Method for preparing double-parent potassium-containing super absorbent resin from carboxymethyl starch and starch phosphate serving as raw materials

A technology of carboxymethyl starch and starch phosphate, which is applied in the field of superabsorbent resin preparation, can solve the problems of long production process, difficulty in industrialization, and high production cost, and achieve the effects of accelerating growth, accelerating cell division, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

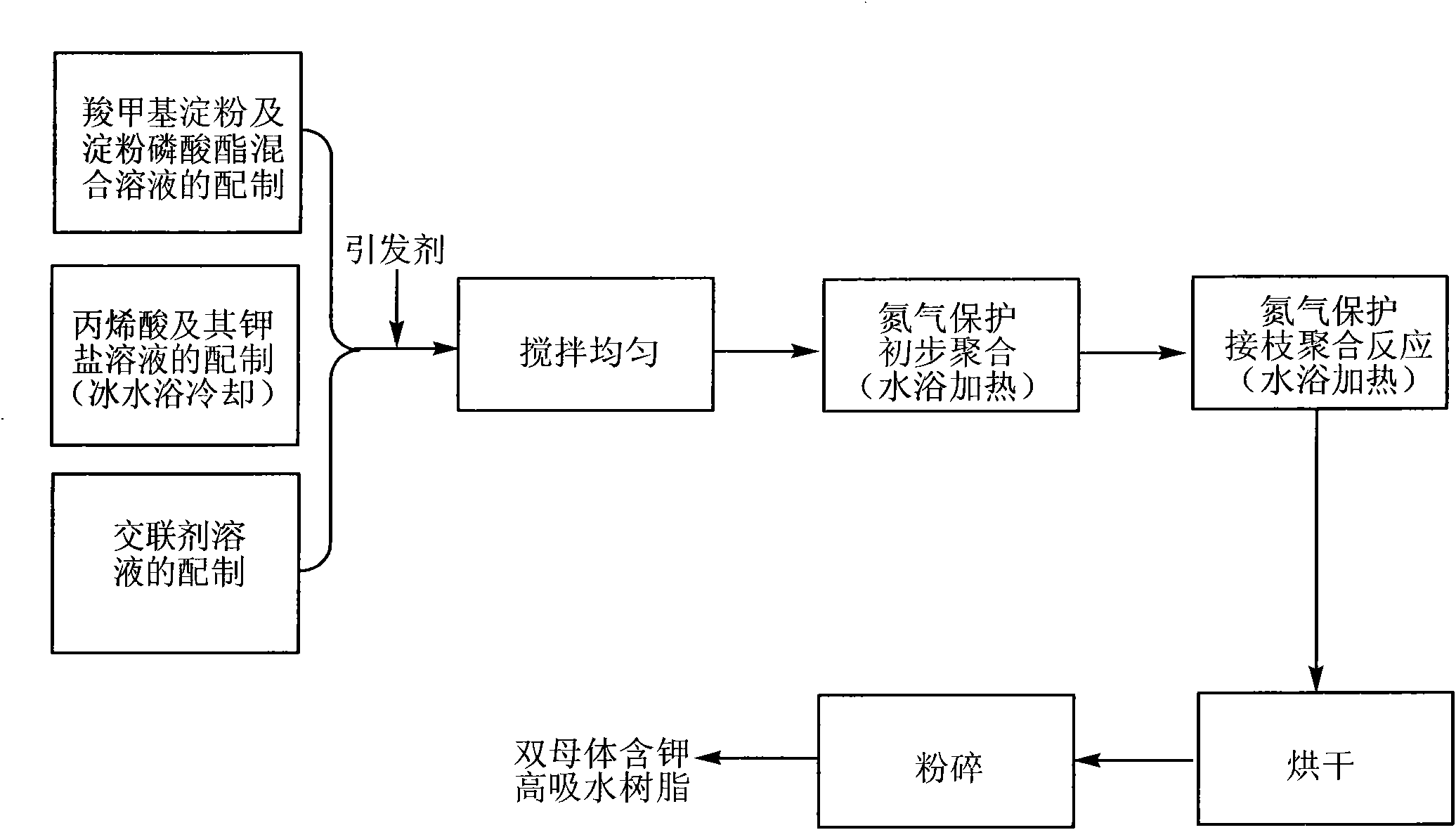

Method used

Image

Examples

Embodiment 1

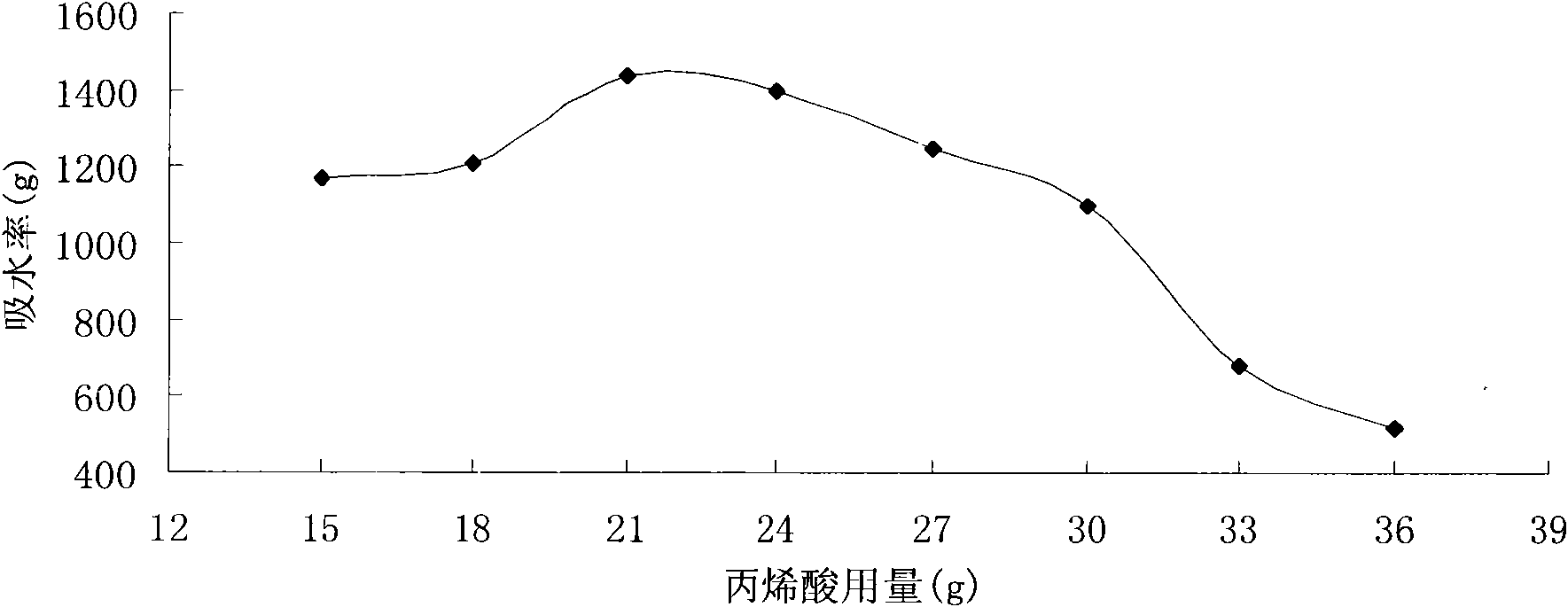

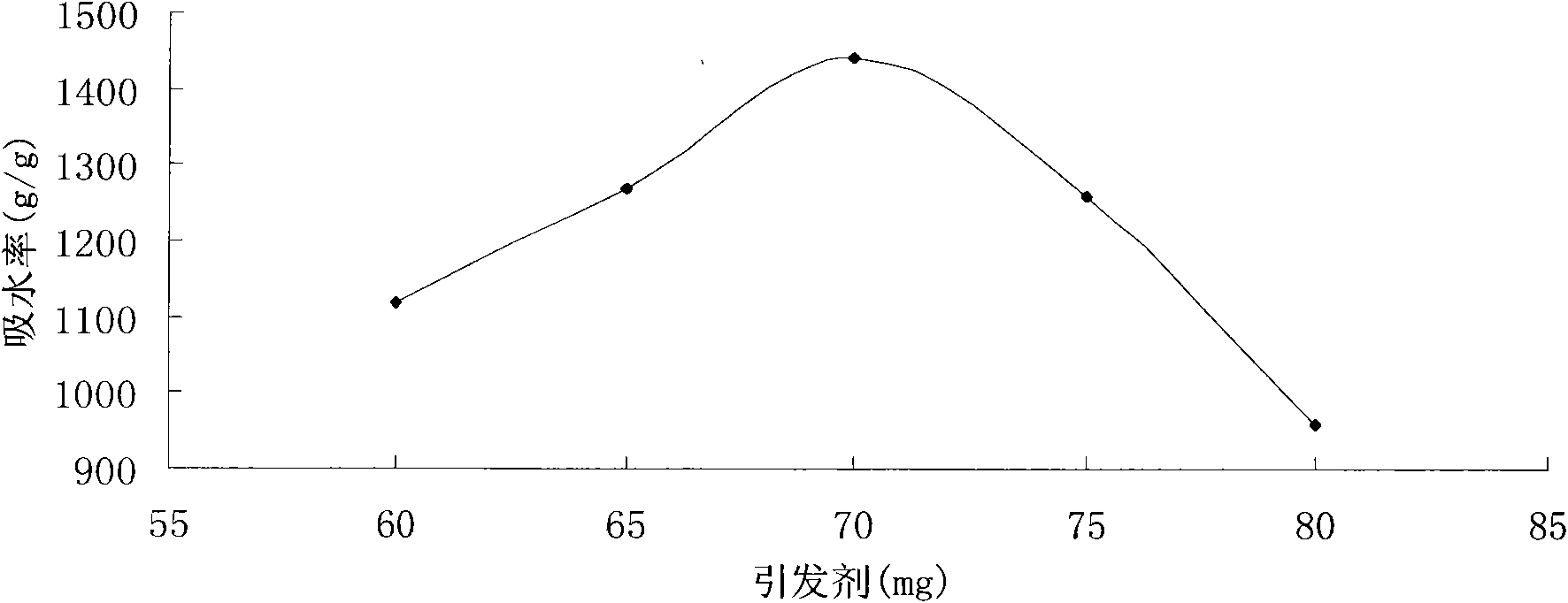

[0025] Embodiment 1: Weigh 6.5g potassium hydroxide, measure 20.0ml deionized water, be mixed with potassium hydroxide solution, under ice-water bath cooling and stirring, neutralize 