Mesoporous silica particles loaded amidoxime polymer uranium adsorption material and preparation method

A mesoporous silica gel and adsorption material technology, which is applied in the preparation of uranium compounds, uranium compounds, alkali metal compounds, etc., can solve the problems of uneven distribution, unfavorable later use, and difficulty in large-scale production, and achieve simple preparation process and good structure The effects of stability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

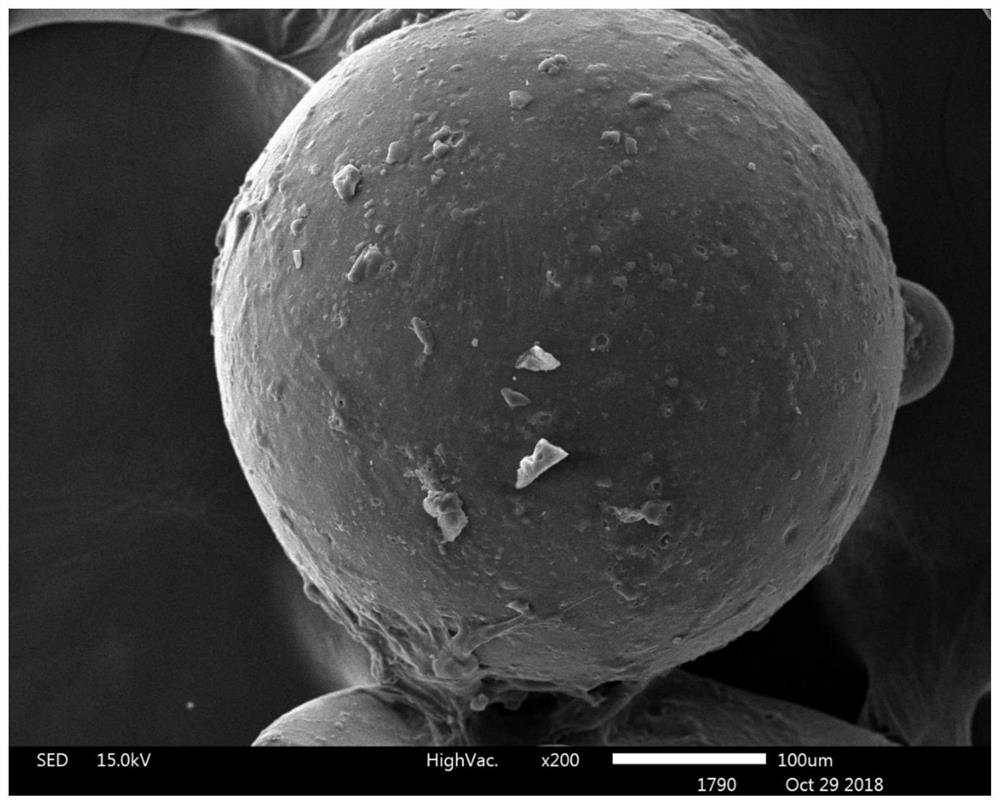

[0029] Step 1: Weigh 100g of polyacrylonitrile powder and 26g of lithium chloride particles into a 1L beaker, then add 600mL of N,N-dimethylformamide into it and stir until completely dissolved. Take 52g of the above-mentioned polyacrylonitrile solution and add it into 30g of 50 mesh mesoporous silica gel particles, stir evenly, and degas under reduced pressure. The above defoamed mixture was poured into a three-necked flask equipped with a stirrer and 500 mL of water, and stirred at 3000 rpm for 2 h. Afterwards, the solid was filtered out and dried in an oven for 24 hours to prepare mesoporous silica particles coated with polyacrylonitrile.

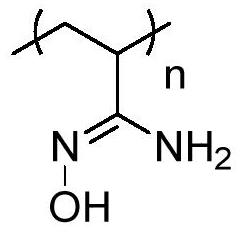

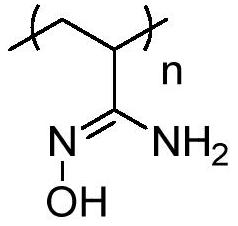

[0030] Step 2: Add 500mL of methanol-water with a volume ratio of 1:1 to a 1L Erlenmeyer flask containing 10g of hydroxylamine hydrochloride and 8g of sodium carbonate, and stir at room temperature until completely dissolved. Put 50 g of the mesoporous silica gel particles coated with polyacrylonitrile prepared in the first step into th...

Embodiment 2

[0033] Step 1: Weigh 100g of polyacrylonitrile powder and 26g of polyvinylpyrrolidone into a 1L beaker, then add 600mL of dimethyl sulfoxide into it and stir until completely dissolved. Take 52g of the above-mentioned polyacrylonitrile solution and add it into 30g of 50 mesh mesoporous silica gel particles, stir evenly, and degas under reduced pressure. The above defoamed mixture was poured into a three-necked flask equipped with a stirrer and 500 mL of water, and stirred at 3000 rpm for 2 h. Afterwards, the solid was filtered out and dried in an oven for 24 hours to prepare mesoporous silica particles coated with polyacrylonitrile.

[0034] Step 2: Add 500mL of methanol-water with a volume ratio of 1:1 to a 1L Erlenmeyer flask containing 10g of hydroxylamine hydrochloride and 8g of sodium carbonate, and stir at room temperature until completely dissolved. 55 g of mesoporous silica gel particles coated with polyacrylonitrile prepared in the first step were put into the above-...

Embodiment 3

[0037] Step 1: Weigh 75g of polyacrylonitrile powder and 30g of ammonium chloride into a 1L beaker, then add 450mL of dimethyl sulfoxide into it and stir until completely dissolved. Take 40 g of the above polyacrylonitrile solution and add it into 30 g of 50 mesh mesoporous silica gel particles, stir evenly, and degas under reduced pressure. The above defoamed mixture was poured into a three-necked flask equipped with a stirrer and 500 mL of water, and stirred at 3000 rpm for 2 h. Afterwards, the solid was filtered out and dried in an oven for 24 hours to prepare mesoporous silica particles coated with polyacrylonitrile.

[0038] Step 2: Add 500mL of methanol-water with a volume ratio of 1:1 to a 1L Erlenmeyer flask containing 10g of hydroxylamine hydrochloride and 8g of sodium carbonate, and stir at room temperature until completely dissolved. Put 50 g of the mesoporous silica gel particles coated with polyacrylonitrile prepared in the first step into the above-mentioned Erl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com