Film with self-cleaning property and preparation method thereof

A self-cleaning, high-performance technology, applied in the field of super-hydrophobic film and its preparation, can solve the problems of being unsuitable for large-scale processing and cumbersome preparation methods, and achieve the effects of low cost, simple and controllable process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

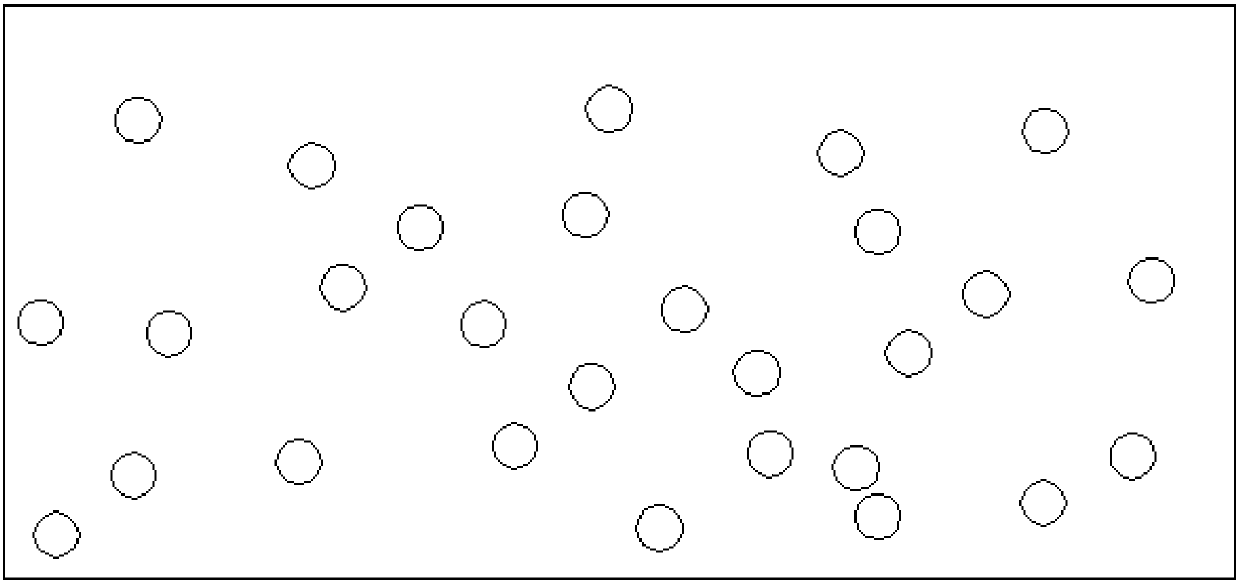

[0048] (1) Put polyvinylidene fluoride and nano-silica (particle size 1~100nm) in a vacuum oven at 100°C for 24 hours; take 0.2g of dried nano-silica and add it to 17.0g dimethyl sulfoxide 40KHZ ultrasonic vibration for 3 hours to form a dispersion, add 2.0g of dried polyvinylidene fluoride, 0.4g of acetone and 0.4g of lithium chloride to the dispersion in turn, stir on a magnetic stirrer for 6h, and stir until the temperature is 80°C , to form a casting solution, let it stand for 9 hours for degassing, and set aside;

