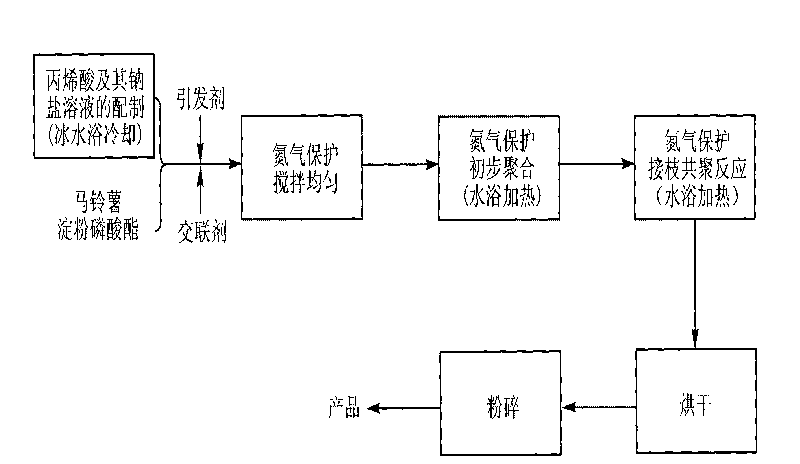

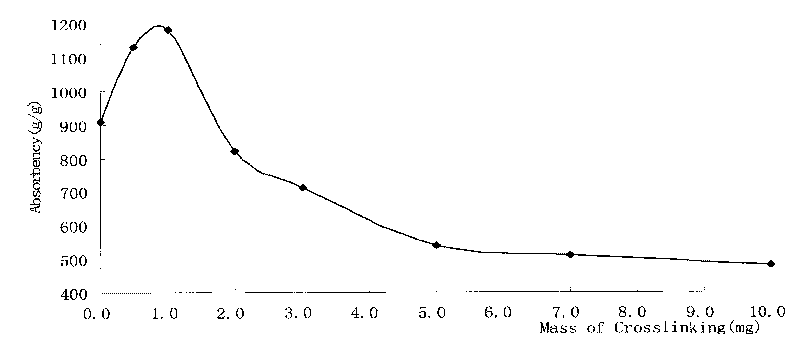

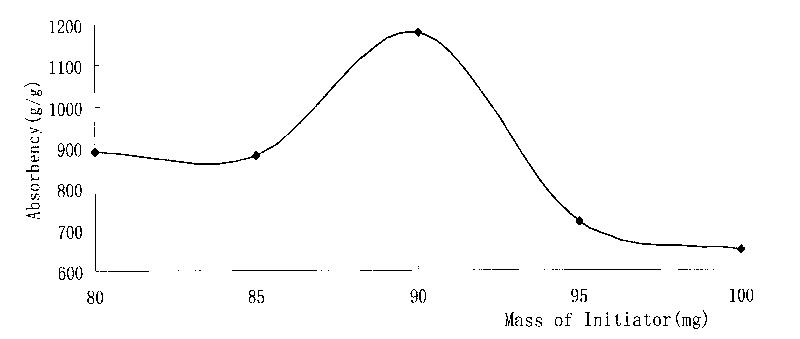

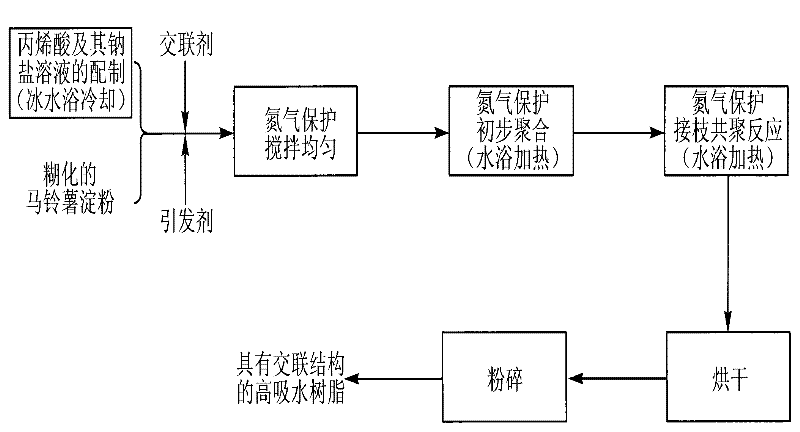

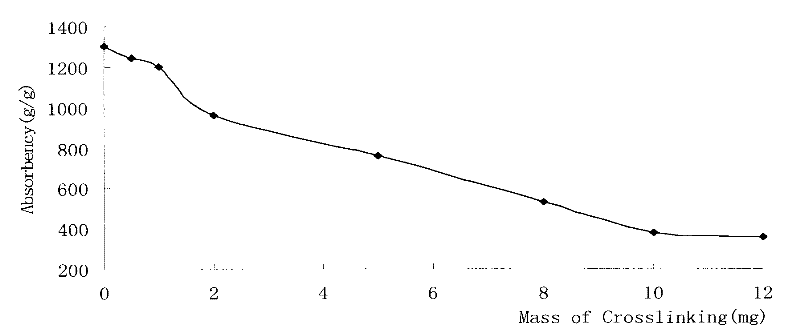

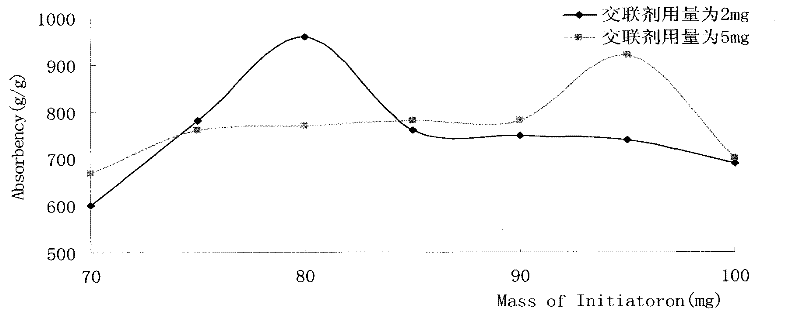

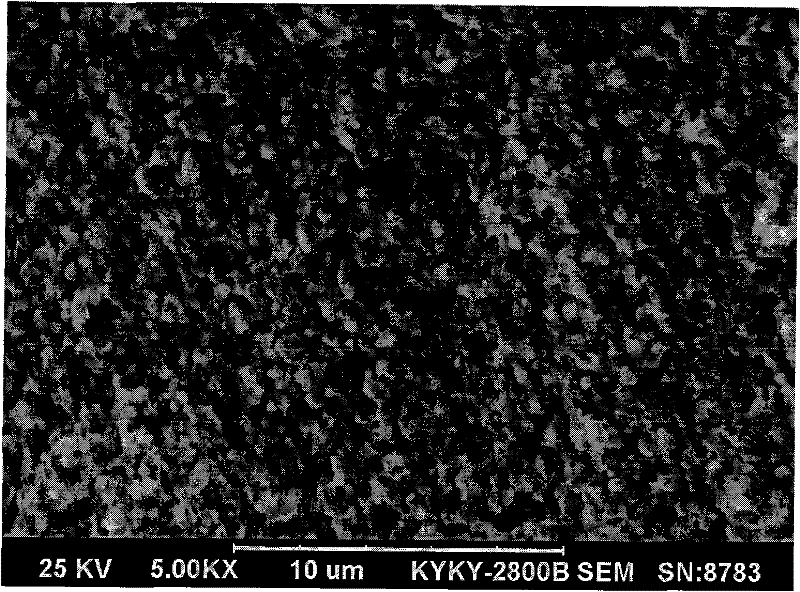

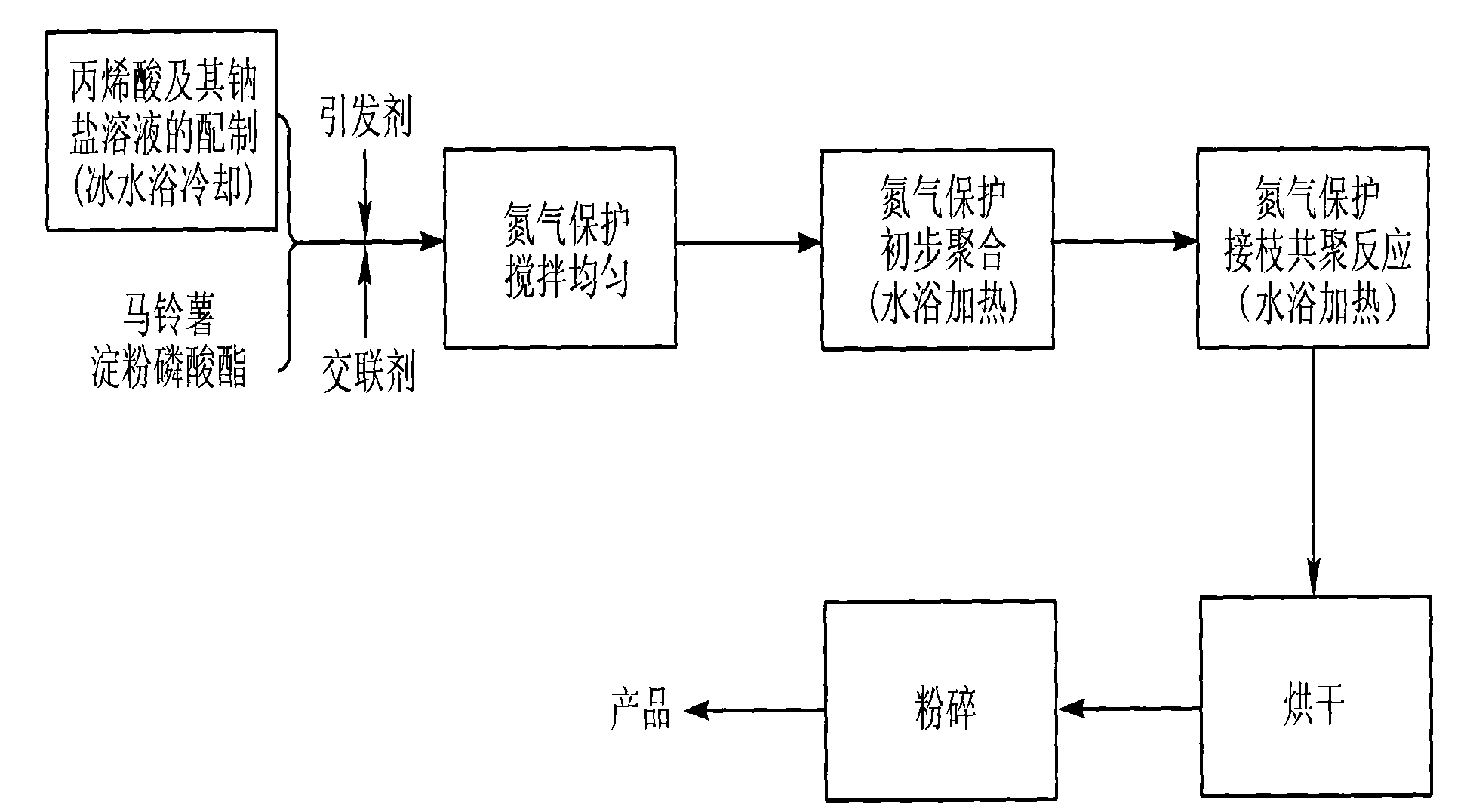

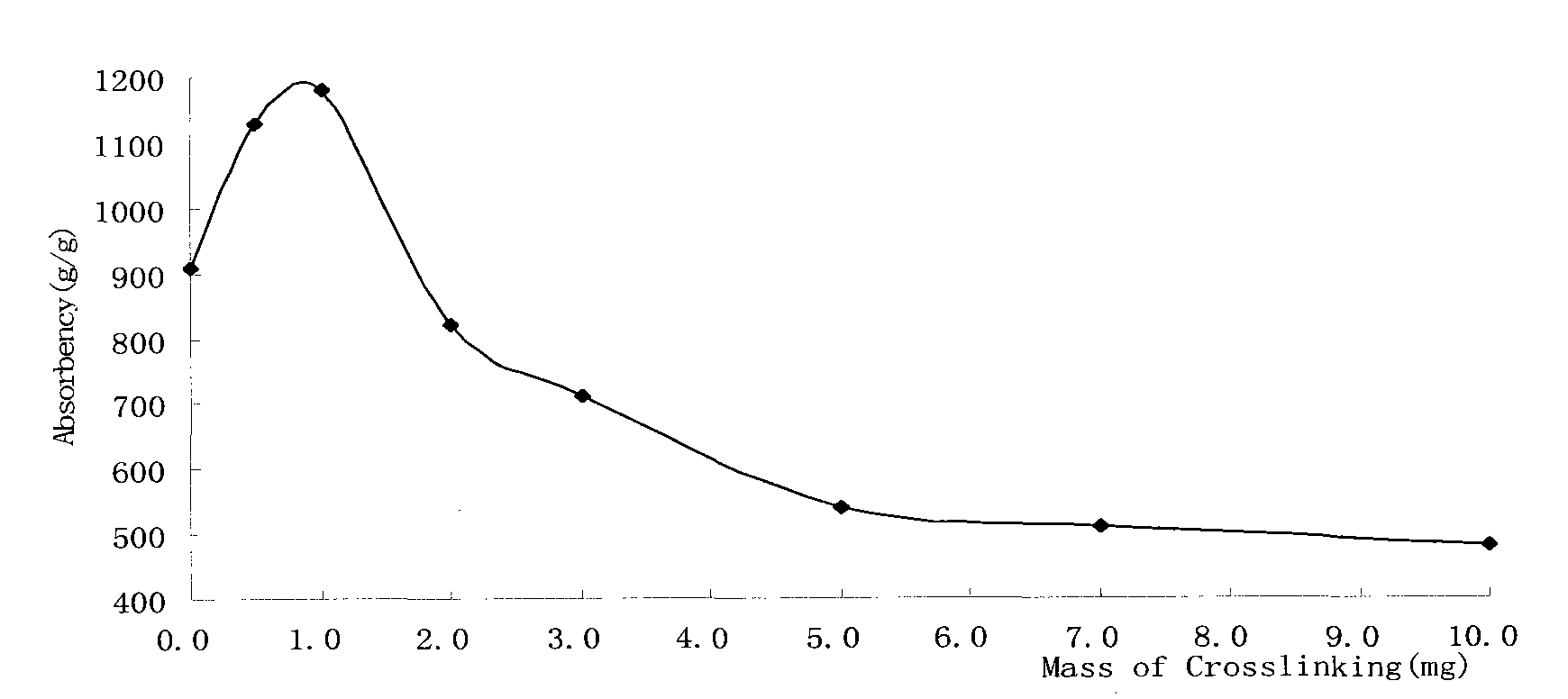

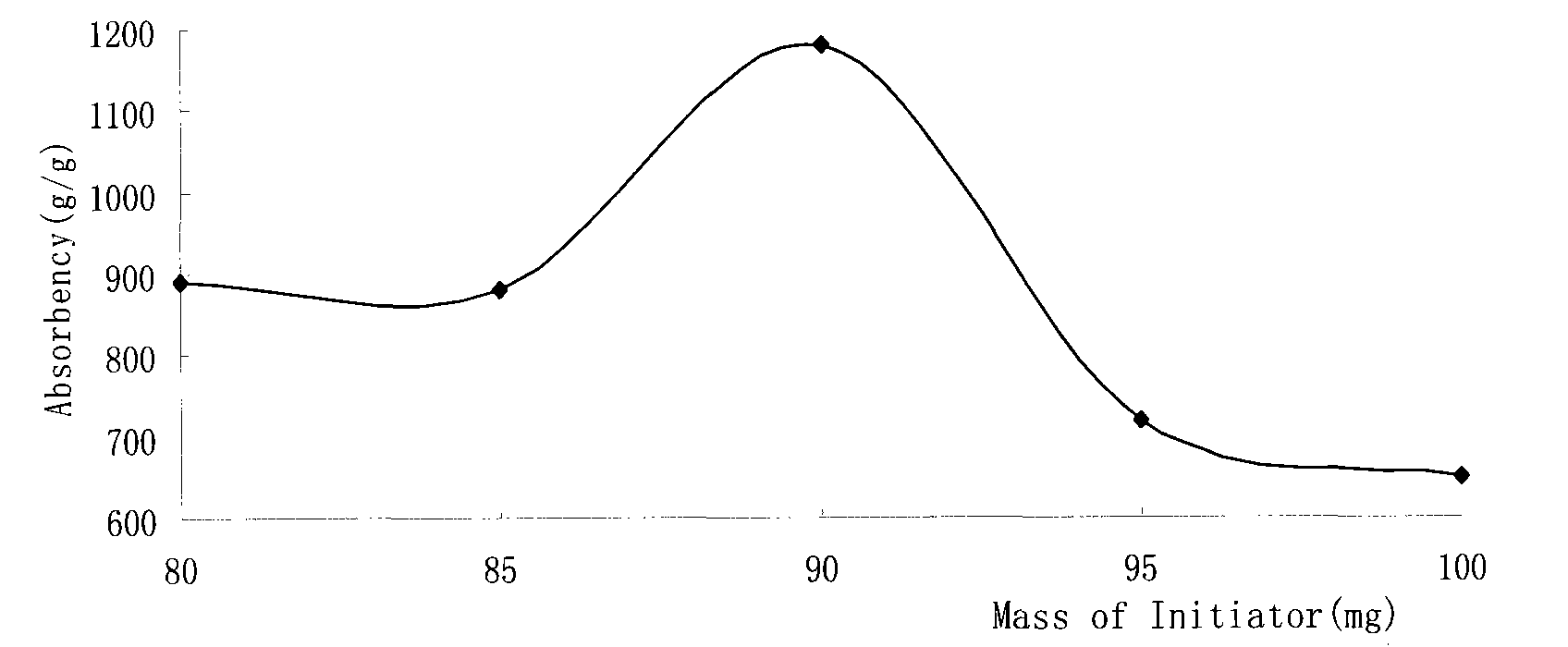

Method for preparing super absorbent resin with cross-linked structure from potato starch phosphate graft co-polymeric acrylic acid and sodium salt thereof

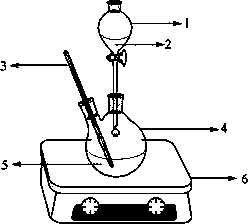

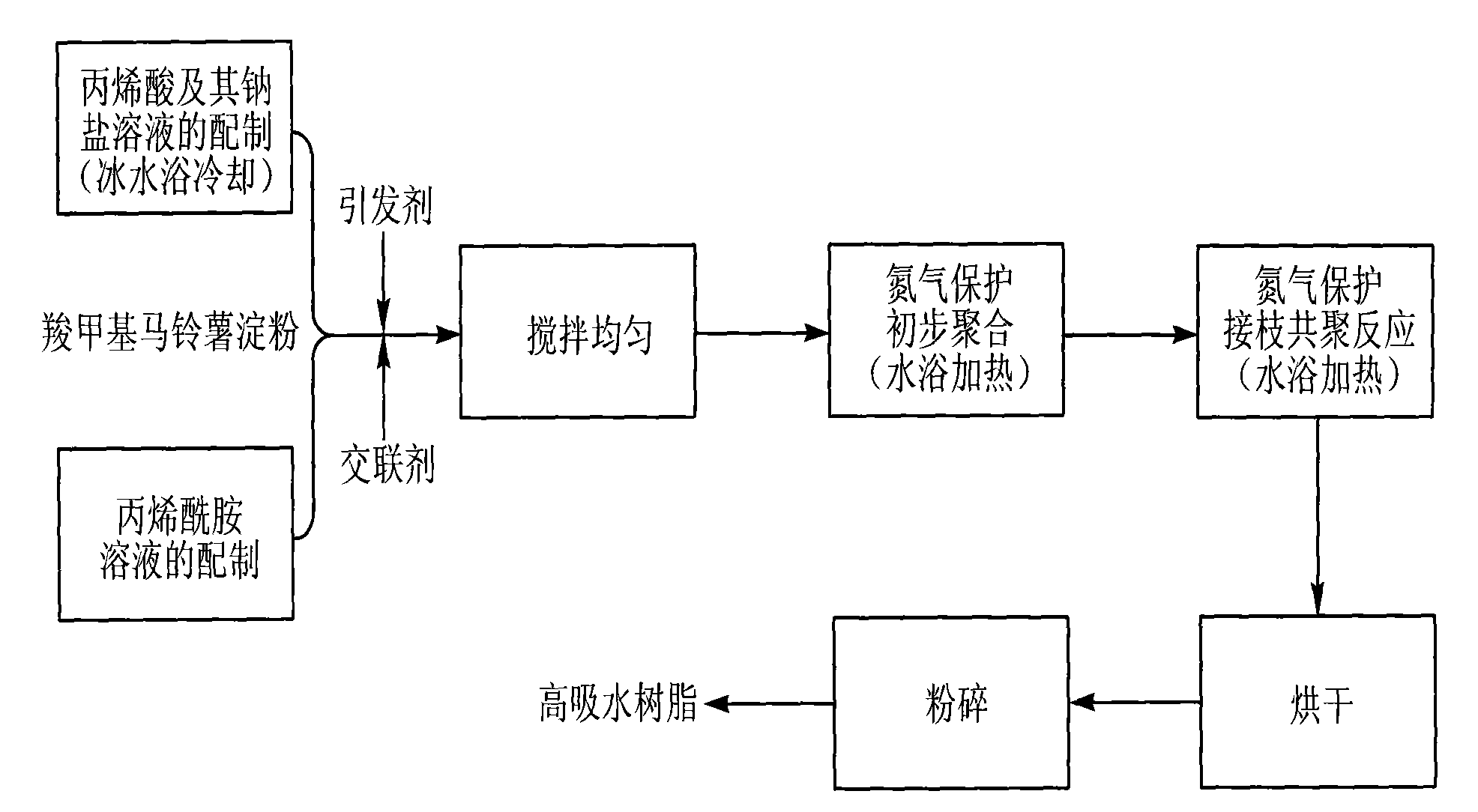

The invention discloses a method for preparing super absorbent resin with a cross-linked structure from potato starch phosphate graft co-polymeric acrylic acid and a sodium salt thereof. The method comprises the following main technological processes of: under ice water bath cooling, performing neutralization reaction between a sodium hydroxide solution and acrylic acid used for removing a polymerization inhibitor so as to prepare the acrylic acid and a sodium salt solution of the acrylic acid; mixing the prepared acrylic acid and the sodium salt solution of the acrylic acid with potato starch phosphate; adding an initiator of persulfate, a crosslinking agent of N,N'-methylene bi-acrylamide so that the mixture is mixed evenly under stirring; then under the protection of nitrogen gas, heating the mixture in a water bath and stirring the mixture so that the potato starch phosphate performs graft copolymerization with the acrylic acid and the sodium salt solution of the acrylic acid; stopping stirring after reaching a certain temperature, performing heat preservation reactions, and then stopping introducing the nitrogen gas; and taking out a product, cutting the product into small pieces, drying the small pieces in a drying oven to have constant weights, and crushing the small pieces to obtain the super absorbent resin.

Owner:INNER MONGOLIA UNIVERSITY

Preparation method of temperature-sensitive macroporous acrylamide/N-isopropyl acrylamide composite microsphere

InactiveCN102408515ALarge specific surface areaUniform and dense pore sizeOn/in organic carrierMicrosphereReaction temperature

