Method for synthesizing high-molecular water-absorbent resin from cottonseed byproduct

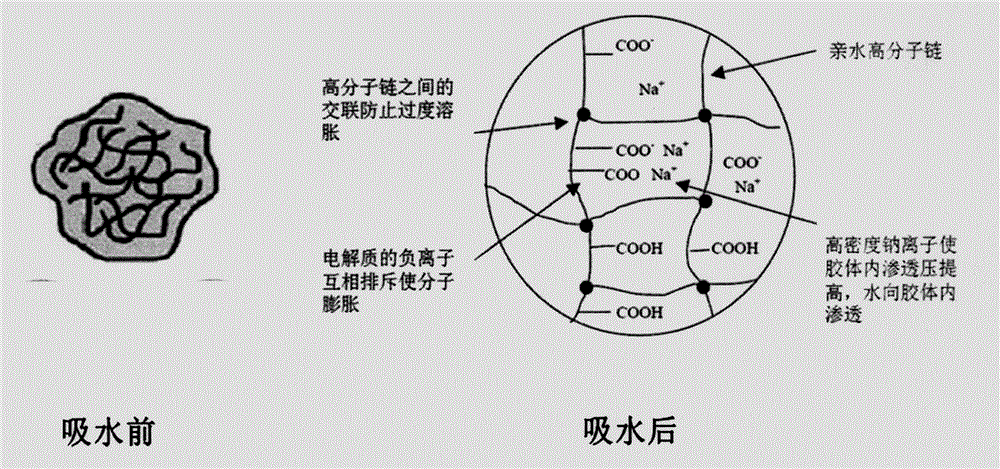

A technology for synthesizing polymers and water-absorbing resins, which is applied in the field of functional superabsorbent resins, can solve the problems of protein resources not being well utilized and protein resources being wasted, and achieve development and utilization value, prevent soil erosion, and improve aggregate structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

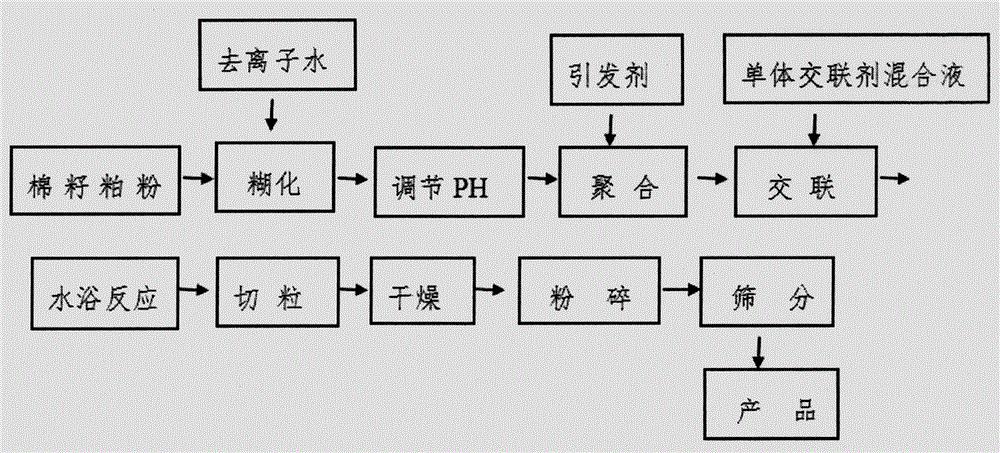

[0026] A method for synthesizing a polymer water-absorbent resin from cottonseed by-products, the specific steps are as follows:

[0027] (1) 120g of acrylic acid is dissolved in 50ml of deionized water to form an aqueous solution of acrylic acid;

[0028] (2) 40g sodium hydroxide is dissolved in 150ml deionized water to form a sodium hydroxide solution;

[0029] (3) Slowly add the sodium hydroxide solution dropwise to the acrylic acid aqueous solution at room temperature until the degree of neutralization is 75%;

[0030] (4) Cool to room temperature, add 0.036g cross-linking agent N-N' methylenebisacrylamide, fully stir evenly, obtain the mixed liquid of monomer and cross-linking agent;

[0031] (5) Add 15g of cottonseed meal powder into a three-neck flask equipped with a stirrer, add 150g of distilled water, and stir and gelatinize in a constant temperature water bath at 60°C for 15min;

[0032] (6) Regulate the pH of mixed solution to 8.5 with sodium hydroxide solution, ...

Embodiment 2

[0036] Specific steps are as follows:

[0037] (1) 120g of acrylic acid is dissolved in 50ml of deionized water to form an aqueous solution of acrylic acid;

[0038] (2) 50g sodium hydroxide is dissolved in 150ml deionized water to form a sodium hydroxide solution;

[0039] (3) Slowly add the sodium hydroxide solution dropwise to the acrylic acid aqueous solution at room temperature until the degree of neutralization is 75%;

[0040] (4) Cool to room temperature, add 0.036g cross-linking agent N-N' methylenebisacrylamide, fully stir evenly, obtain the mixed liquid of monomer and cross-linking agent;

[0041] (5) Add 20g of cottonseed meal powder into a three-necked flask equipped with a stirrer, add 100g of distilled water, and stir and gelatinize in a constant temperature water bath at 80°C for 30min;

[0042] (6) Regulate the pH of the mixed solution to 8.0 with sodium hydroxide solution, and feed nitrogen for 20min, then add 0.2g initiator potassium persulfate;

[0043] ...

Embodiment 3

[0046] Specific steps are as follows:

[0047] (1) 150g of acrylic acid is dissolved in 50ml of deionized water to form an aqueous solution of acrylic acid;

[0048] (2) 50g sodium hydroxide is dissolved in 150ml deionized water to form a sodium hydroxide solution;

[0049] (3) Slowly add the sodium hydroxide solution dropwise to the acrylic acid aqueous solution at room temperature until the degree of neutralization is 75%;

[0050] (4) Cool to room temperature, add 0.036g of cross-linking agent N-N' methylenebisacrylamide, fully stir evenly, and obtain a mixed liquid of monomer and cross-linking agent;

[0051] (5) Add 15g of cottonseed meal powder into a three-necked flask equipped with a stirrer, add 100g of distilled water, and stir and gelatinize in a constant temperature water bath at 60°C for 30min;

[0052] (6) Regulate the pH of mixed solution to 8.0 with sodium hydroxide solution, and pass into nitrogen 20min, then add 0.19g initiator potassium persulfate;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com