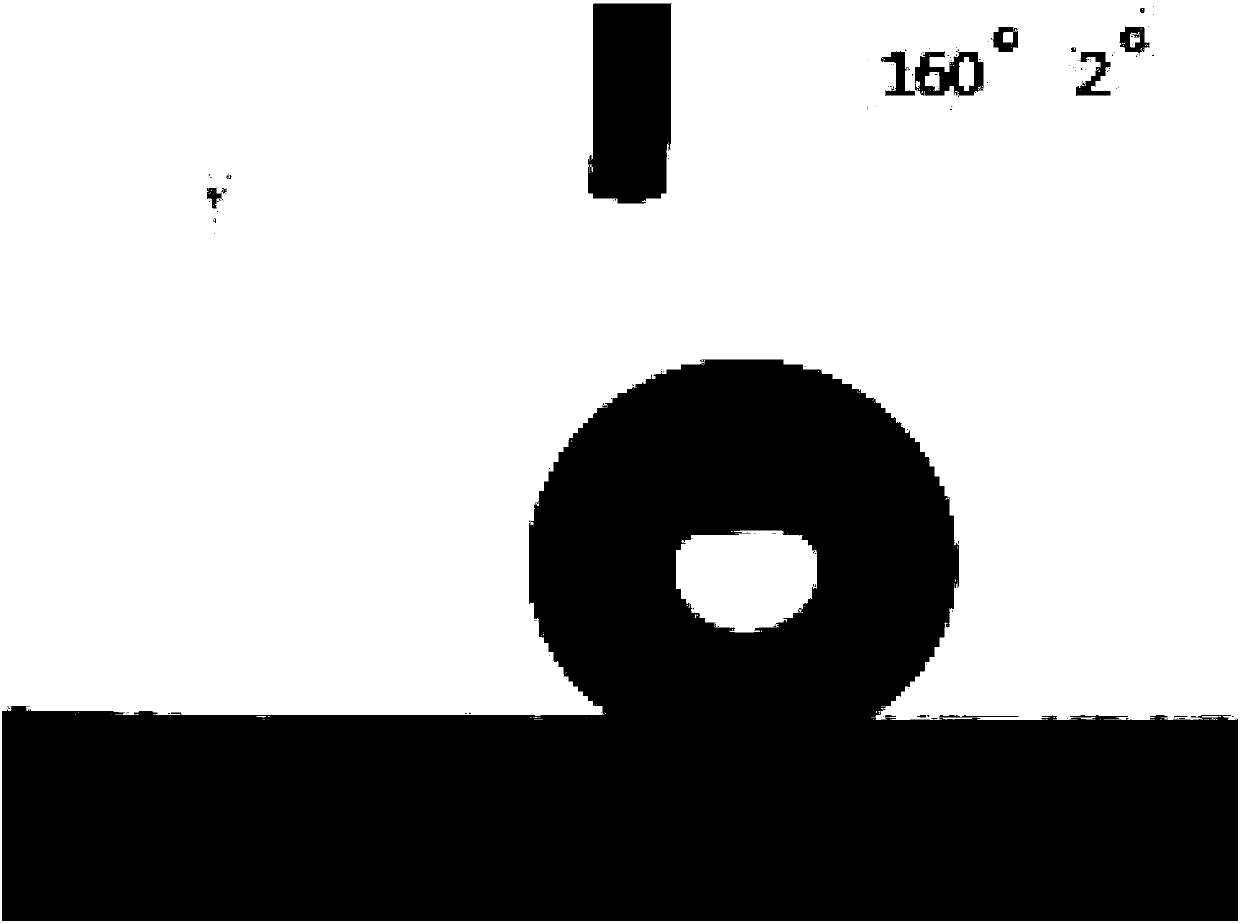

[0049](2) Make a flat film from the defoamed casting solution by using a film-making process, apply the casting solution on a clean glass plate with a mechanical film coater, let it stand in the air for 20 seconds, and then put it in a 20°C Stand in the coagulation bath for 1 hour to remove the film, soak the peeled film in deionized water at 25°C for 18 hours, then take it out and dry it with a hair dryer, and then put the film in 15 μl of 1H, 1H, 2H, 2H-perfl...

Embodiment 2

[0055] (1) Put polyvinylidene fluoride and nano-silica (particle size 1~100nm) in a vacuum oven at 100°C for 24 hours; take 0.2g of dried nano-silica and add it to 16.1g of dimethyl sulfoxide , 40KHZ ultrasonic vibration for 5 hours to form a dispersion, sequentially add 2.5g of dried polyvinylidene fluoride, 0.4g of acetone and 0.8g of polyethylene glycol to the dispersion, stir on a magnetic stirrer for 6h, and stir to a temperature of 80 ℃, until the casting solution is formed, let it stand for 12 hours for defoaming, and set aside;

[0056] (2) Make a flat film from the defoamed casting solution by using a film-making process, apply the casting solution on a clean glass plate with a scraper knife, let it stand in the air for 30s, and then put it in a solidification machine at 20°C Stand in the bath for 2 hours to remove the film, soak the peeled film in deionized water at 25°C for 24 hours, then take it out and dry it with a hair dryer, and then put the film in 15 μl of 1H...