A preparation method of temperature-sensitive macroporous acrylamide / N-isopropyl acrylamide composite microspheres adopts toluene as a pore-forming agent; a water phase obtained by mixing acrylamide, N-isopropyl acrylamide, ammonium persulfate, N,N'-methylene diacrylamide, and deionized water is allowed to react with an oil phase obtained by mixing span-60, span-80, and cyclohexane so as to prepare acrylamide / N-isopropyl acrylamide composite microspheres. The preparation method of the invention is simple, has a low reaction temperature, and the prepared acrylamide / N-isopropyl acrylamide composite microspheres have an obvious macroporous structure, a uniform and dense pore size, a relatively large specific surface area, and strong water absorbability and adsorptivity.

Owner:SHAANXI NORMAL UNIV

Method for preparing bleaching bamboo pulp cellulose water absorbing material

InactiveCN102040709AHigh liquid absorptionImprove graft copolymerization abilityPulp beating methodsPulp bleachingCelluloseFiber

The invention relates to a method for preparing a bleaching bamboo pulp cellulose water absorbing material. The method is characterized by comprising the following preparation steps of: stewing bleaching bamboo pulp by a sulfate process; carrying out subsequent four-section bleaching with oxygen delignification, chlorine dioxide, peroxide and chlorine dioxide to prepare the bleaching bamboo pulp fiber; defibrinating and pretreating the bleaching bamboo pulp fiber by a PFI beater; carrying out graft copolymerization synthesis on the defibrinated bleaching bamboo pulp fiber with an aqueous solution polymerization method, i.e. taking ammonium persulfate as initiator, and taking N-N'-bisacrylamide as a crosslinker; meanwhile, and finishing the graft copolymerization synthesis by taking crylicacid and acrylamide as the monomers; and precipitating and washing the copolymerization composite with absolute ethyl alcohol, freezing, drying, grinding, then freezing, drying, and sealing to obtainthe finished product. The water absorbing material prepared with the method has high water absorbing efficiency and can effectively develop and utilize the bleaching bamboo pulp cellulose.

Owner:KUNMING UNIV OF SCI & TECH

Inverse emulsion synthesis process of printing paint thickener

The process of synthesizing printing paint thickener includes the first adding acrylic acid solution in certain neutralization degree into kerosene containing certain amount of activator to form reverse emulsion, adding cross-linking agent N, N' -methylene bisacrylamide and / or N-hydroxymethyl acrylamide, and adding initiator redox system at low temperature to initiate reaction. The technological process has no need of removing reaction heat and reaction period of about 3 hr, and is simple and suitable for industrial production.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

