Method for preparing temperature stimuli responsive intelligent chromatographic column

A chromatographic column and intelligent technology, applied in the field of preparation of temperature-stimulated-responsive intelligent chromatographic columns, can solve the problems of difficult to guarantee separation effect, cumbersome operation in bonding process, affecting separation ability, etc., and achieve low cost of raw materials, environment-friendly, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a temperature stimulation-responsive intelligent chromatographic column, the steps of which are:

[0033] A. Mix 0.3g N-isopropylacrylamide, 0.20g N,N′-methylenebisacrylamide, 0.08g polyethylene glycol-20000, 10μL 10% w / v ammonium persulfate, 1.4mL deionized Ultrasonic mixing of water;

[0034] Among them, N-isopropylacrylamide is used as polymerized monomer, N, N'-methylenebisacrylamide is used as polymerized crosslinking agent, polyethylene glycol-20000 is used as porogen, 10% w / v ammonium persulfate as an initiator;

[0035] B. Add 10 μL of 10% v / v N, N, N', N'-tetramethylethylenediamine to the reaction product in the previous step after deoxygenation, and mix well;

[0036] Wherein, 10% v / v N, N, N', N'-tetramethylethylenediamine is used as a catalyst;

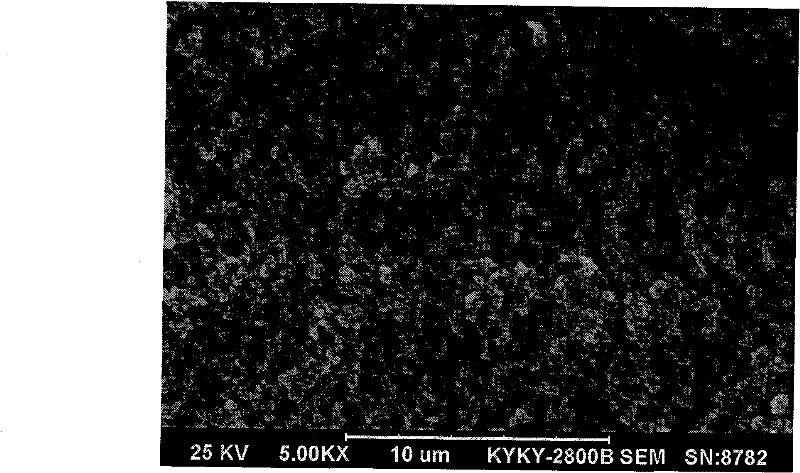

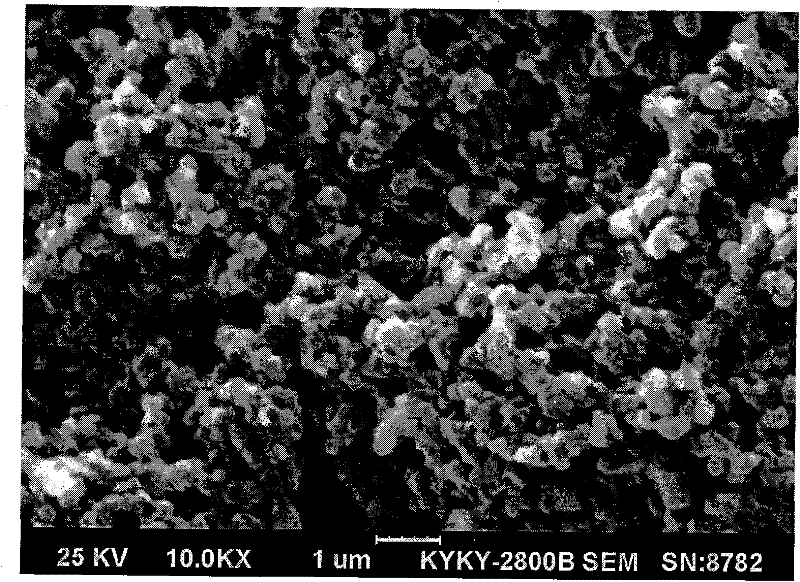

[0037]C. Pour the reaction product from the previous step into a stainless steel chromatographic column tube and react at -18°C for 24 hours. Install the chromatographic column head at bot...

Embodiment 2

[0041] The difference between the second embodiment of the present invention and the first embodiment is that the amount of each component is: 0.3 g of N-isopropylacrylamide, 0.2 g of N, N'-methylenebisacrylamide, polyethylene glycol Alcohol-20000 0.08 g, 10% w / v ammonium persulfate 10 μL, deionized water 1.4 mL, 10% v / v N,N,N′,N′-tetramethylethylenediamine 10 μL; reaction temperature in Step C The temperature is 25°C, and the reaction time is 24h.

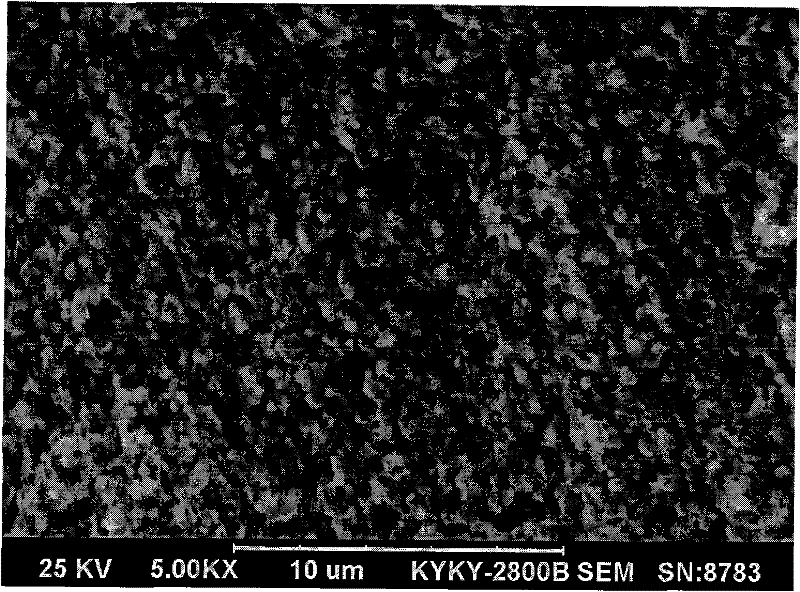

[0042] image 3 From the scanning electron microscope image of the internal morphology of the chromatographic column prepared for this example, it can be seen that the chromatographic column prepared in this example also has micron-sized through holes and a three-dimensional continuous framework.

[0043] Using water as the mobile phase and controlling the temperature, the monolithic chromatographic column prepared in this example can also achieve high-efficiency separation of the six steroid drugs and the three benzene series in...

Embodiment 3

[0045] The difference between the third embodiment of the present invention and the first embodiment is: the amount of each component is: 0.3g of N-isopropylacrylamide, 0.2g of N,N'-methylenebisacrylamide, polyethylene glycol Alcohol-20000 0.01 g, 10% w / v ammonium persulfate 100 μL, deionized water 1.4 mL, 10% v / v N,N,N′,N′-tetramethylethylenediamine 14 μL; reaction temperature in Step C The temperature is 60°C, and the reaction time is 100h.

[0046] Figure 4 From the scanning electron microscope image of the internal morphology of the chromatographic column prepared for this example, it can be seen that the chromatographic column prepared in this example also has micron-sized through holes and a three-dimensional continuous framework.

[0047] Using water as the mobile phase and controlling the temperature, the monolithic chromatographic column prepared in this example can also achieve high-efficiency separation of the six steroid drugs and the three benzene series in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com