Method for preparing super absorbent resin with cross-linked structure from potato starch phosphate graft co-polymeric acrylic acid and sodium salt thereof

A technology of starch phosphate ester and super absorbent resin, applied in the field of super absorbent resin, can solve the problems of complex production process, low gel strength and high product cost, and achieve the effect of simplifying the process flow, good performance and increasing income

Inactive Publication Date: 2011-01-05

INNER MONGOLIA UNIVERSITY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, the gel strength after water absorption is low, the production process is complicated, and the product cost is high, and the product is prone to mildew and rot during storage.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

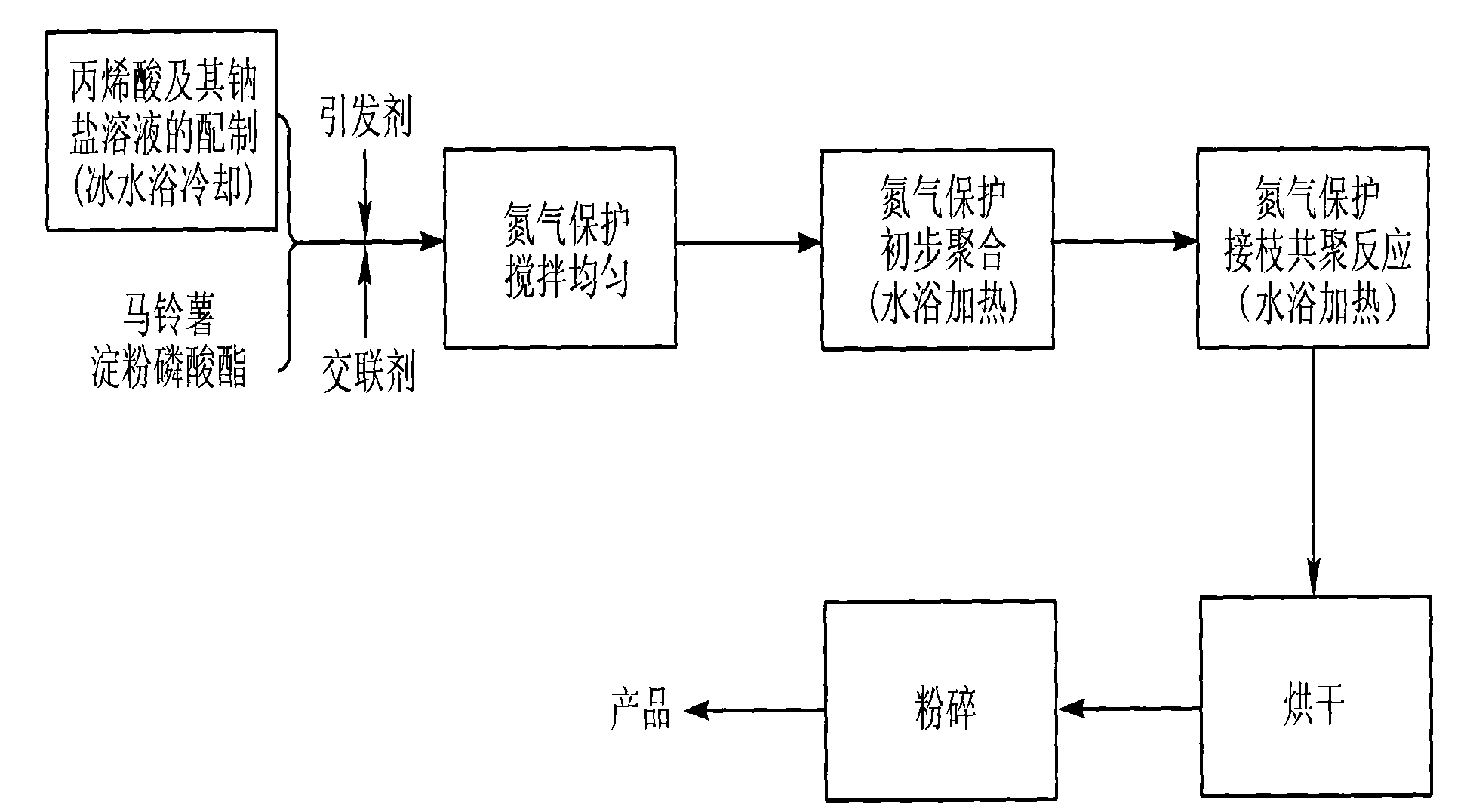

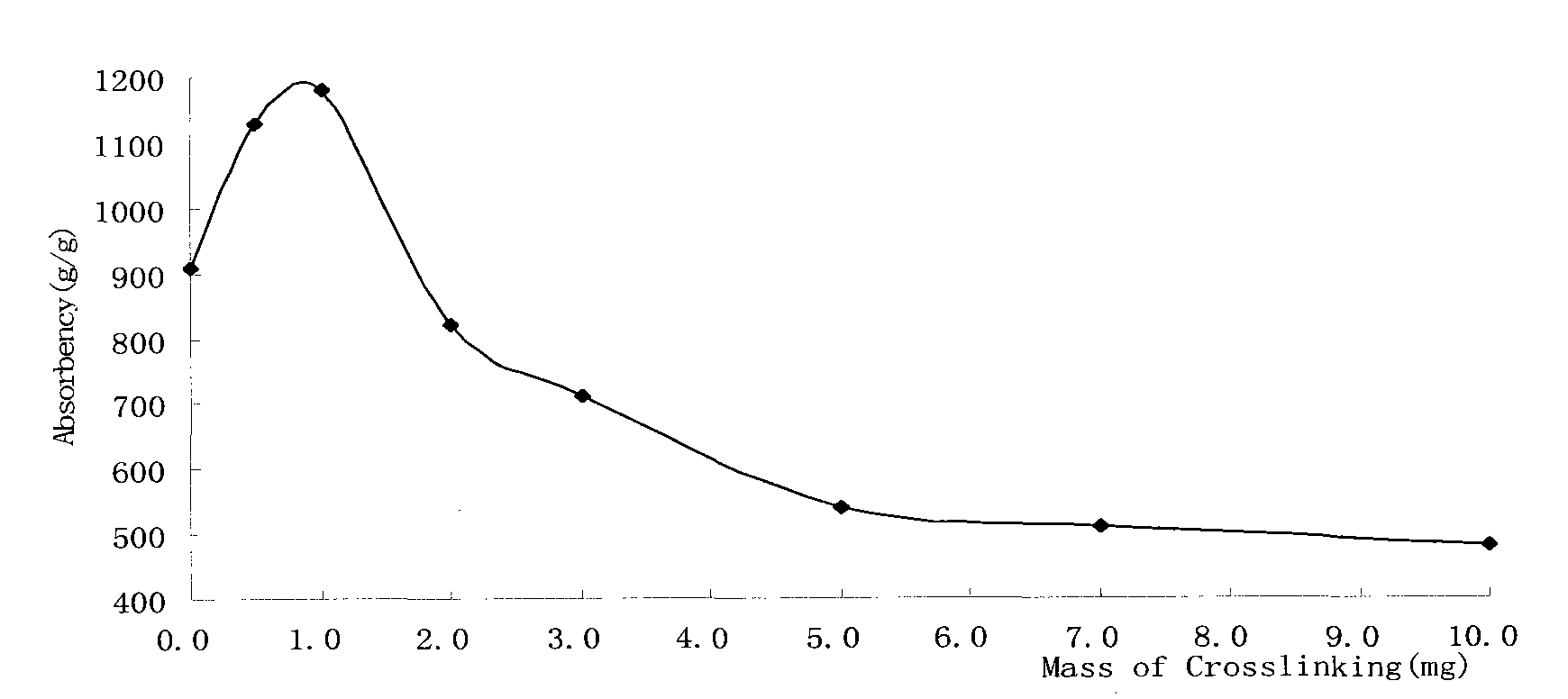

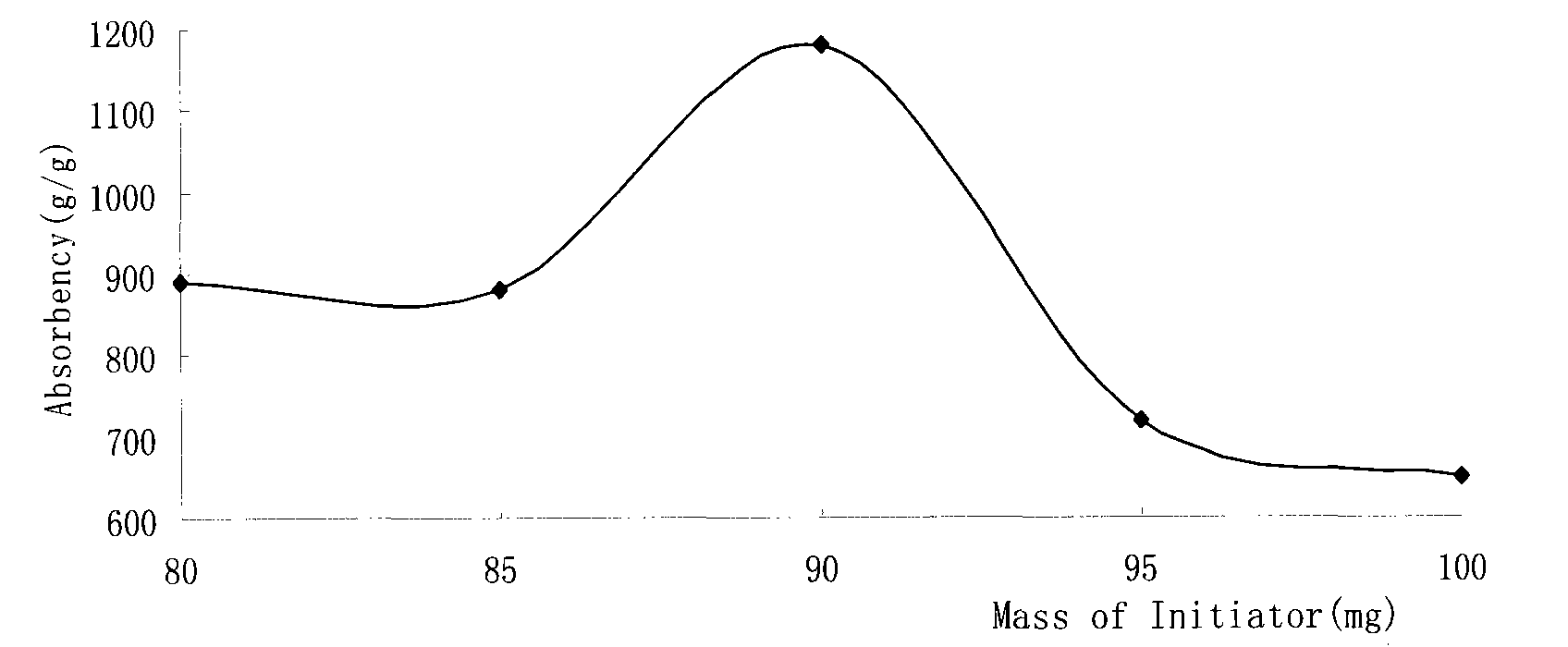

The invention discloses a method for preparing super absorbent resin with a cross-linked structure from potato starch phosphate graft co-polymeric acrylic acid and a sodium salt thereof. The method comprises the