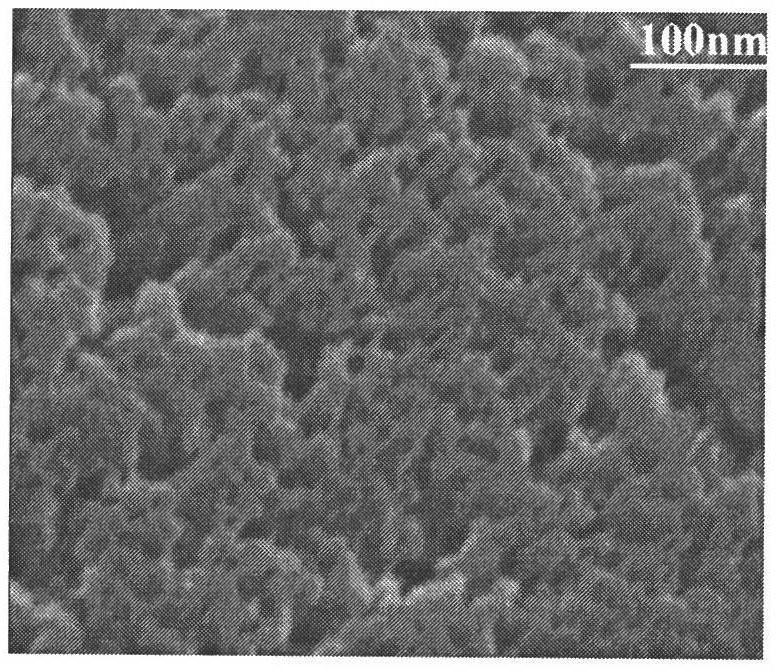

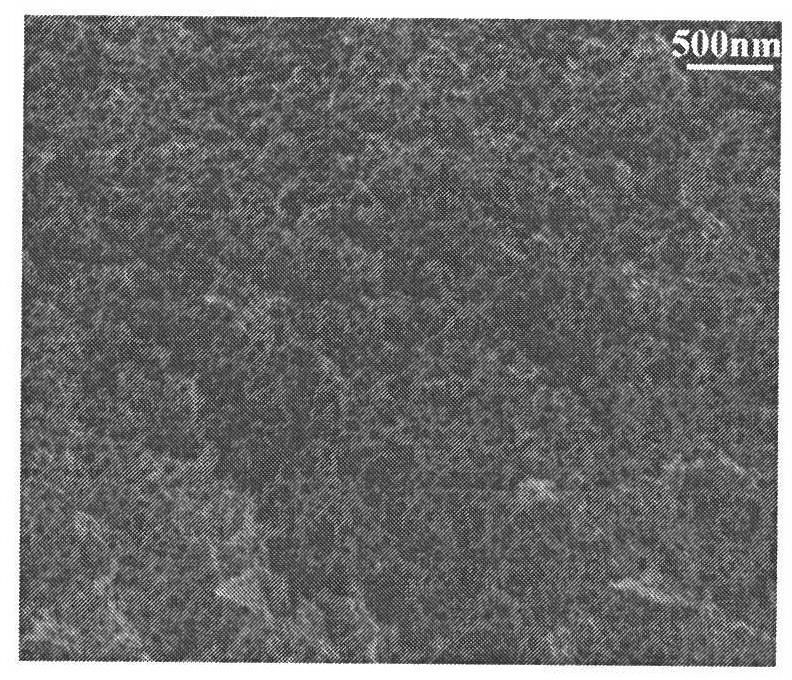

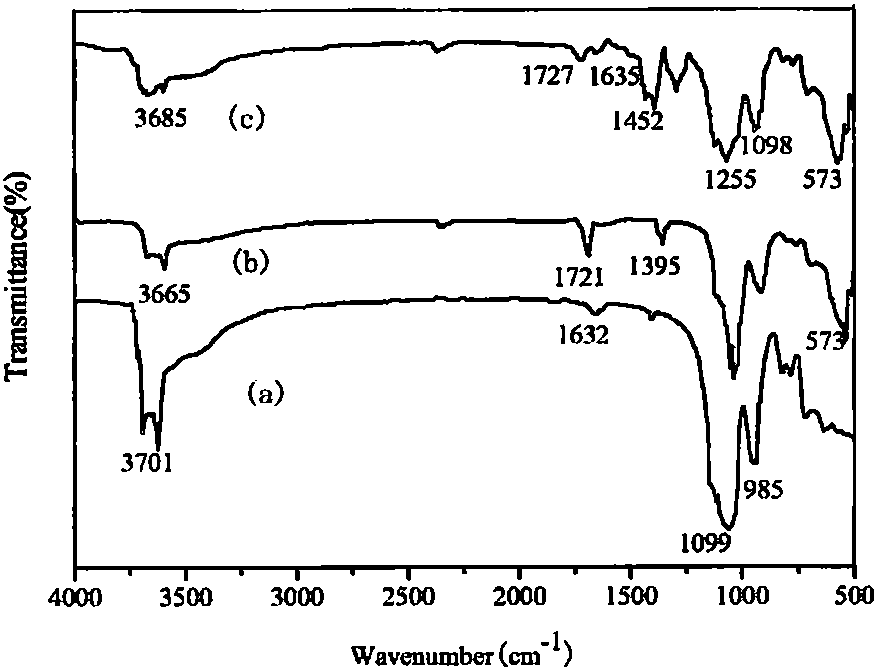

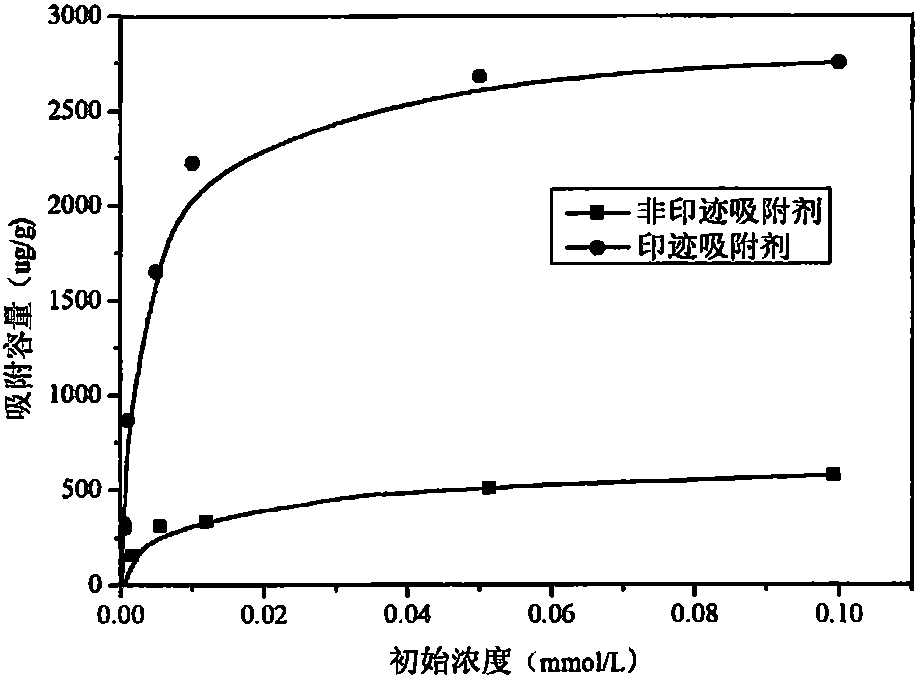

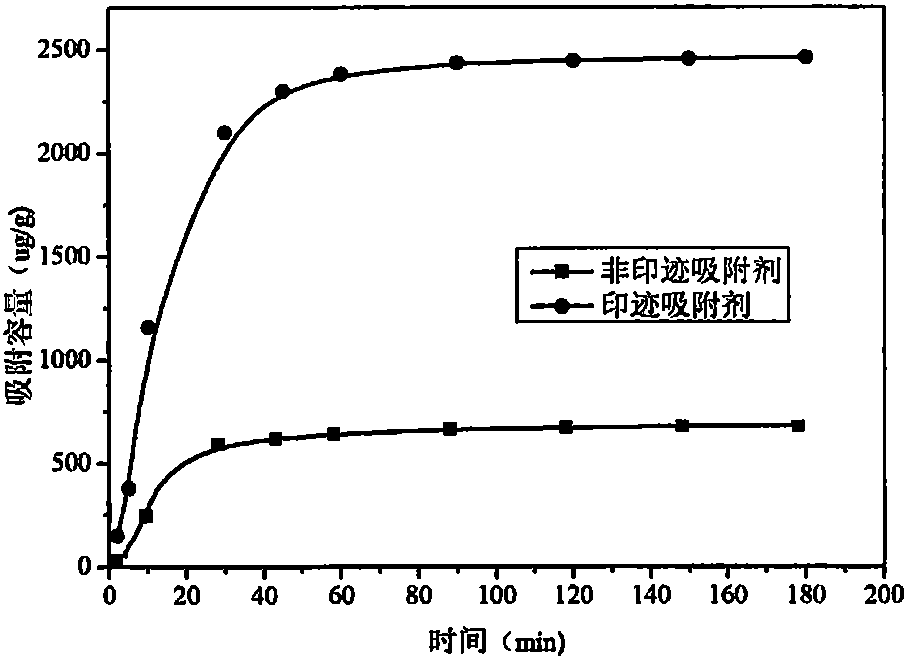

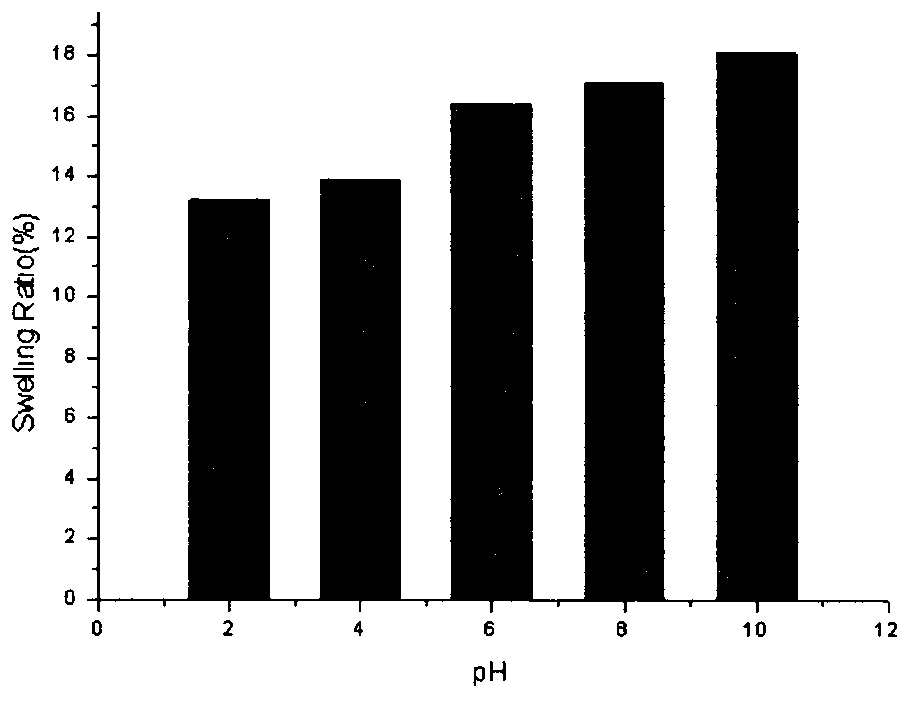

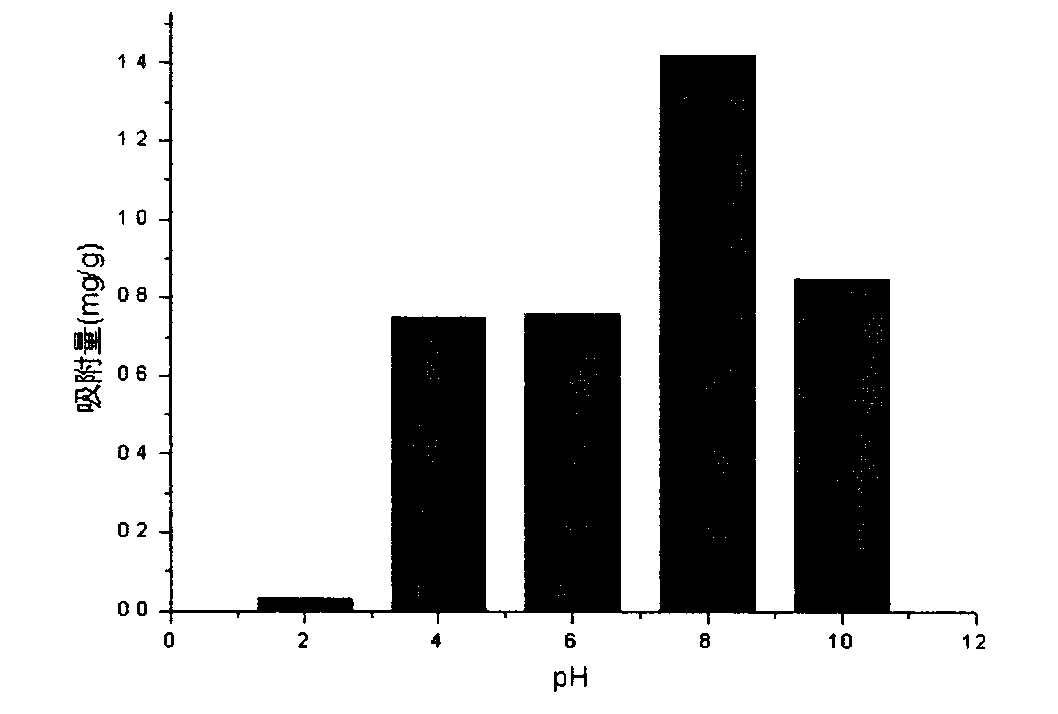

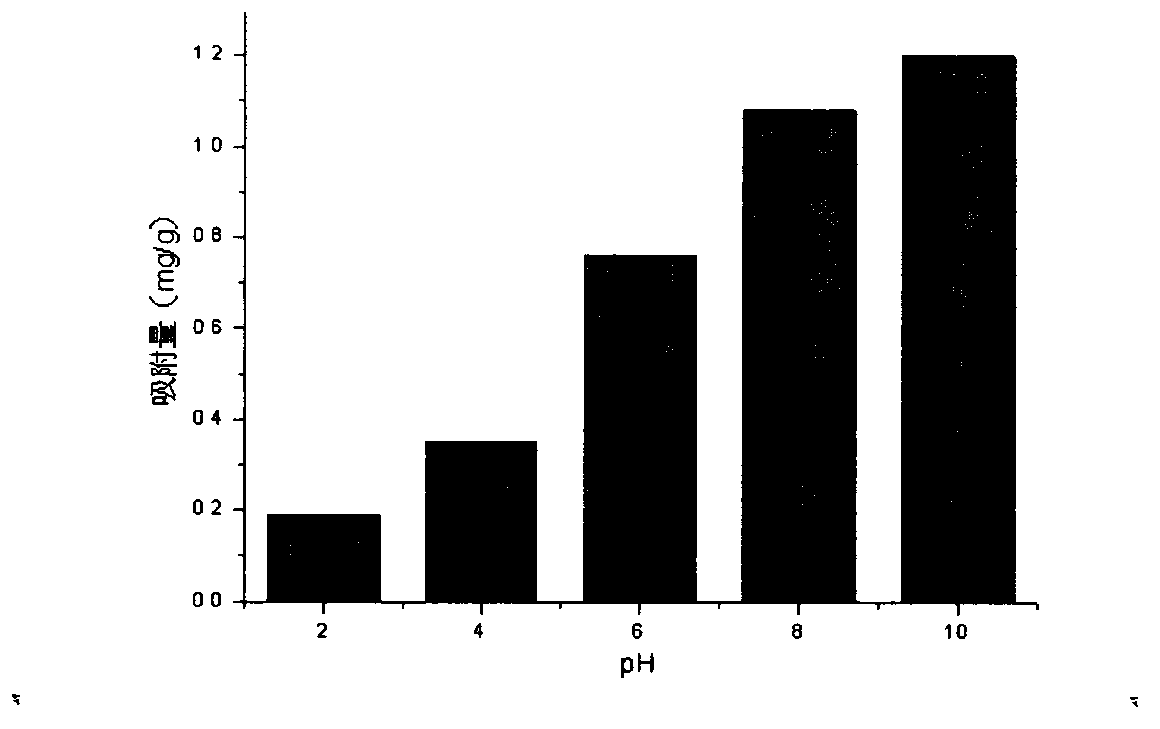

Preparation method for nafcillin molecular imprinting adsorbent

ActiveCN105056906AOther chemical processesAlkali metal oxides/hydroxidesCross-linkFunctional monomer

The invention relates to a preparation method for a nafcillin molecular imprinting adsorbent. The preparation method for the the nafcillin molecular imprinting adsorbent takes functionalized illite as a substrate, takes nafcillin as a template molecule, takes methylacrylic acid (MAA) as a functional monomer, takes N, N'-methylene bisacrylamide (MBAA) as a cross-linking agent, takes a catalyst copper chloride (CuCl2) and a ligand N, N, N', N", N"-pentamethyldiethylenetriamine (PMDETA) as a catalytic system, and takes ascorbic acid (AsAc) as a reducing agent through an atom transfer radical polymerization (AGET ATRP) process which adopts electron activation transfer to generate a catalyst; and the preparation method is used for selectively recognizing and separating nafcillin. The method is low in cost and simple in preparation, and a product has high recognition, high selectivity and high separation and enrichment capacity on a target molecule.

Owner:HENAN UNIV OF URBAN CONSTR

Pectin/acrylamide semi-interpenetrating hydrogel material

InactiveCN103319831AHigh biosecurityGood water solubilityOther chemical processesWater/sewage treatment by sorptionPotassium persulfateCross-link

The invention discloses a pectin / acrylamide semi-interpenetrating hydrogel material. The material is composed of pectin, acrylamide and the chemical cross-linking agent N,N'-methylene bisacrylamide, wherein a mass ratio of pectin to acrylamide is 17-50: 83-50, and the mass of N,N'-methylene bisacrylamide is 1.7 to 6.7% of the total mass of monomers. A preparation method for the material comprises the following steps: mixing and dissolving pectin, acrylamide and N,N'-methylene bisacrylamide; and allowing acrylamide to undergo crosslinking and copolymerization under the action of N,N,N',N'-tetramethyl diethylamine and potassium persulfate so as to form a pectin / acrylamide semi-interpenetrating hydrogel. The method has the advantages of simple process, low cost, convenience in industrial popularization and application, etc. The pectin / acrylamide semi-interpenetrating hydrogel has the advantages of good biosecurity, degradability, good mechanical strength, a high swelling rate, pH-sensitivity and capacity of adsorbing harmful chemical substances like dye and metal ions, so the pectin / acrylamide semi-interpenetrating hydrogel can be used for adsorption separation of chemical substances and sewage treatment.