21.0g (20.0ml) acrylic acid (neutralization degree is 40 %). Weigh 1.50g carboxymethyl potato starch and 1.50g potato starch phosphate, measure 27.0ml deionized water, mix evenly under stirring, add neutralized acrylic acid and its potassium salt solution, then add 70mg potassium persulfate as trigger and 8.00ml of N,N′-methylenebisacrylamide solution with a concentration of 1mg / ml as the crosslinking agent, stirred under nitrogen protection and heated in a water bath while controlling the heating rate to slowly increase the temperature of the water bath. At 65 ° C, the viscosity of the reactant began to increase, and the stirring was stopped. Thereafter, the temperature was gradually raised, and when the temperature of the water bath was 90°C-96°C, the heating was continued to keep it in this te...

Embodiment 2

[0026] Embodiment 2: The implementation conditions are the same as in Example 1, except that the potassium hydroxide consumption is 7.5g, the acrylic acid consumption is 24.0g (22.8ml), and the stirring is stopped at 67° C. After the reaction, the acrylic acid consumption is 24.0g. The matrix contains potassium superabsorbent resin, and the deionized water absorption capacity of this product is 1400g / g.

Embodiment 3

[0027] Embodiment 3: The implementation conditions are the same as in Example 1. The difference is that the amount of potassium hydroxide is 5.6g, and the amount of acrylic acid is 18.0g (17.1ml). Stirring is stopped at 65°C. After the reaction, the amount of acrylic acid is 18.0g. The matrix contains potassium superabsorbent resin, and the deionized water absorption capacity of this product is 1210g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com