following main technological processes of: under ice water bath cooling, performing neutralization reaction between a sodium hydroxide solution and acrylic acid used for removing a polymerization inhibitor so as to prepare the acrylic acid and a sodium salt solution of the acrylic acid; mixing the prepared acrylic acid and the sodium salt solution of the acrylic acid with potato starch phosphate; adding an initiator of persulfate, a crosslinking agent of N,N'-methylene bi-acrylamide so that the mixture is mixed evenly under stirring; then under the protection of nitrogen gas, heating the mixture in a water bath and stirring the mixture so that the potato starch phosphate performs graft copolymerization with the acrylic acid and the sodium salt solution of the acrylic acid; stopping stirring after reaching a certain temperature, performing heat preservation reactions, and then stopping introducing the nitrogen gas; and taking out a product, cutting the product into small pieces, drying the small pieces in a drying oven to have constant weights, and crushing the small pieces to obtain the super absorbent resin.

Description

Method for preparing superabsorbent resin with cross-linked structure by graft-copolymerizing acrylic acid and sodium salt of potato starch phosphate technical field The invention relates to a method for preparing a superabsorbent resin with a cross-linked structure by graft-copolymerizing acrylic acid and its sodium salt with potato starch phosphate. This kind of super absorbent resin with a large amount of water absorption or binding has a wide range of applications in many fields, such as breeding seedlings, drought resistance, income increase, soil erosion prevention and desertification control, etc., and has achieved great success in the above fields . Background technique Superabsorbent resin is a new type of three-dimensional network functional polymer material with lightly cross-linked structure. It is insoluble in water and in organic solvents. It has the ability to absorb water hundreds or even thousands of times its own weight. It absorbs water fast and has goo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F251/00C08K5/20

Inventor 温国华杜青慧曲秀清目仁更付渊张伟

Owner INNER MONGOLIA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com