Owner:TIANJIN POLYTECHNIC UNIV

Technique for producing alumina foamed ceramic by gelcasting

The invention provides a technique for producing alumina foamed ceramic by gelcasting, relating to a production method of alumina foamed ceramic for refining and filtering aluminum alloy, copper alloy and high-temperature molten steel. The technique comprises the following steps: heating a polyurethane foam sodium hydroxide water solution, washing with water until no alkaline liquor is residual, and drying; mixing powder alumina, monomer acrylamide, initiator ammonium persulfate, cross-linking agent N,N'-methylene-bis-acrylamide and toughener zirconium dioxide with water; immersing the dried polyurethane foam in the slurry, and carrying out slurry dipping and extrusion repeatedly, thereby obtaining the biscuit; putting the biscuit in a drying oven, and carrying out polymerization reaction on the monomer to obtain a gelcasting body; and putting the gelcasting body in a high-temperature furnace, and naturally cooling to obtain the product. The invention has the advantages of no need of any dispersant for preparing the slurry, simple formation equipment, low cost and the like, and can form complicated shapes; and in particular, the net dimension stability of the product is high, thereby greatly reducing the probability of biscuit cracking due to dimension shrinkage in the normal-temperature drying period and the early sintering period.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for synthesizing selective adsorption film material of ofloxacin

InactiveCN102350320AHigh selectivityShort polymerization timeOther chemical processesAlkali metal oxides/hydroxidesFunctional monomerSorbent

The invention relates to a method for synthesizing a selective adsorption film material of ofloxacin, which is mainly and technically characterized in that the ofloxacin is used as a template molecule, acrylamide and methyl methacrylate are used as functional monomers, N,N'-methylene bisacrylamide is used as a crosslinking agent, and an ammonium persulphate solution and tetramethyl ethylene diamine are used as initiating agents so as to synthesize an adsorption film material with high selectivity to the ofloxacin. According to the method for synthesizing the selective adsorption film material of the ofloxacin, the process is scientific, the cost is low, the operation is simple and quick, and the reaction condition is easy to control. The polymer film material used as an adsorbent can be selectively used for enriching a trace ofloxacin medicine in animal foods.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Method for preparing super absorbent resin with cross-linked structure by using potato starch as raw material

Owner:CHIFENG TIANZE BIO TECH

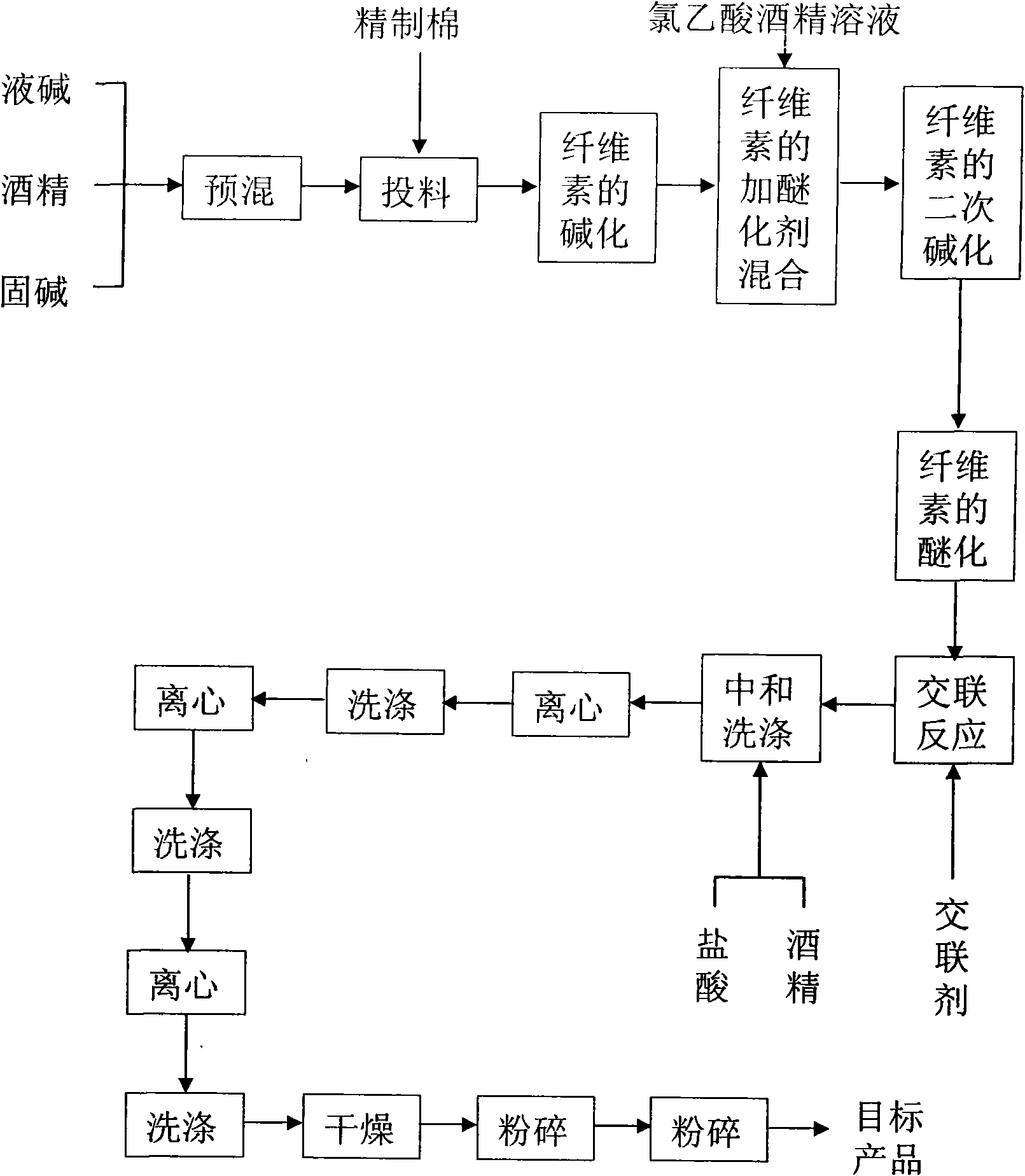

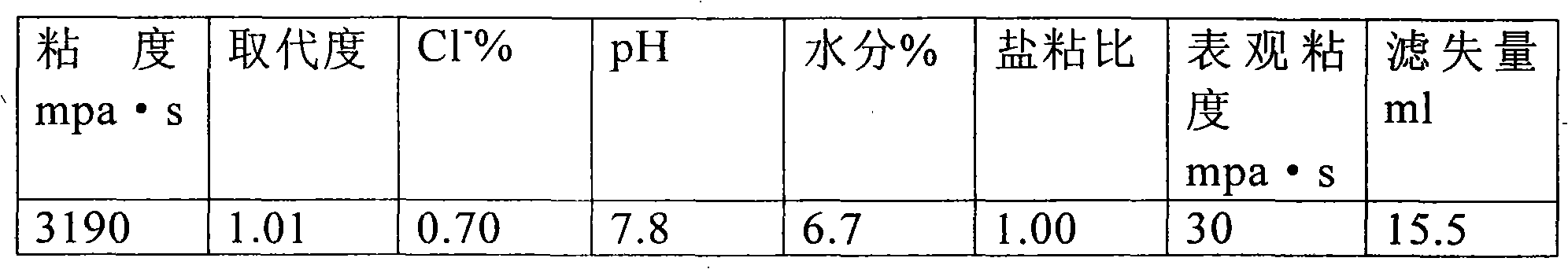

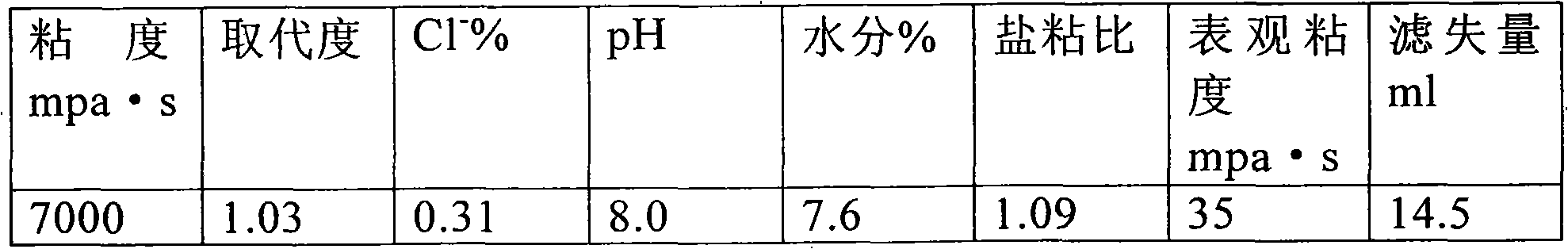

Method for preparing high viscosity polyanionic cellulose

The invention discloses a method for preparing high viscosity polyanionic cellulose, comprising the following steps with refined cotton as the cellulose raw material of alkalizing cellulose, mixing cellulose by adding an etherifying agent, etherifying cellulose, neutralizing and washing, and performing post treatment of the product; and the preparation method further comprises the step of crosslinking reaction which is performed between the step of etherifying cellulose and the step of neutralizing and washing by adding a crosslinking agent N,N'-methylene-bis-acrylamide into polyanionic cellulose to perform crosslinking reaction. The invention is a solution to the problem that the polyanionic cellulose obtained by the traditional method for preparing high viscosity polyanionic cellulose has low viscosity, poor salt tolerance and high filtration loss.

Owner:上海长光企业发展有限公司

Method for preparing resin type water-retaining preparation

InactiveCN1279075CAvoid destructionLow reaction temperatureOrganic fertilisersSoil conditioning compositionsPotassium persulfatePotassium hydroxide

The invention discloses a preparation method of a resin-type water-retaining agent. Starch, acrylic acid and acrylamide are used as raw materials, a redox system formed by potassium persulfate-sodium bisulfite is used as an initiator, and N, N'-methylene The specific steps are as follows: 1) first gelatinize the starch in the reactor, then neutralize the acrylic acid with potassium hydroxide, cool to room temperature and pour it together with the acrylamide aqueous solution Put into the reactor and mix with the starch after gelatinization; 2) add initiator, cross-linking agent, in N 2 Stirring at a constant temperature under protection until the end of the polymerization reaction; 3) adjusting the pH to neutral with lye, and washing, filtering, drying and pulverizing the grafted product to obtain a white granular resin product. The water-retaining agent obtained by the invention has fast water absorption rate and high water absorption rate, and replaces traditional sodium hydroxide with potassium hydroxide, which can prevent excessive sodium ions from destroying soil structure in agricultural applications, and can provide potassium fertilizer for crops at the same time.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

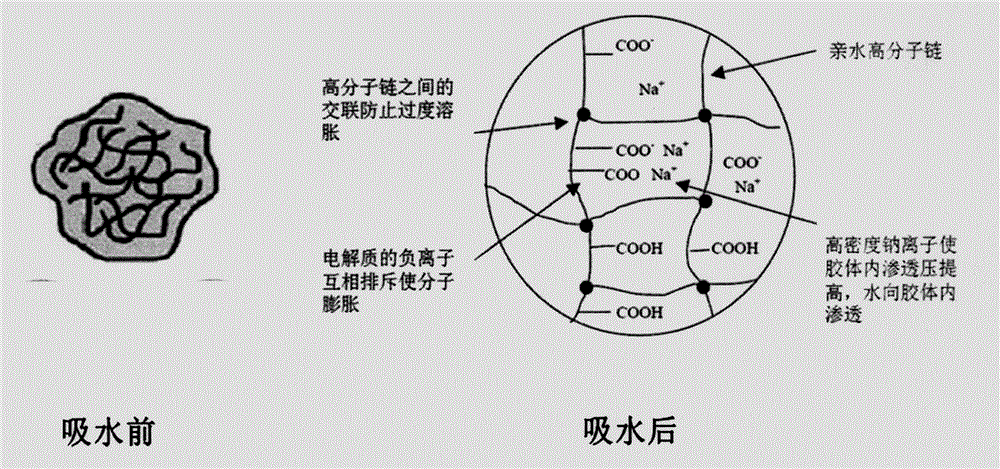

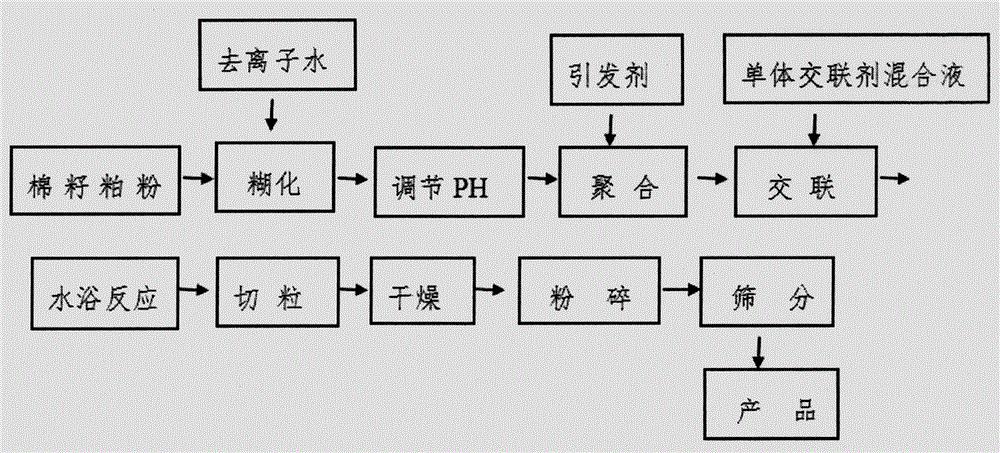

Method for synthesizing high-molecular water-absorbent resin from cottonseed byproduct

The invention discloses a method for synthesizing high-molecular water-absorbent resin from a cottonseed byproduct. The method comprises the following steps: slowly adding a sodium hydroxide solution to an aqueous acrylic acid solution in a dropwise manner at room temperature until the neutralization value is 75%, cooling the neutralized solution, and adding a cross-linking agent N-N'-methylenebisacrylamide to obtain a monomer and cross-linking agent mixed solution; adding distilled water to cottonseed meal, stirring the distilled water and the cottonseed meal in constant-temperature water bath to gelatinize the cottonseed meal, adjusting the above obtained mixed solution to be alkaline by using the sodium hydroxide solution, introducing nitrogen, adding an initiator potassium persulfate, stirring, adding the prepared monomer and cross-linking agent mixed solution, continuously stirring until the obtained reaction mixed solution is thickened, immediately pouring the reaction mixed solution to a pallet, and carrying out a reaction in the constant-temperature water bath to obtain polymer gel; and taking out the polymer gel, cutting the polymer gel, carrying out vacuum drying, crushing the dried polymer gel, screening the crushed polymer gel, and packaging the screened polymer gel to obtain the target product. The product has the advantages of strong water absorption effect, small volume expansion, excellent compressive strength, good heat stability, slow degradation speed and harmlessness to crops, and is especially suitable for oilfield and the agriculture.

Owner:山东中商研高分子材料有限公司

Method for improving adsorption selectivity of sodium polyacrylat oil dewatering material

InactiveCN103382235AHigh adsorption rateEfficient dehydrationOther chemical processesAlkali metal oxides/hydroxidesPotassium persulfateCross-link