Embodiment 3

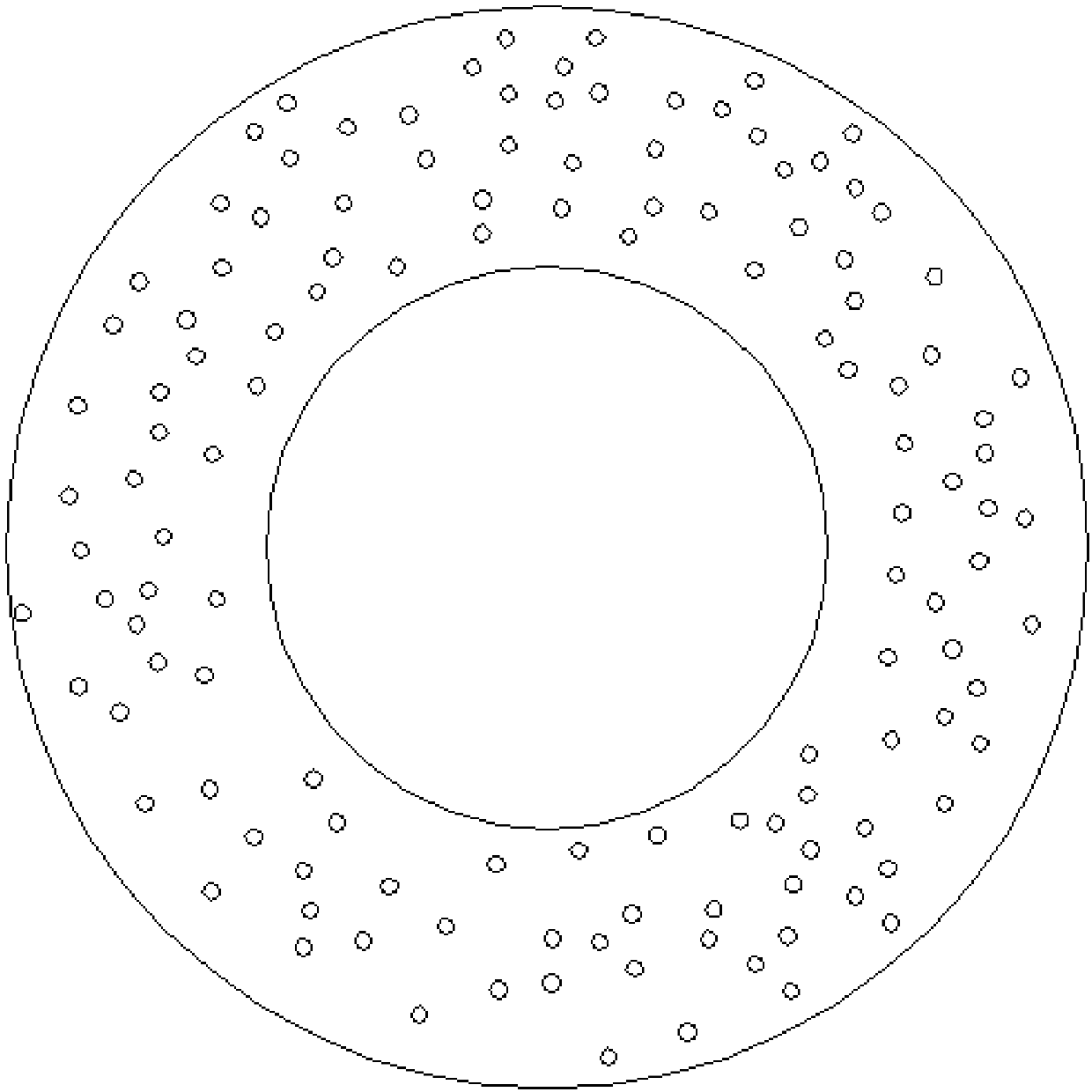

[0060] (1) Put polyvinylidene fluoride and nano-silica (with a particle size of 1-100nm) in a vacuum oven at 100°C for 24 hours; take 0.8g of dried nano-silica and add it to 15.1g of dimethylformamide 30KHZ ultrasonic vibration for 5 hours to form a dispersion, add 3.0g of dried polyvinylidene fluoride, 0.6g of acetone and 0.5g of polyethylene glycol to the dispersion in turn, stir on a magnetic stirrer for 8 hours, and stir until the temperature is 80 ℃, until the casting solution is formed, let it stand for 12 hours for defoaming, and set aside;

[0061] (2) Make a flat film from the defoamed casting solution by using a film-making process, apply the casting solution on the non-woven fabric with a mechanical film coating machine, let it stand in the air for 50 seconds, and then put it in a 30°C Stand in the coagulation bath for 2 hours to remove the film, put the peeled film in deionized water at 25°C for 24 hours, then take it out and dry it with a hair dryer, and then put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com