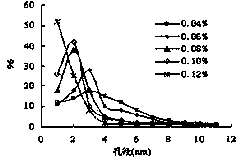

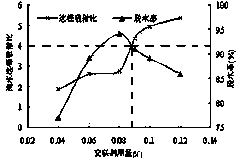

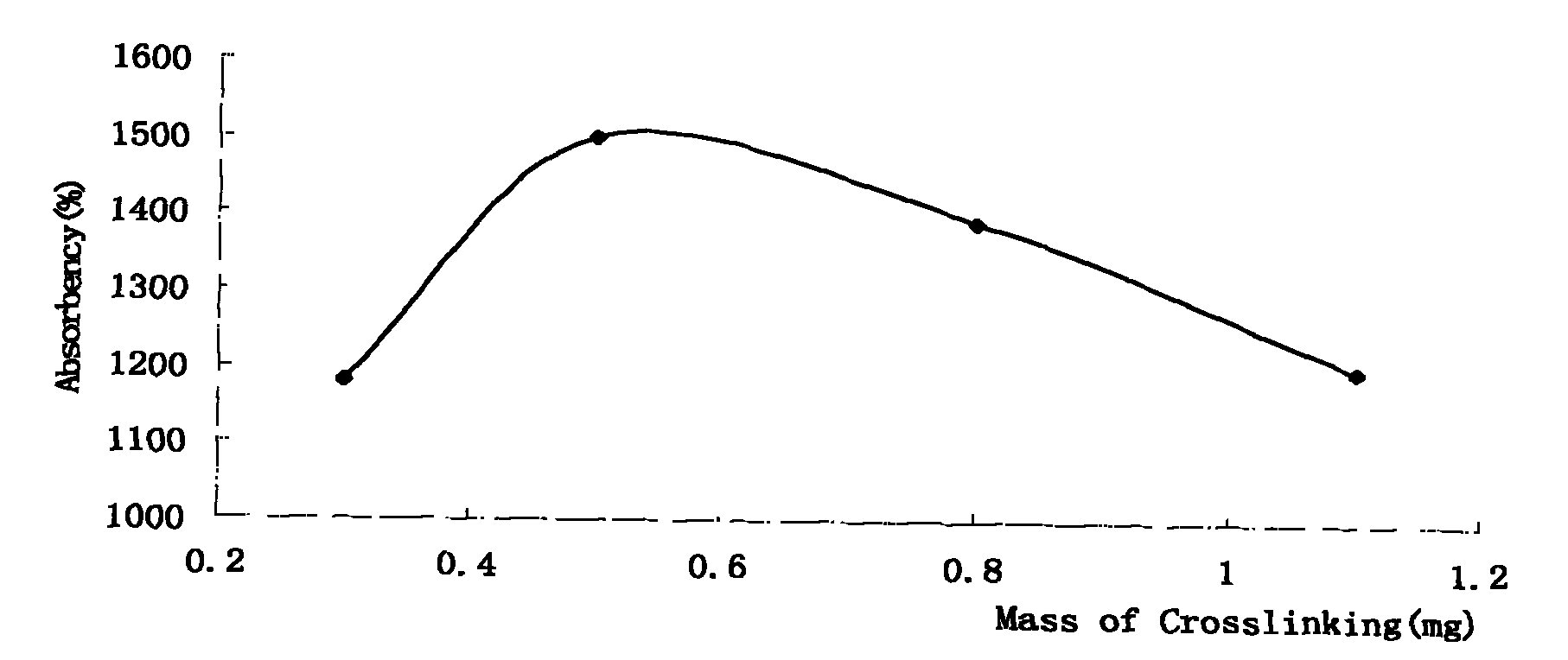

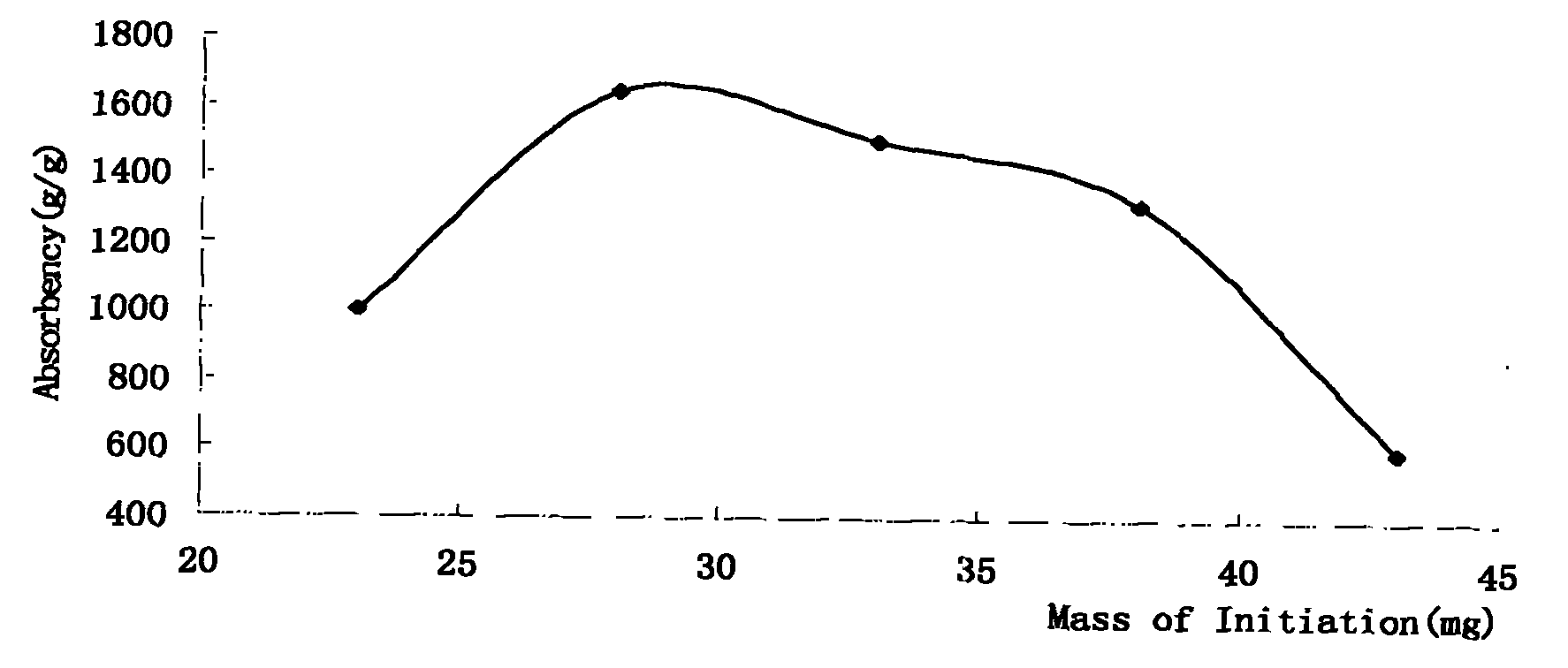

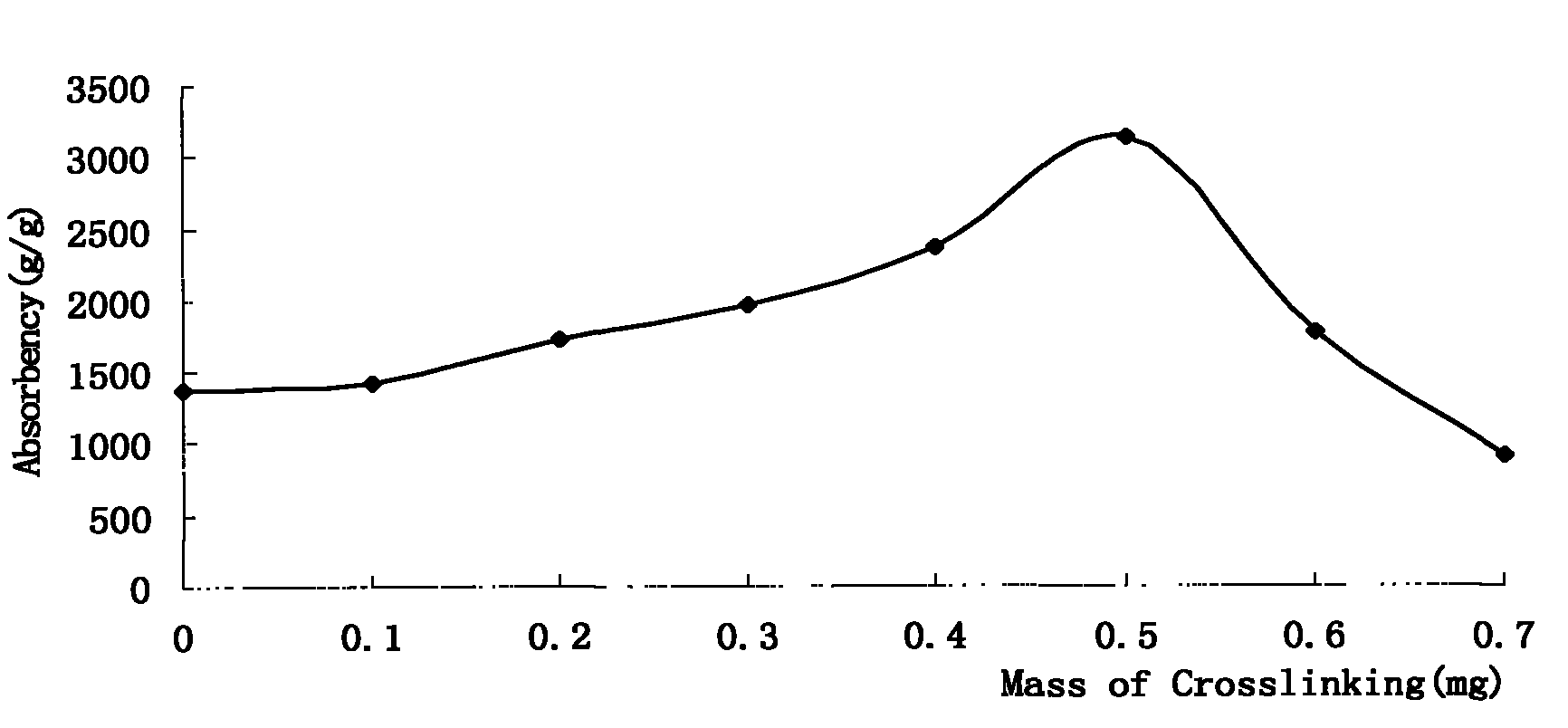

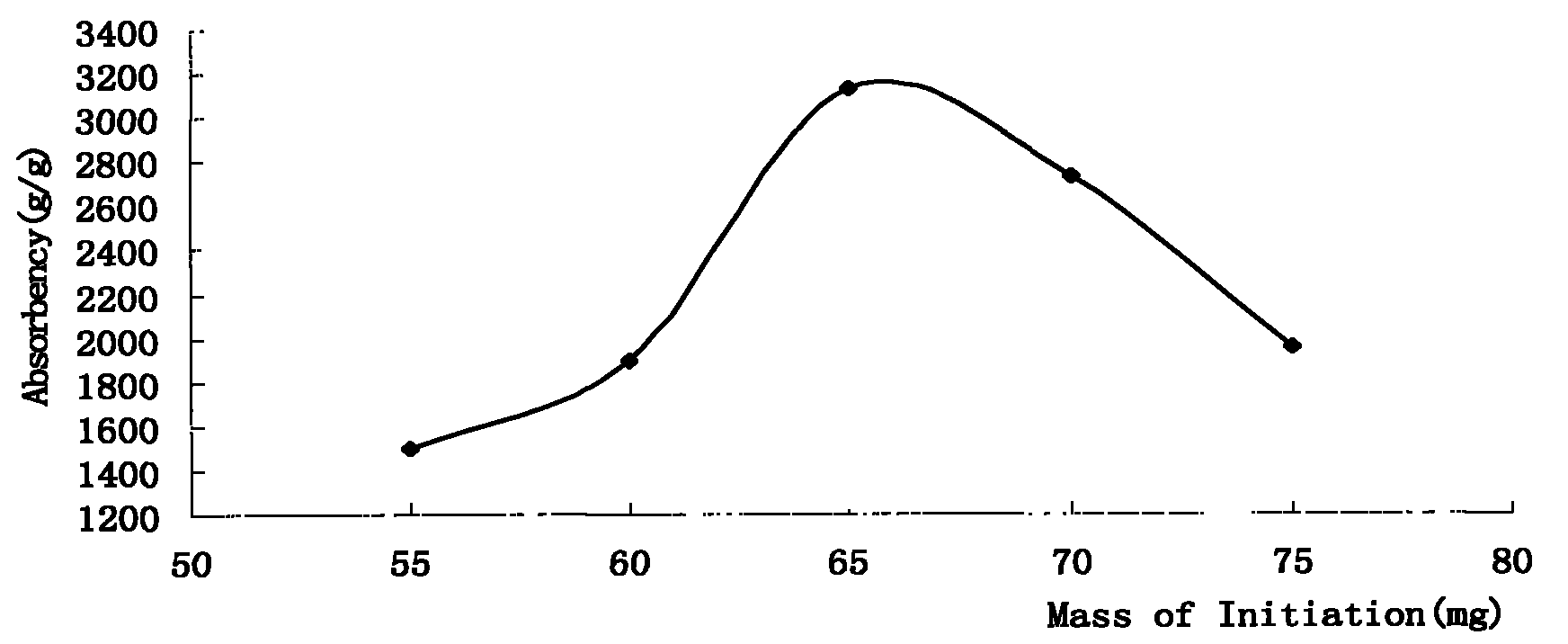

The invention belongs to a method for improving oil-water adsorption selectivity of an oil adsorbing separating purifying dewatering material sodium polyacrylat. The method mainly consists of the following steps: (1) taking N, N'-Methylenebisacrylamide as a cross-linking agent, potassium persulphate as an initiator and cyclohexane as a continuous phase, adjusting the amount of the cross-linking agent, and employing inverse suspension polymerization to prepare a series of sodium polyacrylat dewatering resin materials; (2) respectively determining dewatering performance and oil-water adsorption selectivity of a series of the sodium polyacrylat dewatering resin materials; and (3) according to the performance data of a series of the sodium polyacrylat dewatering resin materials, drafting a curve map to determine optimum balance control amount of the cross-linking agent, and adopting the optimum balance control amount of the cross-linking agent to prepare an adsorptive resin material with high dewatering performance and high adsorption selectivity.

Owner:CHONGQING TECH & BUSINESS UNIV

Preparation method of high-strength nano-composite hydrogel with rapid dual responses of pH and temperature

The invention relates to a preparation method of high-strength nano-composite hydrogel capable of rapidly responding to pH and temperature. The preparation method taking dimethylaminoethyl methacrylate as a monomer, inorganic nanometer clay and N,N'-methylenebisacrylamide as co-crosslinking agents, and a nanometer cellulose whisker as a gel composite reinforcer comprises the following steps of: stirring the components, carrying out uniform ultrasonic oscillation, carrying out photo-initiation free radical polymerization in 0 DEG C ice-bath, then reacting at -18 DEG C for 24 hours to obtain the final gel product. The hydrogel prepared by the method has the dual responses of temperature and pH and excellent mechanical performance and can rapidly swell and deswell; and the lowest transformation temperature of the hydrogel is close to temperature of human bodies; raw materials are cheap; the preparation method is simple; and the high-strength nano-composite hydrogel has the potential of application in fields such as sustained release of medicines and tissue engineering.

Owner:HUNAN UNIV OF TECH

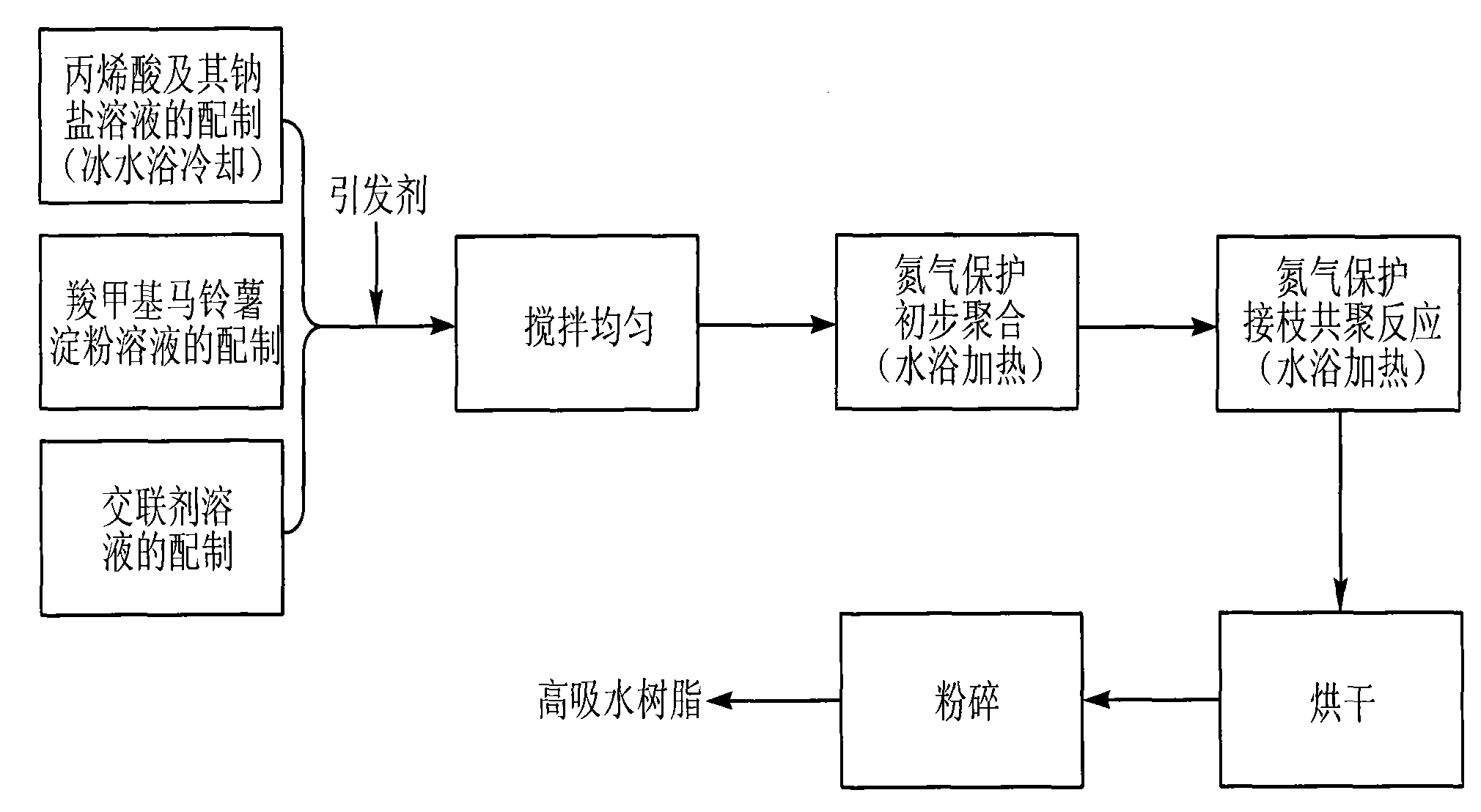

Method for preparing super absorbent resin by graft copolymerization reaction of carboxymethyl potato starch, acrylamide, acrylic acid and sodium salt thereof

The invention discloses a method for preparing super absorbent resin by the graft copolymerization reaction of carboxymethyl potato starch, acrylamide, acrylic acid and sodium salt thereof, which comprises the following main processes: carrying out neutralization reaction between a sodium hydroxide solution and acrylic acid from which polymerization inhibitor is removed under the cooling of ice-water bath; mixing acrylamide with de-ionized water to obtain an acrylamide solution; mixing the carboxymethyl potato starch with the prepared acrylic acid and the sodium salt solution and the acrylamide solution; adding an evocating agent persulfate and a cross-linking agent N,N'- methylene-bisacrylamide; stirring the mixture under room temperature; heating the mixture by water bath to rise the temperature so as to ensure that the carboxymethyl potato starch, the acrylic acid and the sodium salt thereof and the acrylamide generate graft copolymerization reaction under the protection of nitrogen; keeping the temperature of the reaction; drying and crashing to obtain the super absorbent resin with high potassium content by using carboxymethyl potato starch as the raw material. Compared with the similar products, the water absorption of the super absorbent resin is greatly enhanced; the super absorbent resin contains nitrogen nutrition element, does not need pasting in comparison with theprocess of directly using starch and greatly improves the preparation process. The super absorbent resin has great effect on the water conservation, the desert control, the plant growth promotion andthe like of soil in dry regions.

Owner:内蒙古永业生物技术有限责任公司

Crosslinked cationic polyacrylamide microgranule flocculant containing polyxyethylene branched chain

InactiveCN1179892CHas anti-aging degradation propertiesReduced settling timeSedimentation separationWater/sewage treatment by flocculation/precipitationEthylenediamineMicroparticle

The present invention relates to a polyacrylamide microgranular flocculent containing polyoxyethylene branched chain crosslinked cation. It is a transparent or semitransparent microlatex whose average grain size is 40-90 nm, dispersion coefficient is 0.50-0.70 and 0.1% aqueous solution viscosity is 1.2-2.0 mPa.s, and is obtained by using acrylamide, (methyl) acryloyloxyethyltrimethyl ammonium chloride, acryloyl terminal polyoxyethylene macromonomer and N,N'-methylene diacrylamide through reversed phase microemulsion four-component copolymerization preparation process. Said invention utilizes the addition of EDTA chelating agent and water-soluble azo after accelerating agent to raise monomer conversion rate and obviously raise flocculeting effect.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing temperature stimuli responsive intelligent chromatographic column

InactiveCN101869828BLow priceUniform structureOther chemical processesPolyethylene glycolHigh pressure

The invention discloses a method for preparing a temperature stimuli responsive intelligent chromatographic column, which comprises the following steps of: A, uniformly mixing N-Isopropyl acrylamide, N,N'-methylene-bis-acrylamide, polyethylene glycol-20,000, 10 percent w / v ammonium persulfate and deionized water by using ultrasonic waves; B, deoxidizing reaction products in the step A, adding 10 percent v / v N,N,N',N'-tetramethyl ethylene diamine, and uniformly mixing fully; and C, pouring reaction products in the step B into a stainless steel chromatographic column tube, performing reaction at the temperature of between -18 and 60 DEG C for 10 to 100 hours, arranging chromatographic column heads at two ends of the column tube, connecting the column tube to a high pressure pump, and washing the chromatographic column body by using ultrapure water as a mobile phase. The method has the advantage of simple process; the prepared monolithic column has good pore structure, high mechanical strength and high column efficiency; during use, the water is taken as the mobile phase, so the waste and pollution caused by using a large quantity of organic solvent can be avoided; and in the separation process, the action force between reagents and the monolithic column can be controlled only by changing temperature, so the separation is simple and feasible, and the separation effect is good.

Owner:HEBEI UNIVERSITY

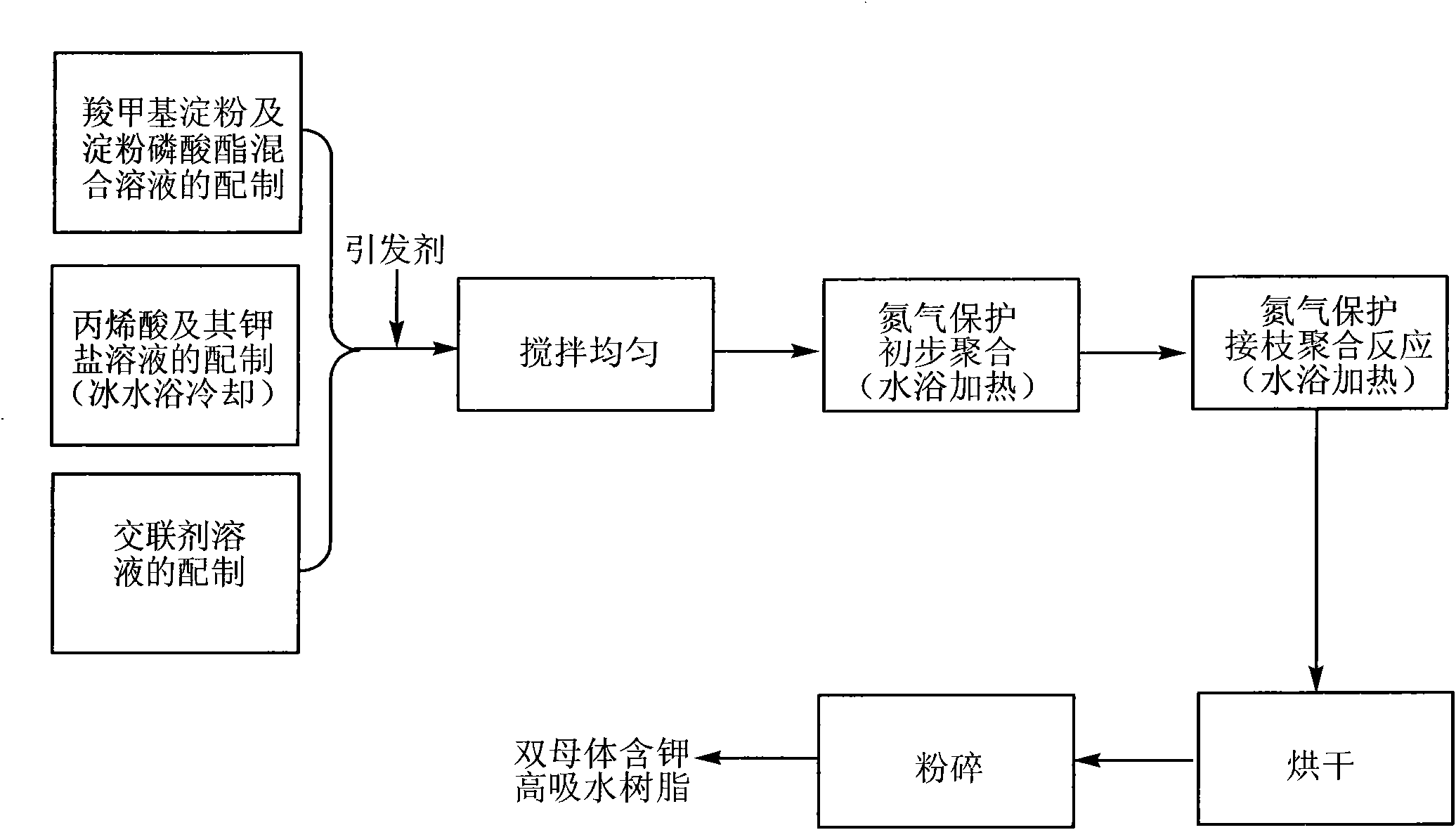

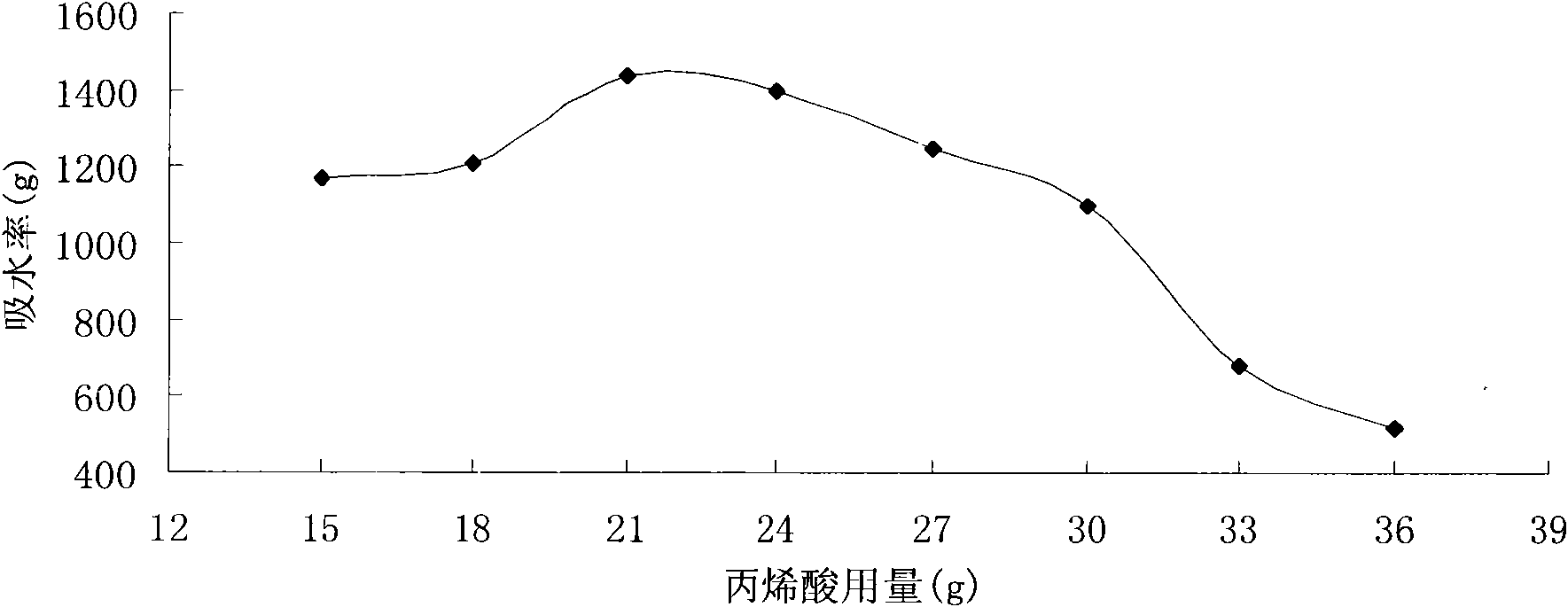

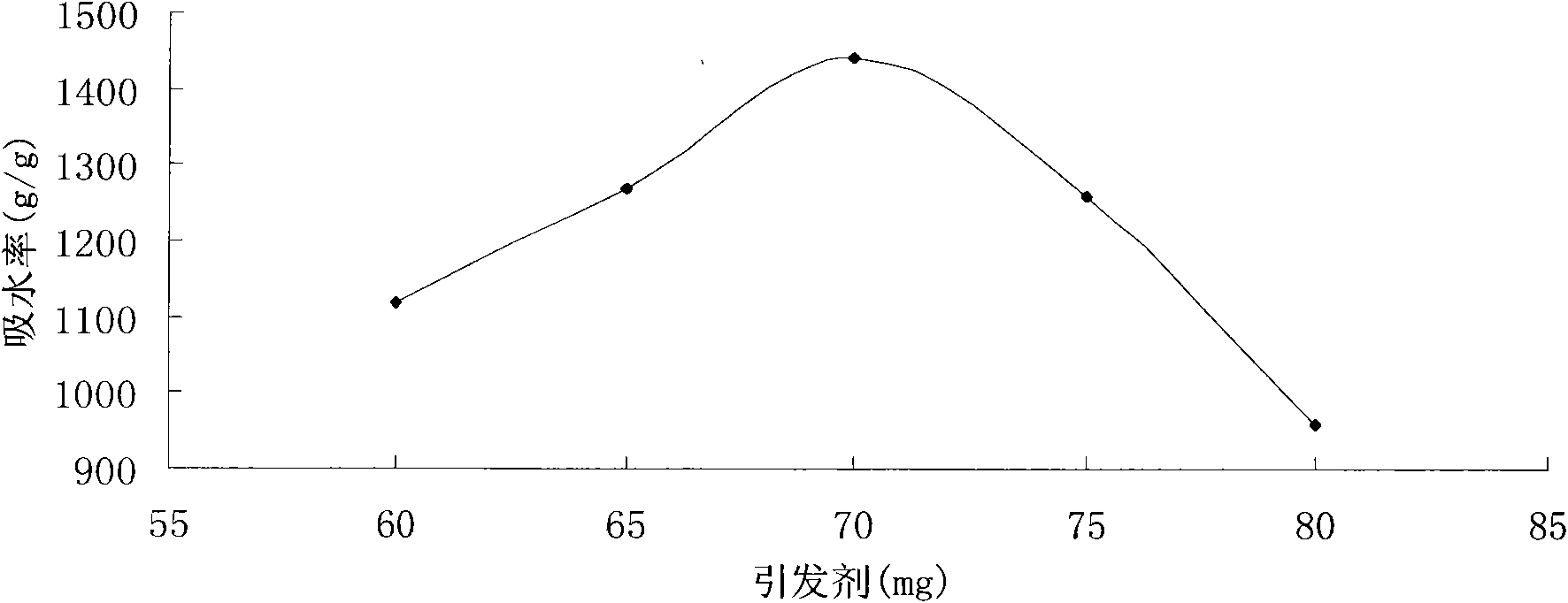

Method for preparing double-parent potassium-containing super absorbent resin from carboxymethyl starch and starch phosphate serving as raw materials

The invention discloses a method for a double-parent potassium-containing super absorbent resin. The method mainly comprises the following process steps of: under the cooling action of an ice-water bath, performing a neutralization reaction on solution of potassium hydroxide and acrylic acid from which a polymerization inhibitor is removed; mixing carboxymethyl starch, starch phosphate and deionized water; adding the acrylic acid and sylvite solution thereof, potassium persulfate serving as an initiator and solution of N,N'-methylene bisacrylamide serving as a cross-linking agent; stirring under the protection of nitrogen gas and heating in a water bath so as to perform graft polymerization on the carboxymethyl starch, the starch phosphate, the acrylic acid and sylvite thereof; and reacting while preserving heat, drying and grinding so as to obtain the double-parent potassium-containing super absorbent resin taking the carboxymethyl starch and the starch phosphate as raw materials. The super absorbent resin prepared by the method has high water absorption, contains nutrient elements such as potassium and phosphorus and has wide application prospect in the aspects of water conservation of soil, desertification control, promotion of plant growth and the like.

Owner:INNER MONGOLIA UNIVERSITY

High-strength insulation material for communication cables

InactiveCN109181128AHigh mechanical strengthReduce manufacturing costPlastic/resin/waxes insulatorsSodium bicarbonateSodium stearate

The invention belongs to the technical field of a composite material used for a communication product, and especially relates to a high-strength insulating material for communication cables. The high-strength insulating material comprises the following component in parts by weight: 60-70 parts of chlorinated polyethylene rubber; 4-7 parts of sodium stearate; 20-28 parts of cellulose fiber; 9-12 parts of sodium bicarbonate; 15-18 parts of polyethylene terephthalate; 6-9 parts of sodium dodecylbenzene sulfonate; 4-6 parts of N-N'-methylenebisacrylamide; and 10-14 parts of benzoate. The modifiedcellulose fiber with low cost is used as a reinforcing material, which greatly reduces the production cost, and the material has high mechanical strength, and can be widely used.

Owner:南京途酷信息科技有限公司

Surface patterning high-strength and high-toughness hybrid hydrogel membrane and preparation method thereof

With the continuous development of tissue engineering, a surface patterning technology is concerned by people more and more and widely applied; and a micro-patterning technology is already used for accurately controlling the position and form of a cell and the co-culture of multiple cells, but a micro-pattern is more difficult to be directly constructed on the surface of hydrogel with good biocompatibility. The high-elasticity and high-toughness patterning hydrogel membrane is prepared on a patterning silicon slice base body by taking sodium alginate as a high-molecular framework, acrylamide and a derivative thereof as polymerization monomers, divinylbenzene, N,N'-methylene bisacrylamide or ethylene glycol dimethacrylate as chemical cross-linking agents and a metal salt water solution as an ionic cross-linking agent and adding inorganic nanoparticles as strengthening agents. The preparation method disclosed by the invention has the advantages of good controllability, simple process, low cost, good material biocompatibility, and the like; and the patterning hydrogel membrane disclosed by the invention is hopeful to be applied to the fields of stem cell culture, tissue regeneration, and the like.

Owner:嘉兴智德睿控新能源有限公司

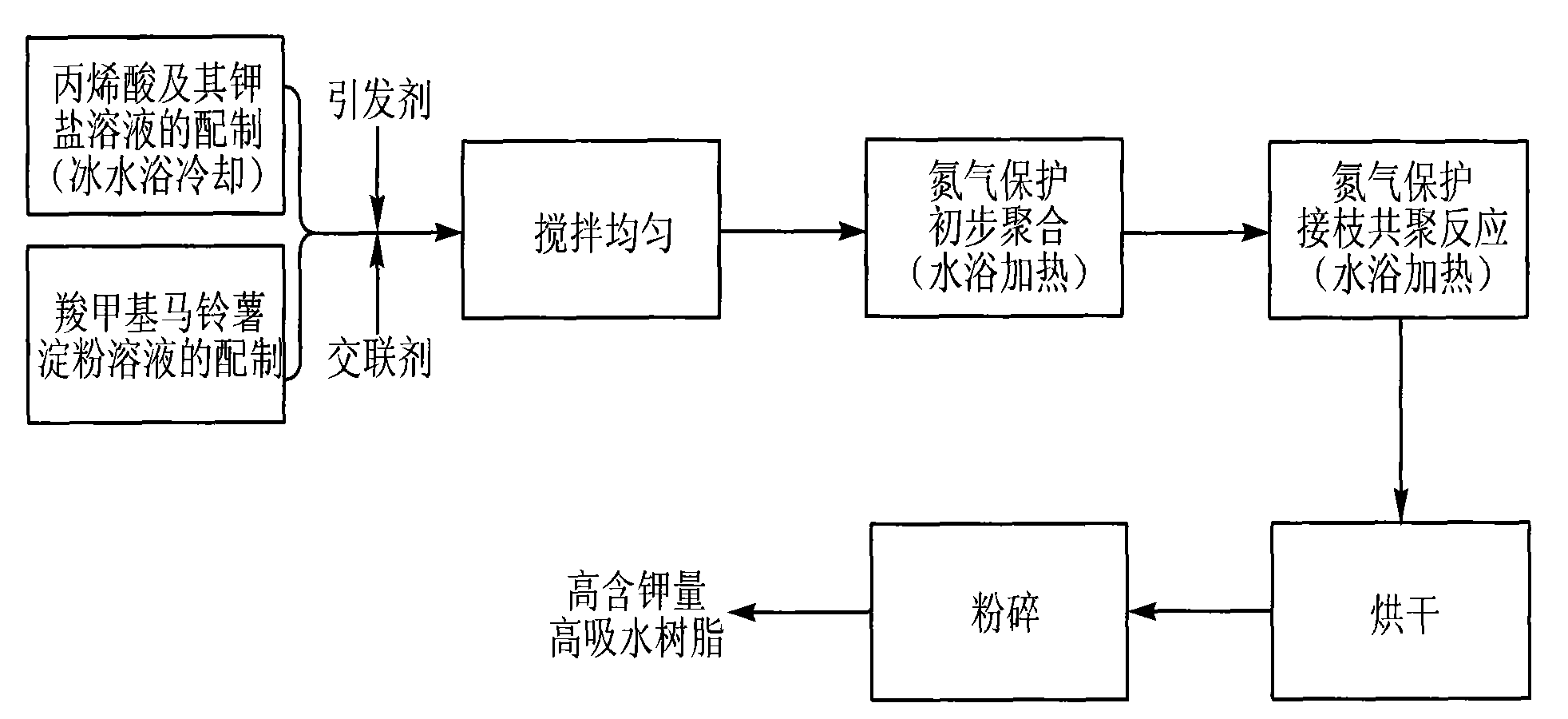

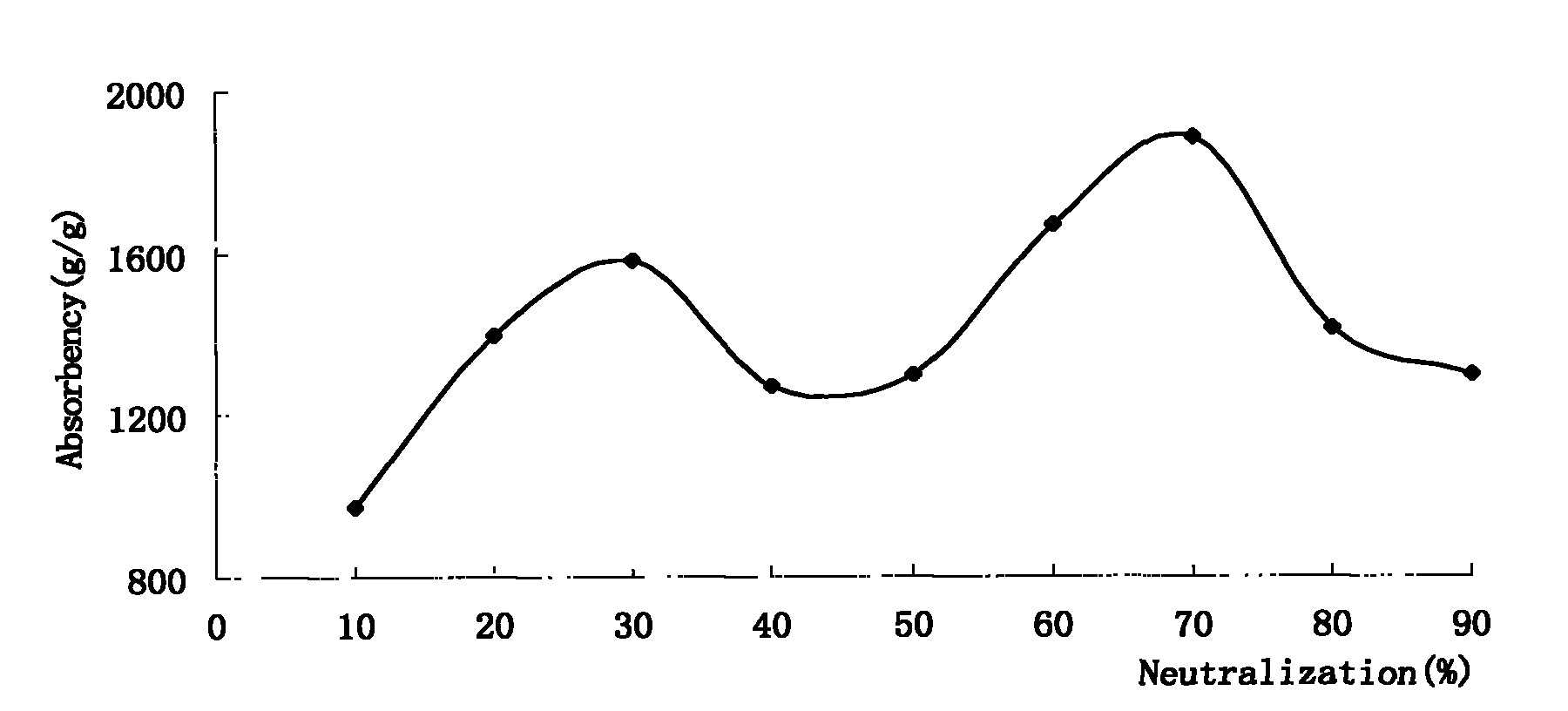

Method for preparing super absorbent resin with high potassium content by using carboxymethyl potato starch as raw material

The invention discloses a method for preparing super absorbent resin with high potassium content by using carboxymethyl potato starch as the raw material, which comprises the following main processes: carrying out neutralization reaction between a potassium hydroxide (potassium carbonate) solution and acrylic acid from which polymerization inhibitor is removed under the cooling of ice-water bath;mixing carboxymethyl potato starch with de-ionized water; mixing the prepared acrylic acid and the sylvite solution thereof with the carboxymethyl potato starch solution; adding an evocating agent persulfate and a cross-linking agent N,'- methylene-bisacrylamide; stirring the mixture under room temperature; heating the mixture by water bath to rise the temperature to rise to ensure that the carboxymethyl potato starch and the acrylic acid and the sylvite thereof generate graft copolymerization reaction under the protection of nitrogen; keeping the temperature of the reaction; drying and crashing to obtain the super absorbent resin with high potassium content by using carboxymethyl potato starch as the raw material. Compared with the similar products, the water absorption of the super absorbent resin is greatly enhanced; the super absorbent resin contains higher content of potassium nutrition element and greatly improves the preparation process by not pasting the carboxymethyl potato starch. The super absorbent resin has great effect on the water conservation, the desert control, the plant growth promotion and the like of soil in dry regions.

Owner:内蒙古永业生物技术有限责任公司

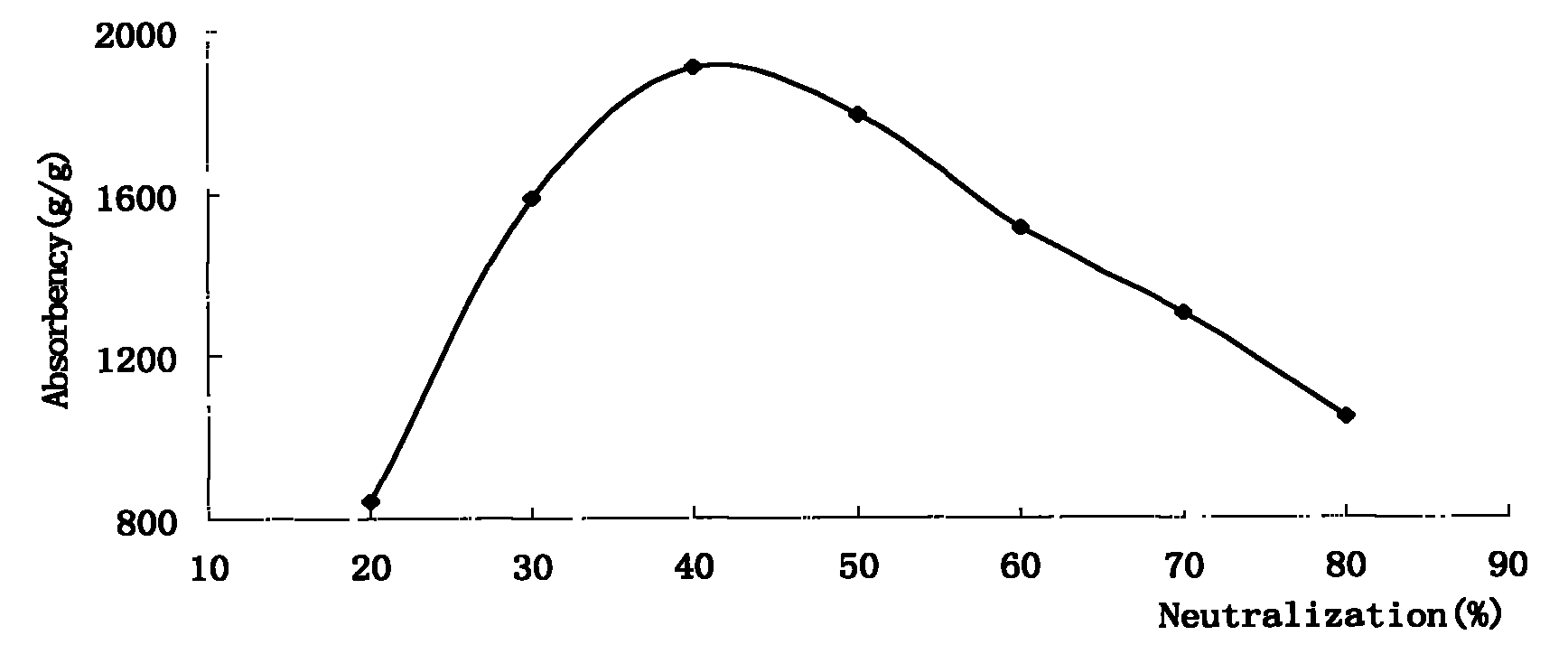

Method for preparing super absorbent resin by using carboxymethyl potato starch as raw material

The invention discloses a method for preparing super absorbent resin by using carboxymethyl potato starch as the raw material, which comprises the following main processes: carrying out neutralization reaction between a sodium hydroxide solution and acrylic acid from which polymerization inhibitor is removed under the cooling of ice-water bath; mixing carboxymethyl potato starch with de-ionized water; mixing the prepared acrylic acid and the sodium salt solution thereof with the carboxymethyl potato starch solution; adding an evocating agent persulfate and a cross-linking agent N,N'- methylene-bisacrylamide; stirring the mixture under room temperature; heating the mixture by water bath to rise the temperature gradually so as to ensure that the carboxymethyl potato starch and the acrylic acid and the sodium salt thereof generate graft copolymerization reaction under the protection of nitrogen; keeping the temperature of the reaction; drying and crashing to obtain the super absorbent resin by using carboxymethyl potato starch as the raw material. Compared with similar products, the water absorption of the super absorbent resin is greatly enhanced, the process of pasting is omitted in comparison with the process of using starch as the raw material and the preparation process is greatly improved. The super absorbent resin has great effect on the water conservation, the production of the physical hygiene sundries, the environmental improvement, the desert control, the plant growth promotion and the like of soil in dry regions.

Owner:广西珅信科技有限公司

Electric response intelligent high molecular catalyst and its preparing process

InactiveCN1253244CAddress accessibility issuesEasy to spreadOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceArtificial enzyme

An electro-responsive intelligent polymer catalyst and a preparation method thereof, comprising 40% to 20% of vinylimidazole, 40% to 20% of 2-acrylic acid amino-2-methyl-1-propanesulfonic acid, N, N'- 11% to 22% of methylene bisacrylamide forms a cross-linked polymer compound, and at the same time, it is composed of 9% to 18% of reagents; the preparation method is: Step 1: from raw materials vinylimidazole, 2-acrylic acid amino-2-methanol Radical-1-propanesulfonic acid and N, N'-methylenebisacrylamide were polymerized by radical emulsion to obtain a cross-linked electro-responsive intelligent polymer catalyst; step 2: test of catalytic activity. The advantages of the present invention: 1. The electrical response intelligent polymer catalyst introduces flexibility and mobility into the structure of the polymer catalyst, which can solve the accessibility problem of the polymer catalyst and improve the catalytic activity; 2. The electrical response intelligence is high Molecular catalysts can be used as an artificial enzyme model to simulate the flexibility of enzymes.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

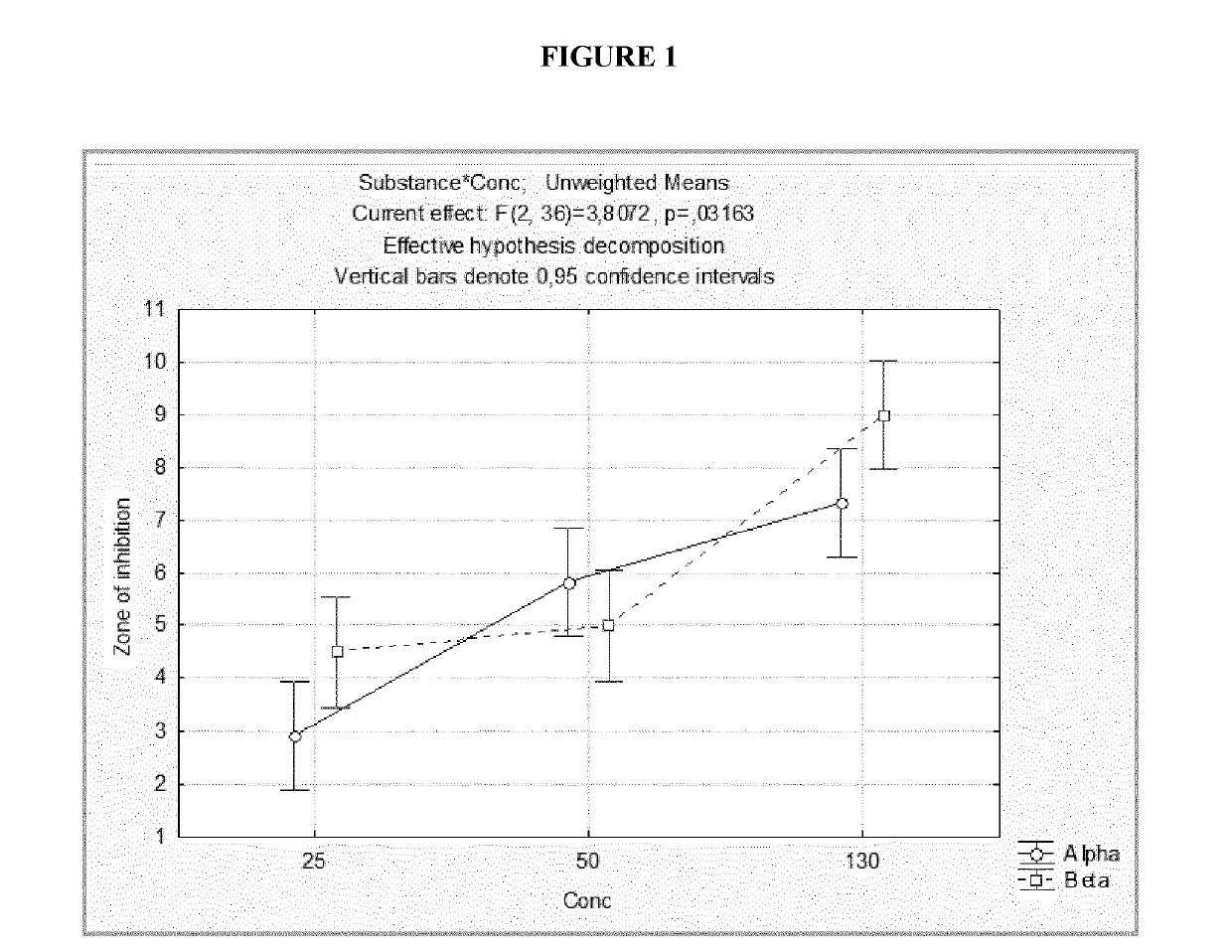

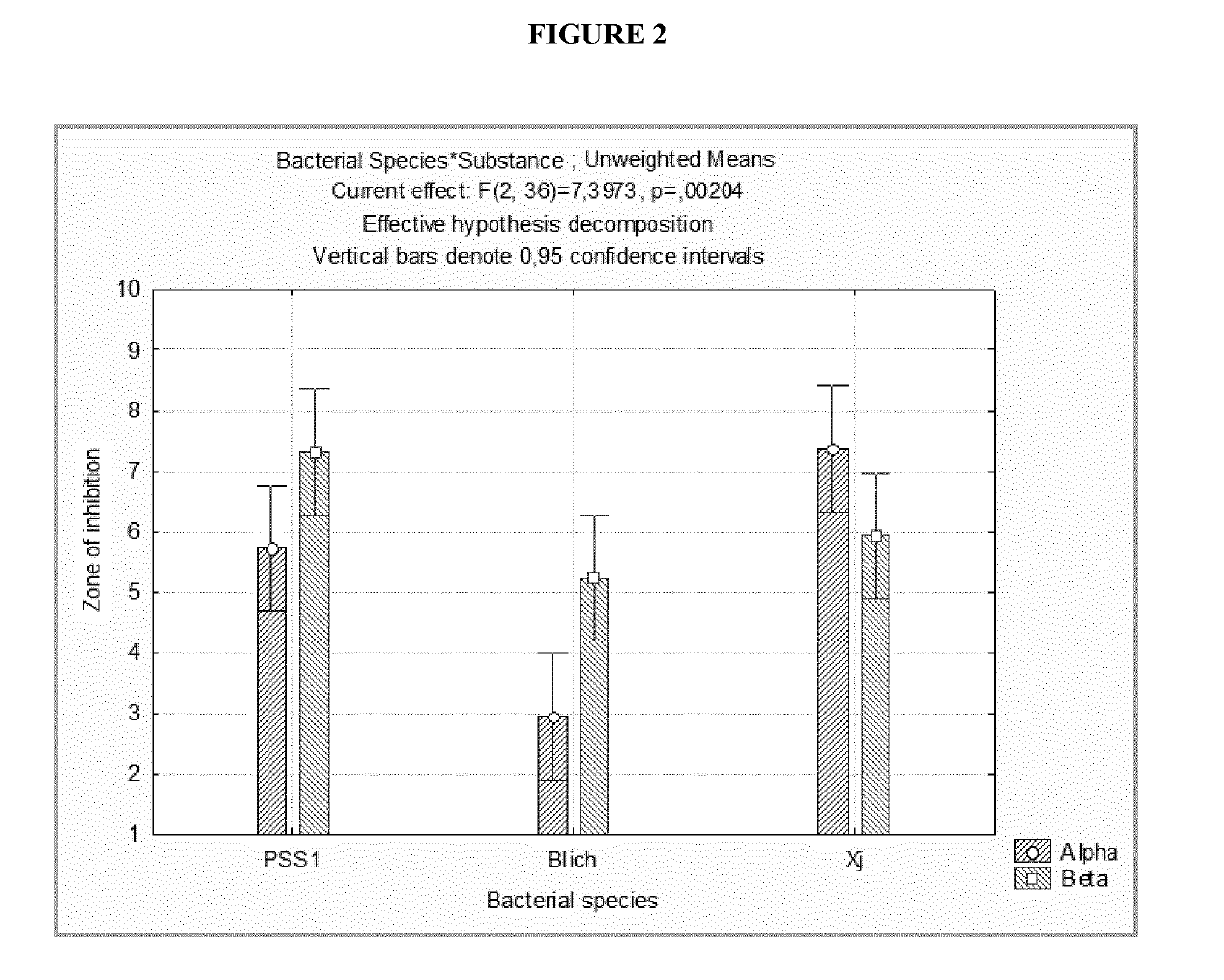

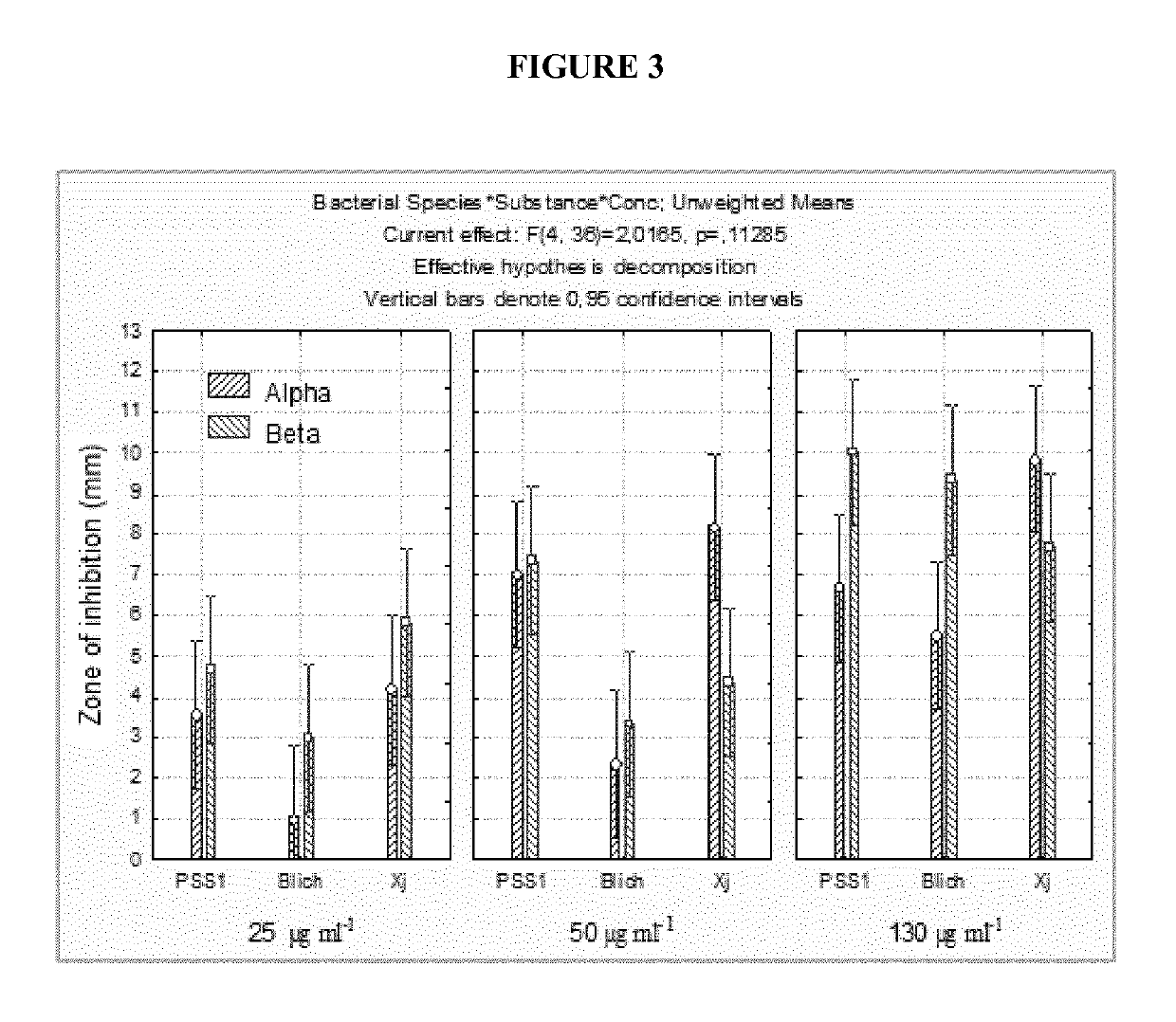

Polyamidoamines with antimicrobial activity

Disclosed are polyamidoamines having a number average molecular weight ranging between 1,000 Da and 200,000 Da, obtained by copolymerisation of N,N-methylenebisacrylamide, glycine and 4-aminobutylguanidine (agmatine), and having the following formula (I) wherein n and m are two numbers such that the value of (n+m) can range from 5 to 1,000, preferably from 20 to 200, and even more preferably from 45 to 55. The compounds according to the invention are useful as active ingredients of pharmaceutical compositions for the treatment and / or prevention of microbial infections, or as plant protection products to counteract bacterial and fungal pathogens in organic farming.

Owner:ALFA CM SRL

Method for preparing super absorbent resin with cross-linked structure from potato starch phosphate graft co-polymeric acrylic acid and sodium salt thereof

The invention discloses a method for preparing super absorbent resin with a cross-linked structure from potato starch phosphate graft co-polymeric acrylic acid and a sodium salt thereof. The method comprises the following main technological processes of: under ice water bath cooling, performing neutralization reaction between a sodium hydroxide solution and acrylic acid used for removing a polymerization inhibitor so as to prepare the acrylic acid and a sodium salt solution of the acrylic acid; mixing the prepared acrylic acid and the sodium salt solution of the acrylic acid with potato starch phosphate; adding an initiator of persulfate, a crosslinking agent of N,N'-methylene bi-acrylamide so that the mixture is mixed evenly under stirring; then under the protection of nitrogen gas, heating the mixture in a water bath and stirring the mixture so that the potato starch phosphate performs graft copolymerization with the acrylic acid and the sodium salt solution of the acrylic acid; stopping stirring after reaching a certain temperature, performing heat preservation reactions, and then stopping introducing the nitrogen gas; and taking out a product, cutting the product into small pieces, drying the small pieces in a drying oven to have constant weights, and crushing the small pieces to obtain the super absorbent resin.

Owner:INNER MONGOLIA UNIVERSITY

Self-reinforced hybrid hydrogel used for artificial muscles and preparation method thereof

InactiveCN103224633BHigh strengthAvoid breakingProsthesisMetal ions in aqueous solutionControllability

The invention relates to a self-reinforced hybrid hydrogel used for artificial muscles and a preparation method thereof. According to the invention, sodium alginate is used as a high-molecular skeleton, acrylamide and derivative thereof are used as polymerizable monomers, divinyl benzene, N,N'-methylene bis acrylamide or ethylene glycol dimethacrylate is used as a chemical cross-linking agent, an aqueous metal salt solution is used as an ion cross-linking agent, and then the hydrogel with high elasticity and high toughness is prepared. During a process of preparing the hydrogel, an organic matter emulsion containing metal ion aqueous solution is added. When the prepared hydrogel is stretched by external forces to a certain extent, the gel deforms to extrude the organic matter emulsion, and metal ions are released and then crosslinked with the sodium alginate in the hybrid gel, thereby substantially improving gel intensity and preventing gel fracture. The preparation method has advantages of good controllability, simple technology and low cost, the obtained hydrogel material can be self-reinforced, and is expected to be applied in fields of artificial cartilage, artificial muscle, flexible robot manufacture, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com